Professional Documents

Culture Documents

ISO 17020 Checklist

Uploaded by

Adrian Wong0 ratings0% found this document useful (0 votes)

3 views6 pagesOriginal Title

ISO 17020 Checklist Copy

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views6 pagesISO 17020 Checklist

Uploaded by

Adrian WongCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 6

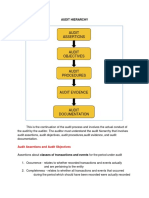

Clauses Evidence

Administrative Requirements Contractucal Conditions

-Documented inspection history

-Responsibility for safe site access

-Timely availability of key client personnel

-Preparation of items for inspection

-Response to adverse weather conditions

-Level of Reporting

-Terms of payment

-Level of liability insurance, etc

Independence, Impartiality and Reporting and recording of any incidents of

Integrity undue pressure experienced by personnel

-This includes through financial, marketing,

customer relations and personal matters, as

well as by other technical or non-technical

considerations.

Organization and Management Organization chart- Include position and

responsibilities in quality system

documentation

Quality System ·Policy statements

·Training records

·Document control system

· Internal feedback, complaints, preventative

action plan

·Management review

Personnel ·All stages of training records

·Recording duration of inspections

Facilities and equipment ·Measurement traceability

·Appropriate uncertainty of measurement

·In-service records of equipment checks

·Inspection reports

·Software validation and checks records

Inspection methods and ·Documentation of standard and all

procedures non-standard inspection methods

·Record of checking points and verification

of checks made

Records Inspection records-

·client instructions

·details of job review

• details of the items inspected &

inspection conditions

• information provided by the client &

identity of the person who performed the

inspection

• equipment used

• equipment verification records

• the inspection procedures used

• inspection observations & conformity

decisions (with supporting justification)

• aspects not inspected, with reasons

given, e.g. lack of safe access

Inspection records and inspection Inspection records and inspection certificates

certificates

Subcontracting ·Technical competence assessment

Complaints and appeals ·Complaint records

·Appeal records

Comments

In the case of Type C inspection

bodies the conditions of contract should include a clear

statement of the activities that prevent it being classified as a

Type A inspection body.

In the case of type C inspection

bodies, contractual conditions should include a clear

statement summarising the interests or activities of the

inspection body or associated bodies that resulted in the

type C classification. This statement should be sufficiently

explicit to enable potential clients to make informed

decisions on the adequacy of the level of independence

offered.

Functions of the technical manager may include,

but not be limited to, authorisation of inspection methods,

and technical support for inspectors.

In cases where an inspection body has a number

of offices in different locations, responsibility for the practical

maintenance of the quality system should be assigned to a

named individual in each office.

There must be a clear and authoritative means for all

employees to identify the current authorised version of any

controlled document.

Effective systems must be in place to ensure that each

relevant employee has

been made aware of and understands updates to any

document which could affect the conduct, outcome,

recording or reporting of an inspection.

Procedures for feedback and corrective action should

normally include but not be limited to the following

constituents:

• description of the issue

• investigation of the cause

• description of immediate action taken

• description of corrective action to be taken to prevent

recurrence

• identification of the person responsible for corrective

action

• target date for completion of corrective action

• monitoring of progress of corrective action

• sign off of completed corrective action

Note: Training records do not establish competence. They are a

statement that the management considers the individual to be

competent to perform specific inspection tasks and, where

relevant, to use specific equipment.

An inspection body that performs large numbers of routine

inspections may perform less than 100% checking. In such

cases justification of the sampling method and sample size

should be documented

Additional information requirements should be considered at

the times of the inspection and subsequent reporting.

Accreditation cannot normally be claimed for an inspection

report that relies upon material provided by a subcontractor

that does not have demonstrated competence as required by

clause 14.2 of ISO/IEC 17020. Where regulations or other

authoritative requirements stipulate that a report must

include a claim of accreditation, all information, critical to the

inspection decision, provided by a body that does not have

demonstrated competence, should be clearly identified as

such.

Complaints should include all feedback from dissatisfied

clients,

regulators or other stakeholders, however received.

