Professional Documents

Culture Documents

Erp 5

Uploaded by

Vikas Rajput0 ratings0% found this document useful (0 votes)

2 views5 pagesOriginal Title

erp5

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views5 pagesErp 5

Uploaded by

Vikas RajputCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

SRS Scope Remarks SRS Page no

User Roles Not provided

6 Milk Procurement

Integration of DPMCU and ERP Still Pending

6.4 BMC Milk Procurement

The staff of the truck also delivers the Acknowledgement of

Acknowledgement of previous shift, letters from 66

previous shift not provided

milk union, other materials as indented by the

society and BMC. This is done quickly to avoid

any stoppage of the vehicle more than the schedule

a)Society and tanker sheet Records

The BMC employee maintains the records

regarding milk received, dispatched, stored and

accepted/rejected from each Society during whole

month and also total milk received. This task is not provided 63

performed on daily basis to prevent any mistake.

Along with this the record of tanker’s dispatch

note duplicate copies is also maintained at BMC

side.

c) Approved Indents

Approved indents will be those who are approved Process for approval of

by procurement department. DCS employee will procurement

158

have provision to export/Print the Indent report department/Incharge

based on the requirement. Procurement not provided

Reports as per page no 375-478 not provided

7 Milk Plant Gate Entry

b) Gate out:

After the weighment, vehicle moves to Gate for

Gate out. At Gate, helper with the vehicle submits

the Gate pass to security official in which empty Outward Gate pass not

75

cans are mentioned. The other security official, do provided

the counting of Can again and if there is any miss

match they hold the vehicle inside the milk plant

until clarification is Done

7.7 Attendance Registers

i. Employees IN & OUT Register:

ii. Register of Employment and Remuneration of

Employees: Not provided 88-91

iii. Employee Summary Register

vi. Labour Attendance Register:

v. Security Attendance Register

Reports as per page no 375-478 not provided

8 Quality Control

8.6 Plant Quality Control

8.7 Water testing & Other records

i. Water testing records Not provided 108

MBRT report Not provided 233

Reports as per page no 375-478 not provided

9 Production

Production Department is responsible for

converting raw material and other inputs into

finished products based on the demand raised by

marketing team. The production Unit, works in 3 shifts wise report not

shifts to meet the demand and in these shifts 111

provided

volume of products, Milk (Pasteurized,

standardized, Raw), In-Process products, finished

products, are being monitored with the help of

registers and log books.

vi. Position of Tanks

· Quantity of Milk along with

FAT/SNF not provided 113

FAT/SNF/Temp/Acidity/COB is being mentioned

in this section as respective to tank no.

· Quantity of Milk along with

FAT/SNF not provided 113

FAT/SNF/Temp/Acidity/COB is being mentioned

in this section as respective to silo Number

· Quantity of Milk along with

FAT/SNF not provided 113

FAT/SNF/Temp/Acidity/COB is being mentioned

in this section as respective to Tank Cream no.

not provided 113

9.5 Packing Material Consumption and Log books

9.6 Product Records 113

i. Milk and Milk Product Records 113

Once the production of milk and milk products get

kicked off, the designated team, starts preparing

the Milk and Milk Product Records. These records

day wise consolidated report

contain the data of current balance, in production, 113

not provided

total, issued quantity, issued for packing quantity,

and closing balance for different products with

different packing sizes.

· Can outward Gate pass Report Not provided 186

· Can account Report Not provided 186

Reports as per page no 375-478 not provided

10 Store

10.1 Store types

i. Main Store

i. Outward Gate Pass Generation

ii. Production Store not provided 126

iii. Cattle Feed Store:

Reports as per page no 375-478 not provided

11 Marketing and sales

iii. Vehicle inspection not provided 131

iv. Finished goods stock ledger not provided 131

v. Demand and Supply register not provided 131

11.3 Customer retention

i. Customer complaints record not provided 132

Reports as per page no 375-478 not provided

12 Purchase Department

Process for approval of CEO

135

12.1 Sanction Note not provided

Quotation evaluation not

137

12.3 Quotation: provided

12.4 Purchase Orders not provided 137

Reports as per page no 375-478 not provided

13 Account/Finance

13.1 Milk Bills Generation

In milk billing main reports

i. Truck Sheet Punching

are not available i.e. Bank

ii. Routes

summary, Detail of milk

iii. Societies

billing payment, recovery

iv. Banks

from MPCS, Transporter

v. Processing milk Bills

recovery, Route summary,

Invoices not provided in

13.2 Store Invoices Procurement Store

13.3 Production Invoices/Challans not provided

13.4 Transport Bills not provided

13.5 Sales and Marketing Invoices not provided

13.6 Purchase Invoices not provided

Reports as per page no 375-478 not provided

14Management Information

System (MIS)

