Professional Documents

Culture Documents

X.mill M 640

Uploaded by

Frederik HenderwanzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X.mill M 640

Uploaded by

Frederik HenderwanzaCopyright:

Available Formats

• Mineral-casting reduces vibration 6 times faster than cast-iron (GG25) and up to 10

times faster than steel - ensuring exceptionally quiet operation and excellent milling

capacity. Excellent thermal stability handles the challenges in everyday production

Environments

• superior mechanical properties of the total component package ensure longer tool life

• Spindle oil-cooler ensures stable thermal conditions during continuous Operation

• Precision linear guides with extra-wide layout and reliable stainless steel protective

covers

• Precision preloaded ball screws and powerful servo-drives on all 3 axes

• Dual-arm 16-station tool changer for quick and precise tool changes

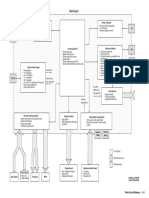

Specifications X.mill M 640

Working area

X axis travel mm 640

Y axis travel mm 400 Siemens Sinumerik 828 D - the control for demanding

Z axis travel mm 500 milling operations

Table height mm 850

Table dimensions mm 750x360

Table load capacity kg 500 • enclosed work space ensures safe and

T-slots (number/width/spacing) mm 3x18x100 contamination-free work

Spindle nose-to-table surface distance mm 50 - 550 • An electronic hand-wheel and very accessible

work table for easy setup of clamping tools and

CNC Machining

Headstock workpieces

Speed range 1/min 12.000

• LED lighting ensures good visibility in the

Spindle thoat mm 430 Workspace

Spindle mount MAS BT 40 • effective coolant system ensures optimum

Feed use of tools and excellent chip removal

Work feed mm/min 10 - 5.000 • an automatic lubrication system reduces the

Rapid feed X / Y / Z axis mm/min 36.000 operator’s workload and simplifies maintenance

Tool Carrier

Number of tool stations Pieces 16

Tool size Ø x L (max.) mm 78x250

Tool weight max. kg 8

Tool-changing time chip/chip s 4 Standard Equipment

Tool-change time tool/tool s 2 control Fanuc Oi-Mf or control Siemens 828D with

4th axis with tailstock, vertical and horizontal setup (option) ShopMill, electronic hand-wheel, spiral chip conveyor,

Manual lathe chuck mm 160 16-station tool changer, pneumatic tool clamping, air

Positioning accuracy ± 40 s conditioner for cabinet, totally enclosed work space,

Repeatability 4s work lamp, Ethernet, USB interface, automatic central

Braking torque Nm 230 lubrication, spindle oil cooler, operating tools, Bedi-

enungsanleitung

Gear ratio 90 : 1

4th axis spindle mount A-6

4th axis dimensions mm 185x90x175

Weight (with motor) kg 70 Options Par t No.

Accuracies • autom. tool length on request

Positioning accuracy ± 0,003 mm measurement

Repeatability ± 0,0025 mm • X.div 125 for 125767

Accuracies Siemens Control

Main drive motor rating (cont./30 min) • Manual chuck 127 125769

- Siemens 828D Control kW 7 / 10 • 4th and 5th axis on request

- Fanuc 0i-MF kW 7,5 / 11 • X.div 170 for 125772

Measures and weights Siemens Control

Overall dimensions (length x width x height) m 2,3x1,8x2,4 • tool measurement on request

Weight kg 4.500 (laser)

Part No with Fanuc Control 181290 • direct drive BT40 with Speed on request

5000 rpm

Preis € mit Fanuc Steuerung 0,-

Part No with Siemens Contgrol 181289

Preis € mit Siemens Steuerung 62.400,- For additional options for this machine, visit our web-

site and search for X.mill M 640 (Product Search)

For more information and quick online quote requests, please visit www.knuth.de 69

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Service Manual PDFDocument428 pagesService Manual PDFAprajita Kayastha100% (2)

- VMC Programing ManualDocument171 pagesVMC Programing Manualsujoylud100% (2)

- c16 PDFDocument4 pagesc16 PDFcmgankl0% (1)

- Variaxis I SeriesDocument22 pagesVariaxis I Seriesbhandge8850% (2)

