Professional Documents

Culture Documents

JSEA042022002 - Borehole Drilling

JSEA042022002 - Borehole Drilling

Uploaded by

Weru Morris0 ratings0% found this document useful (0 votes)

2 views9 pagesOriginal Title

JSEA042022002_borehole drilling

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views9 pagesJSEA042022002 - Borehole Drilling

JSEA042022002 - Borehole Drilling

Uploaded by

Weru MorrisCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 9

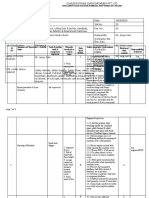

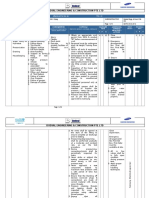

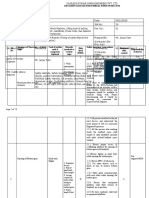

Job Safety and Environmental Analysis (JSEA)

Site: Makueni Agri hub Project JSEA No. 042022002

JSEA title:

JSEA for Borehole Drilling

Task Borehole drilling, Pump Testing and Installation of Pump

description:

Work zone: Makueni Agrihub

Which companies are involved? Identify the company & their role in the work:

Lexis International Ltd- Main Contractor

Where is the job described and the hazards and control measures identified?

Document Type & Reference (e.g. JSA, SOP, WI, Method Statement, Reviewed & Satisfactory?

Client MS or/and Contractor MS etc.)

Job description Borehole drilling Yes / No

Hazard identification Listed in the task table below Yes / No

Control measures Listed in the task table below Yes / No

QHSE / SOP/ 001 / V5

Tasks, Hazards and Control Measures – Complete table, unless tasks, hazards and controls are satisfactorily identified

elsewhere.

Task Masonry works

Step Hazard Associated Risk Rating Control Measures Residual Additional Responsibility

Risk risk control

rating measures

1. Identification of Striking electric Electrocution Medium Low All workers

underground line or water pipe Service providers shall PTW authorities

utilities be conducted to help in (Issuing

identification of the Authority,

underground utilities performing

such as power lines, authority,

authorizing

and water pipes.

authority and

area authority).

2. Setting up drill Unstable and Machine High The outrigger pads low All workers

rig/ Pump testing uneven ground rollover of the rig shall rest PTW authorities

unit on a dry, stable flat (Issuing

ground. Authority,

performing

Proper procedures in authority,

operator's manual authorizing

shall be followed authority and

area authority).

while on inclines.

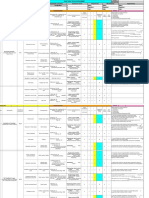

3. Welding the welding flash Inflammation medium Welding helmet shall be low All workers

surface casing and/or spatter of cornea worn with proper grade

QHSE / SOP/ 001 / V5

of filter plate. PTW authorities

(Issuing

Authority,

performing

authority,

authorizing

authority and

area authority).

UV/infrared Burns from High The recommended low

radiation UV/infrared protective clothing All workers

radiation shall be worn PTW authorities

ensuring any exposed

(Issuing

skin is covered during

the welding process Authority,

Metal jewelry and performing

clothing with cuffs authority,

and/or pockets shall authorizing

not be worn. authority and

area authority).

Welding fumes or asphyxiation Medium Welding shall be done in low

displaced fumes open space with free All workers

circulation of air PTW authorities

(Issuing

Authority,

performing

authority,

authorizing

authority and

area authority).

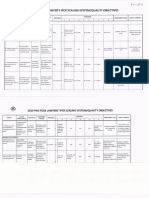

QHSE / SOP/ 001 / V5

Faulty electrical Electrical High The welding machine Low

cables and plugs, shock hazard shall be properly All workers

wet ground grounded. PTW authorities

Welder should be

(Issuing

insulated from live

electrical parts and Authority,

dry. performing

Do not weld when authority,

wet. authorizing

Inspect and replace authority and

cables, plugs and leads area authority).

that show any signs of

defect.

Combustible Fire High Any combustible low All workers

materials material shall be PTW authorities

removed from the (Issuing

immediate welding

Authority,

site.

Fire extinguisher shall performing

be radially available authority,

If the object to be authorizing

welded or cut cannot authority and

be moved, all area authority).

combustible materials

in the vicinity should

be taken to a safe

place away from the

area (at least 35 feet)

A fire watch shall be

continuously present

during the entire hot

QHSE / SOP/ 001 / V5

work activity and 30

minutes after

completion.