You might also like

- SupplierAudit FormateDocument5 pagesSupplierAudit FormateimamudeenNo ratings yet

- QMS Inspection ProcedureDocument5 pagesQMS Inspection ProcedureSang Hà100% (1)

- Qualifications and Validation in Pharmaceutical Industry 1662371200Document63 pagesQualifications and Validation in Pharmaceutical Industry 1662371200Cyclone Pharmaceuticals Pvt Ltd PuneNo ratings yet

- Qualification and Validation 1701994798Document65 pagesQualification and Validation 1701994798Andrés PacompíaNo ratings yet

- QMS Inspection ProcedureDocument5 pagesQMS Inspection ProcedureReyhan MfNo ratings yet

- Calibration and Validation IntroDocument42 pagesCalibration and Validation Introujjwal100% (1)

- Qualification and Validation-34163308Document31 pagesQualification and Validation-34163308atif saadaoui100% (1)

- Calibration of EquipmentDocument80 pagesCalibration of EquipmentVivek Sagar100% (3)

- Qualification ValidationDocument29 pagesQualification ValidationmrugeshjNo ratings yet

- Introduction To Internal AuditingDocument59 pagesIntroduction To Internal AuditingPaviththira sivaNo ratings yet

- Calibration - Qualification and ValidationDocument60 pagesCalibration - Qualification and ValidationPardeep Kumar100% (1)

- 560-S27 QUALITY CONTROL PROGRAM Rev.4Document27 pages560-S27 QUALITY CONTROL PROGRAM Rev.4AbdelmuneimNo ratings yet

- Notes On PSA-330Document75 pagesNotes On PSA-330Desree GaleNo ratings yet

- ObjectivityDocument7 pagesObjectivityvaratharaj bNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Audit Evidence and Audit Documentation Nature and Types Audit EvidenceDocument4 pagesAudit Evidence and Audit Documentation Nature and Types Audit EvidenceCattleyaNo ratings yet

- HSE Auditors TrainingDocument66 pagesHSE Auditors Trainingparadigman100% (4)

- Qualification and Validation in Pharmaceutical ManufacturingDocument65 pagesQualification and Validation in Pharmaceutical Manufacturingabdelhakim ougaidaNo ratings yet

- CIS ReportDocument10 pagesCIS ReportMarieNo ratings yet

- Sample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7Document7 pagesSample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7YAMA ENGINEERSNo ratings yet

- M5 Internal Audit - TUVDocument55 pagesM5 Internal Audit - TUVSytco QualityNo ratings yet

- Audit PlanningDocument21 pagesAudit Planningablay logeneNo ratings yet

- Equipment Maintenance and UseDocument53 pagesEquipment Maintenance and UseRam Mohan S100% (1)

- Metodología PropuestaDocument16 pagesMetodología PropuestaDaniel ThomsonNo ratings yet

- NR 09 - Occupational Radiation Protection 13Document50 pagesNR 09 - Occupational Radiation Protection 13CPSSTNo ratings yet

- At.3204 Nature and Type of Audit EvidenceDocument7 pagesAt.3204 Nature and Type of Audit EvidenceDenny June CraususNo ratings yet

- AT.3404 - Audit Evidence and DocumentationDocument6 pagesAT.3404 - Audit Evidence and DocumentationMonica GarciaNo ratings yet

- NRC Inspection Manual: Nmss/RiiDocument10 pagesNRC Inspection Manual: Nmss/RiiFery MahardikaNo ratings yet

- Materi Test of ControlDocument66 pagesMateri Test of ControlIntan100% (1)

- At.106.2 Audit Evidence Gathering My StudentsDocument7 pagesAt.106.2 Audit Evidence Gathering My StudentsLimuel NievoNo ratings yet

- CIC 3 - InternalAudit2Document4 pagesCIC 3 - InternalAudit2ssabih75No ratings yet

- Ais3 NotesDocument26 pagesAis3 NotesHatdogNo ratings yet

- Process Validation Update: Jerry Holatko Pharmeng Technology IncDocument34 pagesProcess Validation Update: Jerry Holatko Pharmeng Technology IncAbd Al-Rahmman Al-qatananiNo ratings yet

- LS 3.00 - PSA 330 Auditor's Response To Assessed RiskDocument5 pagesLS 3.00 - PSA 330 Auditor's Response To Assessed RiskSkye LeeNo ratings yet

- Class 13 - Audit EvidenceDocument18 pagesClass 13 - Audit EvidenceTimothy AndreasNo ratings yet

- CMS Control of Calibration Verification and ValidationDocument5 pagesCMS Control of Calibration Verification and ValidationAmine RachedNo ratings yet

- Calibrations Basic WhitepaperDocument4 pagesCalibrations Basic WhitepaperMaruthiRajeshAmbatipudiNo ratings yet

- Controls in Computer AuditingDocument13 pagesControls in Computer AuditingPANASHE MARTIN MASANGUDZANo ratings yet

