Professional Documents

Culture Documents

An Application of Fuzzy Delphi and Fuzzy Ahp On Evaluating 4qxlincxjv

Uploaded by

HẠNH PHẠM HIẾUOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Application of Fuzzy Delphi and Fuzzy Ahp On Evaluating 4qxlincxjv

Uploaded by

HẠNH PHẠM HIẾUCopyright:

Available Formats

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

An Application of Fuzzy Delphi and Fuzzy AHP on Evaluating Wafer

Supplier in Semiconductor Industry

JAO-HONG CHENG1, CHIH-MING LEE2, CHIH-HUEI TANG3

Department of Information Management

National Yunlin University of Science and Technology

No.123, Sec. 3, Dasyue Road, Douliou City, Yulin Country, 640

Taiwan, R.O.C.

jhcheng@yuntech.edu.tw ; g9723806@yuntech.edu.tw2; ellistang@gmail.com3

1

Abstract: - Because of the pressure of globalization in the last two decades, professional services has become an

important strategic decision so that supplier selection is a prime concern. In the semiconductor industry, the prior

researches worked on analyzing and improving the process, and evaluating the equipment manufacturers. Therefore,

being the semiconductor industry applying a wide huge of advanced technologies, wafer suppliers and foundry and

DRAM manufacturers acquire a large volume of critical materials and components. Consequently, this study is to

identify critical factors related to the wafer supplier selection. It also has become a new subject by how to prompt

current position of semiconductor industry and their wafer supplier in Taiwan. Primary criteria to evaluate supplier

selection is acquired by the literatures survey, wafer manufacturers’ data and applying fuzzy Delphi method (FDM),

and then fuzzy analytic hierarchy process (FAHP) is employed to calculate the weights of these criteria, so as to

establish the fuzzy multi-criteria model of wafer supplier selection. The results indicated a greatest weight on the

dimension of wafer supplier selection, and seven critical criteria related to wafer supplier selection were: (1) wafer

quality, (2) delivery time, (3) service, (4) price, (5) process capability, (6) reputation, and (7) past performance.

Key-Words: - Wafer Supplier, Supply Chain, Semiconductor, Analytic Hierarchy Process (AHP), Fuzzy Delphi

Method (FDM), Fuzzy Analytic Hierarchy Process (FAHP), Fuzzy Multi-Criteria Decision Making (FMCDM).

1 Introduction main of aspects is to select the right sources of

In high capital investment semiconductor industry, a suppliers in the global business environment, with

key to success and profits of the foundry firms and reducing the operational risks and costs. Since then,

DRAM manufacturers is the ability to introduce the semiconductor industry has combined a process

innovative process, high productivity, and quality within upstream and downstream cooperative

products ahead of its competitors. Consequently, they manufacturers to become the whole semiconductor

have needs and demand lower price to wafer materials industrial chain. It is very important to select the

with stable and higher quality, with advanced process component suppliers because they must link together

capability with greater flexibility, and exact delivery closely within the product connects and interacts with

with good after-sales service for their production surrounding components in a limited number of ways.

facilities. For semiconductor industry is like a Concerning semiconductor industry, the prior

development paradigm industry. Therefore, it has researches worked on analyzing and improving the

become a new subject by how to prompt current process, and evaluating the equipment manufacturers,

position of semiconductor industry and their wafer etc. Today, the foundry and DRAM manufacturers

supplier in Taiwan. would want to be successful and survival in the high

Being the semiconductor industry applying a wide competitive environment, they must have the

huge of advanced technologies, wafer suppliers and strategies to build the industrial system linking with

foundry and DRAM manufacturers acquire a large the upstream and downstream manufacturers, such as

volume of critical materials and components. To the wafer suppliers, IC (Integrated Circuit) test, IC

ensure long-term availability of these items at a packaging, and so on. In order to achieve this

competitive cost, manufacturers have to manage the successful goal ahead of its competitors, the foundry

risk and complexities of global sourcing in an efficient and DRAM manufacturers need to identify and

and effective manner (Chan and Chan, 2004). One implement performance that are appropriate, valid,

ISSN: 1790-0832 756 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

reliable, and measurable that fit their production more concerns by industrial experts’ consensus served

processes criteria within whole semiconductor as primary evaluation criteria in wafer industry. At

industry. Therefore, the foundry and DRAM this stage, the questionnaire was designed in a fuzzy

manufacturers need to select the wafer suppliers linguistic scale, and every expert rated the importance

carefully and successfully through low cost and high of individual criterion in the form of a triangular fuzzy

quality wafer under competitive operating number, and then they reached a consensus in

environment (Weber et al, 1991). One of the most determining the importance to serve as the primary

important decisions is to select a competent group of evaluation criteria of wafer industry. At the fourth

suppliers (Weber et al, 1991). In this perspective, they stage, the statistic results were provided to these

need index measures to evaluate, control, and improve experts and pair-comparison of all criteria was made,

production processes. The core purpose of this study thus the weight of individual criteria is calculated by

is to find out a more complete and concerned FAHP. Hence, the fuzzy multi-criteria model of wafer

collection of explanatory variables and identify industry was established through the process of the

critical factors of wafer supplier selection from the experts’ rating of the criteria.

collections. Thus, we adopted a perspective of The remainder of the paper is structured as follows.

foundry and DRAM manufacturers to explore the In Section 2, we discussed the literatures concerning

supplier selection criteria when the manufactory chose our topic. Section 3 we described our methodology

the wafer suppliers. including choosing the experts and characteristics,

In our research, the survey of studies is to identify survey design, and the application of FDM and

critical factors related to the wafer supplier selection, FAHP. Finally, section 4 presented our final

and the collection of variables are divided into seven conclusions and suggestions.

groups to serve as preliminary evaluation dimensions.

Primary criteria to evaluate supplier selection is

obtained by the literatures survey, wafer 2 Literature Review

manufacturers’ data and applying FDM, and then 2.1 Semiconductor Industry

FAHP is employed to calculate the weights of these In the early 1970’s, Taiwan’s government and local

criteria, so as to establish the fuzzy multi-criteria and foreign scholars realized that Taiwan should

model of wafer supplier selection. The selection establish an export-oriented strategy for economic

criteria include characteristics of wafer quality, development, which should develop high-tech

delivery time, service, price, process capability, industries to sustain economic growth. They searched

reputation, and past performance Hence, the aims of the no existing industry in Taiwan could lead the way

this paper are: (1) to identify wafer manufacture to to sustain economic growth for more than ten years.

select and practices based on the industry’s opinion, They recognized and anticipated that the high-tech

wafer manufactures’ data, and literature reviews in industries were the future industries to the country.

supply chain, and (2) to built the actual selection Hence, in order for the domestic industry to acquire

criteria when manufacture makes decisions. the fundamental expertise required for developing

The questionnaire investigation with four stages high-tech, the government had to support the initial

was conducted in this study. At the first stage, development of high-tech industries. The main

according the literatures review and wafer high-tech industries were the IC industry and the

manufacturers’ data, we came up with more semiconductor industry.

dimensions. And, we sought three industrial experts to Due to the high risk, high competition, high

evaluate and to select the some key dimensions, in investment, and high technology intensity of the IC

order to let the dimensions converged that we used the industry, the semiconductor industry increased the

triangulation on qualitative method. At the second speed of R&D and competitiveness for it. The IC

stage, we designed the instruments to explore and industry and semiconductor industry supported

extract potential variables related to wafer supplier Taiwan’s high-tech industries in increasing its

selection. And, potential explanatory variables related competitiveness in world markets has become the

to wafer supplier were obtained from literature survey main focus at present. In semiconductor industry, the

based on the first-stage dimensions. Then, at the third type of manufacturing can separate into three related

stage, the questionnaire investigation of explanatory markets, the market for original equipment

variables was conducted by FDM. The variables with manufacturers (OEM), the original design

