Professional Documents

Culture Documents

Monitoring_and_Controlling_Electric_Powe

Uploaded by

Asso Raouf MajeedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monitoring_and_Controlling_Electric_Powe

Uploaded by

Asso Raouf MajeedCopyright:

Available Formats

Kurdistan Journal of Applied Research (KJAR)

Print-ISSN: 2411-7684 | Electronic-ISSN: 2411-7706

Website: Kjar.spu.edu.iq | Email: kjar@spu.edu.iq

Monitoring and Controlling Electric

Power Stations Using GSM Network

Goran H. Ismail Bilal A. Mubdir

Electrical Engineering Department Communication Department,

Faculty of Engineering Technical Institute of Sulaimani

University of Sulaimani Sulaumani Polytechnic University

Sulaimani, Iraq Sulaimani, Iraq

goran.hama@gmail.com bilal.mubdir@spu.edu.iq

Asso R. Majeed Asaad M. Jassim Al-Hindawi

Electrical Engineering Department Communication Engineering Department

Faculty of Engineering Technical College of Engineering

University of Sulaimani Sulaimani Polytechnic University

Sulaimani, Iraq Sulaimani, Iraq

asso.majeed@univsul.edu.iq asaad.jasim@spu.edu.iq

Volume 4 - Issue 2 Abstract

December 2019 This paper introduces a system design for monitoring and

controls the components of power generation station and

DOI: substation with help of existing communication link based

10.24017/science.2019.2.7 on GSM network. In this design, a selected Programmable

Logic Controller (PLC) connected to the fields that needed

Received: to be monitored and continuously read changes in

23 July 2019 measurements of electrical parameters like voltage, current,

bus bar circuit breakers…..etc.. These parameters have been

Accepted: monitored by PLC, on the base of conditions that PLC is

03 October 2019 programmed. PLC generates a text message and forward to

other side; control center or mobile phone of engineer and

technicians; who are responsible of monitoring. At control

center, another GSM modem which has capability to

connect with personal computer, receives that text massage

using SMS and executes it. Software written with Vb.Net,

works as Human Machine Interface (HMI) for this purpose.

The system performance is acceptable in terms of errors in

readings and time delay. The percentage error for the

current is about 1%, and for the voltage is about 0.2%. The

delivery time to receive new analog and digital inputs data is

about 14.125 seconds, while the control of the circuit done

after 4.68 seconds.

Keywords: GSM Modem, HMI, PLC, Sensor, SMS

1. INTRODUCTION

At present, the recent technologies developed strongly and the popularity for the electric

vehicles is increasing and so the energy consumption is increasing day by day. The Energy

represents the vital need of the humans being where the energy demand is much greater than

the actual energy generated in almost all countries. The Energy considered as one of the basic

infrastructure for the growth of any economy and a key factor in assessing the progress of any

country. In the last two decades, many studies have been conducted to design and implement

different types of electrical power management systems based on the use of modern

telecommunication system, such as those conducted by Ganiyu, et al [1], and Al-Hindawi, et

al. [2],[3],[4] for the system management and electric energy saving. In those papers, an

inexpensive products have been used to establish monitoring and control system based on an

open source software.

Dabont, et al. [5] found that the long distance between generators and loads was an important

parameter. Thus, large quantity of energy exchanges through long distances has been

transformed by the lack of electrical power; a great deal of energy is lost during the

transmission of generated energy, resulting in a reduction in the amount of energy received at

substations. Therefore, measurements must be obtained either by one party or by both parties.

Petrescu, et al. [6] designed and implemented a system of monitoring and control based on

SMSfor the application of telemetry. They tested some wireless technologies, but they focused

on the GSM modem and the efficiency of using SMS. SMS is used to report a particular

position such as power outages. In addition, a controller is used as a processing unit and a

GSM modem used for communication purposes.

Jawarkar et al. [7] developed a remote control system and mobile-based controls, and alerts

the user when abnormal conditions such as power outages occur. They have programmed an

algorithm to create a text message that can be transmitted to the user's phone. Their system

embodies a mobile device designed to connect to the GSM network and receive and execute

the desired arrangement of the user.

Xiao, et al [8] presented a system depends on the GSM network, which can monitor the power

lines reliably. Using the SMS service, the network is realized for remote data transfer. The

system consists of a control center and smart power lines monitoring instruments. This system

was mainly based on information theory and SMS system that are analyzed. Instruments

consist of hardware and software designs. The hardware design consists of the 89C2051

microcomputer, the data transmission mode of GSM, the ground line monitoring service, the

IC memory card module (the identification card), and so on. Using the SMS G100A serial

connection controller, the performance of data transmission could be efficient. The designs of

communication protocol and transceiver program were the basic of the software programs.

Test results and practicality show that the design of this system can meet user requirements.

