Professional Documents

Culture Documents

Filtration Techniquein

Uploaded by

yousefatwa7Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filtration Techniquein

Uploaded by

yousefatwa7Copyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/235706947

Filtration

Article · January 2008

CITATIONS READS

0 8,068

5 authors, including:

Selvaraj Jagannathan Shivanandappa.KC kukkaler channappa

41 PUBLICATIONS 143 CITATIONS 10 PUBLICATIONS 20 CITATIONS

SEE PROFILE SEE PROFILE

Bheeman Sundaran Kavaratty Raju Mani

Pasteur Institute of India and Central Research Instituter, Kasauli

6 PUBLICATIONS 29 CITATIONS

35 PUBLICATIONS 3,226 CITATIONS

SEE PROFILE

SEE PROFILE

All content following this page was uploaded by Selvaraj Jagannathan on 22 May 2014.

The user has requested enhancement of the downloaded file.

Tools & Techniques

Filtration Technique in

Vaccine Manufacturing

S.Jagan Nathan1*,K.C.Shivanandappa2 B.Sundran3 ,K.N.Venkataramana4 ,K.R.Mani5

Abstract entire process against contamination. flows are directed across the membrane

Membrane technology is critically reviewed surface. This sweeping action helps to keep

The Pharmaceutical products must conform in international pharmacopeias, with a the retained material from settling on the

to well defined quality standards. Vaccines concentration on sterilizing grade filters. In membrane surface and thus will help the

play a vital role in humanity, vaccines the vaccine production the process namely membrane to perform effectively for long

safeguard the children from life threatening filtration is an important manufacturing periods. They are so-called depth filters

diseases and in vaccine production and process and this article deals with various whose effectiveness is influenced by the

filtration is one of the most imperative steps. filtration technologies. whole complex of the following

The various filtrations like microfiltration,

ultrafiltration, membrane chromatography,

crossflow filtration are important play an

important role during the production of

immunobiologicals. All the filtration

techniques in same principle and they are

differentiated from their principle only. The

techniques of filtration are same for bacterial

and viral vaccines. In the complex of

manufacturing environment of vaccines for

fulfilling all necessary processing

requirements under validation control and

good manufacturing practices.

Keywords: Vaccine, Microfiltration,

Crossflow filtration and hollow fiber. Figure 1-A General flow diagram of a purification train in the

vaccine process (Paul K Ng. et. al)

Introduction

characteristics: mechanical retention of

Vaccines play the vital role for humanity as

Filtration

particles, absorbability, pH values, surface

their use safeguard the children from life Filtration is a process for separating two quality, thickness and strength of the filter

threatening diseases like tuberculosis, polio, substances of two different physical states. It paper and the shape, density and quantity of

whooping cough, tetanus, encephalopathy, is used for separating solids from turbid particles to be filtered.

yellow fever, measles etc. The national liquids (filtrate), pure gases or solids.

governments are responsible for Microfiltration

Filtration is classified in two ways based on

immunization and they are adhering with the principle of operation as follows (Fig2). Micro filtration is defined as the process of

WHO immunization project, and their removing contaminants in the 0.25 to 10µm

guidance. The UNICEF plays an important 1. Dead end filtration

range of particles present in the process fluids,

role in this regard. The Pharmaceutical 2. Tangential Flow Filtration by passage through a microporous medium,

products must conform to well defined quality such as membrane filter. Although micron

standards. The production of infusion and In the Dead end filtration, all the flows are

sized particles can be removed by use of non-

injectable solutions, or those which come in directed through the membrane with material

membrane or depth filters, particles found in

contact with open wounds, are regulated by building up on the surface of filter. As these

fibrous media can be removed only by the

such standards. Quality results can only be particles build up, flow through the filter is