ISSN: 1790-0832 757 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

manufacturing (ODM), and own branding and competitive advantage. Today, from a managerial

manufacturing (OBM). However, in Taiwan, most of point of view, a lot set of supplier selection criteria

the semiconductor manufacturers are belong to the have to be identified in any industry. Regarding the

OEM. The OEM manufactories must base on the supplier selection criteria literatures, many

customers’ demand to product and to ship the researchers have studied and addressed the supplier

production, even if, to select the component suppliers selection criteria in many industries (i.e. Barbarosoglu

Since the mid-1980’s, with the TSMC built to OEM and Yazgac, 1997; Chan and Chan, 2004; Choi and

model for the IC manufactured in the semiconductor Hartley, 1996; Dickson, 1966; Dulmin and Mininno,

industry fast changing the semiconductor operation, 2003; Ellram, 1990; Swift, 1995; Watts, Kim, and

and many high-tech firms began to establish in Hahn, 1992; Weber et al., 1991; Weber and Ellram,

Taiwan. This not only brought the high economics 1993).

rate for the country but also changed the high-tech The firms must usually trade off to select the

industrial chain for the world. Unfortunately, the supplier among the existing various criteria. In prior

predominance of small- and medium-sized firms in researches, Dulmin and Mininno (2003) considered

the industrial structure of the country may be a burden the supplier selection based on cost and supplier’s

to developing high-tech sectors. In order to ahead of ability to meet quality requirements and delivery

its competitors to satisfy the market demands, the schedule. Dickson (1966) studied and analyzed the

foundry and DRAM manufacturers stress on the vendor selection systems and decisions, and posited

productive capability, such as low cost, high speed the 23 criteria to select the suppliers. Based on the

productivity, innovative process, product flexibility, Dickson’s research (1966), Weber et al. (1991)

and high yield, quality, and services. For these goals, analyzed and summarized the literatures of supplier

the key successful factor is to integrate the choice, and addressed 11 criteria factors (quality,

semiconductor industrial chain. Then, in order to delivery, net price, geographical location, production

supporting the semiconductor industrial chain, the facilities and capacity, technical capability, attitude,

wafer suppliers have appeared in the early 1990s, management and organization, packaging, operational

which supplies the high quality and stable wafer controls, and repair service) to select vendor of

materials for the foundry and DRAM manufacturers. just-in-time systems. In linking purchasing to

At the same time, there are few academic researches corporate competitive strategy, Watts et al. (1992)

in discussing the semiconductor supplier selection posited 8 criteria (process capability, product

criteria, especially to evaluate the wafer suppliers. capability, operation capability, management

The wafer component market is similar to the capability, technology, quality, delivery, and cost) to

primary market for the computer industry, while the select supplier. Leong, Snyder, and Ward (1990)

related, which is characterized by a higher degree of expanded the number of generic capabilities to five

competition. Hence, wafer supplier selection not only criteria (cost, delivery performance, quality,

plays an important role in semiconductor industry flexibility and innovation). Swift (1995) analyzed 21

chain due to increasing the quality and service but also instruments and extracted the items to 5 criteria

is a critical in building and maintaining competition factors (product, availability, dependability,

for the foundry and DRAM manufacturers. experience, and price) to evaluate the supplier. Choi

and Hartley (1996) explored the supplier selection

practices and extracted 26 instruments to 8 criteria

2.2 Relative Criteria of Supplier Selection factors (finances, consistency, reliability, relationship,

To analyze the criteria and measuring in performance technological capability, flexibility, price, and service)

of suppliers has been the focus of many researchers to choose the supplier cross the supply chain. Chan

and practitioners since Dickson (1966) and Weber et and Chan (2004) studied and pointed out 6 criteria

al. (1991). More firms pay attention to the evaluation factors (cost, delivery, flexibility, innovation, quality,

and selection between suppliers (Barbarosoglu and and service.) to evaluate suppliers in advanced

Yazgac, 1997; Chan and Chan, 2004; Choi and technology industry. For interested readers, all of the

Hartley, 1996; Ellram, 1990; Swift, 1995; Weber et al., supplier selection criteria of the literatures were

1991; Weber and Ellram, 1993). To manufacturer, the summarized in Table 1.

selection and evaluation is one of the most critical In sum, Choi and Hartley (1996) considered

activities by which to attempt to achieve positional

ISSN: 1790-0832 758 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

supplier selection criteria differ among industries well understood. We doubt the wafer supplier

different layers levels of supply chain, direct suppliers, selection criteria may be less different with the prior

and indirect suppliers. Although supplier selection researches. Hence, we investigated the semiconductor

was an important strategic issue that has been industrial information to evaluate the wafer supplier in

explored by researchers (i.e. Barbarosoglu and practice. We gathered some wafer supplier evaluation

Yazgac, 1997; Chan and Chan, 2004; Choi and Hartley, criteria form three firms of foundry and DRAM

1996; Dickson, 1966; Dulmin and Mininno, 2003; manufacturers. These criteria were summarized: (1)

Ellram, 1990; Swift, 1995; Watts, Kim, and Hahn, quality, (2) delivery time, (3) service, (4) price, and (4)

1992; Weber et al., 1991; Weber and Ellram, 1993) in process capability. Therefore, we adopt the literatures,

many different topics and industries, the wafer manufacturers’ data, and industry experiences

supplier selection criteria used by the semiconductor regarding semiconductor manufacturers’ perspective

industry in direct and indirect supplier firms were less to our study.

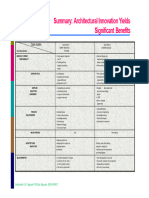

Table 1 Summary the supplier selection criteria literatures

Literatures Supplier selection criteria factors

Quality, Delivery, Performance history, Warranties and claim policies, Production facilities and

capacity, Price, Technical capability, Financial position, Procedural compliance, Communication

Dickson (1966) system, Reputation and position in industry, Desire for business, Management and organization,

Operating controls, Repair service, Attitude, Impression, Packaging ability, Labor relations

record, Geographical location, Amount of past business, Training aids, and Reciprocal

arrangements.

Leong et al.(1990) Cost, Delivery performance, Quality, Flexibility, and Innovation.

Quality, Delivery, Net price, Geographical location, Production facilities and capacity, Technical

Weber et al. (1991) capability, Attitude, Management and organization, Packaging, Operational controls, and Repair

service.

Watts et al. (1992) Process capability, Product capability, Operation capability, Management capability, Technology,

Quality, Delivery, and Cost.

Swift (1995) Product, Availability, Dependability, Experience, and Price

Choi and Hartley (1996) Finances, Consistency, Reliability, Relationship, Technological capability, Flexibility, Price, and

Service.

Chan and Chan (2004) Cost, Delivery, Flexibility, Innovation, Quality, and Service.

2.3 FDM and FAHP decision-making model and experts’ suggestion can

Reviewed the literatures (Chan and Chan, 2004; Chen, be more emphasized and applied in various fields.

Tzeng, Tang, 2005; Cheng, Chen, Chuang; 2008; Delphi method is a technique for structuring an

Dickson, 1966; Dulmin and Mininno, 2003; effective group communication process by providing

Narasimhan, 1983; Nydick and Hill, 1992; Swift, feedback of contributions of information and

1995; Weber et al., 1991) and summarized the assessment of group judgments to enable individuals

existing approaches to supplier selection shows that to re-evaluate their judgments. Since its development

these aim to fulfill a combination of objectives in the 1960s at Rand Corporation, Delphi method has

between qualitative and quantitative. Therefore, there been widely used in various fields. On the other hand,

is no straightforward methodology which can be Delphi Method use crisp number and mean to become

applied to solve supplier selection especially when the the evaluation criteria, these shortcomings might

different organizations have different qualitative distort the experts’ opinion.

requirements. The tools, FDM and FAHP, can take In order to deal with the fuzziness of human

both perspectives into consideration. The participants’ judgments in traditional Delphi method,

methodology of combining the FDM and FAHP is a Ishikawa et al. (1993) posited fuzzy set theory

good candidate for these kinds of supplier selection proposed by Zadeh (1965) into the Delphi method to

problem that both qualitative and quantitative improve time-consuming problems such as the

objectives have to be considered. convergence of experts’ options presented by Hwang

The role of decision-making has become more and Lin (1987). Fuzzy set theory is increasingly

complicated today. And, the importance of applied in many researches such as by Caballero et al.

