Professional Documents

Culture Documents

Spuf 450

Uploaded by

Dhiven VesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spuf 450

Uploaded by

Dhiven VesCopyright:

Available Formats

SPUF 450

SPRAY- ON POLYURETHANE FOAM

TWO-COMPONENT CLOSED CELL POLYURETHANE RIGID SPRAY-ON FOAM

SPUF 450 spray on polyurethane foam is a two-component designed foam that form a seamless layer

to a specific thickness with high insulation proper ties. SPUF 450 is very versatile for multiple

application e.g. for cavity filling, sound insulation, and void sealing. SPUF 450 has excellent chemical

resistance to acid and alkaline beside able to withstand water permeability. Due to its closed cell

structure & hydrophobic natures, rigid polyurethane foam show little propensity to absorb water.

ADVANTAGES

High insulation properties

Primary waterproofing resistance

Hydrophobic & Seamless

Bonding to many types of surface

Closed-cell structure

SURFACE PREPARATION

The substrate must be sound, clean, dry, and

free of laitance, dust, and grease.

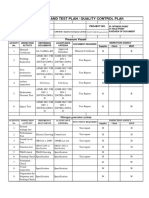

IMPORTANT INFORMATION TECHNICAL CHARACTERISTIC

SPUF 450 system consists of methylene Gel time 3s

diphenyl diisocyanate (MDI) as part A, and Dry time 16s

part B consists of polyol, catalyst and other R Value 6.5/inch ASTM C518

additives. Core Density 43-47 kg/m3 ASTM D1622

The machine’s heating element & surface Tensile Strength 75-85 psi ASTMD 1623

temperature would have an impact on foam Closed-cell Content > 90%

density. Water absorption < 2%

Spray SPUF 450 in several layers to Shelf life (un-open) 6 months @ <26°C

achieve a desired thickness or volume.

Avoid spraying onto raising foam.

Workers must wear protective gear during

the process of handling machine.

Standard professional procedure shall be

followed for best result and safety.

APPLICATION

A primer coat shall be recommended on dusty

surface. SPUF 450 can be applied on

waterproofing layer like asphalt, bitumen,

polyurethane, acrylic and most substrate.

SPUF 450 shall be applied by using a plural

machine with heating parameters.

POLYCELL TECHNICAL DEPARTMENT

OUR COMPANY COMMITMENT – Polycell’s personnel are all fully trained to provide product information, guideline, training and technical assistance. We also provide

product presentation and technical specification to Architects and Engineers.

Disclaimer: The technical data and recommendations relating to the application and end-use of the product are given in good faith and based on tests which we believe to be reliable. However, no warranty in

respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal relationship, whatsoever, can be inferred either from this information, or from any written

recommendations, or from any other advise offered. No guarantee of their accuracy can be made because of the great range of field conditions and variations encountered in raw materials, manufacturing

equipment and methods. Thus, the products are sold with limited warranty only, and on condition that purchasers will make their own tests to determine the suitability of the product for their particular purposes.

Under no circumstances will Polycell be liable to anyone except for replacement of the products or refund of the purchase price. We assume no responsibility for the coverage, performance & injuries resulting

from its used. ALLSALES ARE EXPRESSLY LIMITED TO THE TERMS AND CONDITIONS OF SALE OF POLYCELL COMPANY.

Polycell Sdn Bhd

No.14 Jalan PJS 1/30,Taman Petaling Utama, 46000 Petaling Jaya, Selangor

Tel : +603-7783 4368, +603-7496 2788 Fax : + 603- 7783 4369

Web site : http://www.polycell.com.my/ email : polycellsb@gmail.com, enquiry@polycell.com.my

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- 7 2 1 1 6 1 Polyflex 10 PDFDocument2 pages7 2 1 1 6 1 Polyflex 10 PDFFourier MakambioNo ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- POLYCELL PU 510WB 22sDocument2 pagesPOLYCELL PU 510WB 22snorlailiNo ratings yet

- Polycoat Rbe FR: Rubberized Bitumen EmulsionDocument2 pagesPolycoat Rbe FR: Rubberized Bitumen EmulsionAbidNo ratings yet

- Polycell Pu510 TdsDocument3 pagesPolycell Pu510 TdsnorlailiNo ratings yet

- TDS 202 Dura ProofDocument2 pagesTDS 202 Dura ProofGhulam WaheedNo ratings yet

- Flexseal PU440 TDSDocument2 pagesFlexseal PU440 TDSkumaraguruNo ratings yet

- Masterflow 400 TdsDocument3 pagesMasterflow 400 TdsverNo ratings yet

- 6 2 1 6 1 Polyflex PDFDocument2 pages6 2 1 6 1 Polyflex PDFFourier MakambioNo ratings yet