- DS DMG HSC 55 Linear Medical Bone Plate en PDFDocument1 pageDS DMG HSC 55 Linear Medical Bone Plate en PDFPaul VeramendiNo ratings yet

- Eng - DNM Ii - 1401 - Su - E20Document20 pagesEng - DNM Ii - 1401 - Su - E20Nikolat840% (1)

- Power Bend Pro Rev.02 ENGDocument36 pagesPower Bend Pro Rev.02 ENGFabien ProuvezNo ratings yet

- Deckel Fp4 Ma enDocument10 pagesDeckel Fp4 Ma enRenan ValenteNo ratings yet

- Generator Protection PDFDocument162 pagesGenerator Protection PDFhemantgupta226100% (1)

- 22m Boom - Circuit + Bom-Vr-0628 (1) - 1Document7 pages22m Boom - Circuit + Bom-Vr-0628 (1) - 1MuthuNo ratings yet

- X.mill M 900Document1 pageX.mill M 900Frederik HenderwanzaNo ratings yet

- Vertical Turret Lathe Imo Kd4S 40: AnlagenbauDocument6 pagesVertical Turret Lathe Imo Kd4S 40: AnlagenbauSamik MukherjeeNo ratings yet

- Mill 55Document4 pagesMill 55Manuel XamanNo ratings yet

- Direct: CNC Machining CentreDocument2 pagesDirect: CNC Machining CentreRivas IsaacNo ratings yet

- High Quality Machine Tools: Your Address ForDocument4 pagesHigh Quality Machine Tools: Your Address FortayefehNo ratings yet

- Router Family BrochureDocument15 pagesRouter Family BrochurealexNo ratings yet

- Milling Machine Concept Mill 55 En-1Document4 pagesMilling Machine Concept Mill 55 En-1EmzyNo ratings yet

- E1. MC-044 CNC Milling Machine (Siemens Controller)Document3 pagesE1. MC-044 CNC Milling Machine (Siemens Controller)manual imbNo ratings yet

- 1260 VMC JyotiDocument3 pages1260 VMC JyotiPavan KhengarNo ratings yet

- AccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21Document5 pagesAccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21EnriqueMiguelPriceNo ratings yet

- CNC Mill Machine PICODocument4 pagesCNC Mill Machine PICOVlastimir PejićNo ratings yet

- Tachyon Series - English - 2019 09Document4 pagesTachyon Series - English - 2019 09Kiril AngelovNo ratings yet

- Galaxy Midas 0Document2 pagesGalaxy Midas 0suresh0% (1)

- TRUMPF CNC-Sheet Metal Machining Centre: Punching, Nibbling and Forming With Rotation of All ToolsDocument9 pagesTRUMPF CNC-Sheet Metal Machining Centre: Punching, Nibbling and Forming With Rotation of All ToolsGreyphen GreyNo ratings yet

- 2018 - UMC-1000 2016 - NewDocument16 pages2018 - UMC-1000 2016 - NewAbhishek VelagaNo ratings yet

- VARIAXIS C 600 BrochureDocument24 pagesVARIAXIS C 600 Brochureadrienbridel80No ratings yet

- Company ProfileDocument20 pagesCompany ProfileTung Bui ThanhNo ratings yet

- TX Catalogue EnglishDocument12 pagesTX Catalogue EnglishDjuraTheHarpYNo ratings yet

- Cka6130 CNC Lathe: Detailed DescriptionDocument6 pagesCka6130 CNC Lathe: Detailed DescriptionIvona JovanovskaNo ratings yet

- Maxmill Fanuc Manual PDFDocument426 pagesMaxmill Fanuc Manual PDFRaul LupuNo ratings yet

- QP L SeriesDocument16 pagesQP L Seriesluis arriagaNo ratings yet

- Tsugami M08J Focus Brochure 1Document8 pagesTsugami M08J Focus Brochure 1Aryan DhimanNo ratings yet

- Vertical Machining Center ModelDocument2 pagesVertical Machining Center Modelatishay shNo ratings yet