This system will be strongly applied in many fields and has a great economic level.

Sachan[9]introduced a project to obtain remotely the electrical parameters such as voltage,

current and frequency and transmit these values in addition to the temperature at the power

plant in real time via modem / phone based on GSM network system. By using arunning

electromagnetic relay, the proposed system can protect the electric circuits. When the

electrical parameters exceed certain values that are specified previously then the relay will be

on. This relay can activate the circuit breaker in order to turn off the main power source. The

reading of electric parameters could be obtained remotely when the user transmits the required

commands in the shape of SMS. At regular periods the user can receive the electrical

parameters in real time as short massages (depends on time setting).The designed system can

alert the user via SMS when the circuit breakers are disconnected or when the voltage or

current increases over the preset levels. The proposed project uses a computer on board,

usually called a microcontroller. This computer can communicate efficiently with the required

various sensors. For holding the required code, some of internal memory is provided with the

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 81

used controller. The function of this memory is to dump some set of assembly instructions in

the controller. The work of the controller depends on these assembly instructions. It is

programmed based on the built-in C language. Jusoh, et al. [10] designed a smart Remote

Terminal unit (RTU) which is used as an automatic technology for low voltage (LV)

downstream operation of 415 / 240V to increase the power reliability of consumers. The

proposed design depends on (GSM) communication. Siregar, et al.[11] used the ACS712

sensor and the voltage sensor based on the circuit of voltage divider and communicating by

GSM system for controlling the battery and the solar panel. The data obtaining from the

current and voltage sensors are then processed by a microcontroller. Bhaskarwar, et al. [12]

studied and focused on control system implementation of heat exchangers of the type of shell

and tube through a number of tools such as PLC, Supervisory Control and Data Acquisition

SCADA, Lab VIEW and the Internet.

The above efforts and works can serve and support the smart grid technology that basically

consists of smart meters, sensors, proper monitoring and data management system

[13][14][15][16]. The point of the present proposed system in this paper, related to the above

selected papers, is most of the work done before, SMS has been used to monitor and control

the home appliances, transformer and single cable. While in this paper, the proposed system is

to use SMS service of GSM data transmission network as a simple and easy communication

link between the power station and the power substations and control centers for the purpose

of monitoring and control. In this kind of system there is high number of signals, therefore

time delay is significant, and the control centers transceivers “GSM modem” topology must

be designed carefully. Therefore, a remote monitoring and control system is designed and

developed using SMS technology. SMS uses signaling channels instead of custom data

channels. These messages can be transmitted / received at the same time via proposed GSM

link. The main feature of using SMS is to follow the method of storage and forwarding, and

SMS processing can go on during the specified validity period if the network is currently busy

or if the user is outside the coverage area. The proposed system offers several features like:

1. Monitor remote electrical parameter like “voltage, current, frequency….etc.”

2. Receive status of circuit breakers.

3. Send control command to change status of breakers remotely.

4. The defined user can send read command to monitor specific parameter.

SMS users or technicians working on this system can alert when abnormal conditions

occurred such as power outages, over-rated parameters, or any other abnormal situation.

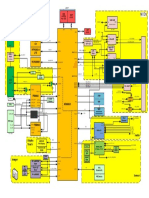

2. PROPOSED SYSTEM DESIGN

The proposed system design consists of electrical power generating plants, power

substation and control center, as shown in figure1. The proposed communication link

between them is based on SMS of GSM network and this needs programmable logic

controller PLC (at the generating plant and substation) to gather information from the

field and GSM modems as transceivers.

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 82

Power Power

PLC PLC

Plant Substation

GSM Modem GSM Modem

GSM Modem

Control

Station

Figure1: Block diagram of proposed system based on GSM.

The electrical station (may represent the power generating plant or substation)

consists of, transducers, relay, AC to DC convertor, PLC, and GSM modem while

the control center consists of GSM modem, cell phone and HMI, as plotted in figure

2 and as follows:

Figure 2: Block diagram of the electrical station and control center.

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 83

1. Sensor: It is an energy transformer designed to sense (in the sense of discovering) some of

the characteristics of its surroundings [17]. It is used to detect the parameter in one form of

energy, and to report it in a certain amount of material. The input signal to the transducer will

be changed to physical quantity at output; there are many types of sensors based on output

signal such as bipolar signals (±2V, ±10V), true Zero signals (0-2/10 V | 0-20 mA) and live

Zero signals (1/2-10 V | 4-20 mA).

2. Relay: A relay is usually an electromechanical device that used to close the open circuit or

to open the closed circuit when the current or voltage on the coil of relay is changed. Digital

output in programmable logic controller (PLC) is working as switch to close and open power

on the coil terminals.