membrane or screen filters having a precisely

achieved by effectively safe guarding an quickly reduced and finally it ceases

defined pore size. The retention boundary

completely. In tangential flow filtration, the

37 | Advanced Biotech | August 2008

Tools & Techniques

membrane process used to concentrate,

separate or purify macromolecules. The

separation is based on molecular weight of the

macromolecule. The membrane is a thin semi-

permeable polymeric material that will retain

macromolecules and allow smaller dissolved

solutes to pass through the membrane. The

Table 3 shows the various companies dealing

with the hollow fiber technology. The

retentive abilities of UF membranes are

described by the nominal weight limit

(NMWL). UF membranes for spiral

ultrafiltration cartridge are available in the

NMWL ranges of 1000 to 3, 00,000. These

filtration techniques are applied in

concentration of virus and bacteria. Before

concentration process the input materials are

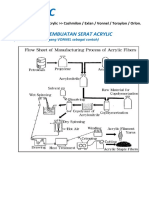

Figure -2 Schematic diagrams for (a) dead-end or conventional

inactivated/detoxified by the chemical

filtration and (b) cross-flow filtration (R.G.Harrision et al)

method and it should have passed the in-

process quality control test. During this

which a membrane filter defines can also be increase until the accumulation of retained

process the desired proteins and their allied

used as an analytical tool to validate the molecules form a concentrated, dense gel

products are separated by their molecular

integrity and efficiency of a system. These layer. The gel layer becomes the limiting

weight, and the volume is reduced thereby

filtration techniques are applied in factor to filtrate flow rate and further pressure

increasing the purity considerably compared

clarification of viral harvest as well as the increases will have little to no effect. This type

to the starting volume.

bacterial cell mass those are produced by the of filtration is referred to as gel limited ultra

fermentation techniques or the roller bottle filtration which is a pressure driven

culture. During this process the desired

proteins and products are separated from the

media components which are a part of

cultivation.

Ultrafiltration (UF)

Ultrafiltration is a technique for separating

dissolved molecules in solution on the basis of

size rating the particles will be retained at the

surface of the membrane and not in the

polymer matrix as they are in micro porous

membranes (Fig 3). The accumulation of

retained molecules may form a concentrated

gel layer which can significantly alter the

performance characteristics of the membrane.

This phenomenon is commonly referred to as

concentration polarization. Understanding

the effects of concentration polarization and

the operating conditions that can minimize

this phenomenon will lead to optimal flux and

retention properties in separation process. As

the gel layer gets formed the filtrate flow rate

is controlled by the permeability of the

membrane and the applied pressure, this

condition is said to be membrane controlled.

As the pressure is increased, the filtrate flow Figure - 3 Schematic representations of filter modules (a) Hollow fiber, plate,

rate and concentration of retained molecules and spiral-wound membrane modules (b) A rotating cylinder module (Zeman et. al)

38 | Advanced Biotech | August 2008

Tools & Techniques

Table 3 Comparison of various systems from different Nanofiltration

manufacturers Removal of virus and virus like particles from

Feature Crossflow Tubular Hollow-fiber Plate and Spiral the mammalian cell culture by this method is

cassettes Modules Modules frame wound mainly on the basis of size difference between

system Modules proteins and viruses. It was an advantage over

Hold up volume Low High Average High Average chemical treatment (Horowitz, and

Energy Highsmith). For reducing the virus load in

consumption Low High High High Average biological products since it does not entail the

Easy to cleaning Excellent Good Average Poor Average use of toxic reagents that subsequently have to

Pressure be eliminated from the proteins. The

Resistance Excellent Excellent Average Good Good procedure also ensures the least disturbance to

Steaming-in- Yes Depends Depends Not for No the therapeutically active protein

place on the on the ultrafiltra- composition. It makes use of tangential flow

material configuration tion across a nanofilter with nominal cutoff values

Scalability Excellent Poor Poor Poor Poor of 70 and 160 KDa and15 to 75 nm (Dileo).

Membrane Chromatography

Tangential Flow Filtration process used to concentrate separate or purify Membrane chromatography for protein

macromolecules. Membrane selection for purification is a recent technology that has

The cross flow technology is commonly used

Crossflow filtration is determined by the been used successfully in a wide range of

during the downstream processing of

properties of the target molecule and the aim applications with a variety of membrane

proteins. Various applications such as product

of the step. Cross flow filtration modules are geometrics and interaction modes (Zeng

clarification and concentration are best

available from manufacturers for carrying out et.al).For this particular application, the

achieved by the use of cross flow filtration.