14.1 DSO Report

14.2 Milk Situation Report

14.3 Performance Report

14.4 Transportation Report

14.5 Area Wise Report

14.6 BRC Report

14.7 Plant Dock Report

Not provided

14.8 IDIS Report

14.9 Labour Cost Report

14.10 Milk Received & Dispatched Report

Not provided

14.11 MIS Progress Report

14.12 P & I Report

14.13 Plant Data Report

14.15 RKVY Report

AS per Purchase Order

Plant Account

2.4.1

Chilling Center/BMC Not provided

Products (conversion Norms) Not provided

2.4.2

Receipts-Purchase from other Dairies Not provided

Milk/Products stock transfer from other Dairies Not provided

2.4.3

Output-Bulk Sales/Conversion Not provided

2.4.6

MBC/Chilling Center Closing Stock Not provided

2.4.7

Weekly/Monthly CC/BMC Milk Account Not provided

2.5.1

Consumable Opening Balance Not provided

2.5.4

Production Loss(Fat/SNF) Not provided

2.7.2

Issues(Department/CC/BMC/DCS Definition of

Not provided

bill of material/Stock Transfer)

2.7.3

Stock Valuation Report(based on Chosen

Not provided

valuation method FIFO,Average cost)

2.8.5

DCS MBRT Report Not provided

Third party inspection Not provided

2.13.6

Stock Transfer Invoice(including transfers to

Not provided

Depots

SRS Page no

You might also like

- Schaum's Outline of Principles of Accounting I, Fifth EditionFrom EverandSchaum's Outline of Principles of Accounting I, Fifth EditionRating: 5 out of 5 stars5/5 (3)

- Gyratory Crusher Reference List 20170619Document7 pagesGyratory Crusher Reference List 20170619Maruja Abigail Dominguez SalazarNo ratings yet

- Coursebook Chapter 16 AnswersDocument3 pagesCoursebook Chapter 16 AnswersAhmed Zeeshan80% (5)

- 10) Cold Storage Warehouse Manual - 2012 NHBDocument30 pages10) Cold Storage Warehouse Manual - 2012 NHBaedwinNo ratings yet

- Hydrostatic Test Pressure For Flanges PDFDocument2 pagesHydrostatic Test Pressure For Flanges PDFChegg ChemNo ratings yet

- QMS 065 Manufacturing Rework Procedure SampleDocument5 pagesQMS 065 Manufacturing Rework Procedure Sampleevil genius100% (1)

- Econ 122 Week 1-9 by DwexDocument19 pagesEcon 122 Week 1-9 by Dwexjohn100% (3)

- Night AuditDocument16 pagesNight AuditKumarasamy Vijayarajan100% (1)

- Chapter 11: Standard Costs and Variance Analysis: True / FalseDocument31 pagesChapter 11: Standard Costs and Variance Analysis: True / Falsejerome de guzman100% (1)

- Account Opening and Servicing Part 1.odtDocument159 pagesAccount Opening and Servicing Part 1.odtpriyankaNo ratings yet

- OL Accounting P1Document181 pagesOL Accounting P1Luqman KhanNo ratings yet

- ICAEW Accounting QB 2023Document322 pagesICAEW Accounting QB 2023diya p100% (1)

- Chapter 5-The Expenditure Cycle Part I: Purchases and Cash Disbursements Procedures True/False - TDocument8 pagesChapter 5-The Expenditure Cycle Part I: Purchases and Cash Disbursements Procedures True/False - TKwini CBNo ratings yet

- Financial Controls Review Audit ReportDocument16 pagesFinancial Controls Review Audit Reportbob2nkongNo ratings yet

- FI Entries For MTO ScenarioDocument3 pagesFI Entries For MTO ScenarioAchanti Dp100% (1)