3. AC/DC Convertor: The circuit switch status connected to digital input of PLC must be a

DC voltage, the value of highest DC voltage that PLC consider as ON depends on the PLC

configuration. The PLC used in our system input voltage with (24) VDC represents ON and

(0) VDC is OFF status. A 220 VAC to 24 VDC convertor is used, the output terminals of DC

voltage connected to input of PLC.

4. Programmable Logic Controller (PLC): The word "programmable" is distinguished from

the conventional hard-wired relay logic. It can be easily programmed or changed according to

the required application. The PLC passed the risk of changing the wires. The most important

PLC ingredientsare [18]:

Power Supply:It can be an external unit or can be built in same PLC. The common required

voltage levels at the PLC (with and without power supply) are 24Vdc, 120Vac, 220Vac.

Central Processing Unit (CPU):It is a computer where the logic of the ladder is stored and

processed.

Input/output (I/O):A number of input / output terminals are provided so that PLC can monitor

the process and initiate actions. There are two analog and digital PLC I / O.

Analog measurement:Analog data includes all continuous and variable signals over time from

the domain. Examples include current, voltage, active energy, interactive power, power factor,

etc.

Digital measurement:Digital signals are intermittent signals that change from one state to

another in descriptive steps, and separate signals behave as binary keys, simply leading to a

signal (on or off) (1 or 0, True or False, respectively). Digital signals include switching

positions, isolation positions and circuit breakers in the power system.

5. GSM Modem: A GSM modem is a specialized type of modem that accepts a SIM card and

operates via a subscription to a mobile phone operator, just like a mobile phone, it can be a

dedicated modem device with a serial connection. Instructions AT commands used to control

the modem. AT is the abbreviation Attention, and each command line starts with "AT" and for

this reason modems are sometimes called AT commands. The GSM modem supports a set of

GSM AT commands that include relevant SMS commands such as AT + CMGS, AT +

CMSS, AT + CMGL (SMS list), AT + CMGR (Read SMS message).

6. Human Machine Interface (HMI): For monitoring and control purpose, the operators can

use the mobile phone or can use a software as human machine interface (HMI). HMI presents

the measured values, generate alarms, and sent control commands…etc. The visual studio is

used to create HMI. The used GSM modem is Wavecom WM 17253, the port settings are:

Baud Rate 9600, Data Bit 8, Stop bit 1 and Flow control none. The software connection

illustrated with flow chart in figure 3.

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 84

Figure3: Flow chart of serial port connection [3].

3. RESULTS OF THE SYSTEM TEST AND DISCUSSION

A modeled system designed and tested in the lab, an electrical circuit with variable AC source

and resistor used to generate the desired current. The measurements are monitored by using

two transducer, 24 VDC relay used to control electrical circuit remotely, as it can be seen the

single line diagram in figure 4. The current desired in the circuit connected to a current

transducer “0-5A” and AC source connected to a voltage transducer “0-250VAC”, the output

of the transducers are 4-20 mA. The output of transducers connected to analog inputs of PLC.

An AC to DC transformer is used to convert the AC input voltage of the circuit to 24 VDC,

the VDC output is a circuit switch status, 0 VDC means circuit switch OFF, 24 VDC means

circuit switch ON. The PLC is programmed for any new reading of current or voltage and

circuit status (ON/OFF) sent the data by SMS to mobile phone or another GSM modem that

connected to PC and decode new message by HMI that is written by using Vb.Net, also the

user can send a control command to Switch ON/OFF remotely by sending SMS the content of

message must be the same as it defined at the PLC.

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 85

The system tested in different ways to see the performance of the communication link based

on SMS of GSM technology.

Figure 4: Virtual lab prototype single line diagram

3.1. Monitor Circuit with Cell Phone: The data of sent current, voltage measurement and

switch status to mobile phone, are merged in one SMS. The test performed by changing

variable resistance or variable voltage, the delivery time for new status by mobile phone

measured as illustrated in Table 1.

Table 1:SMS delivery time to mobile phone

Multi-meter SMS receive

Deliver Time

Current Voltage Current Voltage (second)

0.64 220.5 0.63 220.31 10.65

1.95 224.8 1.93 224.80 12.55

2..61 205 2.60 205.10 11.30

3.23 221 3.21 221.00 14.81

0.66 220.2 0.65 220.00 12.25

1.99 230 1.96 229.40 10.92

1.22 220 1.21 220.31 13.92

Average 12.22

It can be shown from Table 1, the average time to deliver a status of new reading with a

mobile phone is nearly 12.22 seconds. If it compared to the normal SMS delivery between two

mobiles, the average time is 4.94 second. Where, the difference is 7.28 seconds. This

difference is the time that the transducer converts new input to 4-20 mA, PLC scanning input

that is normally around (0-5 seconds) and transmits this new status to the serial port.A sample

of received SMS to a mobile phone can be described in Figure 5 which shows the receive a

message with 16-signals which are separated by comma (,). The first eight signals are analog

inputs and the last eight signals are digital inputs measurements connected to the PLC, the

second reading is current measurement (0.63 A), the third reading is voltage measurement

(230.31) and the signal number nine is the circuit status (1) is means the circuit is switched on.

