Professional Documents

Culture Documents

Gas Welding Register

Uploaded by

deonstuurman777Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Welding Register

Uploaded by

deonstuurman777Copyright:

Available Formats

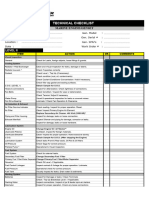

Gas Welding & Cutting Equipment Register

COMPANY:

SITE: EQUIP. NO.:

INSPECTED BY: PAGE OF

MONTHS

ITEMS CHECKED

J F M A M J J A S O N D

CYLINDERS

Properly secured?

Valva guards fitted? Valves undamaged?

Valves free of oil / grease?

Spindle key / valve wheel on cylinder?

Valves closed when not in use?

REGULATORS

Free of oil / grease?

Identifiable: what gas?

Correct range and capacity for work in hand?

Bullnose stem straight? Nut and seat

undamaged? Outlet connection undamaged?

Outlet pressure steady: no creep or pressure

build-up on closing down?

Pressure adjustment screw turns freely?

Gauges undamaged? No zero error?

FLASHBACK ARRESTORS

Are any fitted?

Body and connecting nuts undamaged?

Reset lever in good condition?

HOSES

To SABS spec. / correct colours?

Free from oil / grease / surface defects / cuts /

burns / cracks?

Connection nuts undamaged?

Hoses secured with approved hose clamps?

Safety check valves / flashback arrestors fitted

at torch end?

Reverse flow on check valves tested?

TORCHES/NOZZLES/FLAME LIGHTERS

Free of superficial damage?

Free of oil / grease?

Valves turn easily and close off easily?

Valve spindle straight/knobs intact and well

secured?

Cutting oxygen valve closes completely?

Lever firmly hinged?

Nozzle nut in good condition?

All threads and connections in good condition:

no leaks?

Nozzle correct size / type for gas used?

Friction type lighters used?

GOGGLES

Approved type?

Frame and headband in good condition / clean?

Cover lenses fitted?

Each operator has own set of welding goggles?

INITIAL: COMPETENT PERSON

DATE:

You might also like

- Two Cycle Carburetor and the Back Alley MechanicFrom EverandTwo Cycle Carburetor and the Back Alley MechanicRating: 4.5 out of 5 stars4.5/5 (2)

- Bulldozer MonthlyDocument1 pageBulldozer MonthlyFlorfloresta Alfa OneNo ratings yet

- Checklist Vibratory CompactorDocument3 pagesChecklist Vibratory Compactorlaurdesfatima999No ratings yet

- Checklist BulldozerDocument3 pagesChecklist Bulldozerlaurdesfatima999No ratings yet

- Mercedes PM Check ListsDocument6 pagesMercedes PM Check Listsalexberhane3No ratings yet

- 1ge PDFDocument8 pages1ge PDFJoko SukarionoNo ratings yet

- Maintenance RecommendationsDocument15 pagesMaintenance Recommendationsmsalem730% (1)

- Eil FormatDocument1 pageEil Formatsales.aquavalvesNo ratings yet

- How To Inspect Gear BoxDocument11 pagesHow To Inspect Gear BoxSubbarayan SaravanakumarNo ratings yet

- Checklist Fuel TruckDocument4 pagesChecklist Fuel Trucklaurdesfatima999No ratings yet

- Checklist Mixer TruckDocument4 pagesChecklist Mixer Trucklaurdesfatima999No ratings yet

- 1823 Chapter VDocument10 pages1823 Chapter VberkahharianNo ratings yet

- Checklist Water TruckDocument5 pagesChecklist Water Trucklaurdesfatima999No ratings yet

- Checklist ChainsawDocument2 pagesChecklist Chainsawlaurdesfatima999No ratings yet

- PM Schedule Plan For All MachinesDocument32 pagesPM Schedule Plan For All MachineskumaresanNo ratings yet

- Annual Inspection Checklist PDF 2Document14 pagesAnnual Inspection Checklist PDF 2Tarek ElghazzalyNo ratings yet

- Daily Checklist Air Track Crawler Drill R.001Document2 pagesDaily Checklist Air Track Crawler Drill R.001angger aminda noorcipta joharNo ratings yet

- Vehicle Maintenance ManualDocument51 pagesVehicle Maintenance ManualIbaadNo ratings yet

- Vehicle Maintenance PDFDocument58 pagesVehicle Maintenance PDFPethuraj100% (1)

- TTT Inspection SheetDocument9 pagesTTT Inspection Sheetkhaled fathyNo ratings yet

- Checklist Dump TruckDocument3 pagesChecklist Dump Trucklaurdesfatima999No ratings yet

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- Pelwatte Dairy Industries LTD.: Check List of Boiler MaintenanceDocument2 pagesPelwatte Dairy Industries LTD.: Check List of Boiler MaintenanceChanaka ThilakaratnaNo ratings yet

- Alarm Check Valve - MECHDocument5 pagesAlarm Check Valve - MECHGabriel TapiaNo ratings yet