- Inventory Report 2021-FinalDocument19 pagesInventory Report 2021-FinalEngr Mohammad Al-AminNo ratings yet

- Super Petchili BondsDocument2 pagesSuper Petchili BondsJP BERNARDINONo ratings yet

- Business Model On Milk Collection Unit by FPODocument17 pagesBusiness Model On Milk Collection Unit by FPOPrabhakara Rao ThanikondaNo ratings yet

- Accounting Question Bank 2022Document334 pagesAccounting Question Bank 2022tafsirmhinNo ratings yet

- Case Studies in Performance Management: A Guide from the ExpertsFrom EverandCase Studies in Performance Management: A Guide from the ExpertsRating: 5 out of 5 stars5/5 (1)

- Assignment 4 - Casestdudies 1 Iso 9001-2015Document2 pagesAssignment 4 - Casestdudies 1 Iso 9001-2015Iena Marlyssa Jaffar33% (3)

- Valuated and Non-Valuated Sale Order Scenarios - Business Process FlowDocument3 pagesValuated and Non-Valuated Sale Order Scenarios - Business Process FlowvrkattulaNo ratings yet

- Erp 1Document4 pagesErp 1Vikas RajputNo ratings yet

- Yogurt Icecream Pasteurised Milk A Beginners Guide ToDocument24 pagesYogurt Icecream Pasteurised Milk A Beginners Guide ToFátima DuarteNo ratings yet

- Procurement of Capital GOodsDocument11 pagesProcurement of Capital GOodsBryant AdhitiaNo ratings yet

- Aa Checklist Processing EstablishmentsDocument34 pagesAa Checklist Processing EstablishmentsAkhila MpNo ratings yet

- (SRM) (0616) SALES RETURN Manual: 1.0 ContextDocument12 pages(SRM) (0616) SALES RETURN Manual: 1.0 ContextroseNo ratings yet

- Procurement of Import MaterialsDocument9 pagesProcurement of Import MaterialsBryant AdhitiaNo ratings yet

- Jan Marie Valencia Kharla Baladjay Recca Anna Laranan Rex Martin GuceDocument46 pagesJan Marie Valencia Kharla Baladjay Recca Anna Laranan Rex Martin GuceElsie AdornaNo ratings yet

- Agenda: We Shall Discuss The Case On DairyDocument10 pagesAgenda: We Shall Discuss The Case On DairyRuchi SharmaNo ratings yet

- Project Report On PDP1Document31 pagesProject Report On PDP1SandhirNo ratings yet

- CAF 8 Volume 2 TOC & SP IT WD LogoDocument549 pagesCAF 8 Volume 2 TOC & SP IT WD LogoZarian NadeemNo ratings yet

- Sapficenvatentries 140726041259 Phpapp01Document5 pagesSapficenvatentries 140726041259 Phpapp01Biranchi MishraNo ratings yet

- Test of Controls': School of Business Studies ACCA F8 - Audit & Assurance P2P Session by SK - Test of Controls (TOC) 1/2Document44 pagesTest of Controls': School of Business Studies ACCA F8 - Audit & Assurance P2P Session by SK - Test of Controls (TOC) 1/2Falguni PurohitNo ratings yet

- Process of 2550M/2550Q and SLSP: Esubmission@bir - Gov.phDocument1 pageProcess of 2550M/2550Q and SLSP: Esubmission@bir - Gov.phavelito bautistaNo ratings yet

- CIN Accounting Entries-SAPDocument7 pagesCIN Accounting Entries-SAPGopal's DestinyNo ratings yet

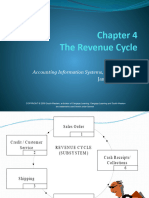

- CH04 - Revenue CycleDocument45 pagesCH04 - Revenue CycleIan Vincent Lazaga MaribaoNo ratings yet

- Auditing and Assurance Services 6th Edition Louwers Test Bank 1Document36 pagesAuditing and Assurance Services 6th Edition Louwers Test Bank 1alyssaschwartzicrtpzjkaf100% (20)

- Chapter 4Document32 pagesChapter 4Pinky RoseNo ratings yet

- Store ProcedureDocument74 pagesStore Procedurevysakhbabu06No ratings yet

- Auditing and Assurance Services 6th Edition Louwers Test Bank 1Document60 pagesAuditing and Assurance Services 6th Edition Louwers Test Bank 1mark100% (28)

