Professional Documents

Culture Documents

X.mill M 900

Uploaded by

Frederik HenderwanzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

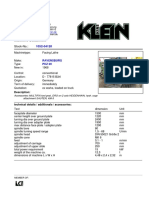

X.mill M 900

Uploaded by

Frederik HenderwanzaCopyright:

Available Formats

• standard mainspindlemotor with 8.

000 1/min

• spindle oil-cooler ensures stable thermal conditions during continuous operation

• precision linear guides with extra-wide layout and reliable stainless steel protective

covers

• precision preloaded ball screws and powerful servo-drives on all 3 axes

• dual-arm 16-station tool changer for quick and precise tool changes

• fully enclosed work space ensures safe and contamination-free work

• an electronic hand-wheel and very accessible work table for easy setup of

clamping tools and workpieces

• LED lighting ensures good visibility in the workspace

• Effective coolant system ensures optimum use of tools and excellent chip remova

• an automatic lubrication system reduces the operator‘s workload and simplifies

maintenance

• chain-type chip conveyor with 1200 mm high ejector ensures efficient chip removal

Handles Circular milling under serious conditions

CNC Machining

Specifications X.mill M 900 Standard Equipment:

Working area Fanuc 0i MF control with Manual Guide 0i or Siemens

X-/Y-/Z-axis travel mm 850 / 550 / 700 828 D with Shopmill, direct drive- main spindle ST

table dimensions mm 950x550 40 with max.12,000 rpm, Synchronous threading,

table load capacity kg 700 hydraulic counterweight, indicator light for program

spindle nose-to-table distance mm 100 - 800 status, 24-station dual-arm tool changer, pneumatic

tool clamping, electronic hand-wheel, chain-type

throat mm 612

chip conveyor, totally enclosed housing, air-conditions

t-slots (qty x width x distance) mm 5x18x100

control cabinet, memory Card and RS 232 interface,

Main spindle

automatic central lubrication, LED work lamp, spindle

spindle speed 1/min 8.000 oil cooler, coolant system, air gun, coolant gun, setup

spindle mount BT / SK 40 and alignment elements, operating tools, operator

Rapid feed manual, programming instructions

X-/Y-axis rapid feed mm/min 48.000

Z axis rapid feed mm/min 32.000

work feed X-/Y-axis mm/min 1 - 12.000

work feed X-/Y-axis mm/min 1 - 12.000

Tool carrier

number of tool stations Stück 24

OD tool size x tool length (max.) (Big Tool max. Ø) mm 78 x 300 (120)

tool weight (max.) kg 8 Options Par t No.

tool changing time, chip/chip - on average s 4 • Spindle BT / SK 40 12.000 rpm on request

for X.mill M 900 with Fanuc control

tool changing time, tool/tool s 2

• Tool measuring system T24E-04-27 252632

Accuracy

positioning accuracy / repeatability mm ± 0,003 / ± 0,002 • Inside spindle cooler 30 bar with 252498

dual filter

Drive Capacities

• Tool magazine 32 pieces 252499

main motor rating Siemens cont./30 min kW 9 / 12

main motor rating Fanuc const./30 min kW 15 / 18,5

for more information about options, please visit our

motor rating for X-/Y-/Z-axis Z with brake kW 3

website and look for X.mill M 900 (product search)

Dimensions/Weight

dimensions (LxWxH) m 2,3x2,22x2,65

weight kg 5.500

Part No. with Siemens 828 D control 170098

Preis € XXX.XXX,-

Part No. with Fanuc 0i MF control 170099

Preis € 0,-

For more information and quick online quote requests, please visit www.knuth.de 65

You might also like

- X.mill M 640Document1 pageX.mill M 640Frederik HenderwanzaNo ratings yet

- TX Catalogue EnglishDocument12 pagesTX Catalogue EnglishDjuraTheHarpYNo ratings yet

- High Quality Machine Tools: Your Address ForDocument4 pagesHigh Quality Machine Tools: Your Address FortayefehNo ratings yet

- MMV 1300 1500 - EnglDocument2 pagesMMV 1300 1500 - EnglEmilian PopaNo ratings yet