- S C P (P) S: DescriptionDocument2 pagesS C P (P) S: DescriptionEng-Medrar AlkateryNo ratings yet

- 1050 Plastigard 100 Percent Acrylic High Build CoatingDocument1 page1050 Plastigard 100 Percent Acrylic High Build Coatingjustin trochezNo ratings yet

- Basf Masterseal P 640 Tds 2Document3 pagesBasf Masterseal P 640 Tds 2Bashir SolimanNo ratings yet

- Polypoxy BF: Epoxy Repair Putty and Blow Hole FillerDocument2 pagesPolypoxy BF: Epoxy Repair Putty and Blow Hole FillerAlexi ALfred H. TagoNo ratings yet

- MoyaShield PUDocument3 pagesMoyaShield PUrmltechnicalservicesNo ratings yet

- 6 2 3 6 4 Polybond Ep PDFDocument2 pages6 2 3 6 4 Polybond Ep PDFHtun ZarniNo ratings yet

- Soudafoam 1KDocument2 pagesSoudafoam 1KCHERIF YAHIANo ratings yet

- Don't Just Buy Another Product Buy A SOLUTION: Characteristics: CH TitiDocument2 pagesDon't Just Buy Another Product Buy A SOLUTION: Characteristics: CH TitiLion YangNo ratings yet

- 1325Document1 page1325aleerossNo ratings yet

- Olycryl Olycryl: Acrylic Based Waterproofing CoatingDocument2 pagesOlycryl Olycryl: Acrylic Based Waterproofing CoatingVaittianathan MahavapillaiNo ratings yet

- Pu Sealant Mccoy Soudal Soudaflex 611 Pu SealantDocument2 pagesPu Sealant Mccoy Soudal Soudaflex 611 Pu SealantsasidharkanthetiNo ratings yet

- 6640 SIP-SPLASH 640 June-12Document2 pages6640 SIP-SPLASH 640 June-12ShaikhRizwanNo ratings yet

- EVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data SheetDocument3 pagesEVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data Sheetsamira bashirvandNo ratings yet

- Dr. Fixit USPRO Foam: Single Component Expanding Multi-Purpose Polyurethane FoamDocument3 pagesDr. Fixit USPRO Foam: Single Component Expanding Multi-Purpose Polyurethane FoamDeep GandhiNo ratings yet

- Korapur PU 928 Marine InglesDocument2 pagesKorapur PU 928 Marine InglesselvaNo ratings yet

- Sika® Tite WPU: Product Data SheetDocument3 pagesSika® Tite WPU: Product Data SheetZèlia FláviaNo ratings yet

- 3579 Primer DataDocument2 pages3579 Primer DataSeguridad BratiNo ratings yet

- Sika Boom: Expanding Polyurethane FoamDocument3 pagesSika Boom: Expanding Polyurethane FoamBalasubramanian MahadevanNo ratings yet

- Mastertop 1324 v1Document3 pagesMastertop 1324 v1mahmoodawadhNo ratings yet

- Powerproof: One Component Polyurethane Dispersion Waterproofing MembraneDocument2 pagesPowerproof: One Component Polyurethane Dispersion Waterproofing MembraneFritz Natividad67% (3)

- Hyperself 1.5 MM - TremcoDocument4 pagesHyperself 1.5 MM - TremcoSenthilkumar NarayananNo ratings yet

- FEXIPRO Brochure New Design 16Document4 pagesFEXIPRO Brochure New Design 16gerardNo ratings yet

- Polycoat RTLDocument2 pagesPolycoat RTLniaz05288No ratings yet

- Sikarep - 100: 1-Component Polymer Modified Ultra-Fine Fairing CoatDocument3 pagesSikarep - 100: 1-Component Polymer Modified Ultra-Fine Fairing CoatSudhanshuGuptaNo ratings yet

- Sikabond 542 ID TDSDocument3 pagesSikabond 542 ID TDSRialno TambunanNo ratings yet

- TEC-042226 - MET-DoR-001c-Corrotech Corroprufe DPC PDFDocument2 pagesTEC-042226 - MET-DoR-001c-Corrotech Corroprufe DPC PDFvelmurug_balaNo ratings yet

- TDS Polybit-Easyfelt-P en Mea 1Document2 pagesTDS Polybit-Easyfelt-P en Mea 1dinescNo ratings yet

- CP MoyaShield BEDocument3 pagesCP MoyaShield BEGanesh MurthyNo ratings yet

- Basf Masterprotect h1100 Tds PDFDocument2 pagesBasf Masterprotect h1100 Tds PDFpangalengan zaxNo ratings yet

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocument2 pagesMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNo ratings yet