ISSN: 1790-0832 759 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

(2004) and by Lin et al. (2006). Furthermore, because and to build the wafer supplier selection criteria.

people are often uncertain in assigning the evaluation Before designing the survey, we gathered the

in crisp number, to overcome the problem, this study industrial evaluation criteria on wafer supplier from

adopts the fuzzy linguistic scale. the foundry and DRAM manufacturers. The three

The analytic hierarchy process (AHP) methodology firms indicated the quality, delivery time, service,

was a systematic method developed by Satty (1980). price, and process capability were the index

It is a powerful and flexible method in solving measurements. We summarized the industrial

complex, and multi-criteria decision problems. AHP evaluation criteria and measurement index:

method helps decision-makers’ organize the critical (1) Quality: IQA gate reject rate, supplier process

components and aspects of a problem into a capability, process quality performance, and

hierarchical structure similar to a family tree. By supplier quality system.

reducing complex decisions to a series of simple pair (2) Price: net price, delivery term, and payment term.

wise comparisons and rankings, then synthesizing the (3) Delivery: lead time, on-time delivery, accuracy of

results, the AHP not only helps the analysts to arrive delivered quantities, support of EDC, and Request

at the best decision, but also provides a clear rationale for waiving or incidents of premium freight.

for the choices made. Cheng et al. (2008) employed (4) Service: efficiency of reply and technical support.

the fourth party logistics using the concept of FAHP Beside, according the literatures, we combined the

method to assist supply chain integration capabilities industrial criteria of wafer supplier selection and prior

and information technology capabilities. Antón et al. researches in related or other arenas, and generalized

(2004) and Oddershede et al. (2006) also employ the 13 important constructs. After the stage, we selected

AHP method to solve their decision-making problems. three industrial experts (Mr. Tang, senior engineer in

Besides, due to the defect of traditional AHP production Div., IMI; Mr. Lin, section manager in

application by Buckley (1985) such as the quality department, FST; and Mr. Chen, section

characteristics of subjectiveness, fuzziness, and manager in purchasing department, PSC.) who were

imprecision, many researches incorporated the Fuzzy rich experience related the wafer suppliers in the

theory into the AHP method to improve its application semiconductor industry to evaluate the constructs. We

(Cheng, Chen, Lee, 2006). Hence, AHP approach has adopted the triangulation method to select the core

been widely applied in various relative fields to solve constructs on qualitative research. Based the

the decision-making problems with multiple triangulation method, we extracted seven evaluation

hierarchies under the situation of uncertainty. criteria which were wafer quality, delivery time,

FAHP method is adopted increasingly by service, price, process capability, reputation, and past

researchers. Hsieh et al. (2004) employed fuzzy performance. The results were presented in Table 2,

analytic hierarchy process (FAHP) method to solve which also described the reputation and past

the problem of planning and design tenders selection performance appropriated for the wafer supplier

in public office building. And FAHP method was also selection.

applied in the research of Chen et al. (2005) to

Based the extracting constructs, we referred the

evaluate expatriate assignments. Thus, in this study,

related literatures to develop the instruments. A

due to the fuzziness existed in the part of evaluation

pre-test was performed with two expert academics and

criteria, we decide to adopt the FDM to form the

two Ph.D. students on a questionnaire consisting of 39

primary evaluation criteria of wafer supplier selection,

items of the survey instrument to consider

and employ the FAHP to calculate the weight of

improvement in its content and appearance. The

individual criteria so as to establish the Fuzzy

responses suggested only minor cosmetic changes,

Multi-criteria Model of wafer supplier selection

and no statements were removed. After minor changes

criteria.

were made, and further review by three other

industrial experts, the instrument was deemed ready to

3 Methodology and the Analysis of be sent to the main firms in order to gather data for

Results building the wafer supplier selection criteria. A survey

3.1 Extracting Constructs and Designing the package, including a cover letter explaining the

Survey research objectives, the questionnaire, and a stamped,

The survey methodology was used to gather the data return-addressed envelope, was distributed to

ISSN: 1790-0832 760 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

purchasing managers and practiced staffs of each 4 Returned rate for feed test

participating firm. The respondents were asked to 5 Process quality performance

6 Request rate for correction measures

complete the all questionnaires and as well as on the 7 Request rate after wafer used

overall appearance and content of the instruments. At 8 Suppliers’ quality system

the same time, we offered the gift coupons of five Delivery Time

hundred NT dollars to appreciate the support. 9 Delivery lead time

10 Delivery time accuracy

Table 2 Core criteria of wafer supplier selection 11 Delivery quantity accuracy

Experts Mr. Mr. Mr. 12 Emergency delivery after order changed

Result 13 Incident for over freight

Criteria Tang Lin Chen Past Performance

Price ˇ ˇ ˇ ○ 14 Production line operation in the past

Delivery ˇ ˇ ˇ ○ 15 Long-term revenue growth

Quality ˇ ˇ ˇ ○ 16 Quality of records in the past

Business Relationship ˇ 17 Long-term record prices

Process Capability ˇ ˇ ˇ ○ Reputation

Past Performance ˇ ˇ ○ 18 Supporting for manufacturer in the past

19 Long-term corporate identity and position

Guarantee and compensation ˇ 20 After-sales service in the past

Reputation ˇ ˇ ○ 21 Compensation for against the contract

Financial Situation ˇ 22 Follow-up of abnormal counterpart of man-made

Ability to Process Improve ˇ Service

Service ˇ ˇ ˇ ○ 23 Supporting when abnormal process occurred

Production Control ˇ 24 Returned rate for customer response

Location ˇ 25 Complain process and responsibility

26 Ability to identify problems quickly

27 Ability to solve problems quickly

3.2 Survey Instruments Price

Our overall survey instrument was based on both past 28 Satisfaction of purchasing cost

literature published surveys (Chan and Chan, 2004; 29 Company's payment

Choi and Hartley, 1996; Dickson, 1966; Leong et al.,

Process Capability

30 Understanding semiconductor process technology

1990; Swift, 1995; Watts et al., 1992; Weber et al., 31 R&D speed in core technology

1991) and the industrial experiences. To consider the 32 Systems integration capability

wafer supplier selection practices in semiconductor 33 Manufactured automation capability

34 Considerations of machine and equipment safety

industry, we built on the supplier selection criteria of 35 Process control capability

Chan and Chan (2004), Choi and Hartley (1996), 36 Production scale

Dickson (1966), Leong et al. (1990), Swift (1995), 37 R&D personnel quality

Watts et al. (1992), and Weber et al. (1991). We 38 Process stability and incidence abnormal rate

39 Process R&D capability

gathered and developed the instruments of supplier

selection criteria from these different sources. All of

instruments were distributed in 7 critical constructs, chosen were the professionals in the arena related to

including quality, delivery time, service, price, our study with the experience of industrial experts.

process capability, reputation, and past performance. Besides, they should be rich working experience with

All of the instruments were represented in Table 3. the semiconductor industry and their positions were at

least the rank of department managers in the

department on purchasing or production. In general,

the numbers of expert were from three to fifteen

3.3 Choosing the Experts

(Manoliadis, Tsolas, and Nakou, 2006). This study

This study focused on the analysis of evaluation

was sent out to nine industrial experts of foundry and

criteria of wafer supplier selection. Thus, the experts

DRAM manufacturers as the questionnaire subjects

Table 3 Wafer supplier selection instruments from the semiconductor industry in Taiwan, the name

No. Content of constructs/instruments list as the TSMC, UMC, VIS, IMI, PSC, NTC,

Quality ProMOS, Winbon, and Rexchip.