- Deckel Fp4 Ma enDocument10 pagesDeckel Fp4 Ma enRenan ValenteNo ratings yet

- Manual Del Usuario MaxxturnDocument14 pagesManual Del Usuario MaxxturnOlmetalNo ratings yet

- f573 Okuma Ma 600 HB Space Center Technical DetailsDocument4 pagesf573 Okuma Ma 600 HB Space Center Technical DetailsJordan Martinez LizNo ratings yet

- Tsugami M08J Focus Brochure 1Document8 pagesTsugami M08J Focus Brochure 1Aryan DhimanNo ratings yet

- RAVENSBURG PKZ 20, EnglDocument1 pageRAVENSBURG PKZ 20, EnglNenad JarakovicNo ratings yet

- TRUMPF CNC-Sheet Metal Machining Centre: Punching, Nibbling and Forming With Rotation of All ToolsDocument9 pagesTRUMPF CNC-Sheet Metal Machining Centre: Punching, Nibbling and Forming With Rotation of All ToolsGreyphen GreyNo ratings yet

- Machine Data SheetDocument3 pagesMachine Data SheetThaslimNo ratings yet

- Chapter 2 Machine IntroductionDocument4 pagesChapter 2 Machine IntroductionTech CIMNo ratings yet

- BC Doosan DB130 Lot 1Document3 pagesBC Doosan DB130 Lot 1Welly CholilNo ratings yet

- UC-481 2040, European MarketDocument4 pagesUC-481 2040, European MarketAchmatAfipudinNo ratings yet

- High-Speed CNC Vertical Machining Center: Page 1 of 8 May 1, 2017Document8 pagesHigh-Speed CNC Vertical Machining Center: Page 1 of 8 May 1, 2017Saad MughalNo ratings yet

- Maho MH 600 e enDocument8 pagesMaho MH 600 e enDragan PanovicNo ratings yet

- Vertical Turret Lathe Imo Kd4S 40: AnlagenbauDocument6 pagesVertical Turret Lathe Imo Kd4S 40: AnlagenbauSamik MukherjeeNo ratings yet

- Maxmill Fanuc Manual PDFDocument426 pagesMaxmill Fanuc Manual PDFRaul LupuNo ratings yet

- CNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WDocument16 pagesCNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WSot DesignNo ratings yet

- 1200 Tablet Press Extreme Versatility Economical Small Batches Very Low Space RequirementDocument12 pages1200 Tablet Press Extreme Versatility Economical Small Batches Very Low Space RequirementMIguel BotelloNo ratings yet

- Direct: CNC Machining CentreDocument2 pagesDirect: CNC Machining CentreRivas IsaacNo ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- Offer For ACCURL Smart Swing Beam Shear MS7-12x3200-Crys PDFDocument7 pagesOffer For ACCURL Smart Swing Beam Shear MS7-12x3200-Crys PDFJ Jack GutierrezNo ratings yet

- CNC Shop MachinesDocument15 pagesCNC Shop Machinesv2brotherNo ratings yet

- Mill 55Document4 pagesMill 55Manuel XamanNo ratings yet

- Deckel Fp4 NC enDocument9 pagesDeckel Fp4 NC enRenan Valente100% (1)

- Dugard X5 Five Axis Vertical Machining Centre: Ex-Demo Price - 110,000Document1 pageDugard X5 Five Axis Vertical Machining Centre: Ex-Demo Price - 110,000Laurentiu ZavodNo ratings yet

- TSL-500 EnglDocument2 pagesTSL-500 EnglEmilian Popa100% (1)

- TAJMAC-ZPS ProductionProgram enDocument68 pagesTAJMAC-ZPS ProductionProgram endarkojevNo ratings yet

- AccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21Document5 pagesAccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21EnriqueMiguelPriceNo ratings yet

- Sales Manual of VESTA-660 (6.2) (20200408)Document59 pagesSales Manual of VESTA-660 (6.2) (20200408)Văn Duy ĐinhNo ratings yet

- Tachyon Series - English - 2019 09Document4 pagesTachyon Series - English - 2019 09Kiril AngelovNo ratings yet

- VMC & HMC PDFDocument103 pagesVMC & HMC PDFNARENDER SINGHNo ratings yet

- Cka6130 CNC Lathe: Detailed DescriptionDocument6 pagesCka6130 CNC Lathe: Detailed DescriptionIvona JovanovskaNo ratings yet