- Bituprime SB: Solvent Based Bitumen PrimerDocument2 pagesBituprime SB: Solvent Based Bitumen Primerfaisal nadeemNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Masterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembraneDocument3 pagesMasterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembranehemantrulzNo ratings yet

- Sikaflex 11FC - PDS PDFDocument4 pagesSikaflex 11FC - PDS PDFrajeevNo ratings yet

- Sikarep® Microcrete-4: Product Data SheetDocument2 pagesSikarep® Microcrete-4: Product Data Sheetsidharthsud28No ratings yet

- Spua 351Document3 pagesSpua 351AliZenatiNo ratings yet

- Sikalastic Primer PDFDocument3 pagesSikalastic Primer PDFShaik FazilNo ratings yet

- Presentación - Grupo Burry - SosaDocument2 pagesPresentación - Grupo Burry - SosaFranco SosaNo ratings yet

- Hi Pon 50 10 Polyester PU Primer Ver 2.0 PDFDocument4 pagesHi Pon 50 10 Polyester PU Primer Ver 2.0 PDFPushpendraNo ratings yet

- SikaMonoTop 620MY en MY (11 2018) 1 1Document3 pagesSikaMonoTop 620MY en MY (11 2018) 1 1chanqiming51No ratings yet

- Sikatop - 107 Sealid 221102 105735Document4 pagesSikatop - 107 Sealid 221102 105735Andre SitumeangNo ratings yet

- Fisa Tehnica Soudal Vapourseal Adeziv Folii ConstructiiDocument2 pagesFisa Tehnica Soudal Vapourseal Adeziv Folii ConstructiiRĂZVANNo ratings yet

- SikaMonoTop 910N en MY (08 2021) 1 1Document3 pagesSikaMonoTop 910N en MY (08 2021) 1 1chanqiming51No ratings yet

- Polydeck 4000Document2 pagesPolydeck 4000YASIRNo ratings yet

- Product Data Sheet: Product Description Technical SpecificationDocument1 pageProduct Data Sheet: Product Description Technical SpecificationYASHICA VAITTIANATHANNo ratings yet

- KCC DataSheet WH3350 (ENG)Document2 pagesKCC DataSheet WH3350 (ENG)Trịnh Minh KhoaNo ratings yet

- TDS - Polpox EC 945 LV + Hardener EP 945 LV-1Document2 pagesTDS - Polpox EC 945 LV + Hardener EP 945 LV-1Mithilesh MaratheNo ratings yet

- Epidermix 326Document2 pagesEpidermix 326Yasher Meera Saib100% (2)

- Heresite Technical Data Sheet (VR-514)Document5 pagesHeresite Technical Data Sheet (VR-514)Wadu DetutsNo ratings yet

- Quotation: Master Engineering & Trading Sdn. BHDDocument1 pageQuotation: Master Engineering & Trading Sdn. BHDDhiven VesNo ratings yet

- CC-0001-23-PU FoamDocument2 pagesCC-0001-23-PU FoamDhiven VesNo ratings yet

- Part Modelling Test - Design EngDocument1 pagePart Modelling Test - Design EngDhiven VesNo ratings yet

- A4VG Pump (A4VG56) - SpecificationDocument4 pagesA4VG Pump (A4VG56) - SpecificationDhiven VesNo ratings yet

- Unidrum Lever: Push-Pull and Pull-Only Hand ControlDocument4 pagesUnidrum Lever: Push-Pull and Pull-Only Hand ControlDhiven VesNo ratings yet

- Live 4D2U Results - Keputusan 4D - Magnum 4D, Toto, DaMaCai MalaysiaDocument1 pageLive 4D2U Results - Keputusan 4D - Magnum 4D, Toto, DaMaCai MalaysiaDhiven Ves100% (1)

- Cost Declaration: Business Unit: IHC Engineering Malaysia SDN BHD Department: ShipbuildingDocument1 pageCost Declaration: Business Unit: IHC Engineering Malaysia SDN BHD Department: ShipbuildingDhiven VesNo ratings yet

- Wordpress Pods - User GuideDocument18 pagesWordpress Pods - User Guidehusterk100% (6)

- Consolidation Step by Step GuideDocument36 pagesConsolidation Step by Step GuideKrishna100% (3)

- C++ Programming LabDocument24 pagesC++ Programming LabManjusha KulkarniNo ratings yet

- PrecautionsDocument15 pagesPrecautionsyajur_nagiNo ratings yet

- Uptime Tier Designer DocumentDocument5 pagesUptime Tier Designer DocumentManoj67% (3)

- TIJ Cartridge Care and Maintenance-ZDocument3 pagesTIJ Cartridge Care and Maintenance-ZCloudcst SoteloNo ratings yet