1 Formal quality department and affiliate

2 Internal quality audit system

3 Norm of quality standards

ISSN: 1790-0832 761 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

3.4 Determining the Evaluation Criteria maximum u of all experts’ most conservative

3.4.1 Collecting the Experts’ Opinions cognition score for each individual element,

At this stage, we designed the questionnaire in a respectively.

9-point fuzzy semantic differential scale of Triangular fuzzy number A = (L, M, U)L-R of all

“absolutely important”, “very important”, “pretty experts’ most optimistic cognition for each individual

important”, “quite important”, “no comment”, “fairly element and triangular fuzzy number a = (l, m, u)L-R of

unimportant”, “quite unimportant”, “very all experts’ most conservative cognition for each

unimportant”, and “absolutely unimportant”. And, we individual element were established respectively and

asked the selected experts to answer instrument illustrated in Figure 1.

survey. The selected experts assigned a relative Degree

importance to every collected variable with respect to of

seven dimensions of quality, delivery time, service, Member-

price, process capability, reputation, and past ship 1

performance in order to confirm critical constructs as

the evaluation criteria of wafer supplier selection.

0 1 m L uM U

3.4.2 Applying the FDM to Select Critical Gray Interval Score

Evaluation Criteria Fig. 1. Triangular fuzzy number of the most optimistic

At this stage, we used the FDM to select the critical cognition and the most conservative cognition

evaluation criteria through the three step processes.

Step 2. Analyzing the Value of Triangular Fuzzy

Step 1. Establishing the Triangular Fuzzy Function Function

All experts’ estimations gathered by prior step were To organize and analyze the expert questionnaires

used to establish the triangular fuzzy function of each collected, triangular fuzzy function with respect to

individual criterion through the process of FDM every potential variable was established as

proposed by Ishikawa et al. (1993). The process of represented in Table 4.

application was as follows:

(1) The elements of evaluation set were determined Step 3. Selecting Critical Evaluation Criteria

by expert questionnaires of bicycle supplier When selecting the evaluation criteria, it was

selection. Given a score of 100 and 0 to the generally considered important if relative importance

traditional binary logics of “absolutely important“ is greater than 80%. It is for gaining the criteria,

and ”absolutely unimportant” respectively, the hence, we calculated the median of gray interval for

other elements of evaluation set were quantified every potential variable and took 85% as the threshold

objectively through the treatment of FDM. to filter out those variables with the score of less than

(2) The questionnaires were designed for the 85% on the median of gray interval. Thus, important

elements of evaluation set other than “absolutely criteria consistently agreed by selected experts are

important“ and ”absolutely unimportant”, and accordingly obtained.

selected experts are invited to fill the quantitative According to the above filtering treatment, we

score interval of every element in the evaluation obtained from the collected experts’ questionnaires,

set. The maximum of interval value was the there are 39 important criteria commonly agreed by 7

experts’ most optimistic cognition of the experts. And, totally 14 instrument items were

quantitative score for the element, and the eliminated. They were listed as follows.

minimum of interval value was the experts’ most (1) Quality: No. 2: Internal quality audit system, No.

conservative cognition of the quantitative score 3: Norm of quality standards, and No. 5: Process

for the element. quality performance.

(3) Solving the minimum L, geometric mean M, and (2) Delivery time: No. 9: Delivery lead time, No.10:

the maximum U of all experts’ most optimistic Delivery time accuracy, and No.12: Emergency

cognition score for each individual element, along delivery after order changed.

with the minimum l, geometric mean m, and the (3) Past performance: No. 16: Quality of records in

ISSN: 1790-0832 762 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

the past. (6) Price: No. 28: Satisfaction of purchasing cost.

(4) Reputation: No. 21. Compensation for against the (7) Process capability: No. 35: Process control

contract. capability, No. 38: Process stability and incidence

(5) Service: No. 26. Ability to identify problems abnormal rate, and No. 39: Process R&D

quickly and No. 27: Ability to solve problems capability.

quickly.

Table 4 The triangular fuzzy function with respect to every potential variable

Potential The Most The Most The

Factor Conservative Gray Optimistic Median

Dimensions Variables

No. Cognition Interval Cognition of Gray Results

[min, med, max] [min, med, max] Interval

1 [49, 70, 100] [100, 58] [58, 76.16, 100] 79

2 [71, 80.82, 92] [92, 88] [88, 93.81, 100] 90 V

3 [69, 79.67, 92] [92, 89] [89, 94.34, 100] 90.5 V

Quality 4 [67, 73.67, 81] [81, 90] [90, 94.87, 100] 84.5

5 [68, 79.09, 92] [92, 87] [87, 93.27, 100] 89.5 V

6 [49, 63.77, 83] [83, 55] [55, 74.16, 100] 69

7 [61, 71.15, 83] [83, 77] [77, 87.75, 100] 80

8 [69, 79.67, 92] [92, 76] [76, 87.18, 100] 84

9 [55, 74.16, 100] [100, 77 [77, 87.75, 100] 88.5 V

10 [78, 86.08, 95] [95, 88] [88, 93.81, 100] 91.5 V

Delivery Time 11 [49, 66.78, 91] [91, 58] [58, 76.16, 100] 74.5

12 [55, 70.75, 91] [91, 87] [87, 93.27, 100] 89 V

13 [59, 69.13, 81] [81, 67] [67, 81.85, 100] 74

14 [61, 71.15, 83] [83, 77] [77, 87.75, 100] 80

Past 15 [39, 56.2, 81] [81, 46] [46, 67.82, 100] 63.5

Performance 16 [68, 78.23, 90] [90, 81] [81, 90, 100] 85.5 V

17 [58, 73.05, 92] [92, 77] [77, 87.75, 100] 84.5

18 [67, 73.67, 81] [81, 77] [77, 87.75, 100] 79

19 [58, 73.05, 92] [92, 68] [68, 82.46, 100] 80

Reputation 20 [61, 71.15, 83] [83, 67] [67, 81.85, 100] 75

21 [55, 71.13, 92] [92, 78] [78, 88.32, 100] 85 V

22 [69, 79.24, 91] [91, 78] [78, 88.32, 100] 84.5

23 [67, 78.08, 91] [91, 78] [78, 88.32, 100] 84.5

24 [67, 78.08, 91] [91, 77] [77, 87.75, 100] 84

Service 25 [68, 79.09, 92] [92, 77] [77, 87.75, 100] 84.5

26 [68, 79.09, 92] [92, 78] [78, 88.32, 100] 85 V

27 [68, 79.09, 92] [92, 78] [78, 88.32, 100] 85 V

28 [67, 78.51, 92] [92, 78] [78, 88.32, 100] 85 V

Price

29 [55, 70.75, 91] [91, 67] [67, 81.85, 100] 79

30 [55, 70.75, 91] [91, 78] [78, 88.32, 100] 84.5

31 [49, 66.78, 91] [91, 58] [58, 76.16, 100] 74.5

32 [49, 63.77, 83] [83, 58] [58, 76.16, 100] 70.5

33 [49, 66.78, 91] [91, 58] [58, 76.16, 100] 74.5

Process 34 [49, 66.78, 91] [91, 58] [58, 76.16, 100] 74.5

Capability 35 [67, 78.51, 92] [92, 90] [88, 93.81, 100] 91 V

36 [49, 63, 81] [81, 58] [58, 72.25, 90] 69.5

37 [49, 66.78, 91] [91, 55] [55, 74.16, 100] 73

38 [67, 78.51, 92] [92, 88] [88, 93.81, 100] 90 V

39 [67, 78.51, 92] [92, 88] [88, 93.81, 100] 90 V

Note: Gray zones are the sum of weight that exceeds 85 percent. “V” is the more important criteria.