- Production and Machinery: Wikov Manufacturing FacilityDocument2 pagesProduction and Machinery: Wikov Manufacturing FacilitytayefehNo ratings yet

- TP TP: Turret Punch Turret PunchDocument20 pagesTP TP: Turret Punch Turret PunchMaly AliNo ratings yet

- VARIAXIS C 600 BrochureDocument24 pagesVARIAXIS C 600 Brochureadrienbridel80No ratings yet

- CDP Mini Split Quick ReferenceDocument7 pagesCDP Mini Split Quick ReferenceMiguel GomezNo ratings yet

- High Precision & Productivity: Improved Chucking System Built-In Motor Enabling High AccuracyDocument2 pagesHigh Precision & Productivity: Improved Chucking System Built-In Motor Enabling High Accuracyguisela02No ratings yet

- DS DMG DMC 80 U DuoBLOCK Aerospace Chassis Frame enDocument1 pageDS DMG DMC 80 U DuoBLOCK Aerospace Chassis Frame enPaul VeramendiNo ratings yet

- TRUMPF TRUBEND 5230 Technical DataDocument11 pagesTRUMPF TRUBEND 5230 Technical DatacoronaqcNo ratings yet

- Eng - DNM Ii - 1401 - Su - E20Document20 pagesEng - DNM Ii - 1401 - Su - E20Nikolat840% (1)

- QP L SeriesDocument16 pagesQP L Seriesluis arriagaNo ratings yet

- 363C-024-30 Rotary Actuator: ActuatorsDocument5 pages363C-024-30 Rotary Actuator: ActuatorsSiddique AhmedNo ratings yet

- 1260 VMC JyotiDocument3 pages1260 VMC JyotiPavan KhengarNo ratings yet

- Twinmaster 16 III EDocument2 pagesTwinmaster 16 III ECristian HenaoNo ratings yet

- Exercise Book Making MachinesDocument7 pagesExercise Book Making MachinesdevyanidagarNo ratings yet

- Macpower CNC Machines Limited: QTN. NO.: MAC/BRD/JAP/2020-21/VER-6/158 DateDocument6 pagesMacpower CNC Machines Limited: QTN. NO.: MAC/BRD/JAP/2020-21/VER-6/158 DateVirjibhai khokhaniNo ratings yet

- Simba L6CDocument4 pagesSimba L6CsasidharreddyNo ratings yet

- Trumpf TC 200 R: With Complete EquipmentDocument7 pagesTrumpf TC 200 R: With Complete EquipmentOscar Ivan Rendon GuangaNo ratings yet

- Maho MH 600 E: CNC Tool Milling MachineDocument10 pagesMaho MH 600 E: CNC Tool Milling MachineOussama ArfaNo ratings yet

- Total Solution 5-Axis Universal Machining Center: HS-M272-R8.12-20120925Document62 pagesTotal Solution 5-Axis Universal Machining Center: HS-M272-R8.12-20120925tsmutz5No ratings yet

- PDF FanucDocument28 pagesPDF Fanucheart princeNo ratings yet

- N.1 Flexographic Printing Press "Stack Type" Mod Sirio S-Plus 8 Colours - 1200 WidthDocument9 pagesN.1 Flexographic Printing Press "Stack Type" Mod Sirio S-Plus 8 Colours - 1200 WidthMahmoud FathiNo ratings yet

- A81nx CatalogueDocument4 pagesA81nx CatalogueArvind Kushwaha100% (1)

- Axera T12 DATA-315: Technical Description Components in Basic ModelDocument4 pagesAxera T12 DATA-315: Technical Description Components in Basic ModelLechung NguyenNo ratings yet

- Gildemeister CTX 400 - Serie 2: CNC LatheDocument10 pagesGildemeister CTX 400 - Serie 2: CNC LatheEllyanNo ratings yet

- Cat-14 UWIFDocument8 pagesCat-14 UWIFudaysahgalNo ratings yet

- SYIL 7 Epoxy Granite Small Milling CenterDocument2 pagesSYIL 7 Epoxy Granite Small Milling CenterXi FengNo ratings yet