Unauthorized Accidents to High Authorization for hot low Authorization for

hot works personnel or works shall be given hot works shall All workers

fire outbreak only and only if all not be granted if: PTW authorities

safety precautions and

(a) The welder (Issuing

requirements listed on

the hot work permit or cutter is Authority,

are met. not properly performing

Under no trained in authority,

circumstances is a welding or authorizing

permit to be issued cutting authority and

sight unseen. operations. area authority).

(b) If welding

An inspection of the

or cutting

work site must be

equipment

conducted by the

is not in

authorizing authority

proper

prior to authorization

operating

condition

and free

from defect

or damage.

If the authorizing

authority feels

that the

operation may

QHSE / SOP/ 001 / V5

jeopardize the

safety workers

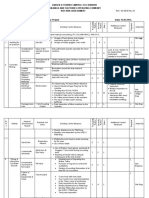

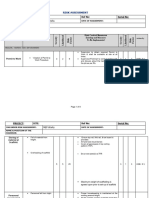

4. Drilling Dust Silicosis Medium All the workers shall low All workers

always have their dust PTW authorities

mask on to prevent any (Issuing

entry of dust in the Authority,

nostrils. performing

authority,

authorizing

authority and

area authority).

Eye irritation Medium Clear googles shall be low In case dust gets All workers.

worn by all workers at all into2 the eye, PTW authorities

the times to prevent any the eye should (Issuing

entry of the dust into the

be washed with Authority,

eyes.

water or open performing

and close the authority,

eyes inside authorizing

water. authority and

area authority).

Oil spill Kill the soil Low All spills from the Low All workers.

micro- machine shall be arrested

organism before they reach the

ground, either through

bucket or spill kits

Moving or Crush body Medium All moving parts Low

rotating parts parts (fingers, shall have a guard All workers

hands etc.) The drill shall be set PTW authorities

to minimize amount (Issuing

QHSE / SOP/ 001 / V5

of pipe exposed Authority,

outside of the entry performing

pit. authority,

All bystanders shall authorizing

be kept away from authority and

the rig machine and area authority).

rotating parts while

drilling.

5. Manually loading Moving or Crush body Medium All hands and Low

& unloading drill rotating parts parts (fingers, clothing shall be All workers

pipe/ Casing hands etc) away from the pipe PTW authorities

pipe/UPVC pipes and moving parts (Issuing

before any Authority,

movement is performing

engaged after the authority,

pipe has been set. authorizing

All parts shall be authority and

stopped, not moving area authority).

before loading pipe,

and pipe guide is in

place.

No pipe shall be

loaded while drilling

is in operation.

Once the pipe is

placed in the

magazine, workers

should step back at

QHSE / SOP/ 001 / V5

least 3m.

Stop rotation when

the drill head

surfaces.

Pumping out water Pressurized water Hit by Medium Low All workers

pressurized The working area shall

water be delimitated

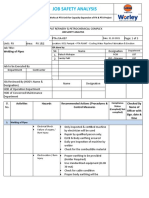

Authorization to commence work

With reference to this PTW and relevant SOPs, WIs, JSAs and MSs (identified above), I confirm:

This JSA addresses the applicable hazards and necessary controls. Yes / No

The control measures have reduced risks as low as is reasonably practicable. Yes / No

The appropriate resources (people and equipment) are available to do the job Yes / No

safely

QHSE / SOP/ 001 / V5

Others that could be affected by the work have been informed Yes / No

All required safety equipment (including PPE and monitoring equipment) is Yes / No

available.

The job has been satisfactorily discussed in a Toolbox Talk with all relevant staff, Yes / No

including all control measures and safety equipment (including PPE).