3.5 Applying the FAHP Method supplier selection. The process was listed as follows.

We applied the FAHP to calculate the weights of

individual dimension and individual criteria of bicycle Step 1. Building the Hierarchical Structure

ISSN: 1790-0832 763 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

First was to build the hierarchical structure. The subordinated to the i-th general criterion

hierarchical structure was described as follows. The δ ij : The maximum of the j-th subcriterion

goal was placed at the top of hierarchy, and the subordinated to the i-th general criterion

general criteria were placed at second level. The L-R: Fuzzy interval of triangular fuzzy numbers

secondary sub-criteria with respect to each dimension

were placed at third level. Step 4. Building the Fuzzy Positive Reciprocal

In our case, the ultimate goal at the top level was Matrix

“evaluation of wafer supplier selection”, and there After triangular fuzzy numbers were solved to

were seven general criteria, “quality”, “delivery represent the fuzziness of experts’ opinions, the fuzzy

time”, “past performance”, “reputation”, “service”, positive reciprocal matrix A can be further built.

“price”, and “process capability” at second level. As

to each individual criterion, there were subordinate

[ ]

A = α~ij

[ ]

…………….....(2)

sub-criteria listed at third level. For example, fourteen α~ij = α ij , β ij , δ ij

sub-criteria including (1) quality: No. 2: Internal

quality audit system, No. 3: Norm of quality

standards, and No. 5: Process quality performance, (2) Step 5. Calculating the Fuzzy Weights of Fuzzy

delivery time: No. 9: Delivery lead time, No.10: Positive Reciprocal Matrix

Delivery time accuracy, and No.12: Emergency In our study, the method developed by Buckley

delivery after order changed, (3) Past performance: (1985) and improved by Hsu (1998) was employed to

No. 16: Quality of records in the past, (4) Reputation: calculate the fuzzy weights. This method was based

No. 21. Compensation for against the contract, (5) on the experts’ precise value and synthesized the

Service: No. 26. Ability to identify problems quickly experts’ opinions with the geometric mean instead of

and No. 27: Ability to solve problems quickly, (6) the fuzzy numbers input directly by experts.

Price: No. 28: Satisfaction of purchasing cost, and (7) Thus, not only the consistency but also the

Process capability: No. 35: Process control capability, concept of normalization was easily achieved.

No. 38: Process stability and incidence abnormal rate, Through the following formulas, the positive

and No. 39: Process R&D capability. reciprocal geometric mean Zi of triangular fuzzy

numbers and the fuzzy weight Wi can be obtained.

Step 2. Building the Pair-wise Comparison Matrix Z i = [α~i1 ⊗ ... ⊗ α~in ]1 / n , ∀ i

By the second questionnaires gathered from selected ………………. (2)

experts, we obtained the relative importance of paired Wi = Z i ⊗ ( Z 1 ⊕ ... ⊕ Z n ) −1

criteria factors at level n+1 under the evaluation of α~1 ⊗ α~2 ≅ (α 1 × α 2 , β1 × β 2 , δ 1 × δ 2 ) ……… (3)

criteria at level n by individual experts’ opinions, and

the pair-wise comparison matrix was accordingly α~1 ⊕ α~2 ≅ (α 1 + α 2 , β1 + β 2 , δ 1 + δ 2 ) …….. (4)

conducted. (

Z1−1 = δ 1−1 , β1−1 , α 1−1 )

L − R ……………………(5)

1 ⎛ 1 1 1 ⎞

Step 3. Calculating Triangular Fuzzy Numbers

α 1 = ⎜⎜ α 1n , β1n , δ 1n

~ n ⎟ ……………………….. (6)

Concerning the relative importance of each individual ⎜ ⎟⎟

evaluation construct in pair-wise comparison matrix, ⎝ ⎠

triangular fuzzy number was calculated to integrate all

experts’ opinions. It can be used to present the Step 6. Defuzzification

fuzziness of all experts’ opinions with respect to the Since the weights of all evaluation criteria were fuzzy

relative importance of paired factors. values, it was necessary to compute a non-fuzzy value

( )

α~ij = α ij , β ij , δ ij L− R …………(1) by the process of defuzzification. In our study, the

Centroid method was employed to defuzzy because of

Where two reasons: (1) the Centroid method was widely used

α~ij : Triangular fuzzy number in relative literatures such as Klir and Yuan (1995),

α ij : The minimum of the j-th subcriterion and (2) the solution can be figured out quite quickly.

subordinated to the i-th general criterion Through the following formulas, the defuzzified

weight Wi can be obtained.

β ij : The geometric mean of the j-th subcriterion

ISSN: 1790-0832 764 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

Wα i + Wβ i + Wδ i

Wi = ………….(7) Step 8. Synthesis of Hierarchy

3

The weight of each individual evaluation criterion at

Wα i : The right-end value of the fuzzy weight

bottom level can be obtained by the implementation of

Wβ i : The value of the fuzzy weight with the step 1 through step 7. And the weights of criteria or

degree of membership as 1 sub-criteria at upper level were the synthesis of the

Wδ i : The left-end value of the fuzzy weight weights of their subordinations applying the following

formula. Hence, the weights of all criteria at every

level of hierarchy can be obtained.

Step 7. Normalization

NWk = NWi × NWi p ………………………(9)

In order to effectively compare the relative

importance among evaluation criteria, we normalized The detail of hierarchical structure and results were

the obtained weights using the following formula. illustrated as Figure 2.

W

NWi = i = n i ……………………………… (8)

∑ Wi

i =1

Level 1: Goal Evaluation of Wafer Supplier Selection

Level 2: Delivery Past Reputation Service Price Process

Quality

General 0.2509 [1] Time Performance 0.0873 [6] 0.1576 [3] 0.1196 [5] Capability

Criteria 0.2007 [2] 0.0633 [7] 0.1206 [4]

Internal

Quality Delivery Lead Compensation Ability to Process

Level 3: Audit Time for Against the Control

Identify

Sub- System 0.0305 [14] Contract Problems Capability

criteria 0.1171 [2] 0.0873 [4] Quickly Satisfaction of 0.0324 [12]

Delivery Time Quality of Purchasing

0.0775 [7]

Norm of Accuracy Records in Cost Process

Quality 0.1040 [3] the Past Ability to 0. 1196 [1] Stability and

Standards 0.0633 [9] Solve Incidence

0.0857 [5] Emergency Problems Abnormal

Delivery after Quickly Rate

Process Order Changed 0.0801 [8] 0.0569 [10]

Quality 0.0661 [8]

Performance Process R&D

0.0481 [11] Capability

Note: [number] was the weight rank. 0.0313 [13]

Fig. 2. Hierarchy structure for evaluation criteria of wafer supplier selection

4 Conclusions and Suggestions evaluation framework of wafer supplier, which built

Suppliers are viewed as critical resources for the by the key criteria in the complex business

foundry and DRAM manufacturers in semiconductor environment. To address this decision problem, we

industry. The manufacturers must manage to drive the have presented a FDM and FAHP to develop the

maximum potential benefits in the supply chain, and criteria model in a fuzzy group MCDM approach with

how to select the supplier is one of the most critical an effective to extend the concept of the degree of

tasks in supply management. Actually, to evaluate optimality. Adopting the FDM and FAHP model, the

decision alternatives in a new and complex problem criteria for supplier selection are clearly identified and

setting often involves subjective evaluation by a the problem is structured systematically. This helps

group of decision makers with respect to a set of decision makers to examine the strengths and

qualitative criteria. The aim of the study is to offer an weaknesses of the supplier by comparing them with

ISSN: 1790-0832 765 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

respect to appropriate criteria and sub-criteria. In the Management Journal, 1st quarter, 1997, pp.

result, we presented that there were fourteen 14-21.

sub-criteria in the seven dimensions of wafer supplier [3] Buckley, J.J., Fuzzy Hierarchical Analysis, Fuzzy

selection criteria, as shown in Fig. 2. Sets & Systems, Vol.17, No.3, 1985, pp. 233-247.