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 86

Figure 5: Mobile phone receive SMS.

3.2. HMI for Circuit Monitoring and Control: The HMI used for this test created by using

visual basic; the same connection in section 3.1 is used. The results are shown in Table 2.

Table 2: SMS delivery time with HMI

HMI Multi- Error HMI Multi- Error Time

Current meter percentage (Voltage) meter percentag (sec.)

Current voltage e

0.65625 0.66 0.5682 % 223.4375 225.7 1.0024 % 12.08

1.321875 1.34 1.3526 % 224.6875 224.5 0.0835 % 15.86

1.96875 1.99 1.0678 % 223.28125 223.2 0.0364 % 14.05

2.628125 2.68 1.9356 % 222.1875 222.2 0.005 % 15..25

3.296 3.32 0.7229 % 220.78125 221 0.099 % 14.24

1.809375 1.84 1.6644 % 205.78125 205.7 0.0395 % 14.76

1.2125 1.22 0.6148 % 205.9375 205.7 0.1155 % 12.08

1.803125 1.84 2.0041 % 205.46875 205.4 0.0335 % 14.68

Average 1.2413 % 0.1769 % 14.125

As it can be observed in Table 2, the average time to receive a new measurement and

represent it on HMI is 14.125 seconds. The time difference for monitoring the same circuit by

mobile phones in previous test is 2.186 seconds. This extra time delay is because of execution

time needed by visual basic and presents it on monitoring window. The precision of the result

in HMI compared to the measurements in multi-meters for the current is about of 2% and for

the voltage is about of 1%. Example for last results in Table2 is shown in figure 6.

Figure 6: Result comparison HMI with multi-meter

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 87

3.4. Sending Control Commands: The time needed for controlling electrical circuit breakers

is very significant, for the proposed system, the times is measured when a message is sent to

change switch status and the updated data presented on HMI, the results are shown in Table 3.

Table 3: Control circuit time

Current / New Circuit Switch Change HMI update

Status Time (sec.) Time (sec.)

OFF/ON 6.75 24.02

ON/OFF 4.26 20.20

OFF/ON 4.63 22.46

ON/OFF 2.94 19.21

OFF/ON 3.84 20.11

ON/OFF 5.23 21.67

OFF/ON 6.36 22.31

OFF/ON 3.46 19.73

Average 4.68 21.21

From Table 3, the time needs to change switch status by using SMS is about (4.68 sec.) and

(21.21 sec.) to update HMI for new switch status.

4. CONCLUSIONS

The proposed system has two main parts which are prototyped and tested successfully by

using an existing GSM infrastructure. First part was the unit that designed to be installed in the

power station and aggregate the sensors readings and processed them into a packet ready to

send for the monitoring side. Second part was the HMI, that designed by using GSM modem

and an application built based on Visual Basic open source platform in order to visualize the

received packets of reading from the power stations. PLC was used in the first part due to its

simplicity and reliability for the industrial and heavy duties usage. The proposed system with

its features is very fixable and ready for any expansion without any revisions on the current

installed units. Testing the system in different situations and environments show that the

operation is very easy and cost effective since the only paid cost is the SMS toll by the sending

side. The time required for the message to be delivered is ranged from 19 to 24 seconds, where

21.21 seconds was the average delay time for the message to be delivered. This time is

adequate for monitoring and control purposed in a soft real time application. For applications

that required hard real time, it is recommended to use a technique that provides less delay.

REFERENCE

[1] R. Ganiyu, O. Arulogun,A. Adetunji, O. Okediran, “Development of a GSM Based Household Power

Management System”,British Journal of Science,Vol. 1 (2), 1 September 2011.

[2] B. Mubdir, A. Al-Hindawi, N. Hadi, “Design of Smart Home Energy Management System for Saving Energy”,

European Scientific Journal, Edition,Vol. 12, No. 33, pp. 521-536, 2016.

[3] N. Hadi, B.Mubdir, A. Al-Hindawi, A. Ahmed, “Design and Implementation of Smart Home Energy

Management System Based on GSM Network”, Kurdistan Journal for Applied Research, Volume 2, Issue 3,

2017.

[4] B. Mubdir, A. Al-Hindawi, S.Hussien, H. Al-Rizzo, “Smart Energy Monitoring and Control System Based on

Wireless Communication”, International Journal of Engineering and Advanced Technology, Vol. 3 Issue 1, pp.