All pre-job inspections and checks have been made. Yes / No

The job area has been prepared as required. Yes / No

That the work covered by this JSA can commence. Yes / No

Name Signature Date

Task Supervisor:

HSE Officer

(Performer):

HSE inspector

(Client)

QHSE / SOP/ 001 / V5

You might also like

- TRA-Installation of Cathodic ProtectionDocument9 pagesTRA-Installation of Cathodic ProtectionGilbert Gill100% (4)

- RA 012 Taking Trial PitsDocument2 pagesRA 012 Taking Trial Pitsahmedshah512100% (1)

- Risk Assessment For Trial Pit Excavation-RevDocument15 pagesRisk Assessment For Trial Pit Excavation-RevRawoofuddin Chand100% (1)

- 1 RA 1410 Demolition & Site ClearanceDocument11 pages1 RA 1410 Demolition & Site ClearanceMuhammad Shahid Iqbal100% (5)

- Risk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Document12 pagesRisk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Anandu Ashokan100% (1)

- Hirarc Bridge ConstructionDocument9 pagesHirarc Bridge ConstructionAdib Ikhwan100% (3)

- Paytm University AssignmentDocument40 pagesPaytm University AssignmentJasmeen MatharuNo ratings yet

- MFC Youth Songboard 2020Document1,221 pagesMFC Youth Songboard 2020Shea SancoverNo ratings yet

- Calculus 3208 Curriculum Guide PDFDocument258 pagesCalculus 3208 Curriculum Guide PDFLuckyNo ratings yet

- JSA Transformer InstallationDocument10 pagesJSA Transformer InstallationWeru Morris100% (1)

- Hirarc Bridge ConstructionDocument9 pagesHirarc Bridge ConstructionKalai ArasanNo ratings yet

- PTW Logic DiagramDocument1 pagePTW Logic DiagramAdrianNo ratings yet

- PTWDocument22 pagesPTWaliabdallah20232023No ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Hirarc 2Document5 pagesHirarc 2dibhmNo ratings yet

- Annual Pre Shutdown JSADocument2 pagesAnnual Pre Shutdown JSAKeerthi RaajNo ratings yet

- Jsa For Cable PullingDocument9 pagesJsa For Cable Pullingshaibaz chafekarNo ratings yet

- 10 Damansara HIRARCDocument34 pages10 Damansara HIRARCTri Subakti50% (2)

- SFM-08.10-SHEM-009 Job Safety Analysis FormDocument6 pagesSFM-08.10-SHEM-009 Job Safety Analysis FormsalmankhanehsNo ratings yet

- Jsa PDFDocument5 pagesJsa PDFVAMSINo ratings yet

- Sanction To Test - HV - EmptyDocument3 pagesSanction To Test - HV - EmptyGo andWatchNo ratings yet

- Step No. Sequence of Activities Hazard Who or What May Be Harmed? Control Measures / Recovery Measures Action / Responsible PartyDocument7 pagesStep No. Sequence of Activities Hazard Who or What May Be Harmed? Control Measures / Recovery Measures Action / Responsible PartyameeraliNo ratings yet

- New JuneDocument6 pagesNew JuneShovon khanNo ratings yet

- Raft Foundation-RA 005Document20 pagesRaft Foundation-RA 005Anonymous kWfNFbNo ratings yet

- Hirarc 3Document6 pagesHirarc 3dibhmNo ratings yet

- Nomination Form - Author Is EdDocument2 pagesNomination Form - Author Is EddamonclarkeNo ratings yet

- HirarcDocument34 pagesHirarcBungsu HiperkesNo ratings yet

- Name Designation 1) Name: Name: Name: 2) Signature: Signature: Signature: 3) Date: Date: DateDocument34 pagesName Designation 1) Name: Name: Name: 2) Signature: Signature: Signature: 3) Date: Date: DateHarry Hasbullah100% (7)

- Risk Assesment @ro, WTP & STP PremDocument6 pagesRisk Assesment @ro, WTP & STP PremvarunthalariNo ratings yet

- Risk AssessmentDocument13 pagesRisk Assessmentmohsin.meizaNo ratings yet

- Displine & Appeal Rules - U.C.BodakeDocument31 pagesDispline & Appeal Rules - U.C.BodakeHabib Ur RahmanNo ratings yet

- RA 002 - Mechanical ExcavationDocument2 pagesRA 002 - Mechanical ExcavationZaki Abdullah ALQweaenNo ratings yet

- SK Vin Builders: Hazard Identification Risk Assessment & Determining Control (Hiradc)Document9 pagesSK Vin Builders: Hazard Identification Risk Assessment & Determining Control (Hiradc)Sanket0% (1)