In our empirical study, we approved the wafer [4] Caballero, A., Ahmed, S., Azhar, S., Risk

quality, delivery time, service, price, process Evaluation Using a Fuzzy Logic Model, WSEAS

capability, reputation, and past performance are the Transactions on Business and Economics, Vol.1,

critical criteria to choose the wafer suppliers. No.1, 2004, pp. 18-23.

However, the results indicate that there are different [5] Chan, F.T.S., Chan, H.K., Development of the

weight criteria between the industrial experiences and supplier selection model a case study in the

our results. Actually, the results show that the highest advanced technology industry, Proceedings of the

priority criteria are quality (weight, 0.25), delivery Institution of Mechanical Engineers - Part B -

time (weight, 0.20), and service (weight, 0.16). The Engineering Manufacture, Vol. 218, No. 12, 2004,

results also explained the industrial properties in pp. 1807-1824.

semiconductor industry, which is high capital [6] Chen, M., Tzeng, G., Tang, T., Fuzzy MCDM

investment industry and continuity in line production Approach for Evaluation of Expatriate

for foundry and DRAM manufacturers. All of the Assignments, International Journal of

machines and equipments are very expensive. And, Information Technology and Decision Making,

many machines and equipments can process and Vol.4, No.2, 2005, pp. 277-296.

produce mutil-processing layers. Based on the [7] Cheng, J.H., Chen, C.W., Lee, C.Y., Using Fuzzy

conductions, the managers of foundry and DRAM Analytical Hierarchy Process for Multi-criteria

manufacturers are afraid of the pollution of particle, Evaluation Model of High-Yield Bonds

liquid photoresists, and metal in the line production, Investment, IEEE International Conference on

which they must avoid. Hence, the results of the wafer Fuzzy Systems, 2006, pp. 1049-1056.

supplier selection criteria are most importance in the [8] Cheng, J.H., Chen, S.S., Chuang, Y.W., An

quality, delivery time, and service. Application of Fuzzy Delphi and Fuzzy AHP for

This study contributes to extract critical factors Multi-criteria Evaluation Model of Fourth Party

related to more complete dimensions rather than only Logistics, WSEAS Transaction on Systems, Vol.7,

cost ones on the selection of wafer supplier and to No.5, 2008, pp. 466-478.

estimate the relative importance of these constructs in [9] Choi, T.Y., Hartley, J.L., An exploration of

the industrial experts’ views. It can be used to supplier selection practices across the supply

facilitate the decision-making process of evaluation of chain, Journal of Operations Management,

wafer supplier selection for foundry and DRAM Vol.14, No.4, 1996, pp. 333-343.

manufacturers. Our results can be referred and [10] Dickson, G.W., An analysis of vendor selection

extended in the future to develop more in-depth systems and decisions, Journal of Purchasing,

researches. Many fuzzy multi-attribute Vol.2, 1966, pp. 5-17.

decision-making methods, like fuzzy DEA, fuzzy [11] Dulmin, R., Mininno, V., Supplier selection using

TOPSIS, and fuzzy ANP, can be used to build a multi-criteria decision aid method, Journal of

different evaluation models and then their results can Purchasing and Supply Management, Vol.9,

be analyzed and compared. No.4, 2003, pp. 177-187.

[12] Ellram, L.M., The Supplier Selection Decision in

References: Strategic Partnerships, Journal of Purchasing

[1] Antón, J.M., Grau, J.B., Angina, D., Electre and and Materials Management, Vol.26, No.4, 1990,

AHP MCDM Methods versus CP Method and the pp. 8-14.

Official Choice Applied to High-Speed Railway [13] Hsieh, T., Lu, S., Tzeng, G., Fuzzy MCDM

Layout Alternative Election, WSEAS Approach for Planning and Design Tenders

Transactions on Business and Economics, Vol.1, Selection in Public Office Buildings,

No.1, 2004, pp. 64-69. International Journal of Project Management,

[2] Barbarosoglu, G., Yazgac, T., An application of Vol.22, No.7, 2004, pp. 573-584.

the analytic hierarchy process to the supplier [14] Hsu, T.H., The Fuzzy Delphi Analytic Hierarchy

selection problem, Production and Inventory Process, Journal of Chinese Fuzzy Systems

ISSN: 1790-0832 766 Issue 5, Volume 6, May 2009

WSEAS TRANSACTIONS on

INFORMATION SCIENCE and APPLICATIONS Jao-Hong Cheng, Chih-Ming Lee, Chih-Huei Tang

Association, Vol.4, No.1, 1998, pp. 59-72. selection procedure, International Journal of

[15] Hwang, C.L., Lin, M.L., Group Decision Making Purchasing and Materials Management, Vol.28,

under Multiple Criteria, Springer-Verlag, Berlin No.2, 1992, pp. 31-36.

Heidelberg, New York, 1987. [23] Oddershede, A., Carrasco, R., Ontiveros, B.,

[16] Ishikawa, A., Amagasa, T., Tamizawa, G., Perception of Wireless Technology Provision in

Totsuta, R., Mieno, H., The Max-Min Delphi Health Service Using the Analytic Hierarchy

Method and Fuzzy Delphi Method via Fuzzy Process, WSEAS Transactions on

Integration, Fuzzy Sets & Systems, Vol. 55, 1993, Communications, Vol.5, No.9, 2006, pp.

pp. 241-253. 1751-1757.

[17] Klir, G.J., Yuan, B., Fuzzy Sets and Fuzzy [24] Satty, T.L., The Analytic Hierarchy Process,

Logic-Theory and Applications, Prentice Hall, MaGraw-Hill, New York, 1980.

Inc., 1995. [25] Swift, C.O., Preferences for single sourcing and

[18] Leong, G.K., Snyder, D.L., Ward, P.T., Research supplier selection criteria, Journal of Business

in the process and content of manufacturing Research, Vol.32, No.2, 1995, pp. 105-111.

strategy, Omega, 1990, Vol. 8, No. 2, PP. [26] Watts, C.A., Kim, K.Y., Hahn, C.K., Linking

109-122. Purchasing to Corporate Competitive Strategy,

[19] Lin, C.C., Chen, V., Yu, C.C., Lin, Y.C., A International Journal of Purchasing and

Schema to Determine Basketball Defense Materials Management, Vol.28, No.4, 1992, pp.

Strategies Using a Fuzzy Expert System, 2-8.

Proceedings of the 7th WSEAS International [27] Weber, C.A., Current, J.R., Benton, W.C.,

Conference on Fuzzy Systems, Cavtat, Croatia, Vendor selection criteria and methods, European

June 12-14, 2006, pp. 49-54. Journal of Operational Research, Vol.50, No.1

[20] Manoliadis, O., Tsolas, I., Nakou, A., Sustainable (Jan.), 1991, pp. 2-18.

Construdtion and Drivers of Change in Greece: a [28] Weber, C.A., Ellram, L.M., Supplier Selection

Delphi Study, Construction Management & Using Multi-Objective Programming: A Decision

Economics, Vol. 4, 2006, pp. 113-120. Support Systems Approach, International

[21] Narasimhan, R., An analytic approach to supplier Journal of Physical Distribution and Logistics

selection, Journal of Purchasing and Supply Management, Vol.23, No.2, 1993, pp. 3-14.

Management, Vol.1, 1983, pp. 27-32. [29] Zadeh, L.A., Fuzzy Set, Information and Control,

[22] Nydick, R.L., Hill, R.P., Using the Analytic Vol.8, No.3, 1965, pp. 338-353.

