Professional Documents

Culture Documents

MCC083 0617 Rt-Brkarc

Uploaded by

alemao7x1 DiehlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCC083 0617 Rt-Brkarc

Uploaded by

alemao7x1 DiehlCopyright:

Available Formats

test

ride Brake backing plate with

shoes jigged up on Race

Tech’s brake arcing tool to

cut and match the profile of

Race Tech brake arcing and Pecard leather care the shoes to the drum.

Race Tech brake properly adjusted to work well. to the freshly machined drum.

arcing service First, the brake arms need to be The result? Wow. The new cable

After reading my vent a few issues back correctly oriented: If you remove and proper adjustment were a

about the poor front brake performance them, mark them first to make big help, no question, but the

on my 1973 BMW R75/5, vintage suspen- sure they go back in their origi- front brakes, previously feeble

sion specialist Matt Wiley at Race Tech nal position. Next, tension the at best, now bite with author-

(racetech.com) contacted me, asking if brake cable until the rear shoe ity, pulling the BMW down from

I knew about Race Tech’s brake arcing just touches the drum. Pull the brake when squeezing the lever. It takes a bit of speed with confidence. The pull on the

service for drum brakes. Briefly, brake arc- lever; the rear shoe should touch the fiddling, moving the stop in and out, but lever is firm, and the small amount of

ing involves machining the brake drum drum first, followed almost immediately what you’re looking for is an even pull “chatter” I used to get with a really firm

so that it’s perfectly round, then matching by the front. The front shoe is adjusted between the front and rear arms, with tug on the lever is completely gone.

the brake shoes to the drum for optimum with the brake shoe stop, located just the rear making initial contact, followed So what price performance? Race Tech

contact. Back when drum brakes were the behind the forward brake arm on the immediately by the front. charges $200-$225 for the service, with

norm, brake arcing was common, but with brake backing plate. To adjust tighter, shipping extra. New Ferodo shoes set

the advent of disc brakes it’s become an hold the brake stop with a 5mm Allen Brakes away me back $77. Add $34.60 for the cable

increasingly rare and specialized service. wrench and loosen the 13mm lock nut. With everything back together I made and the total was around $335. Given the

After talking with Matt, I decided to test Pull lightly on the brake lever and turn the several runs up and down a low-traffic return — properly working brakes I can

the concept. stop with the Allen wrench until you can road, running up to speed before hitting count on — if you’re actually riding your

Before sending my wheel off for service, feel it hitting against the brake inside the the brakes hard to heat them up, followed classic, I’d call this one of the smartest

I checked it against Race Tech’s require- backing plate. Turn it back slightly, lock it by a rest to let them cool, repeating this performance upgrades you can make.

ments. First up was inspecting for any in place, then check the pull of both arms several times to bed the new brake shoes More info: racetech.com — Richard Backus

loose spokes; they must be properly ten-

sioned and the wheel must run straight

and true. Re-tensioning the wheel after Pecard leather dressing tint” to cover up abrasions. After lightly cleaning the leather with

machining runs the risk of pulling the Race Tech’s proprietary tool in place to machine the 1973 BMW R75/5 front drum. The mark of a favorite piece of gear around here is when it gets a damp cloth, I applied the dressing using a soft, dry cloth, work-

drum out of shape, negating any improve- used year after year, even with newer options around. I’ve had ing it into the leather. The dressing did wonders. Not only did it

ments. Next was thoroughly cleaning the the cutter removing metal as it does. The and diameter of the cut on the drum, this Joe Rocket Sonic 2.0 perforated leather jacket since August re-dye the rough edges and worn cuffs, it restored the sun-faded

brake backing plate before installing new black squiggles act as a guide, showing matches the cut to the shoes, ensuring 2006, and it immediately turned into a favorite, becoming my jacket to an even coloring again. As a further bonus, it also mois-

shoes (you can use your old ones if high spots as material is removed; wher- the shoes are exactly concentric to the go-to jacket anytime temperatures were above 65 F or so, which turized the leather, making it softer and suppler.