- Planetary Gear DesignDocument3 pagesPlanetary Gear DesignGururaja TantryNo ratings yet

- BSH 7005-15Document129 pagesBSH 7005-15Mark InnesNo ratings yet

- Brahms Symphony No 4Document2 pagesBrahms Symphony No 4KlausNo ratings yet

- Loop Types and ExamplesDocument19 pagesLoop Types and ExamplesSurendran K SurendranNo ratings yet

- Roles and Responsibilities of An InstructorDocument4 pagesRoles and Responsibilities of An InstructorMohanlal SainiNo ratings yet

- Arbans Complete Conservatory Method For Trumpet Arbans Complete ConservatoryDocument33 pagesArbans Complete Conservatory Method For Trumpet Arbans Complete ConservatoryRicardo SoldadoNo ratings yet

- C. Robert Mesle (Auth.) - John Hick's Theodicy - A Process Humanist Critique-Palgrave Macmillan UK (1991)Document168 pagesC. Robert Mesle (Auth.) - John Hick's Theodicy - A Process Humanist Critique-Palgrave Macmillan UK (1991)Nelson100% (3)

- Extract The .Msi FilesDocument2 pagesExtract The .Msi FilesvladimirNo ratings yet

- Enrico Fermi Pioneer of The at Ted GottfriedDocument156 pagesEnrico Fermi Pioneer of The at Ted GottfriedRobert Pérez MartinezNo ratings yet

- Art of War Day TradingDocument17 pagesArt of War Day TradingChrispen MoyoNo ratings yet

- MCQ Floyd ElexDocument87 pagesMCQ Floyd ElexnicoleNo ratings yet

- Honda IzyDocument16 pagesHonda IzyTerry FordNo ratings yet

- Lesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446Document9 pagesLesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446BruntNo ratings yet

- DS Important QuestionsDocument15 pagesDS Important QuestionsLavanya JNo ratings yet

- Outline Calculus3Document20 pagesOutline Calculus3Joel CurtisNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/42Document12 pagesCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaNo ratings yet

- Table of Specification 1st QDocument5 pagesTable of Specification 1st QVIRGILIO JR FABINo ratings yet

- EngHub How To Break HabitsDocument13 pagesEngHub How To Break HabitsViktoria NovikovaNo ratings yet

- Project Chalk CorrectionDocument85 pagesProject Chalk CorrectionEmeka Nicholas Ibekwe100% (6)

- European Construction Sector Observatory: Country Profile MaltaDocument40 pagesEuropean Construction Sector Observatory: Country Profile MaltaRainbootNo ratings yet

- PreviewpdfDocument29 pagesPreviewpdfSoemarlan ErlanNo ratings yet

- Ancient Sumer Flip BookDocument9 pagesAncient Sumer Flip Bookapi-198624210No ratings yet

- Raksha Mantralaya Ministry of DefenceDocument16 pagesRaksha Mantralaya Ministry of Defencesubhasmita sahuNo ratings yet

- Rishika Reddy Art Integrated ActivityDocument11 pagesRishika Reddy Art Integrated ActivityRishika ReddyNo ratings yet

- Reaserch On Effect of Social Media On Academic Performance: Study On The Students of University of DhakaDocument27 pagesReaserch On Effect of Social Media On Academic Performance: Study On The Students of University of DhakaFatema Tuz Johoora88% (114)

- Operations Management Interim ProjectDocument4 pagesOperations Management Interim ProjectABAYANKAR SRIRAM (RA1931201020042)No ratings yet

- Introduction To Password Cracking Part 1Document8 pagesIntroduction To Password Cracking Part 1Tibyan MuhammedNo ratings yet

- Presenters: Horace M. Estrella Jay Mart A. Lazana Princess Camille R. HipolitoDocument23 pagesPresenters: Horace M. Estrella Jay Mart A. Lazana Princess Camille R. HipolitoHorace EstrellaNo ratings yet

- At The Origins of Music AnalysisDocument228 pagesAt The Origins of Music Analysismmmahod100% (1)

- Analytics Designer - Comment Deletion - SAP CommunityDocument6 pagesAnalytics Designer - Comment Deletion - SAP CommunityARPITA BISWASNo ratings yet