- Cow To Consumer With NgrerpDocument22 pagesCow To Consumer With NgrerpMohammad IbrahimNo ratings yet

- Accounts Receivable AS IS Ver1.0Document21 pagesAccounts Receivable AS IS Ver1.0Adventure GroupNo ratings yet

- Sienna Business Scenarios For User Training 1 Sales: 1.1 Masters MaintenanceDocument7 pagesSienna Business Scenarios For User Training 1 Sales: 1.1 Masters MaintenancePadmanabha NarayanNo ratings yet

- Auditing and Assurance Services 6Th Edition Louwers Test Bank Full Chapter PDFDocument67 pagesAuditing and Assurance Services 6Th Edition Louwers Test Bank Full Chapter PDFrickeybrock6oihx100% (13)

- The Delicious Factory Business Requirement Document: Anurag MahajanDocument21 pagesThe Delicious Factory Business Requirement Document: Anurag MahajanBuntyNo ratings yet

- Bank CircularDocument159 pagesBank CircularpriyankaNo ratings yet

- BUGERKING AuditReport 1514263Document12 pagesBUGERKING AuditReport 1514263Khanh Tran ManNo ratings yet

- OptiSuite Forms Tracking - User Manual 710 - 740 v1Document316 pagesOptiSuite Forms Tracking - User Manual 710 - 740 v1sintonaNo ratings yet

- Auditing Theories and Problems Quiz WEEK 1Document19 pagesAuditing Theories and Problems Quiz WEEK 1Sarah GNo ratings yet

- NON INTEGRATED TheoryDocument26 pagesNON INTEGRATED TheorySushant MaskeyNo ratings yet

- The Revenue CycleDocument46 pagesThe Revenue CycleDuaaaaNo ratings yet

- 05 08. Pf441 Rspo PC Public Summary Report Olam Bilala Asa3 ApprovedDocument176 pages05 08. Pf441 Rspo PC Public Summary Report Olam Bilala Asa3 ApprovedJ-Show TVNo ratings yet

- AUDIT II CH-3 EDITED Receivable & SalesDocument24 pagesAUDIT II CH-3 EDITED Receivable & SalesQabsoo FiniinsaaNo ratings yet

- 8 NAW To Be - Customer Invoice Credit MemoDocument10 pages8 NAW To Be - Customer Invoice Credit MemosivasivasapNo ratings yet

- Procurement of Excisable-Non Excisable Jobwork MaterialsDocument9 pagesProcurement of Excisable-Non Excisable Jobwork MaterialsBryant AdhitiaNo ratings yet

- Chimanpal SarasDocument31 pagesChimanpal SarasKRISHNMURARINo ratings yet

- Auditing and Assurance Services 6th Edition Louwers Solutions Manual 1Document36 pagesAuditing and Assurance Services 6th Edition Louwers Solutions Manual 1alyssaschwartzicrtpzjkaf100% (24)

- Dokumen - Tips Meyers Pharmaceutical CompanyDocument7 pagesDokumen - Tips Meyers Pharmaceutical CompanySaktyHandarbeniNo ratings yet

- Implementation Guide - Guest First - HOSPITALITY.EnglishDocument37 pagesImplementation Guide - Guest First - HOSPITALITY.EnglishAung Par SayNo ratings yet

- Erwin-Ogena BSAIS2A AIS Exercise-1Document6 pagesErwin-Ogena BSAIS2A AIS Exercise-1Erwin OgenaNo ratings yet

- Adv ICo Stock Transfer Restrictions 2022 OPDocument8 pagesAdv ICo Stock Transfer Restrictions 2022 OPKiran JadhavNo ratings yet

- ConsignmentDocument6 pagesConsignmentarvindNo ratings yet

- Flowchart RevenueDocument45 pagesFlowchart RevenueRezki PerdanaNo ratings yet

- Scop of Work ErpDocument15 pagesScop of Work ErpVikas RajputNo ratings yet

- Inventory Strategy: Maximizing Financial, Service and Operations Performance with Inventory StrategyFrom EverandInventory Strategy: Maximizing Financial, Service and Operations Performance with Inventory StrategyRating: 5 out of 5 stars5/5 (1)