they’re good, but why would you?) and ever black still shows, the drum hasn’t drum. Simple in concept, it takes the right means I’ve been wearing it for the bulk of my yearly riding. After letting the jacket “dry,” the dressing soaked in nicely. I fig-

making sure the brake cams were properly been cut. This is done in multiple passes, tools and skill to do it correctly. I haven’t given this jacket much care: It’s been wiped down ured it could use one more coat, so for round two I used Pecard’s

lubed. Following that I inspected both the cutter removing as little material as Ten days after sending it out, my wheel with a wet cloth five or six times in its life, but that’s it. The Sonic standard Motorcycle Leather Dressing, applying it outside and

wheel bearings (if they’re old or suspect, possible with each pass until a clean sur- was back and ready for installation, but 2.0 is made from drum-dyed cowhide, and while the finish on in the sun on a 65 F day, letting the leather warm up and really

replace them), then I confirmed the wheel face remains. not before draining the forks and refill- the leather held up and looked sharp for five years or so, after 11 soak in the dressing. I put on a heavy coating, and then hung it

axle was straight before shipping the The shoes are cut next. In this step, ing them with fresh 15 weight fork oil. years it was beyond due for some attention. inside to soak in for a few more days. As the photos show, the

wheel — complete with brake backing the shoes — complete with backing plate Finally, I slipped new fork gaiters in place My jacket had some wear spots on the leather, a brown difference between “before” (left) and “after” (right) is

plate and axle — to Race Tech in Corona, — are held in place while another rotary before reinstalling the forks and bolting shade showing underneath. To restore it, I started with night and day, with my favorite jacket returned to its

California. cutter, set up to exactly duplicate the arc the wheel back up. Pecard’s Motorcycle Black Weatherproof Dressing, former glory — only better. $7 each (4 oz). More

I knew when I started which, they say, “contains a small amount of black info: pecard.com — Landon Hall

Getting true that the original brake

At Race Tech, the wheel cable was stretched almost

is set in a work stand sup- to the limit, so I turned to

ported by its axle. The Barnett Clutches & Cables

inside face of the drum is (barnettclutches.com) for a

then marked with black replacement. Barnett can

squiggly lines. Next, a spe- custom make cables for just

cially made cutting tool about any application, and

designed by Race Tech less than a week after relay-

founder Paul Thede is cen- ing the necessary specs to

tered on the wheel axle. An Ivan at Barnett a new cable

air-powered rotary cutting showed up in the mail.

head attached to the tool is With the new cable

adjusted to just touch the installed, it was time to

drum face. As the cutting adjust the brakes. A twin-

head spins, the tool slowly leading-shoe design, the

revolves around the drum, Black lines act as cutting guide; when they’re gone, the drum’s done. BMW setup needs to be

82 Motorcycle Classics May/June 2017 www.MotorcycleClassics.com 83

You might also like

- Gupta 2022 Eng. Res. Express 4 025039Document21 pagesGupta 2022 Eng. Res. Express 4 025039Mishbah MuwaffaqNo ratings yet

- Manufacturers/suppliers or End-Users of Lubricants and Lubricant-Related ProductsDocument10 pagesManufacturers/suppliers or End-Users of Lubricants and Lubricant-Related ProductsMiguel Angel Cazares GarciaNo ratings yet

- New - Brakes & CkuthesDocument13 pagesNew - Brakes & CkuthesBryan D castroNo ratings yet

- DesignDocument1 pageDesignData GeopageNo ratings yet

- Ingersoll-Rand Sd100D: Customer Owned CertifiedDocument4 pagesIngersoll-Rand Sd100D: Customer Owned CertifiedDiego Alvarez AlvarezNo ratings yet

- Partes ShimanoDocument85 pagesPartes ShimanoMauro Sanchez100% (1)

- XUV300 Brochure Junee 2Document4 pagesXUV300 Brochure Junee 2jigyesh29No ratings yet

- XUV300 Brochure - Aug 20Document4 pagesXUV300 Brochure - Aug 20Rajesh NayakNo ratings yet

- Drum Break Trouble DiagnosisDocument4 pagesDrum Break Trouble DiagnosisnhojyelhsaotigabNo ratings yet

- Touring Bike Lesson 1Document1 pageTouring Bike Lesson 1Mohammad Salem ChowdhuryNo ratings yet

- Traxxas Rad2 - RCCA - 1993-FebDocument3 pagesTraxxas Rad2 - RCCA - 1993-FebRully LlamaNo ratings yet

- Revelator: Lisse PrestigeDocument1 pageRevelator: Lisse PrestigeGalih Adi NugrohoNo ratings yet

- DISC Braking System in CarsDocument8 pagesDISC Braking System in Carsrajib nathNo ratings yet