- Final HMTDocument45 pagesFinal HMTAnubhav SharmaNo ratings yet

- Eumach - Umc - 5 Axis VMC Umc-1000Document16 pagesEumach - Umc - 5 Axis VMC Umc-1000Abhishek VelagaNo ratings yet

- MMV 1300 1500 - EnglDocument2 pagesMMV 1300 1500 - EnglEmilian PopaNo ratings yet

- Highly Accurate Large Vertical Machining CenterDocument17 pagesHighly Accurate Large Vertical Machining Centerletrongthoai18No ratings yet

- Machine Introduction & Technical Data Specification: Vertical Machining Center MS-500 Twin PalletDocument8 pagesMachine Introduction & Technical Data Specification: Vertical Machining Center MS-500 Twin PalletCristian PavanNo ratings yet

- DS DMG HSC 55 Linear Medical Bone Plate enDocument1 pageDS DMG HSC 55 Linear Medical Bone Plate enPaul VeramendiNo ratings yet

- Agma MachineDocument6 pagesAgma MachineNursena SEVİNÇNo ratings yet

- Cat-14 UWIFDocument8 pagesCat-14 UWIFudaysahgalNo ratings yet

- PDF FanucDocument28 pagesPDF Fanucheart princeNo ratings yet

- Machine Data SheetDocument3 pagesMachine Data SheetThaslimNo ratings yet

- c16 PDFDocument4 pagesc16 PDFcmganklNo ratings yet

- Sliding Head Stock High Precision High Productivity: The Best Machine For Flexible NeedsDocument4 pagesSliding Head Stock High Precision High Productivity: The Best Machine For Flexible Needscmgankl100% (1)

- Manual Del Usuario MaxxturnDocument14 pagesManual Del Usuario MaxxturnOlmetalNo ratings yet

- Milling Concept MILL 55 en 01Document4 pagesMilling Concept MILL 55 en 01Heineken Ya PraneetpongrungNo ratings yet

- CGS AG Schoen+Sandt 5050 - En-1 PDFDocument2 pagesCGS AG Schoen+Sandt 5050 - En-1 PDFOscarBarretoNo ratings yet

- Lathe Concept Turn 105 ENDocument4 pagesLathe Concept Turn 105 ENandrefirewallbrNo ratings yet

- UC-481 2040, European MarketDocument4 pagesUC-481 2040, European MarketAchmatAfipudinNo ratings yet

- CNC Vertical Milling Machines: Key PointsDocument4 pagesCNC Vertical Milling Machines: Key PointsJagadisha PandurangaiahNo ratings yet

- Sura 200 350-201803Document8 pagesSura 200 350-201803TharunNo ratings yet

- CNC Router MachineDocument21 pagesCNC Router MachinepurnachmNo ratings yet

- Sales Manual of VESTA-660 (6.2) (20200408)Document59 pagesSales Manual of VESTA-660 (6.2) (20200408)Văn Duy ĐinhNo ratings yet

- SeriesISellSheet1330D PDFDocument2 pagesSeriesISellSheet1330D PDFRicardo Alberto Ortegon BenjumeaNo ratings yet

- TP TP: Turret Punch Turret PunchDocument20 pagesTP TP: Turret Punch Turret PunchMaly AliNo ratings yet

- Flexible Automated Punching Machine: High Productivity - Compact Punching, Nibbling and FormingDocument6 pagesFlexible Automated Punching Machine: High Productivity - Compact Punching, Nibbling and FormingJosko SpehNo ratings yet

- Cutting EquipmentsDocument23 pagesCutting EquipmentsManoj SahuNo ratings yet

- LT 12 15 - EnglDocument2 pagesLT 12 15 - EnglEmilian PopaNo ratings yet

- 1200 Tablet Press Extreme Versatility Economical Small Batches Very Low Space RequirementDocument12 pages1200 Tablet Press Extreme Versatility Economical Small Batches Very Low Space RequirementMIguel BotelloNo ratings yet

- Product Description Height Control KHC1 ARCDocument2 pagesProduct Description Height Control KHC1 ARChollabackcockNo ratings yet

- CNC Milling Center Training Purposes Concept MILL 55Document4 pagesCNC Milling Center Training Purposes Concept MILL 55Mez NacerNo ratings yet