- 8) SOP-1190 QA AuditingDocument2 pages8) SOP-1190 QA AuditingVô ThườngNo ratings yet

- Auditando Un Sistema ValidacionDocument8 pagesAuditando Un Sistema ValidacionIglesias LauraNo ratings yet

- Quality Standards: 1. HardwareDocument3 pagesQuality Standards: 1. HardwareMARFE IMPASTANo ratings yet

- Systems and Controls Kaplan Chapter 8: Acca Paper F8 Int Audit and AssuranceDocument24 pagesSystems and Controls Kaplan Chapter 8: Acca Paper F8 Int Audit and AssuranceAbdullah HaddadNo ratings yet

- WI Quality AssuranceDocument3 pagesWI Quality Assurancearifin rizalNo ratings yet

- SMWW 2882 005Document11 pagesSMWW 2882 005Renan LourençoNo ratings yet

- 2 Into To FS Audit and Pre-Engagement ActivitiesDocument40 pages2 Into To FS Audit and Pre-Engagement ActivitiesKane BuendiaNo ratings yet

- S1194-Audit Report-Modern Precision Engineering FactoryDocument9 pagesS1194-Audit Report-Modern Precision Engineering FactoryMuhammad IrfanNo ratings yet

- Audit TechniquesDocument23 pagesAudit TechniquesHari PurwadiNo ratings yet

- S1248-Audit stage1-SAS RTL CON - EST.Document9 pagesS1248-Audit stage1-SAS RTL CON - EST.Muhammad IrfanNo ratings yet

- Modern Auditing: Modern AuditingDocument31 pagesModern Auditing: Modern AuditingNur AiniNo ratings yet

- Pharmaceutical Quality Management-1 (614-T)Document19 pagesPharmaceutical Quality Management-1 (614-T)Tayyab SiddiquiNo ratings yet

- Nongovernment Organizations (NG O) Solicitation of Sel LER ResponsesDocument13 pagesNongovernment Organizations (NG O) Solicitation of Sel LER ResponsesFrancis PaczNo ratings yet

- 1 - INTRODUCTION - 2018 - Rev. 1Document27 pages1 - INTRODUCTION - 2018 - Rev. 1khamdanNo ratings yet

- Quality System Elements: Contract NoDocument1 pageQuality System Elements: Contract NoTanmay VegadNo ratings yet

- Internal Audit ProceeduresDocument28 pagesInternal Audit ProceeduresMarcos WilkerNo ratings yet

- 4 5850471109056532136Document38 pages4 5850471109056532136Yehualashet MulugetaNo ratings yet

- Cisa Module 1 Part B ExecutionDocument32 pagesCisa Module 1 Part B ExecutionREJAY89No ratings yet

- Audit - Isa 500Document6 pagesAudit - Isa 500Imran AsgharNo ratings yet

- Good Practices in Quality ControlDocument35 pagesGood Practices in Quality Controlmulatu mokononNo ratings yet

- Design and Development ValidationDocument70 pagesDesign and Development ValidationDarwin BaguioNo ratings yet

- Lecture 5 - Completion of Audit (Part 1)Document17 pagesLecture 5 - Completion of Audit (Part 1)Mohammed Saeed Al-rashdiNo ratings yet

- Week 1 - Discrete-Time Signals and Systems (Convolution & Correlation)Document25 pagesWeek 1 - Discrete-Time Signals and Systems (Convolution & Correlation)Adrian WongNo ratings yet

- Chapter 6 - Power System CalculationsDocument34 pagesChapter 6 - Power System CalculationsAdrian WongNo ratings yet

- What Is RC Series Circuit - Phasor Diagram and Power Curve - Circuit GlobeDocument6 pagesWhat Is RC Series Circuit - Phasor Diagram and Power Curve - Circuit GlobeAdrian WongNo ratings yet

- Power Triangle and Power Factor in AC CircuitsDocument10 pagesPower Triangle and Power Factor in AC CircuitsAdrian WongNo ratings yet

- Swot Analysis Edited2Document8 pagesSwot Analysis Edited2Ronnel CompayanNo ratings yet

- Lot 4 - Lamu Sub-Centre - Bill of Quantities, Specifications & Drawings-Tender Reference No-kefri-Ont-011-2022-2023Document297 pagesLot 4 - Lamu Sub-Centre - Bill of Quantities, Specifications & Drawings-Tender Reference No-kefri-Ont-011-2022-2023gonyango561No ratings yet

- Panaya Test Automation DatasheetDocument4 pagesPanaya Test Automation DatasheetpravalikakaranNo ratings yet