- Gearbox MaintenanceDocument19 pagesGearbox MaintenanceShafee Ahmad0% (1)

- 17ex 1SS CLKDocument12 pages17ex 1SS CLKFajar FaisalNo ratings yet

- GE Energy Products - Europe: 9E - GT - M - M02 - C02 - V2 - A Revision: (A) Date: 03/09Document10 pagesGE Energy Products - Europe: 9E - GT - M - M02 - C02 - V2 - A Revision: (A) Date: 03/09Mohammad Ibnul HossainNo ratings yet

- HC - HYDRAULIC EXCAVATOR - Safety & Maint. InspectionDocument2 pagesHC - HYDRAULIC EXCAVATOR - Safety & Maint. InspectionMicah DavidNo ratings yet

- Checklist PMS TBDocument3 pagesChecklist PMS TBalsitorNo ratings yet

- Mac25 Maintenance Section 2Document27 pagesMac25 Maintenance Section 2Wahyu SriharjaNo ratings yet

- Pay Loader Monthly Inspection ChecklistDocument1 pagePay Loader Monthly Inspection ChecklistJoy BD60% (5)

- Air Compressor-RegDocument1 pageAir Compressor-RegBeeNo ratings yet

- F0556 Crane Weekly Check (Offshore)Document2 pagesF0556 Crane Weekly Check (Offshore)Vimal Singh0% (1)

- Halliburton: HWO Power Pack PM Meter Shop Date H03A Suggested Interval: 60 DAYSDocument4 pagesHalliburton: HWO Power Pack PM Meter Shop Date H03A Suggested Interval: 60 DAYSKhalfan Al HabsiNo ratings yet

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekDocument8 pagesWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoNo ratings yet

- Checklist PPM AircondDocument6 pagesChecklist PPM AircondsyahirahafiqahNo ratings yet

- Fullbay Heavy Equipment Maintenance ChecklistDocument3 pagesFullbay Heavy Equipment Maintenance Checklistcgig63No ratings yet

- M/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker ChecklistDocument2 pagesM/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker Checklistprojit basu100% (1)

- Service Bulletin: CLASSIFICATION: Part InformationDocument1 pageService Bulletin: CLASSIFICATION: Part InformationPHÁT NGUYỄN THẾNo ratings yet

- Road Grader Daily Inspection by OperatorDocument1 pageRoad Grader Daily Inspection by OperatorNasrullah Khan Yousafzai100% (1)

- SAU1307Document93 pagesSAU1307jalda srikaranNo ratings yet

- Oil Analysis Report ExplanationDocument2 pagesOil Analysis Report Explanationzrcjsyll100% (1)

- PDI Checklist Master - DozersDocument2 pagesPDI Checklist Master - DozerscribytritNo ratings yet

- Lincoln Welding Machine ChecklistDocument1 pageLincoln Welding Machine ChecklistEjike Francis ChizobaNo ratings yet

- FORM TemplateDocument3 pagesFORM TemplateDikky JulistianNo ratings yet

- Cvse 0014Document1 pageCvse 0014法璋No ratings yet

- Check List ManliftDocument2 pagesCheck List ManliftJose Salas AlvaNo ratings yet

- Checklist For Vehicle: SignatureDocument2 pagesChecklist For Vehicle: SignatureSainu KalathingalNo ratings yet

- 2000H Service 16M GraderDocument3 pages2000H Service 16M GraderMohamedNo ratings yet

- Mcu ChecklistDocument4 pagesMcu ChecklistKoushik DasguptaNo ratings yet

- APE Power Unit Check ListDocument1 pageAPE Power Unit Check Listankesh_ghoghariNo ratings yet

- Daily Checklist Asphalt FinisherDocument1 pageDaily Checklist Asphalt FinisherMaulana YusufNo ratings yet

- Company Name CHECK LIST 1Document24 pagesCompany Name CHECK LIST 1ikponmwonsaNo ratings yet

- Arrival Report Forklift DieselDocument1 pageArrival Report Forklift DieselAkbarNo ratings yet

- Neway Gate 6 X 150 RFDocument6 pagesNeway Gate 6 X 150 RFcomercial 3No ratings yet

- How To Inspect A GearboxDocument13 pagesHow To Inspect A Gearboxkamal arabNo ratings yet

- Daily Checklist TMC R.001Document2 pagesDaily Checklist TMC R.001Maulana Yusuf100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Asbestos Risk Assessment TemplateDocument3 pagesAsbestos Risk Assessment Templatedeonstuurman777No ratings yet

- Excavator ChecklistDocument2 pagesExcavator Checklistdeonstuurman777No ratings yet

- Formwork ChecklistDocument1 pageFormwork Checklistdeonstuurman777No ratings yet

- PPE Issuing RegisterDocument1 pagePPE Issuing Registerdeonstuurman777No ratings yet

- PPE PolicyDocument1 pagePPE Policydeonstuurman777No ratings yet

- Air Powered Tool ChecklistDocument1 pageAir Powered Tool Checklistdeonstuurman777No ratings yet