laboratory or pilot plant test. The apparent advantages of membrane absorbers

For many products cross flow technology is

determination of the size of a plant unit can be at this stage of development are still rather

often the last processing step prior to final

done by a direct scaleup of the filtration area qualitative. The Sartorius S15 membrane

formulation for heat labile products. There are

based on the feed or output flow rate. For this absorbers were determined to be an

two types of filtration in separation. Normal

scale up, however, it is important that the alternative to conventional adsorption column

Flow filtration (NFF) and Tangential Flow

following variables be kept constant chromatography for the isolation of

Filtration (TFF). In normal filtration all flows

(Dater et al). recombinant immunofusion protein. The

is directed to the membranes with retained

material building up on the surface of the l Inlet and outlet pressures membrane in chromatography is having

filter. As these particles build up, the flow advantages like short set up time, low-

l Crossflow (or tangential )velocity pressure operability, high capacity and high

through the filter is slowly reduced until it

ceases completely. In tangential Flow l Flow channel sizes (height and width) volumetric velocity capabilities. These

Filtration, flows are directed across the features are likely to be transferable to the

l Feed stream properties test slurries isolation of other proteins by ion exchange.

membrane surface. The sweeping action of

should be representative of the actual Significant time savings result from the quick

the fluid restricts retained material from

process streams. setup, which amounts to connecting tubing

settling and eventually reduction flow. Some

of the key characteristics are detailed in the and loading a peristaltic pump head, and the

l Membrane type and configuration-test

Table 4 of the cross flow modules. Tangential high volumetric throughput of these

data from one design directly be used to

Flow Filtration is a pressure driven membrane membranes. It requires sufficient chemical

design another geometry.

and thermal stability for repeated sanitization,

of course, a critical requirement for

Table 4 Comparision of key characteristics of Crossflow economical scaleup in the biopharmaceutical

modules (Zeman et al) industry. These techniques are applied in the

final process and it plays a major role in the

Module type Channel Packing Energy Particulate Ease of

purity. The major impurities like residual

spacing density costs Plugging Cleaning

(cm) (m2/ m3) cellular DNA and bacterial endotoxins are

filtered.

Hollow fibre 0.02-0.25 1200 Low High Fair

Tubular 1.0-2.5 60 High Low Excellent High-Performance Tangential-Flow

Flat plate 0.03-0.25 300 Moderate Moderate Good Filtration (HPTFF)

Spiral wound 0.03-0.1 600 Low Very high Poor-fair High-performance tangential flow filtration

Rotating 0.05-0.1 10 Very high Moderate Fair (HPTFF) is a new membrane technology that

39 | Advanced Biotech | August 2008

Tools & Techniques

Table 1 Various product purification's features containing very small pores next to the

processed by the technique of HPTFF filtering surface. However, the thin and thick

layers of such membranes are made up of two

Product (mw) Impurity (mw) Purification Yield(%) Reference

Factor

different types of material.

BSA(68,000) Fab(45,000) 990 94 Van Reis et al 1 Filtration membranes are made from wide

Fab (45,000) BSA (68,000) 830 69 Van Reis et al 1 variety of polymers and inorganic materials.

The polymers that are used include cellulose

BSA (68,000) Hb (67,000) 100 68 Van Eijndhoven

et.al acetate, polyamide, polyether, polycarbonate,

polyester, polyethylene, regenerated

IgG (155,000) BSA (69,000) 30 84 Van Reis et al

cellulose, poly vinyl chloride, poly vinylidene

BSA (68,000) BSA dimer fluoride, PVDF, poly tetra fluoro ethylene

(136,000) 9 86 Van Reis et al

(PTFE), acrylnitrile copolymers, and

polysulfone. The inorganic materials used

include ceramics, zirconium oxide,

Table 2 Comparison of the various separation methods borosilicate glass, stainless steel, and silver.