1-6, 2013

[5] P. Daponte, M. Di Penta, G.Mercurio, “TransientMeter: A Distributed Measurement System for Power Quality

Monitoring”, IEEE Transactions on Power Delivery, Vol. 19, Issue. 2, pp. 456-463, 2004.

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 88

[6] B. Petrescu, D. Chiciudean, R. Cioarga, D. Stanescu, “Wireless Solutions for Telemetry in Civil Equipment and

Infrastructure Monitoring”, 3rd Romanian-Hungarian Joint Symposium on Applied Computational Intelligence

(SACI), May 25-26, 2006.

[7] N. Jawarkar, V. Ahmed, S. Ladhake, R. Thakare, “Microcontroller Based Remote Monitoring using Mobile

through Spoken Commands” , Journal of Networks, Vol. 3, No. 2, 2008.

[8] J. Xiao, Shou Xu ; Guohe Wu “Monitor system of the intelligent power earth lines based on GSM SMS

protocol”, 9th International Conference on Electronic Measurement & Instruments.( ICEMI '09), Beijing, 16-19

Aug. 2009.

[9] A.Sachan “Microcontroller Based Substation Monitoring and Control System with Gsm Modem”,IOSR Journal

of Electrical and Electronics Engineering (IOSRJEEE), ISSN: 2278-1676 Volume 1, Issue 6, pp.13-21, July-

Aug. 2012.

[10] W.Jusoh, M. Ghani, W.Hanafiah, M.A.; S. Raman, “Development of a new modeling circuit for the Remote

Terminal Unit (RTU) with GSM communication”, 2013 IEEE Conference onClean Energy and

Technology(CEAT), pp.18-20, 2013.

[11] S.Siregar, D. Soegiarto, “Solar Panel and Battery Street Light Monitoring System Using GSM Wireless

Communication System”,Second International Conference on Information and Communication Technology

(ICOICT), 2014.

[12] T.Bhaskarwar, S. Giri, R. Jamakar, “Automation of shell and tube type heat exchanger with PLC and

LabVIEW”, Industrial Instrumentation and Control (ICIC) International Conference, 2015.

[13] M. Rehmani, A. Davy, B. Jennings, C.Assi, "Software Defined Networks-Based Smart Grid Communication: A

Comprehensive Survey", IEEE Communications Surveys & Tutorials, vol. 21, no. 3, pp. 2637-2670, 2019.

[14] A. Abbasi, A. Abbasi, S. Shamshirband, A.Chronopoulos, V. Persico, A. Pescapè, "Software-Defined Cloud

Computing: A Systematic Review on Latest Trends and Developments", IEEE Access, Vol. 7, pp. 93294-93314,

2019.

[15] S. Reka, T. Dragicevic, P. Siano, S. Prabaharan, “Future Geharation 5G Wireless Network for Smart Grid: A

Comprehensive Review”, Energies Journal, Vol. 12, Issue 11, 2019.

https://doi.org/10.3390/en12112140

[16] O. Machidon, C. Stanca, P. Ogrutan ,C. Gerigan, L. Aciu, “Power-system protection device with IoT-based

support for integration in smart environments”,PLoS ONE,Vol. 13, No. 12, 2018.

https://doi.org/10.1371/journal.pone.0208168

[17] C.M. Riley, B.K. Lin, T.G. Habetter, R.R. Schoen, “A method for sensor-less on-line vibration monitoring of

induction machines”,IEEE Trans. Ind. Appl., Vol. 34(6), pp. 1240-1245, 1998.

[18] G. Hancke, C. Viljoen, “The Microprocessor Measurement of Low Values of Rotational Speed and

Acceleration”, IEEE Transactions on Instrumentation and Measurement, Vol. 39, No. 6, pp. 1014-1017, 1990.

Kurdistan Journal of Applied Research | Volume 4 – Issue 2 – December 2019 | 89

You might also like

- Electronics For You Express 2 2021Document76 pagesElectronics For You Express 2 2021moez0% (1)

- SFRA Typical Results v1Document39 pagesSFRA Typical Results v1Neelakandan MasilamaniNo ratings yet

- CMZ300 Manual PDFDocument74 pagesCMZ300 Manual PDFPiratsik Orbotana100% (1)

- Auto-Recloser Circuit Breaker in Power System Based On Internet of Things For Smart GridDocument7 pagesAuto-Recloser Circuit Breaker in Power System Based On Internet of Things For Smart GridjiregnaNo ratings yet

- Railway Track Monitoring System: Abstract - The Main Problem Is About Railway Track CrackDocument3 pagesRailway Track Monitoring System: Abstract - The Main Problem Is About Railway Track Crackrashmi netamNo ratings yet