- The Stakeholders Group 3 SRGGDocument15 pagesThe Stakeholders Group 3 SRGGFuyumi HikotoNo ratings yet

- 1: Identification of ActivitiesDocument1 page1: Identification of Activitieslmao idkNo ratings yet

- Contractor Work Preparation Process Improvement Using Lean Six SigmaDocument29 pagesContractor Work Preparation Process Improvement Using Lean Six SigmaJulia De Oliveira MoraisNo ratings yet

- Lecture 6 (Part A) : Supply Chain Management ModelsDocument13 pagesLecture 6 (Part A) : Supply Chain Management ModelsAbelaNo ratings yet

- Process Engineering Manager 1584877653Document2 pagesProcess Engineering Manager 1584877653azerty KuwaitNo ratings yet

- Internal Verification of Assessment Decisions - BTEC (RQF) : Higher NationalsDocument44 pagesInternal Verification of Assessment Decisions - BTEC (RQF) : Higher NationalsJASRA FAZEERNo ratings yet

- Professional SalesmanshipDocument12 pagesProfessional SalesmanshipMarianne Bag-aoNo ratings yet

- 387 P16mba17 2020051606022529Document266 pages387 P16mba17 2020051606022529JcharlesvNo ratings yet

- Hem Chandra Joshi: OBJECTIVE - Render Dedicated Services in A Reputed Company To Achieve Excellence inDocument6 pagesHem Chandra Joshi: OBJECTIVE - Render Dedicated Services in A Reputed Company To Achieve Excellence inGetrafter ANo ratings yet

- SERVICE MANAGEMENT Unit 3Document10 pagesSERVICE MANAGEMENT Unit 3Parth KumarNo ratings yet

- Impact of Service Quality Corporate Image and Perceived Value On Brand Loyalty With Presence and Absence of Customer SatisfactionDocument24 pagesImpact of Service Quality Corporate Image and Perceived Value On Brand Loyalty With Presence and Absence of Customer SatisfactionNurulfitrahhafidNo ratings yet

- 22 27351 002 Matter 1 1 Device Library SpecificationDocument95 pages22 27351 002 Matter 1 1 Device Library Specificationcagona5339No ratings yet

- Running Head: UNIT I CASE STUDYDocument5 pagesRunning Head: UNIT I CASE STUDYPulkit NagpalNo ratings yet

- B - Communication Management PlanDocument1 pageB - Communication Management PlanBig FleaNo ratings yet

- Marketing's AssignmentDocument9 pagesMarketing's AssignmentAyeshaNo ratings yet

- BNK Sector NosDocument22 pagesBNK Sector NosKrishna Reddy SvvsNo ratings yet

- Integration of FI With MM and SDDocument1 pageIntegration of FI With MM and SDNeelesh KumarNo ratings yet

- The Failure of Pepsi Blue in Indian MarketDocument22 pagesThe Failure of Pepsi Blue in Indian MarketAdil MohammedNo ratings yet

- SAP PracticeDocument14 pagesSAP PracticemunafNo ratings yet

- BBC International LTD 1t 24may2020 UbsDocument19 pagesBBC International LTD 1t 24may2020 Ubspezhmanbayat924No ratings yet

- Brochure About Acsv Legal - 1550219536Document4 pagesBrochure About Acsv Legal - 1550219536Ky HàNo ratings yet

- Bid Evaluation Report and Recommendation For Award of ContractDocument11 pagesBid Evaluation Report and Recommendation For Award of ContractAddisu TsegayeNo ratings yet

- APES 325:: Risk Management For Firms Fact SheetDocument2 pagesAPES 325:: Risk Management For Firms Fact SheetVMRONo ratings yet

- BSBWRT411 Project Portfolio FhonDocument19 pagesBSBWRT411 Project Portfolio FhonLisa SripruekNo ratings yet

- Index of Activities: Chartered Accountants Program Financial Accounting & ReportingDocument150 pagesIndex of Activities: Chartered Accountants Program Financial Accounting & ReportingJAGRUITI JAGRITINo ratings yet

- Top 5 Problems On Overhead With Solutions - Cost AccountingDocument1 pageTop 5 Problems On Overhead With Solutions - Cost AccountingAMRITHANo ratings yet

- Quiz in Entrepreneurship LESSON 4: Entrepreneurial Ventures in The PhilippinesDocument3 pagesQuiz in Entrepreneurship LESSON 4: Entrepreneurial Ventures in The PhilippinesJustine Elissa Arellano MarceloNo ratings yet