Hierarchy Process to structure the supplier

ISSN: 1790-0832 767 Issue 5, Volume 6, May 2009

You might also like

- Expert Systems With Applications: Ya-Ti Lin, Chia-Li Lin, Hsiao-Cheng Yu, Gwo-Hshiung TzengDocument9 pagesExpert Systems With Applications: Ya-Ti Lin, Chia-Li Lin, Hsiao-Cheng Yu, Gwo-Hshiung TzengShady BearNo ratings yet

- AHP Supplier Selection CriteriaDocument24 pagesAHP Supplier Selection CriteriaKajal JoshiNo ratings yet

- Textile IndustryDocument8 pagesTextile Industrygogana93No ratings yet

- Suppliers Selection in Manufacturing Industries and Associated Multi-Objective Desicion Making Methods Past, Present and The FutureDocument21 pagesSuppliers Selection in Manufacturing Industries and Associated Multi-Objective Desicion Making Methods Past, Present and The FutureKausikaRaajanNo ratings yet

- Supplier Selection: A Fuzzy-ANP ApproachDocument10 pagesSupplier Selection: A Fuzzy-ANP ApproachAli UlusoyNo ratings yet

- Design of A Gear Grinding Machine and Its CNC System (PDFDrive)Document18 pagesDesign of A Gear Grinding Machine and Its CNC System (PDFDrive)Hạnh LêNo ratings yet

- Chapter One: 1.1background of The StudyDocument31 pagesChapter One: 1.1background of The StudycathyNo ratings yet

- Modeling and Development of A Decision Support System For Supplier Selection in The Process IndustryDocument15 pagesModeling and Development of A Decision Support System For Supplier Selection in The Process IndustryPap AjiNo ratings yet

- Journal - Article - 9OL Apr13esrDocument11 pagesJournal - Article - 9OL Apr13esrAbdirahman_A_OsmanNo ratings yet

- MACHINEDocument9 pagesMACHINEJONAS VIMBANENo ratings yet

- Bài Báo QLTMDocument20 pagesBài Báo QLTMduong.nguyenthuy2406No ratings yet

- A Quantitative Model For The Introduction of RFID in The Fast Moving Consumer Goods Supply ChainDocument35 pagesA Quantitative Model For The Introduction of RFID in The Fast Moving Consumer Goods Supply ChainNasir AliNo ratings yet

- Assignment Help (+1) 346-375-7878Document30 pagesAssignment Help (+1) 346-375-7878Muhammad Sheharyar MohsinNo ratings yet

- 2020-2-May-Scopus-Supplier Selection in A Manufacturing-DOI 10.5373JARDCSV12SP520201784Document9 pages2020-2-May-Scopus-Supplier Selection in A Manufacturing-DOI 10.5373JARDCSV12SP520201784Sakthirama VadiveluNo ratings yet

- Partcipacion 3..Document11 pagesPartcipacion 3..Ivonne CMNo ratings yet

- Sustainability 14 11836 v2Document25 pagesSustainability 14 11836 v2qusinuo19950701No ratings yet

- A Study of Supply Chain Management Performs in Indian MRO Paper Mill ProblemDocument3 pagesA Study of Supply Chain Management Performs in Indian MRO Paper Mill ProblemerpublicationNo ratings yet

- Capacity Planning and Allocation With Multi-Channel DistributionDocument9 pagesCapacity Planning and Allocation With Multi-Channel Distributiondewyekha100% (1)

- Developing The Green Supplier Selection Procedure Based On Analytical Hierarchy Process and Outranking MethodsDocument9 pagesDeveloping The Green Supplier Selection Procedure Based On Analytical Hierarchy Process and Outranking MethodsParastoo AzadNo ratings yet

- A fuzzy-QFD Approach To Supplier Selection: M. Bevilacqua, F.E. Ciarapica, G. GiacchettaDocument14 pagesA fuzzy-QFD Approach To Supplier Selection: M. Bevilacqua, F.E. Ciarapica, G. GiacchettaRenzo ErikssonNo ratings yet

- AHP EvaluationDocument23 pagesAHP EvaluationshivsankzNo ratings yet

- Fuzzy Kano - Vikor Integrated Approach For Supplier Selection - A Case StudyDocument12 pagesFuzzy Kano - Vikor Integrated Approach For Supplier Selection - A Case StudyTJPRC PublicationsNo ratings yet

- Apem5 2 - 075 084 PDFDocument0 pagesApem5 2 - 075 084 PDFrscribdsNo ratings yet

- Ders 2 MakaleDocument9 pagesDers 2 MakaleIREM SEDA YILMAZNo ratings yet

- L.A.R.G. Supplier Selection Based On IntegratingDocument22 pagesL.A.R.G. Supplier Selection Based On IntegratingRossmery Sanchez MendozaNo ratings yet

- Factors Affecting The Selection of Optimal Suppliers in Procurement ManagementDocument5 pagesFactors Affecting The Selection of Optimal Suppliers in Procurement ManagementMarcus Hah Kooi YewNo ratings yet

- 1 s2.0 S1366554522003258 MainDocument23 pages1 s2.0 S1366554522003258 MainAbdallah El NehrawyNo ratings yet

- 1 s2.0 S0957417416303104 MainextDocument14 pages1 s2.0 S0957417416303104 MainextSubash SeshathriNo ratings yet

- An Application of House of Quality in Soft Drink Industry: January 2013Document13 pagesAn Application of House of Quality in Soft Drink Industry: January 2013Monthira IadsenNo ratings yet

- 19-Article Text-104-2-10-20190413Document19 pages19-Article Text-104-2-10-20190413DiptoNo ratings yet

- P 6 Vandor NetworkDocument27 pagesP 6 Vandor NetworkVaibhav GuptaNo ratings yet

- Buyer RelationshipDocument270 pagesBuyer RelationshipceciliawuuNo ratings yet

- Ijet 26753Document7 pagesIjet 26753kevin21790No ratings yet

- Addressing The Operational Challenges inDocument13 pagesAddressing The Operational Challenges inmohammadmehrabi9640No ratings yet

- A Conceptual Framework For Procurement Decision Making Model To Optimize Supplier SelectionDocument5 pagesA Conceptual Framework For Procurement Decision Making Model To Optimize Supplier SelectionNoman ShahNo ratings yet

- Informe Final Inmotion Ingeniería Concurrente EAFITDocument54 pagesInforme Final Inmotion Ingeniería Concurrente EAFITVerónica SánchezNo ratings yet

- Sasitaran (Mrse181032) RMDocument22 pagesSasitaran (Mrse181032) RMSasitaranNo ratings yet

- Rassmusen (2023)Document13 pagesRassmusen (2023)yusufsaputro290896No ratings yet

- Materials of Construction, Operation and Maintenance in The Chemical Process IndustriesDocument37 pagesMaterials of Construction, Operation and Maintenance in The Chemical Process IndustriesNam SanchunNo ratings yet

- Group Decision Making Process For Supplier Selection With VIKOR UnderDocument7 pagesGroup Decision Making Process For Supplier Selection With VIKOR UnderMUHAMAD FAJARNo ratings yet

- MSL Vol2 MSL 2012 98Document26 pagesMSL Vol2 MSL 2012 98rnaganirmitaNo ratings yet

- .Material Selection Criteria For Natural Fibre CompDocument18 pages.Material Selection Criteria For Natural Fibre Compaa23mem6r02No ratings yet

- Supplier Selection in EPC ProjectsDocument11 pagesSupplier Selection in EPC ProjectsMwauraNo ratings yet

- Evolving Trends of Supplier Selection Criteria and MethodsDocument19 pagesEvolving Trends of Supplier Selection Criteria and MethodsSachin NithyanNo ratings yet

- Work Injury Benefits ActsDocument49 pagesWork Injury Benefits ActsjohnNo ratings yet

- Six Sigma in Precast ProductionDocument11 pagesSix Sigma in Precast Productionravi1625100% (1)

- Case Study of Third Party SupplierDocument5 pagesCase Study of Third Party SupplierSAHNo ratings yet

- Resilient and Sustainable Supplier Selection An Integration of SCOR 4 0 and Machine Learning ApproachDocument18 pagesResilient and Sustainable Supplier Selection An Integration of SCOR 4 0 and Machine Learning ApproachAbdallah El NehrawyNo ratings yet