- Tensile Testing Standards and SpecificationsDocument3 pagesTensile Testing Standards and SpecificationsTestronix InstrumentsNo ratings yet

- YORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFDocument12 pagesYORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFFadul Chamie TietjenNo ratings yet

- Oracle Partner Management-I PDFDocument160 pagesOracle Partner Management-I PDFMukesh ManwaniNo ratings yet

- 2co N3 PDFDocument28 pages2co N3 PDFeveswan2008No ratings yet

- ROMrefDocument11 pagesROMrefAmy ReedNo ratings yet

- Make A Boomerang PDFDocument4 pagesMake A Boomerang PDFKarthikeyan VisvakNo ratings yet

- SKF Deep Groove Ball BearingsDocument28 pagesSKF Deep Groove Ball BearingsDenis DavydovNo ratings yet

- FM 200 MDKLDocument4 pagesFM 200 MDKLJeghiNo ratings yet

- 217plus - Buscar Con GoogleDocument2 pages217plus - Buscar Con GooglebibbiblosNo ratings yet

- Ashley Lamp Accessory Features SafetyDocument19 pagesAshley Lamp Accessory Features SafetyLauraW510100% (1)

- 2D Pick and Place RobotDocument41 pages2D Pick and Place RobotVikram BogarNo ratings yet

- Embedded Rail SystemDocument37 pagesEmbedded Rail SystemJoshua MasanqueNo ratings yet

- Sheet1: AC (No. of Bus) DC (No. of Bus) Current Carrying Capacity in Amp (Copper) at 35 Deg.cDocument1 pageSheet1: AC (No. of Bus) DC (No. of Bus) Current Carrying Capacity in Amp (Copper) at 35 Deg.cAllan DiazNo ratings yet

- Liu - Real Time SystemsDocument409 pagesLiu - Real Time SystemsShresth KumarNo ratings yet

- SIMATIC Microbox PC 420 Operating InstructionsDocument209 pagesSIMATIC Microbox PC 420 Operating InstructionsSam eagle goodNo ratings yet

- Fundamental LC-MS Orbitrap Mass Analyzers PDFDocument30 pagesFundamental LC-MS Orbitrap Mass Analyzers PDFAlonso HurtadoNo ratings yet

- Chapter 6 ReactivityDocument22 pagesChapter 6 ReactivityEric ChewNo ratings yet

- SamundraDocument28 pagesSamundraParthiban NagarajanNo ratings yet

- ECE 200 BookDocument237 pagesECE 200 BookCharles William Lawless100% (1)

- Tanker Cargo Calculation GuidelinesDocument3 pagesTanker Cargo Calculation GuidelinesJohn Green80% (5)

- ITP (Can Gas)Document1 pageITP (Can Gas)Kemas Muhandis MancapaniNo ratings yet

- Safety Precautions and Safety Procedures For Maintenance of Circuit BreakersDocument10 pagesSafety Precautions and Safety Procedures For Maintenance of Circuit BreakersSayed NagyNo ratings yet

- Hydrogels in Sensing ApplicationsDocument42 pagesHydrogels in Sensing ApplicationsMasihullah J KhanNo ratings yet

- Notes For A Theory of Making in A Time of NecessityDocument23 pagesNotes For A Theory of Making in A Time of NecessityJohn JohnsonNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Construction Process Planning and Management: An Owner's Guide to Successful ProjectsFrom EverandConstruction Process Planning and Management: An Owner's Guide to Successful ProjectsRating: 4 out of 5 stars4/5 (13)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- The Homeowner's DIY Guide to Electrical WiringFrom EverandThe Homeowner's DIY Guide to Electrical WiringRating: 5 out of 5 stars5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Real Life: Construction Management Guide from A-ZFrom EverandReal Life: Construction Management Guide from A-ZRating: 4.5 out of 5 stars4.5/5 (4)

- Sustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsFrom EverandSustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsNo ratings yet

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- Estimating Construction Profitably: Developing a System for Residential EstimatingFrom EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNo ratings yet

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Connections in Steel Structures III: Behaviour, Strength and DesignFrom EverandConnections in Steel Structures III: Behaviour, Strength and DesignRating: 4 out of 5 stars4/5 (6)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Essential Building Science: Understanding Energy and Moisture in High Performance House DesignFrom EverandEssential Building Science: Understanding Energy and Moisture in High Performance House DesignRating: 5 out of 5 stars5/5 (1)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)

- BIM and Construction Management: Proven Tools, Methods, and WorkflowsFrom EverandBIM and Construction Management: Proven Tools, Methods, and WorkflowsNo ratings yet

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationFrom EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettRating: 4 out of 5 stars4/5 (1)