Traits Cross flow Centrifugation Sedimentation Precipitation

Cellulose Acetate and Triacetate

Yield High Average Low Average

Membrane

Energy consumption Low High Low Low

Scalability Excellent Average Not merely Not merely The cellulose triacetate membrane is a

membrane polymer that is well established in

Time required Little Average Considerable Considerable

the biotechnological and pharmaceutical

Service costs Low High Low High industries. It is extremely hydrophilic;

Degree of purity High Average Low Low virtually non-protein binding (Fig 4).These

features make cellulose triacetate membranes

can be used for the separation of protein asymmetric structure, there is a thin layer next ideally suited for biotechnological

mixtures without limit to their relative size to the filtering surface that has very small applications. It shows minimal adsorption of

(Van Reis et al) HPTFF could potentially be pores. Below this thin layer is a much thicker protein, viruses etc. and also its retention is

used throughout the downstream purification layer that has much larger pores and serves as unaffected by repeated re-use. They are

process to remove specific impurities (e.g., structural support for the membrane. The commercially available in a choice of the

proteins, DNA or endotoxin), clear virus and composite membrane is similar to the following nominal molecular weight cutoffs

eliminate protein oligomers or degradation asymmetric membrane in having a thin layer like 5K, 10K and 20K. They are characterized

products. HPTFF can also be used for the as least protein binding.

purification of natural protein products from

whey. HPTFF is unique among available

separation technologies in that it can affect

simultaneous purification, concentration and

buffer exchange, allowing several different

separation steps to be combined into a single

scalable unit operation. Although HPTFFis

still an emerging technology, a number of

recent studies have clearly demonstrated the

potential of this separation technology. The

results of several such applications are

summarized in Table-1.

Membranes

Three basic structures are commonly used for

membranes: homogeneous, asymmetric and

composite. The homogeneous structure has

no significant variation in pore diameter from

the filtering surface to the other side. In the Figure - 4 Cellulose acetate membrane. Electron micrograph

(1.00 kx, 15 kv 219) (Millipore)

40 | Advanced Biotech | August 2008

Tools & Techniques

POLYTETRFLUOROETHYLENE (PTFE) These biological structures derived mainly R.G.Harrision Paul Toda, Scott R Rudge, and

It is also called as TEFLON, it is a synthetic from the outer membranes of gram-negative Demetris P. Petrider, Bioseperaions Science

fluropolymer and it's melting point is 327oC bacteria are composed of complex and Engineering, New York, Oxford

but its properties degrade above 260 oC (50oC lipopolysaccharides which may cause University Press, 2003: 104-106.

F (7) membrane are stable in the pH range in nonspecific, generally weak toxic reactions

VanReis R,Gadam S, Frautschy LN, Orlando

between 2 to14, it also steam sterilizable. such as fever, redness or swelling at the

S, Goodrich EM Saksena S, Kuriyel R,

Polypropylene-reinforced membranes with injection site. But when contained in larger

simpson CM, Pearl S, Zydney AL. 1997 High

pore size 0, 2µm. amounts in pharmaceutical preparations, the

performance tangential flow filtration.

reaction may be severe. Their elimination

POLY ETHER SULFON (PES) It is Biotechnol Bioeng.56: 71-82.

from biological products, which are derived

hydrophilic and constructed from pure

from the cultivation of bacteria, through Van Reis R, Brske JM, Chsrkoudisn J, burns

polyether sulfon polymer membrane. And it is

appropriate purification procedures DB, Zydney AL. 1997 High performance

low protein and drug binding characteristics.

represents a major task of the manufacturing tangential flow filtration using charges

It also wide range of pore sizes and higher

process. This task is rendered even more membranes. J.Membr Sci 159:133-42.

wick rates with lateral flows, lot to lot

difficult as this endotoxin is chemically and

consistency. are steam sterilizable, their pH Van Eijndhoven HCM, seksena S, Zydney

thermally very stable.

are stable in between 2-14. AL. 1995 Protein fractionation using

membrane filtration: role of electrostatic

POLY VINYL CHLORIDE (PVC) It is Reference

interactions. Biotechnol Bioeng 48: 406-14.

hydrophilic and constructed from pure

Harrision R,Todd P,Rudge SR,Petrides DP, Wang WK, 2001,Membrane separations in

polyester having low protein binding

2003 Bioseparation science and engineering, biotechnology, Marcel Dekker Inc, New

capacity, and stable pH range between 2-14, it

Oxford University Press. New York. York.

is steam sterilizable, has a long life and high

flux rate and is easy to re-cycle. Highsmith F,Xue H,Che L,Bende L, Owens J, Zeng X,Ruckenstein E, 1999 Membrane

Shanbron, Drohan W 1995 Iodine mediated chromatography: preparation and application

Discussion inactivation of lipid and nonlipid enveloped to protein seperation. Biotechnlo. Prog

viruses in human antithrombin III concentrate 15:1003-19.