- ERS - Raptor Wear Product & Dipper Door Solutions PDFDocument12 pagesERS - Raptor Wear Product & Dipper Door Solutions PDFBorisRakelaGonzalezNo ratings yet

- TK PowerFly FS ServiceManual MY23 EN-GB 2023-02-02Document16 pagesTK PowerFly FS ServiceManual MY23 EN-GB 2023-02-02Narcis DobosNo ratings yet

- Gear & Pulley Engineering - How To Specify (AGMA) Face Gear Quality PDFDocument2 pagesGear & Pulley Engineering - How To Specify (AGMA) Face Gear Quality PDFldp162No ratings yet

- Mavic Technical Manual 2018 - 2 - 1Document143 pagesMavic Technical Manual 2018 - 2 - 1Josep A. TERUELNo ratings yet

- RM 64Document632 pagesRM 64Jabita Aguilera CabreraNo ratings yet

- Suspension System Principles: Chapter ObjectivesDocument26 pagesSuspension System Principles: Chapter ObjectivesMallikarjunReddyObbineniNo ratings yet

- PSI DT0732 14feb2020 WO161424365Document1 pagePSI DT0732 14feb2020 WO161424365HubhertusNo ratings yet

- Comprehensive SMG To 6MT ConversionDocument24 pagesComprehensive SMG To 6MT ConversioninthefleshNo ratings yet

- Development of A Dynamic Vibration Absorber To Reduce Frame BeamingDocument11 pagesDevelopment of A Dynamic Vibration Absorber To Reduce Frame Beaminggakada prbNo ratings yet

- Third Generation Montero Aftermarket Accesory Sheet - Sheet1Document4 pagesThird Generation Montero Aftermarket Accesory Sheet - Sheet1Jose Luis Alcivar GuerraNo ratings yet

- Art's Cyclery Blog Science Behind The Magic - Drivetrain CompatibilityDocument10 pagesArt's Cyclery Blog Science Behind The Magic - Drivetrain CompatibilitygkovacsdsNo ratings yet

- Chapter 5 PDFDocument40 pagesChapter 5 PDFNakum VijayNo ratings yet

- 2021 Integration Manual: Tested - Proven - TrustedDocument28 pages2021 Integration Manual: Tested - Proven - TrustedSENTHIL NATHANNo ratings yet

- Parking BrakeDocument17 pagesParking BrakeMarco CalderonNo ratings yet

- Toyota Yaris Hatch BackDocument1 pageToyota Yaris Hatch Backmiki tesfayNo ratings yet

- 2013 TranzX Ebike-SystemDocument2 pages2013 TranzX Ebike-SystemLECLERCQNo ratings yet

- WWW Physicsforums Com Threads What Makes A Connecting Rod Turn A Crank One Way 955322Document9 pagesWWW Physicsforums Com Threads What Makes A Connecting Rod Turn A Crank One Way 955322raja.maharaja789No ratings yet

- Touratech Hard PartsDocument3 pagesTouratech Hard PartsItsaconnetNo ratings yet

- AI Automatic e FVDocument2 pagesAI Automatic e FVgottes_soldat7067No ratings yet

- IZIP Electric Bicycle Owners ManualDocument49 pagesIZIP Electric Bicycle Owners ManualMelissa Ann FernandezNo ratings yet

- Lista Applicazioni - Application List: Bitubo & Xavi Fores With BMW S1000RR Spanish Champion 2010Document84 pagesLista Applicazioni - Application List: Bitubo & Xavi Fores With BMW S1000RR Spanish Champion 2010JoseNo ratings yet

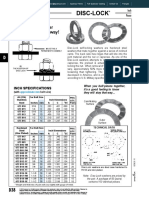

- Bolt It Together and It Stays That Way!: Rondelles de SécuritéDocument1 pageBolt It Together and It Stays That Way!: Rondelles de SécuritéfernandoraiasaNo ratings yet

- Easyboost Carburetor 17.5 MM PHBN Manual ..Document6 pagesEasyboost Carburetor 17.5 MM PHBN Manual ..Tom De BruyckereNo ratings yet

- C - Brake AssembliesDocument36 pagesC - Brake Assembliesorder2614No ratings yet

- Brakes Calculation For ProjectsDocument41 pagesBrakes Calculation For ProjectsRodolfo Correa de LimaNo ratings yet

- Torque Wrench ServicingDocument2 pagesTorque Wrench ServicingTonio DimaculanganNo ratings yet