- Lecture ThyristorsDocument38 pagesLecture ThyristorsHamza Saeed AliNo ratings yet

- Instructions For Use: Healy Electrostimulation DeviceDocument24 pagesInstructions For Use: Healy Electrostimulation DeviceSebastián MardonesNo ratings yet

- Alcatel 1641 SX OptinexDocument6 pagesAlcatel 1641 SX OptinexCarlos Higa100% (1)

- Iot Based Smart Electricity Meter and Power Theft DetectionDocument6 pagesIot Based Smart Electricity Meter and Power Theft Detectionhamed razaNo ratings yet

- Remote Wireless Data AcquisitionDocument7 pagesRemote Wireless Data AcquisitionLalitha RaniNo ratings yet

- Ijarcet Vol 1 Issue 4 273 279Document7 pagesIjarcet Vol 1 Issue 4 273 279hans LimNo ratings yet

- Design and Implementation Smart Transformer Based On Iot: August 2019Document7 pagesDesign and Implementation Smart Transformer Based On Iot: August 2019Tuhafeni HailekaNo ratings yet

- Residential Electrical Cut - Off Using A Network Base Embedded ControllerDocument15 pagesResidential Electrical Cut - Off Using A Network Base Embedded ControllerNick Owusu-debrahNo ratings yet

- Powerline Monitoring System Using Iot - A Review: Sudharshan Duth. P, G. Harish Singh & Anirudh A. KodagaliDocument4 pagesPowerline Monitoring System Using Iot - A Review: Sudharshan Duth. P, G. Harish Singh & Anirudh A. KodagaliTJPRC PublicationsNo ratings yet

- Implementation and Feasibility Analysis of GSM Based Smart Energy Meter For Digitalized Power Consumption With Advanced FeaturesDocument5 pagesImplementation and Feasibility Analysis of GSM Based Smart Energy Meter For Digitalized Power Consumption With Advanced Featuresশুভ MitraNo ratings yet

- Conference 101719Document4 pagesConference 101719Sekhar SankuriNo ratings yet

- 11 R11 E.moniSilviyaDocument6 pages11 R11 E.moniSilviyaReeta DuttaNo ratings yet

- Advanced Metering Infrastructure Over Power Line CommunicationDocument57 pagesAdvanced Metering Infrastructure Over Power Line CommunicationAhmad Abu Doush100% (1)

- Energy Meter Reading System With AutomatDocument6 pagesEnergy Meter Reading System With AutomatNaveen BhajantriNo ratings yet

- GSM-Based Smart Energy Meter With Arduino UnoDocument6 pagesGSM-Based Smart Energy Meter With Arduino UnoGnmagNo ratings yet

- GSM-Based Smart Energy Meter With Arduino UnoDocument6 pagesGSM-Based Smart Energy Meter With Arduino UnoGnmagNo ratings yet

- IJCRT1813479Document2 pagesIJCRT1813479Rohan J EEE-2019-23No ratings yet

- Design of An Intelligent SMS Based Remote Metering System: July 2009Document5 pagesDesign of An Intelligent SMS Based Remote Metering System: July 2009Buck DancerNo ratings yet

- Theft Detection Based GSM Prepaid Electricity SystemDocument4 pagesTheft Detection Based GSM Prepaid Electricity SystemHasnain KazmiNo ratings yet

- 3D Mesh Networking For IoTDocument11 pages3D Mesh Networking For IoTДжондо АнанимидзеNo ratings yet

- 1.ashna GSM Based Energy Meter ReadingDocument9 pages1.ashna GSM Based Energy Meter ReadingEngidNo ratings yet

- GSM Based Automatic Energy Meter Reading System With Instant BillingDocument8 pagesGSM Based Automatic Energy Meter Reading System With Instant BillingAjay SharmaNo ratings yet

- IJEAS0212020Document7 pagesIJEAS0212020erpublicationNo ratings yet

- Automated Meter Reading System - A Study: Satish Palaniappan Raghul Asokan Srinivas Bharathwaj Sujaudeen NDocument8 pagesAutomated Meter Reading System - A Study: Satish Palaniappan Raghul Asokan Srinivas Bharathwaj Sujaudeen NGSK MuhammadNo ratings yet

- Ijaerv13n6 107Document7 pagesIjaerv13n6 107PUB G Gamer FamilyNo ratings yet

- GSM Based Automatic Energy Meter Reading System With Instant BillingDocument9 pagesGSM Based Automatic Energy Meter Reading System With Instant Billingwilsondec25No ratings yet

- Rituraj Project2Document68 pagesRituraj Project2Pratik SinghNo ratings yet

- An Automated Energy Meter Reading System Using GSM TechnologyDocument8 pagesAn Automated Energy Meter Reading System Using GSM TechnologyBarNo ratings yet