- EE24 Lecture 7 - Electrical Plans & SpecificationsDocument9 pagesEE24 Lecture 7 - Electrical Plans & SpecificationsGuianne Carlo Bustamante100% (1)

- Power & Pride: CNH Industrial (India) Pvt. LTDDocument2 pagesPower & Pride: CNH Industrial (India) Pvt. LTDNayaGaadi DavangereNo ratings yet

- Abrir Manual de Partes mt07 2 PDFDocument80 pagesAbrir Manual de Partes mt07 2 PDFAngelo JoséNo ratings yet

- Super Micro X5DA8 User's Manual. Rev 1.1bDocument92 pagesSuper Micro X5DA8 User's Manual. Rev 1.1bGladysMarvNo ratings yet

- Report TextDocument9 pagesReport TextAngka NaNo ratings yet

- Planos Electrónicos Monitor Fetal Corometrics Modelo 170 SeriesDocument88 pagesPlanos Electrónicos Monitor Fetal Corometrics Modelo 170 Seriesviviana vargasNo ratings yet

- Myferrari - Purosangue - 41ADp4dDocument11 pagesMyferrari - Purosangue - 41ADp4dSoom SoomNo ratings yet

- Outdoor Box Isolated AP300 AP400 2012-03Document29 pagesOutdoor Box Isolated AP300 AP400 2012-03Alfian LinuxNo ratings yet

- Sheet 3Document3 pagesSheet 3Mohab SamehNo ratings yet

- Memory Reference Instructions ExecutionDocument13 pagesMemory Reference Instructions ExecutionAditya Singh100% (1)

- Coils and Electronics: Catalog HY15-3502/USDocument27 pagesCoils and Electronics: Catalog HY15-3502/USPartsGopher.comNo ratings yet

- 85010-0089 - Intelligent Audio AmplifiersDocument2 pages85010-0089 - Intelligent Audio AmplifiersmohammadNo ratings yet

- DPS 20Document10 pagesDPS 20Timo LilienbergNo ratings yet

- Intertek UL 508A Standard UpdatesDocument2 pagesIntertek UL 508A Standard UpdatesWilfredo MolinaNo ratings yet

- ABB Bearing Currents Abb Technical Guide 5Document24 pagesABB Bearing Currents Abb Technical Guide 5Fernando MuneraNo ratings yet

- MillerDocument88 pagesMillerkimba worthNo ratings yet

- Desenllantadora Marca Coseng Modelo Cd540aDocument42 pagesDesenllantadora Marca Coseng Modelo Cd540ajhan123j100% (1)

- Chapter 25 Equipment - FurnishingDocument63 pagesChapter 25 Equipment - FurnishingHartomo DK.No ratings yet

- PIC16F18855 ModDocument662 pagesPIC16F18855 Modwhynot05No ratings yet

- Reovib Mfs 168: Unique Selling PointDocument8 pagesReovib Mfs 168: Unique Selling PointMarianNeaguNo ratings yet

- PV Mounting System GroundDocument23 pagesPV Mounting System GroundFerdi BayuNo ratings yet

- Flyer RCS 9698G H GatewayDocument2 pagesFlyer RCS 9698G H GatewayBorisNo ratings yet

- Alcohol Detection and Automatic Ignition Lock System To Check Driving Under Influence (DUI)Document13 pagesAlcohol Detection and Automatic Ignition Lock System To Check Driving Under Influence (DUI)Kshitij Kumar Singh ChauhanNo ratings yet

- RF Final Project PDFDocument18 pagesRF Final Project PDFbelay workyeNo ratings yet

- Anna University ME 9301 Design of Jigs. Fixtures and Press Tools Question PaperDocument5 pagesAnna University ME 9301 Design of Jigs. Fixtures and Press Tools Question PaperMuruga AnanthNo ratings yet

- Aeron Systems: Inertial Sensors and Navigation SystemsDocument7 pagesAeron Systems: Inertial Sensors and Navigation SystemsBhagavad GitaNo ratings yet

- 17 Termografia de PV Con Flir Tau 640 y Drone PDFDocument2 pages17 Termografia de PV Con Flir Tau 640 y Drone PDFOscar ChilcaNo ratings yet