- Popular Mechanics - Curing Premature Brake Wear PDFDocument4 pagesPopular Mechanics - Curing Premature Brake Wear PDFFlorin CostinNo ratings yet

- Commodore - S Garage #25 - Bumpstop Contact in Telemetry - IRacingDocument4 pagesCommodore - S Garage #25 - Bumpstop Contact in Telemetry - IRacingHitesh VashistNo ratings yet

- Ratchet Amb1012Document2 pagesRatchet Amb1012Dennis SinnedNo ratings yet

- Catalogo 2021Document92 pagesCatalogo 2021Abdalan da GamaNo ratings yet

- Timken Premium Wheel Hub Units Info GraphicDocument1 pageTimken Premium Wheel Hub Units Info Graphicjack661688No ratings yet

- HEPI CS How To Kill Your Undercarriage-1Document3 pagesHEPI CS How To Kill Your Undercarriage-1Lord Nafaryus100% (1)

- Bada Dost I4Document4 pagesBada Dost I4Ramesh anurithNo ratings yet

- Akebono Report 2016en 08Document3 pagesAkebono Report 2016en 08Raajeswaran BaskaranNo ratings yet

- Link BeltDocument6 pagesLink Beltnelson santosNo ratings yet

- Design Report DFMEA Validation PresentationDocument65 pagesDesign Report DFMEA Validation PresentationRilberson BatistaNo ratings yet

- SM 22 PDFDocument341 pagesSM 22 PDFdanielNo ratings yet

- Giantbicycles 76098 TCR - Advanced.2Document1 pageGiantbicycles 76098 TCR - Advanced.2Werner SchulzNo ratings yet

- Failure Modes and Effects Analysis (FMEA)Document1 pageFailure Modes and Effects Analysis (FMEA)walterbircherNo ratings yet

- VW Racing Drop and Raise Plates: VW Tech Tip VW Tech TipDocument4 pagesVW Racing Drop and Raise Plates: VW Tech Tip VW Tech Tiprodney_massieNo ratings yet

- Diaphragm Vs Disc Vs Gear Couplings - Who, What, Where, When, and Why - Coupling Answers - Where The World Turns For Coupling KnowledgeDocument5 pagesDiaphragm Vs Disc Vs Gear Couplings - Who, What, Where, When, and Why - Coupling Answers - Where The World Turns For Coupling Knowledgerizqi widodoNo ratings yet

- Tough TO Beat.: Presenting The Bolero With New Looks, More Power and Better SafetyDocument2 pagesTough TO Beat.: Presenting The Bolero With New Looks, More Power and Better SafetyRishabh MahajanNo ratings yet

- Design and Optimization of Disc Brake Rotor: Department of Mechanical EngineeringDocument1 pageDesign and Optimization of Disc Brake Rotor: Department of Mechanical EngineeringAbhishekNo ratings yet

- Popular Mechanics Calming A Pulsating Brake PedalDocument4 pagesPopular Mechanics Calming A Pulsating Brake PedalAdriana OrtegaNo ratings yet

- HawkEye EliteDocument21 pagesHawkEye EliteYgames 2016No ratings yet

- Truck & Off-Highway Engineering - December 2023Document38 pagesTruck & Off-Highway Engineering - December 2023alemao7x1 DiehlNo ratings yet

- ModelEngineersWorkshopMagazineJulyAugust2020 Sanet STDocument68 pagesModelEngineersWorkshopMagazineJulyAugust2020 Sanet STalemao7x1 DiehlNo ratings yet

- Motor Trend - July 2023Document84 pagesMotor Trend - July 2023alemao7x1 DiehlNo ratings yet

- CMMJ2016Document132 pagesCMMJ2016alemao7x1 DiehlNo ratings yet

- Classic Truck Performance 07.2023Document100 pagesClassic Truck Performance 07.2023alemao7x1 DiehlNo ratings yet

- ModelEngineersWorkshopMagazineJune2020 Sanet STDocument68 pagesModelEngineersWorkshopMagazineJune2020 Sanet STalemao7x1 DiehlNo ratings yet

- See Where To Focus Your Efforts For The Greatest Effect - Ralph Williams, Life Coach and MentorDocument2 pagesSee Where To Focus Your Efforts For The Greatest Effect - Ralph Williams, Life Coach and Mentoralemao7x1 DiehlNo ratings yet