- Design and Implementation of Remotely - Monitored SDocument10 pagesDesign and Implementation of Remotely - Monitored SAshaal AalamNo ratings yet

- IoT Based Industrial Production Monitoring System Using Wireless Sensor NetworksDocument8 pagesIoT Based Industrial Production Monitoring System Using Wireless Sensor NetworksIJAERS JOURNALNo ratings yet

- Development of Automated Grid Monitoring and Control System Using IoT A ReviewDocument4 pagesDevelopment of Automated Grid Monitoring and Control System Using IoT A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 2013 - GSM Based Smart Street Light Monitoring and Control SystemDocument3 pages2013 - GSM Based Smart Street Light Monitoring and Control Systemlbk50No ratings yet

- GSM Based Energy Meter With Load ControlDocument6 pagesGSM Based Energy Meter With Load ControlMurtaza RangwalaNo ratings yet

- GSM-based monitoring and control of smart gridDocument5 pagesGSM-based monitoring and control of smart gridMukuro RokudoNo ratings yet

- Secure CommunicationDocument5 pagesSecure CommunicationvinodNo ratings yet

- The Integration of Smart Meters Into Electrical Grids: Bangladesh ChapterDocument8 pagesThe Integration of Smart Meters Into Electrical Grids: Bangladesh ChapterEsmir DoganNo ratings yet

- IOT Power MonitoringDocument5 pagesIOT Power MonitoringanushkaNo ratings yet

- Real - Time Energy Meter With GSM and Arduino For Integrated MeteringDocument10 pagesReal - Time Energy Meter With GSM and Arduino For Integrated Meteringchristopher layupanNo ratings yet

- Substation Monitoring System: Prof. Kunal V.Ranvir, Mayuri A. Solanke, Rohit P. Ratnaparkhi, Ashvini N. SableDocument3 pagesSubstation Monitoring System: Prof. Kunal V.Ranvir, Mayuri A. Solanke, Rohit P. Ratnaparkhi, Ashvini N. SableerpublicationNo ratings yet

- A Novel Approach of Power-Line Monitoring System Using Iot: Sudharshan Duth. P, Anirudh A. Kodagali & G. Harish SinghDocument8 pagesA Novel Approach of Power-Line Monitoring System Using Iot: Sudharshan Duth. P, Anirudh A. Kodagali & G. Harish SinghTJPRC PublicationsNo ratings yet

- Design and Implementation of Control Unit For Railways Using Power Line Data TransmissionDocument5 pagesDesign and Implementation of Control Unit For Railways Using Power Line Data TransmissionEditor IJRITCCNo ratings yet

- 2767 6646 1 PBDocument9 pages2767 6646 1 PBmaria camila CastrillonNo ratings yet

- 10 11648 J Ajesa 20180601 17Document10 pages10 11648 J Ajesa 20180601 17supriyaditi100% (1)

- NAGUM Assignment6.1Document3 pagesNAGUM Assignment6.1Carlnagum 123456789No ratings yet

- 10.1109@iCoMET48670.2020.9073904Document7 pages10.1109@iCoMET48670.2020.9073904gowthamnm.nieNo ratings yet

- The Significance of Wireless Communication For The Metering Data Transmission Via Smart GridsDocument11 pagesThe Significance of Wireless Communication For The Metering Data Transmission Via Smart GridsLeonardo Felipe da Silva Dos SantosNo ratings yet

- Project Info Using GSMDocument7 pagesProject Info Using GSMKurt MacaslingNo ratings yet

- SMS-Controlled-Electric-Connection - EDITED VERSIONDocument57 pagesSMS-Controlled-Electric-Connection - EDITED VERSIONBadad Noemel DhannNo ratings yet

- Web-Based Real-Time Energy Monitoring for Campus BuildingsDocument8 pagesWeb-Based Real-Time Energy Monitoring for Campus BuildingsDedi Satria, S.Si, M.ScNo ratings yet

- An Application of PLC: Remote Detection of Illegal Electricity UsageDocument27 pagesAn Application of PLC: Remote Detection of Illegal Electricity Usage2692rimmiNo ratings yet

- Design and Implementation of GSM Based Automation of Household AppliancesDocument7 pagesDesign and Implementation of GSM Based Automation of Household Appliancesnur ain natasyaNo ratings yet

- Development of An Internet Based Prepaid Energy Meter: Deenmat@unilorin - Edu.ngDocument4 pagesDevelopment of An Internet Based Prepaid Energy Meter: Deenmat@unilorin - Edu.ngAjay SharmaNo ratings yet

- IJCRT21A6081Document7 pagesIJCRT21A6081Yasin OmaryNo ratings yet

- IJEAS0306042Document5 pagesIJEAS0306042erpublicationNo ratings yet

- 1 Azojete 13 (4) 430-439 PDFDocument10 pages1 Azojete 13 (4) 430-439 PDFAZOJETENo ratings yet