Largescale industrial downstream process of

Blood: 86:791-96.

biotechnological products has utilized Zeman, L J,and Zydney A L 1996.

ultrafiltration/diafiltration process since the Horowitz B, Wiebe ME, lippin A, Strykar MH Microfiltration and Ultrafiltration, Dekker,

mid 1970s, when conventional separation 1985 .Inactivation of viruses in labile blood New York.

techniques, such as salt precipitation, derivetis. I Disruption of lipid-enveloped

centrifugation, evaporation, lyophilization, viruses by tri(n-butyl)phosphate detergent

and membrane dialysis were combinations. Transfusion 25: 516-22.

supplemented/replaced with alternative

www 2.dupont.com/Teflon_industrial/ Author For Correspondence

industrial-grade ultrafiltration membranes.

en_us/tech_onfo/techinfo_compare.html.

Two primary objectives have been addressed:

concentration of biological products from DiLeo AJ,Allegrezza AE, Jr.Builder SE. 1992 S. Jagan Nathan

dilute solutions (ultrafiltration), and removal High resolution removal of virus from Assistant Research Officer,

of small molecules via constant-volume protein solutions using the membrane of

Pasteur Institute of India,

buffer exchange (diafiltration). The unique structure. Biotechnology 10:182-88.

Coonoor, The Nilgiris, TamilNadu.

availability of membranes in the NMWL of

Dater, R V and Rosen, C.-G 1993. Cell and Email: seljag2005@yahoo.com,

500 to 1,000,000 Daltons (Da) and

cell debris removal: Centrifugation and

manufactured with a wide range of polymers Mobile: 94860 81990

Crossflow filtration. In Biotechnology, vol 3.

provide a reasonable degree of choice to the

Bioprocessing H-J Rehm and G. Reed

p r o c e s s e n g i n e e r. I n d u s t r i a l g r a d e

eds.VCH publishers, Weinheim, p-486.

ultrafiltration membranes are agreeable to

cleaning in place for reuse and the process of Paul K ng,Alfred C,Dadson Jr,G.Micheal

which is extensively validated. conneww and Bernard P Brutisk. Bayer

corporation California, Filter applications in

Validation of the elimination of

p r o d u c t r e c o v e r y, f r o m M e m b r a n e

endotoxin separations in Biotechnology, Edited by

Endotoxin represents a major potential William K. Wang. New york Mercel Dekker

contaminant in pharmaceutical products. inc.2001: 215-216.

41 | Advanced Biotech | August 2008

View publication stats

You might also like

- Lactation Risk CategoriesDocument9 pagesLactation Risk CategoriesHandre PutraNo ratings yet

- Assignment On Installation Qualification and Operational Qualification of Membrane FilterDocument27 pagesAssignment On Installation Qualification and Operational Qualification of Membrane FilterVenkat Kumar50% (2)

- 35 Spotting and Stain Removal TechniquesDocument38 pages35 Spotting and Stain Removal TechniquesApar Singh100% (9)

- Routsis Injection Molding ReferenceDocument94 pagesRoutsis Injection Molding ReferenceFer Gos100% (1)

- Filtration TechniqueinDocument6 pagesFiltration TechniqueinOmkar DakeNo ratings yet

- Broch Microbiological Testing SM-4017-e PDFDocument36 pagesBroch Microbiological Testing SM-4017-e PDFEuseNo ratings yet

- Brochure Microbiological Nps - 2008Document28 pagesBrochure Microbiological Nps - 2008sorsoleyNo ratings yet

- Contoh Sterilefiltration Pada Viral Vaccine Live AtenuatedDocument10 pagesContoh Sterilefiltration Pada Viral Vaccine Live Atenuatedkomang inggasNo ratings yet

- Official: Á1229.4Ñ Sterilizing Filtration of LiquidsDocument7 pagesOfficial: Á1229.4Ñ Sterilizing Filtration of LiquidsLarissa GolucciNo ratings yet