- Model Engineers Workshop March 2022Document68 pagesModel Engineers Workshop March 2022alemao7x1 DiehlNo ratings yet

- Garelli Moped Workshop Service Repair ManualDocument34 pagesGarelli Moped Workshop Service Repair Manualalemao7x1 DiehlNo ratings yet

- The Economist Uk 18 03 2023Document84 pagesThe Economist Uk 18 03 2023alemao7x1 DiehlNo ratings yet

- Swish! - Volume 2 Number 7 1979Document27 pagesSwish! - Volume 2 Number 7 1979alemao7x1 DiehlNo ratings yet

- 40something - Volume 365 - Summer 2023Document100 pages40something - Volume 365 - Summer 2023alemao7x1 Diehl50% (2)

- Inspired Magazine - Bike Shed Moto - 27 September 2023Document15 pagesInspired Magazine - Bike Shed Moto - 27 September 2023alemao7x1 DiehlNo ratings yet

- Easyriders - July 1995Document14 pagesEasyriders - July 1995alemao7x1 DiehlNo ratings yet

- Motorcycle Classics 09.10 2023Document84 pagesMotorcycle Classics 09.10 2023alemao7x1 DiehlNo ratings yet

- Bloomberg Businessweek USA 05.22.2023Document64 pagesBloomberg Businessweek USA 05.22.2023alemao7x1 DiehlNo ratings yet

- Janus 6.08Document64 pagesJanus 6.08alemao7x1 DiehlNo ratings yet

- Web PT English EnglishDocument32 pagesWeb PT English Englishalemao7x1 DiehlNo ratings yet

- Moto Show 1991 Globo 1Document36 pagesMoto Show 1991 Globo 1alemao7x1 DiehlNo ratings yet

- VJMCDocument32 pagesVJMCalemao7x1 DiehlNo ratings yet

- Cheri - August 1991Document108 pagesCheri - August 1991alemao7x1 DiehlNo ratings yet

- Yz125n Yz125 Yz125 Yz125n: (5MV1) (5MV2) (5MV3) (5MV4)Document56 pagesYz125n Yz125 Yz125 Yz125n: (5MV1) (5MV2) (5MV3) (5MV4)alemao7x1 DiehlNo ratings yet

- Manual Agrale 30.0 - Part VDocument4 pagesManual Agrale 30.0 - Part Valemao7x1 DiehlNo ratings yet

- Upgrade CPU of Aspire 5741. Is It Possible - NotebookReviewDocument8 pagesUpgrade CPU of Aspire 5741. Is It Possible - NotebookReviewalemao7x1 DiehlNo ratings yet

- Suzuki T 350 Service Manual Eng - InglésDocument31 pagesSuzuki T 350 Service Manual Eng - Inglésalemao7x1 DiehlNo ratings yet

- Mx250a Mx360aDocument47 pagesMx250a Mx360aalemao7x1 DiehlNo ratings yet

- Tabela GiglêDocument1 pageTabela Giglêalemao7x1 DiehlNo ratings yet

- Service Manual For M15 and M15D Machines - SuzukiDocument49 pagesService Manual For M15 and M15D Machines - Suzukialemao7x1 DiehlNo ratings yet

- Jamapediatrics Tagarro 2020 LD 200024Document2 pagesJamapediatrics Tagarro 2020 LD 200024alemao7x1 DiehlNo ratings yet

- Night Owl Magazine Issue 15 The Burlesque 2020Document52 pagesNight Owl Magazine Issue 15 The Burlesque 2020alemao7x1 Diehl100% (3)

- 2.61 Internal Combustion Engine: ND RD TH THDocument3 pages2.61 Internal Combustion Engine: ND RD TH THNarendra TummalaNo ratings yet

- 01-43-01 REAR AXLE SYSTEM (PART-1) Dp30N 98733-06110 Cat Chassis, Mast, Options & Internal Hosing Chassis Axle 01-43-01 Rear Axle System (PART-1)Document2 pages01-43-01 REAR AXLE SYSTEM (PART-1) Dp30N 98733-06110 Cat Chassis, Mast, Options & Internal Hosing Chassis Axle 01-43-01 Rear Axle System (PART-1)allNo ratings yet

- TSB Gen 022 Rev 2Document6 pagesTSB Gen 022 Rev 2Trọng Nghĩa VõNo ratings yet

- Carens Brochure Final ENnewDocument8 pagesCarens Brochure Final ENnewAthar KhanNo ratings yet