- Hydrotest & Pneumatic Test - TRADocument6 pagesHydrotest & Pneumatic Test - TRAOws Anish100% (3)

- 2019 Ipcr Scaling For LawyersDocument5 pages2019 Ipcr Scaling For LawyersMeynard MagsinoNo ratings yet

- Administrative Law & Election Law (Atty Gallant Soriano) 2S 2015-2016 Finals ReviewerDocument21 pagesAdministrative Law & Election Law (Atty Gallant Soriano) 2S 2015-2016 Finals ReviewerSofia BrondialNo ratings yet

- Risk Assessment & Determining Significance (RT) : F02-TSM-HSE-OP-02 Rev.Document2 pagesRisk Assessment & Determining Significance (RT) : F02-TSM-HSE-OP-02 Rev.muhammad imtiazNo ratings yet

- Back FillingDocument1 pageBack FillingRohit SinghNo ratings yet

- Air Conditioning and Mechanical Ventilation System (ACMV Electrical Works)Document5 pagesAir Conditioning and Mechanical Ventilation System (ACMV Electrical Works)haidil abd hamidNo ratings yet

- 00332100dwpv12001 - Precommissioning Commissioning Procedure-Rev B-ConvertiDocument41 pages00332100dwpv12001 - Precommissioning Commissioning Procedure-Rev B-ConvertiWalid KhelfaNo ratings yet

- Ptw-Kec - Final v3 - SparkDocument1 pagePtw-Kec - Final v3 - SparkXiang JintaoNo ratings yet

- KOP-RSK-FRM-00001 Water Jetting and Industrial Vacuuming PermitDocument2 pagesKOP-RSK-FRM-00001 Water Jetting and Industrial Vacuuming PermitdrakoniiNo ratings yet

- Site Coordination Meeting: Elimination: Nil Substitution:Scissors Lift PPE:Dust Mask, SafetyDocument2 pagesSite Coordination Meeting: Elimination: Nil Substitution:Scissors Lift PPE:Dust Mask, SafetyRama RajanNo ratings yet

- Lock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorDocument1 pageLock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorShailendraNo ratings yet

- Concreting HSE RADocument5 pagesConcreting HSE RAAnsari HarisNo ratings yet

- HIRARCDocument34 pagesHIRARCNaga Rajan100% (1)

- JSA Trunks InstallationDocument9 pagesJSA Trunks InstallationWeru MorrisNo ratings yet

- QHSEDOCS-Demolition Work Activities Risk AssessmentDocument14 pagesQHSEDOCS-Demolition Work Activities Risk AssessmentLawrence adeleke OmisakinNo ratings yet

- Best Practices For Remote Control Applications (PDF) - Added 4 - 3 - 20Document7 pagesBest Practices For Remote Control Applications (PDF) - Added 4 - 3 - 20Dereck SeckmanNo ratings yet

- PTA-JSA-007-Welding of PipesDocument3 pagesPTA-JSA-007-Welding of PipesSaiyad RiyazaliNo ratings yet

- Work at Height PermitDocument1 pageWork at Height Permitamenmohamm3dNo ratings yet

- JSA Format Internal ReactorDocument13 pagesJSA Format Internal Reactorsakthi venkatNo ratings yet

- JSA - Undergound MappingDocument2 pagesJSA - Undergound Mappingshamierrul shahliNo ratings yet

- JRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaDocument5 pagesJRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaAijaz AhmedNo ratings yet

- Sheikh Jaber Causeway Subcontract No.: KUSC-SC-S-0600: Activity/Task: Installation of Cable TrayDocument7 pagesSheikh Jaber Causeway Subcontract No.: KUSC-SC-S-0600: Activity/Task: Installation of Cable Traywaseem kausarNo ratings yet

- Work at HDocument2 pagesWork at Hmani narayananNo ratings yet

- 3 - RA-mepDocument9 pages3 - RA-mephsem Al EimaraNo ratings yet

- MARINE Construction Safety Risk Register Penang MalaysiaDocument10 pagesMARINE Construction Safety Risk Register Penang MalaysiaNora100% (1)

- 14 Temporary ElectricityDocument1 page14 Temporary ElectricityKhuda BukshNo ratings yet