- Microencapsulation Techniques, Factors in Uencing Encapsulation EfficiencyDocument12 pagesMicroencapsulation Techniques, Factors in Uencing Encapsulation EfficiencyHely PatelNo ratings yet

- Chapter 10Document59 pagesChapter 10MADHUMITHRA KUGANESANNo ratings yet

- Usp-Nf (1229.4) Sterilizing Filtration of LiquidsDocument7 pagesUsp-Nf (1229.4) Sterilizing Filtration of Liquidsainun endarwatiNo ratings yet

- Membrane FiltrationDocument6 pagesMembrane FiltrationAbdulkadir AlbabaNo ratings yet

- Cata Microbiological Control SL-1530amDocument120 pagesCata Microbiological Control SL-1530amsinarar1No ratings yet

- Usp 1229.4Document11 pagesUsp 1229.4Rangga120890No ratings yet

- 〈1229.17〉 MYCOPLASMA STERILIZATIONDocument1 page〈1229.17〉 MYCOPLASMA STERILIZATIONgrace_febiantyNo ratings yet

- Products For Microbiological ControlDocument120 pagesProducts For Microbiological ControlTim Sandle100% (2)

- JPSR 08051605Document8 pagesJPSR 08051605WaleedNo ratings yet

- Filteration 1Document7 pagesFilteration 1api-3739176100% (1)

- Membrane Filtration Method, Types, Advantages, Disadvantages, Applications.Document27 pagesMembrane Filtration Method, Types, Advantages, Disadvantages, Applications.Muhammed SabdatNo ratings yet

- Processing and Preservation by Membrane TechnologyDocument70 pagesProcessing and Preservation by Membrane TechnologyShivani MunishwarNo ratings yet

- A Single Step Assembly of Uniform Microparticles For Controlled Release ApplicationsDocument8 pagesA Single Step Assembly of Uniform Microparticles For Controlled Release ApplicationsLuangenNo ratings yet

- Bacteria Cell Separartion From Blood SamplesDocument7 pagesBacteria Cell Separartion From Blood SamplesShlok MishraNo ratings yet

- 6 PBDocument10 pages6 PBFauzi AlifkaNo ratings yet

- Jurnal 14 - SkripsiDocument5 pagesJurnal 14 - SkripsiBagusSatriyaNo ratings yet

- SLN DiklofenakDocument10 pagesSLN DiklofenakFebrina IchaNo ratings yet

- Membrane Cleaning ReviewDocument11 pagesMembrane Cleaning ReviewAmit Kr GodaraNo ratings yet

- BandagesDocument10 pagesBandagesAkanksha DasNo ratings yet

- Diseño y Construcción de Una Estación de Ultrafiltración para Separación de ProteínasDocument8 pagesDiseño y Construcción de Una Estación de Ultrafiltración para Separación de ProteínasAura UrregoNo ratings yet

- E DAR Filter CatalogDocument38 pagesE DAR Filter CatalogJittiya WatcharotayangulNo ratings yet

- AmericanPharmaReview-Meltzer APR2003Document6 pagesAmericanPharmaReview-Meltzer APR2003الباشمهندس مشروع دكتورNo ratings yet

- Mata Kuliah Teknologi Bioproses Pangan Dan Hasil Pertanian: Mekanisme Filtrasi Untuk SterilisasiDocument5 pagesMata Kuliah Teknologi Bioproses Pangan Dan Hasil Pertanian: Mekanisme Filtrasi Untuk SterilisasiBrilyanNo ratings yet

- Filtration: Sarvajanik College of Engineering & Technology SuratDocument20 pagesFiltration: Sarvajanik College of Engineering & Technology SuratNautam ParasanaNo ratings yet

- Uses and Applications of Centrifugation, Radiation and SedimentationDocument3 pagesUses and Applications of Centrifugation, Radiation and SedimentationVanjared OcampoNo ratings yet

- Sensors 19 05311 PDFDocument56 pagesSensors 19 05311 PDFAvunAvin ROCKSTARNo ratings yet

- Roy 2015Document12 pagesRoy 2015smartlearning1001No ratings yet

- Techniques in Measuring Microbial GrowthDocument7 pagesTechniques in Measuring Microbial GrowthSantos, Kimberly R.No ratings yet