- Automatic Meter Reading PDFDocument8 pagesAutomatic Meter Reading PDFpraveen_kodgirwarNo ratings yet

- Flexible Wireless Sensor Network For Smart Lighting ApplicationsDocument6 pagesFlexible Wireless Sensor Network For Smart Lighting ApplicationsmonikaNo ratings yet

- Arduino and GSM Based Smart Energy Meter For Advanced Metering and Billing SystemDocument6 pagesArduino and GSM Based Smart Energy Meter For Advanced Metering and Billing SystemAjay SharmaNo ratings yet

- On GSM Based Smart Energy MeterDocument17 pagesOn GSM Based Smart Energy MeterNithin PrakashNo ratings yet

- AutomaticEnergyMeterReadingusingSmartEnergyMeter PDFDocument6 pagesAutomaticEnergyMeterReadingusingSmartEnergyMeter PDFDebashis PalNo ratings yet

- Digital Logic Design (EL-227) : Laboratory Manual Spring-2020Document5 pagesDigital Logic Design (EL-227) : Laboratory Manual Spring-2020Demin revisNo ratings yet

- Automatic Street Light Control ProjectDocument25 pagesAutomatic Street Light Control Projectkuldeep59593% (28)

- Restoring Digital Signals with ComparatorsDocument11 pagesRestoring Digital Signals with ComparatorsJeremy PanerioNo ratings yet

- AudioPipe TXXbd215 Users ManualDocument9 pagesAudioPipe TXXbd215 Users ManualjustmeNo ratings yet

- Diagrama de Bloques ServicellDocument1 pageDiagrama de Bloques ServicellJoséViloria100% (1)

- ACS850 Drive Parameters and SignalsDocument17 pagesACS850 Drive Parameters and SignalsRimon ChyNo ratings yet

- Dual-I NFC PADDocument2 pagesDual-I NFC PADSetyo SuhartantoNo ratings yet

- Home Theater Samsung HT-Z210Document10 pagesHome Theater Samsung HT-Z210Luis UrrozNo ratings yet

- Voltage Vs Time: A Suncam Online Continuing Education CourseDocument1 pageVoltage Vs Time: A Suncam Online Continuing Education CourseDanteLupuNo ratings yet

- 007 Trimble BX992 DS USL 0721 LRDocument2 pages007 Trimble BX992 DS USL 0721 LREiji MacabareNo ratings yet

- SG 3524Document3 pagesSG 3524florianosNo ratings yet

- Concept Design of Satellite Communications System For Next Generation Marine Observation - Broadband IP Network Down To UnderwaterDocument7 pagesConcept Design of Satellite Communications System For Next Generation Marine Observation - Broadband IP Network Down To UnderwaterRaj KannanNo ratings yet

- Powerful 5-Band Penta-Port AntennaDocument3 pagesPowerful 5-Band Penta-Port AntennaДмитрийNo ratings yet

- Pw2 - Ac RC Series Circuit - v1Document6 pagesPw2 - Ac RC Series Circuit - v1Hairul Anuar MasrolNo ratings yet

- MN1380 Series DisconDocument24 pagesMN1380 Series DisconDjalma MoreiraNo ratings yet

- Detect 3+ consecutive 1s using FSMDocument2 pagesDetect 3+ consecutive 1s using FSMasadmehmoodsatti786No ratings yet

- Slimline Plus: Wiring DevicesDocument14 pagesSlimline Plus: Wiring DevicesAndhika Hafizh PrasetyaNo ratings yet

- FDE.AI Optimizes POCOPHONE F1Document2 pagesFDE.AI Optimizes POCOPHONE F1Anjas MaraNo ratings yet

- Usecase Semtech Smartutilities Book 110819 (Web)Document8 pagesUsecase Semtech Smartutilities Book 110819 (Web)atif_aman123No ratings yet

- Conducted EMI Filter DesignDocument10 pagesConducted EMI Filter Designbharath prabhuNo ratings yet

- BeoSound 9000 Service ManualDocument96 pagesBeoSound 9000 Service ManualMersin ZeljkovićNo ratings yet

- The Design of Wireless Biometric Attendance SystemDocument4 pagesThe Design of Wireless Biometric Attendance SystemChaitanya WaghuleNo ratings yet

- Wireless LAN BIOS Switch HelpDocument1 pageWireless LAN BIOS Switch HelpSor CaligaganNo ratings yet

- Tri-State Buffers and Schmitt Trigger.: Exp# 6 Exp. Name ObjectivesDocument4 pagesTri-State Buffers and Schmitt Trigger.: Exp# 6 Exp. Name ObjectivesTala JaberNo ratings yet