- INFINITY LIFT PlanDocument1 pageINFINITY LIFT PlanWeru MorrisNo ratings yet

- Fuel PlanningDocument5 pagesFuel PlanningWeru MorrisNo ratings yet

- JSA Trunks InstallationDocument9 pagesJSA Trunks InstallationWeru MorrisNo ratings yet

- JSA Electrical WiringDocument10 pagesJSA Electrical WiringWeru Morris100% (1)

- HP Deskjet Printers - Printing Internal TestsDocument3 pagesHP Deskjet Printers - Printing Internal Testserick_ssNo ratings yet

- RHP - Catálogo de Rodamientos de Super Precisión PDFDocument24 pagesRHP - Catálogo de Rodamientos de Super Precisión PDFljcmexNo ratings yet

- Training With Noise Is Equivalent To Tikhonov RegularizationDocument8 pagesTraining With Noise Is Equivalent To Tikhonov RegularizationJavad RahmannezhadNo ratings yet

- RCAF Ontario Station - Sep 1942Document39 pagesRCAF Ontario Station - Sep 1942CAP History LibraryNo ratings yet

- 1Mhz 1A Synchronous Step-Down Regulator: Features General DescriptionDocument2 pages1Mhz 1A Synchronous Step-Down Regulator: Features General DescriptionM. M.No ratings yet

- Risk Based Auditing Ebook PDFDocument11 pagesRisk Based Auditing Ebook PDFAsepWahyuPrabowo100% (1)

- Appendix A - WMT Berthing and Mooring AnalysisDocument75 pagesAppendix A - WMT Berthing and Mooring AnalysisKarim OuNo ratings yet

- Exodontia Instrumentation PDFDocument6 pagesExodontia Instrumentation PDFRongJuneNo ratings yet

- TCD6 20110408 19 - 44Document316 pagesTCD6 20110408 19 - 44Midhun Pillai (P&M)No ratings yet

- GemuDocument72 pagesGemuSergio GarridoNo ratings yet

- The Gifted StudentsDocument6 pagesThe Gifted StudentsHoàng BùiNo ratings yet

- Yoganidra History and Context PDFDocument23 pagesYoganidra History and Context PDFhari hara100% (1)

- Ella Hepworth Dixons My Flirtations The New Woman and The Marriage Market - Valerie Fehlbaum PDFDocument5 pagesElla Hepworth Dixons My Flirtations The New Woman and The Marriage Market - Valerie Fehlbaum PDFCintia LimaNo ratings yet

- SPLM Analytic Geometry Part 2Document85 pagesSPLM Analytic Geometry Part 2Joey TelinNo ratings yet

- Study On Mechanical Effect of The Vehicle at Corners: Ming NiDocument4 pagesStudy On Mechanical Effect of The Vehicle at Corners: Ming NiJay SoniNo ratings yet

- Balo GunDocument7 pagesBalo GunYeshua ResearchNo ratings yet

- Huawei Parameter StrategyDocument22 pagesHuawei Parameter StrategyTùng NguyễnNo ratings yet

- Selection and Grading of ContentDocument36 pagesSelection and Grading of ContentAli Gamil100% (1)

- Basic Television, Bernard GrobDocument15 pagesBasic Television, Bernard GrobaledieNo ratings yet

- CSRF 1 (CPF) FormDocument4 pagesCSRF 1 (CPF) FormJack Lee100% (1)

- Gpa & Cgpa CalculatorDocument7 pagesGpa & Cgpa CalculatorQaisKhanNo ratings yet

- TD of EdtDocument28 pagesTD of EdtOussama SouidNo ratings yet

- GR NotesDocument13 pagesGR NotesbbteenagerNo ratings yet

- W1 CementDocument2 pagesW1 CementLee LeeNo ratings yet

- Lampiran E8 MATRIKS SIKA, TANGGUNG JAWAB INSIDEN DAN DAMPAK PEKERJAAN NON PEMBORANDocument5 pagesLampiran E8 MATRIKS SIKA, TANGGUNG JAWAB INSIDEN DAN DAMPAK PEKERJAAN NON PEMBORANsamsul zamaniNo ratings yet

- SEM2 Sacraments and SacramentalsDocument2 pagesSEM2 Sacraments and SacramentalsJeg GonzalesNo ratings yet

- Sra Third Party Vendor MGMTDocument11 pagesSra Third Party Vendor MGMTgraeme.mcdonaldNo ratings yet