- 18V38A Instructions For Alignment of Flexible Mounted Engines PDFDocument7 pages18V38A Instructions For Alignment of Flexible Mounted Engines PDFRonald Bienemi100% (1)

- 370-1 AN PREMIUM-BodywExtras - 06-01Document178 pages370-1 AN PREMIUM-BodywExtras - 06-01Wi DuddaaNo ratings yet

- TECHNICAL REPORT Toyota Hilux 2019Document8 pagesTECHNICAL REPORT Toyota Hilux 2019Neven TrencNo ratings yet

- HSE-TP-102-C Lifting Plan Using Mobile CraneDocument13 pagesHSE-TP-102-C Lifting Plan Using Mobile CraneSyed Fawad ShahNo ratings yet

- Taylor TEC950L Forklift Truck Parts Manual PDFDocument212 pagesTaylor TEC950L Forklift Truck Parts Manual PDFNadeem AhmedNo ratings yet

- Perubahan Nilai Ekivalensi Mobil Penumpang Akibat Perubahan Karakteristik Operasional Kendaraan Di Jalan Kota SemarangDocument8 pagesPerubahan Nilai Ekivalensi Mobil Penumpang Akibat Perubahan Karakteristik Operasional Kendaraan Di Jalan Kota SemarangBisnisku BerkahNo ratings yet

- GSRTC - Varun Gandhidham TKTDocument1 pageGSRTC - Varun Gandhidham TKTMANISH AJITWALIANo ratings yet

- Hydraulic Systems and Components For Medium Sized BulldozerDocument4 pagesHydraulic Systems and Components For Medium Sized BulldozerDibas BaniyaNo ratings yet

- 13u-0000-004-2 Erection Kinematics (Cinematique-Montage)Document19 pages13u-0000-004-2 Erection Kinematics (Cinematique-Montage)hanyNo ratings yet

- UntitledDocument100 pagesUntitledRodrigo BerganoNo ratings yet

- SPC Pulsar NS 200 BS IV - AS200 (2018 07 24)Document105 pagesSPC Pulsar NS 200 BS IV - AS200 (2018 07 24)Willy Mansilla ANo ratings yet

- Risk Assessment Template For Film and Video ProductionDocument3 pagesRisk Assessment Template For Film and Video Productionapi-646836603No ratings yet

- Carmix One: ArticulatedDocument2 pagesCarmix One: ArticulatedSuniv ShresthaNo ratings yet

- Portland Traffic Crash Report 2021Document11 pagesPortland Traffic Crash Report 2021KGW NewsNo ratings yet

- SM ZX200-5G-1 PDFDocument502 pagesSM ZX200-5G-1 PDFM Choirul Azhar100% (3)

- Installation Instructions For: EMS P/N 30-1010 00-01 Acura Integra 98-99 Acura 2.3CL 98-02 Honda Accord 99-00 Honda CivicDocument7 pagesInstallation Instructions For: EMS P/N 30-1010 00-01 Acura Integra 98-99 Acura 2.3CL 98-02 Honda Accord 99-00 Honda Civicadulfo03455No ratings yet

- Minutes NDC 2 Construction Meeting 20 June 23Document3 pagesMinutes NDC 2 Construction Meeting 20 June 23GlorieNo ratings yet

- Airworthiness Procedures Manual: Appendix IVDocument2 pagesAirworthiness Procedures Manual: Appendix IVShivamSrivastavaNo ratings yet

- Montaža Dautel RampiDocument61 pagesMontaža Dautel RampiLikNo ratings yet

- Tesla Vs FordDocument14 pagesTesla Vs FordSarah MurphyNo ratings yet

- VP37 Remap Guide Rev 4Document22 pagesVP37 Remap Guide Rev 4Georgiana MarinNo ratings yet

- KTM FEEDbackDocument27 pagesKTM FEEDbackNithish SNo ratings yet

- Tagaya Loi Marie Hm209 Exercise 2Document5 pagesTagaya Loi Marie Hm209 Exercise 2loi tagayaNo ratings yet

- Activity 17 ADocument2 pagesActivity 17 ANewtonNo ratings yet

- Np300 HardbodyDocument11 pagesNp300 HardbodySarol NathanNo ratings yet

- Saint Mary'S High School: Q.1 Fill in The BlanksDocument2 pagesSaint Mary'S High School: Q.1 Fill in The BlanksASIF KHANNo ratings yet