- PGDM 2014-16 IV Supply Chain Management Dr. Parijat Upadhyay Supply Chain Network Decisions OriginalDocument19 pagesPGDM 2014-16 IV Supply Chain Management Dr. Parijat Upadhyay Supply Chain Network Decisions OriginalDebasishChatterjeeNo ratings yet

- Standard Definitions For The Benchmarking of Availability and Utilization of EquipmentDocument14 pagesStandard Definitions For The Benchmarking of Availability and Utilization of EquipmentTyler GoodwinNo ratings yet

- A Study of The MRO Supply Chain For Paper Mills: Final Research ReportDocument51 pagesA Study of The MRO Supply Chain For Paper Mills: Final Research ReportKalpesh Anand ParadkarNo ratings yet

- A Novel Pythagorean Fuzzy AHP and Fuzzy TOPSIS MethodologyDocument13 pagesA Novel Pythagorean Fuzzy AHP and Fuzzy TOPSIS MethodologyLeencaa DambiiNo ratings yet

- Working of Crane in PuneDocument19 pagesWorking of Crane in PuneWilson D AranjoNo ratings yet

- Muhammad Et Al. - 2020 - A Hybrid Multi-Criteria Approach For Evaluation AnDocument22 pagesMuhammad Et Al. - 2020 - A Hybrid Multi-Criteria Approach For Evaluation AnpwunipaNo ratings yet

- CJOM - Sample Paper 2Document13 pagesCJOM - Sample Paper 2clemen_angNo ratings yet

- International Journal of Production ResearchDocument18 pagesInternational Journal of Production ResearchbalakaleesNo ratings yet

- Supplier Selection Method: A Case-Study On A Car Seat Manufacturer in ThailandDocument5 pagesSupplier Selection Method: A Case-Study On A Car Seat Manufacturer in ThailandLess ZamoraNo ratings yet

- 263 AbstractPaperFile 0905104447Document15 pages263 AbstractPaperFile 0905104447ThippawanNo ratings yet

- Supplier Selection Through Analytical Hierarchy Process: A Case Study in Small Scale Manufacturing OrganizationDocument6 pagesSupplier Selection Through Analytical Hierarchy Process: A Case Study in Small Scale Manufacturing OrganizationseventhsensegroupNo ratings yet

- Exercise C7Document14 pagesExercise C7HẠNH PHẠM HIẾUNo ratings yet

- Chapter 1 - Intro To World of Retailing - SVDocument30 pagesChapter 1 - Intro To World of Retailing - SVNHƯ HỒ LỮ QUỲNHNo ratings yet

- 3-N-LSCM Principles and Practices-slide20-BkelDocument1 page3-N-LSCM Principles and Practices-slide20-BkelHẠNH PHẠM HIẾUNo ratings yet

- Strategy Chapter 1n2 - IntroductionDocument57 pagesStrategy Chapter 1n2 - IntroductionHẠNH PHẠM HIẾUNo ratings yet

- 5-N-Strategic LSCM Configuration-BkelDocument16 pages5-N-Strategic LSCM Configuration-BkelHẠNH PHẠM HIẾUNo ratings yet

- 3 N LSCM Principles and Practices BkelDocument18 pages3 N LSCM Principles and Practices BkelVân Anh Nguyễn NgọcNo ratings yet

- Chapter 3 - Locating Facilities Using A Distance-Based Approach (Compatibility Mode)Document5 pagesChapter 3 - Locating Facilities Using A Distance-Based Approach (Compatibility Mode)BẢO ĐẶNG QUỐCNo ratings yet

- Smed AnalysisDocument9 pagesSmed AnalysishajiNo ratings yet

- (FIXED) Chapter 5 Exercise SCD&ADocument6 pages(FIXED) Chapter 5 Exercise SCD&AHẠNH PHẠM HIẾUNo ratings yet

- A New Lean Tool For Efficiency Evaluation in Smed Projects 2yhwxouhDocument16 pagesA New Lean Tool For Efficiency Evaluation in Smed Projects 2yhwxouhHẠNH PHẠM HIẾUNo ratings yet

- BSNL BillDocument3 pagesBSNL BillKaushik GurunathanNo ratings yet

- Collecting, Analyzing, & Feeding Back DiagnosticDocument12 pagesCollecting, Analyzing, & Feeding Back DiagnosticCaroline Mariae TuquibNo ratings yet

- Fortnite Task Courier Pack 1500 V Bucks - BuscarDocument1 pageFortnite Task Courier Pack 1500 V Bucks - Buscariancard321No ratings yet

- Department of Education: Raiseplus Weekly Plan For Blended LearningDocument3 pagesDepartment of Education: Raiseplus Weekly Plan For Blended LearningMARILYN CONSIGNANo ratings yet

- Previews 1633186 PreDocument11 pagesPreviews 1633186 PreDavid MorenoNo ratings yet

- Land CrabDocument8 pagesLand CrabGisela Tuk'uchNo ratings yet

- BAMDocument111 pagesBAMnageswara_mutyalaNo ratings yet

- SY22-23+Annual+Report FinalDocument47 pagesSY22-23+Annual+Report FinalNorus LizaNo ratings yet

- Fce Use of English 1 Teacher S Book PDFDocument2 pagesFce Use of English 1 Teacher S Book PDFOrestis GkaloNo ratings yet

- Advanced Oil Gas Accounting International Petroleum Accounting International Petroleum Operations MSC Postgraduate Diploma Intensive Full TimeDocument70 pagesAdvanced Oil Gas Accounting International Petroleum Accounting International Petroleum Operations MSC Postgraduate Diploma Intensive Full TimeMoheieldeen SamehNo ratings yet

- Pen Pal Lesson Plan 3Document3 pagesPen Pal Lesson Plan 3api-664582820No ratings yet

- Tenses English Grammar PresentationDocument14 pagesTenses English Grammar PresentationMaz Gedi60% (5)

- Caroline Coady: EducationDocument3 pagesCaroline Coady: Educationapi-491896852No ratings yet

- Art Integrated ProjectDocument14 pagesArt Integrated ProjectSreeti GangulyNo ratings yet

- Clinical Skills TrainingDocument12 pagesClinical Skills TrainingSri Wahyuni SahirNo ratings yet

- Aircraft Wiring Degradation StudyDocument275 pagesAircraft Wiring Degradation Study320338No ratings yet

- Economics Exam Technique GuideDocument21 pagesEconomics Exam Technique Guidemalcewan100% (5)

- Kootenay Lake Pennywise April 26, 2016Document48 pagesKootenay Lake Pennywise April 26, 2016Pennywise PublishingNo ratings yet

- Study Notes - Google Project Management Professional CertificateDocument4 pagesStudy Notes - Google Project Management Professional CertificateSWAPNIL100% (1)

- TB 60 Repair Parts PDFDocument282 pagesTB 60 Repair Parts PDFvatasa100% (2)

- Docket - CDB Batu GajahDocument1 pageDocket - CDB Batu Gajahfatin rabiatul adawiyahNo ratings yet

- Microsoft Powerpoint BasicsDocument20 pagesMicrosoft Powerpoint BasicsJonathan LocsinNo ratings yet

- Leather PuppetryDocument8 pagesLeather PuppetryAnushree BhattacharyaNo ratings yet

- QAU TTS Form Annual AssessmentDocument6 pagesQAU TTS Form Annual AssessmentsohaibtarikNo ratings yet

- Intro To MavenDocument18 pagesIntro To MavenDaniel ReckerthNo ratings yet

- Air Blower ManualDocument16 pagesAir Blower ManualshaiknayeemabbasNo ratings yet

- Polyether Polyol Production AssignmentDocument9 pagesPolyether Polyol Production AssignmentanurdiaNo ratings yet

- Cln4u Task Prisons RubricsDocument2 pagesCln4u Task Prisons RubricsJordiBdMNo ratings yet

- Parrot Mk6100 Userguide Zone1Document100 pagesParrot Mk6100 Userguide Zone1Maria MartinNo ratings yet

- BarricadeDocument6 pagesBarricadeJithu PappachanNo ratings yet