- Goodwill ImpairementDocument6 pagesGoodwill ImpairementHassanNo ratings yet

- Nmat Quantitative Simulations (Mock 2) Section 1. Fundamental OperationsDocument2 pagesNmat Quantitative Simulations (Mock 2) Section 1. Fundamental OperationsRACKELLE ANDREA SERRANONo ratings yet

- Footplate Inspection Conducted By: Divisional Telecom Engineer Sukkur, at Roh-Kpr Section On.15.12.2020Document3 pagesFootplate Inspection Conducted By: Divisional Telecom Engineer Sukkur, at Roh-Kpr Section On.15.12.2020Ahmed NoumanNo ratings yet

- Rolando Pacana vs. Atty. Maricel Pascual-Lopez-Case DigestDocument2 pagesRolando Pacana vs. Atty. Maricel Pascual-Lopez-Case Digestrejine mondragonNo ratings yet

- Financial Analyst or Senior Economist or Senior Risk AnalystDocument3 pagesFinancial Analyst or Senior Economist or Senior Risk Analystapi-77399063No ratings yet

- Unitile Raised Access FlooringDocument23 pagesUnitile Raised Access Flooringsaloni patilNo ratings yet

- Ap 2Document8 pagesAp 2Louiejane LapinigNo ratings yet

- ENT300 BUSINESS PLAN Latest - Doc (Ref)Document61 pagesENT300 BUSINESS PLAN Latest - Doc (Ref)Nor HakimNo ratings yet

- 02 TISAX Participant Price ListDocument2 pages02 TISAX Participant Price ListKolhapur ANANo ratings yet

- Acc Statement 1120566636663 2023-10-01 2023-10-31 20231215111413Document1 pageAcc Statement 1120566636663 2023-10-01 2023-10-31 20231215111413Agung MaharNo ratings yet

- So N Unit 9Document8 pagesSo N Unit 9Lam TrúcNo ratings yet

- An Experimental Investigation in Paver Blocks by Replacing Sand With Manufacturing Sand and Its Strength ComparisonDocument13 pagesAn Experimental Investigation in Paver Blocks by Replacing Sand With Manufacturing Sand and Its Strength ComparisonPratik WANKHEDENo ratings yet

- Chapter 3 Overheads: Joudat Ali Malik ACMA, APFA, MA (Economics), CFC (Canada)Document8 pagesChapter 3 Overheads: Joudat Ali Malik ACMA, APFA, MA (Economics), CFC (Canada)sarahNo ratings yet

- Regional Integration in Africa PDFDocument6 pagesRegional Integration in Africa PDFSean JoshuaNo ratings yet

- Stage 2 BOQDocument19 pagesStage 2 BOQFadi DeebNo ratings yet

- Child Labour Within The Framework of Economic Development in CameroonDocument18 pagesChild Labour Within The Framework of Economic Development in CameroonMbua NyanshiNo ratings yet

- Export/Import Data For 10 Years Along With Analysis of Export TrendDocument73 pagesExport/Import Data For 10 Years Along With Analysis of Export TrendHarshvardhan PatraNo ratings yet

- Large bore size Filter Specifications・How to order・Dimensions (0.6MB)Document12 pagesLarge bore size Filter Specifications・How to order・Dimensions (0.6MB)Adrian SetyadharmaNo ratings yet

- Edev 311: Economic Development: Session 1: Economics & Its NatureDocument13 pagesEdev 311: Economic Development: Session 1: Economics & Its NatureCarlNo ratings yet

- Oleh:: Jutawan Dua LogamDocument42 pagesOleh:: Jutawan Dua LogamMustaffa Bin HashimNo ratings yet

- Eco 301Document7 pagesEco 301nhidiepnguyet08112004No ratings yet

- Tugas Review Tri Widodo Protection in ManufacturingDocument18 pagesTugas Review Tri Widodo Protection in ManufacturingAlya RANo ratings yet

- Far Notes - Accounting Cycle of Merchandising BusinessDocument15 pagesFar Notes - Accounting Cycle of Merchandising BusinessVan MateoNo ratings yet

- Al Brooks Advanced CourseDocument5 pagesAl Brooks Advanced CourseAlaa AhbaliNo ratings yet