- Membrane Filtration: Daniel J. Brose, Michael Dosmar, and Maik W. JornitzDocument2 pagesMembrane Filtration: Daniel J. Brose, Michael Dosmar, and Maik W. JornitzAura UrregoNo ratings yet

- Buccal Film Drug Delivery Systeman Innovative and Emerging Technology 2329 9053.1000107Document6 pagesBuccal Film Drug Delivery Systeman Innovative and Emerging Technology 2329 9053.1000107DrAtiq Ur-RahmanNo ratings yet

- Microencapsulation BasicsDocument7 pagesMicroencapsulation BasicsbipabNo ratings yet

- A Review On Downstream Processing of Monoclonal Antibodies (MAbs)Document13 pagesA Review On Downstream Processing of Monoclonal Antibodies (MAbs)IJRASETPublicationsNo ratings yet

- John PaulDocument12 pagesJohn PaulFajar Dwi YudantoNo ratings yet

- Food and Industrial MicrobiologyDocument29 pagesFood and Industrial MicrobiologyAishwarya KashyapNo ratings yet

- Downstream Bioprocess Development of P. Kudriavzevii: Experiment TitleDocument6 pagesDownstream Bioprocess Development of P. Kudriavzevii: Experiment TitleGamze HatlarNo ratings yet

- Membrane Separation ProcessesDocument38 pagesMembrane Separation ProcessesAbdul AzizNo ratings yet

- Review On Micro-Encapsulation With Chitosan For Pharmaceuticals ApplicationsDocument8 pagesReview On Micro-Encapsulation With Chitosan For Pharmaceuticals ApplicationsHASSANI ABDELKADERNo ratings yet

- A Review On Microspheres Types, Method of Preparation, Characterization and ApplicationDocument7 pagesA Review On Microspheres Types, Method of Preparation, Characterization and ApplicationEditor IJTSRDNo ratings yet

- MicroencapsulationDocument10 pagesMicroencapsulationprinceamitNo ratings yet

- Froh 03 838043Document13 pagesFroh 03 838043Edmilson MachadoNo ratings yet

- Viability Testof Lemongrass Extract (Cymbopogon Citratus) On BHK-21 Fibroblast Cell CultureDocument5 pagesViability Testof Lemongrass Extract (Cymbopogon Citratus) On BHK-21 Fibroblast Cell CultureLouis HutahaeanNo ratings yet

- Out PDFDocument6 pagesOut PDFDafne CarolinaNo ratings yet

- Chitosan Nanoparticles: A Promising System For Drug DeliveryDocument17 pagesChitosan Nanoparticles: A Promising System For Drug DeliveryUMY HABIBANo ratings yet

- 5th PaperDocument10 pages5th PaperAmol RastogiNo ratings yet

- Insilico Study of Curcumin NPDocument20 pagesInsilico Study of Curcumin NPSathish SizzyNo ratings yet

- Review On Novel Drug Delivery System of Microsphere Type, Material, Method of Preparation and EvaluationDocument7 pagesReview On Novel Drug Delivery System of Microsphere Type, Material, Method of Preparation and EvaluationEditor IJTSRDNo ratings yet

- 577 704 1 PB PDFDocument9 pages577 704 1 PB PDFRianaNo ratings yet

- Advanced Flow Cell Design For in Vitro Release Testing of Mucoadhesive Buccal FilmsDocument13 pagesAdvanced Flow Cell Design For in Vitro Release Testing of Mucoadhesive Buccal FilmsFilip MartinovićNo ratings yet

- Methods of Bacterial Isolation and Culture and Preservation Microbial Isolation Techniques NotesDocument4 pagesMethods of Bacterial Isolation and Culture and Preservation Microbial Isolation Techniques Notesmervyn balbuenaNo ratings yet

- Comparison of Three Different Methods of Tissue Processing: Journal of Oral and Maxillofacial Pathology January 2007Document4 pagesComparison of Three Different Methods of Tissue Processing: Journal of Oral and Maxillofacial Pathology January 2007Ogut AjaNo ratings yet

- Mrii 2Document11 pagesMrii 2a.mahdieh90No ratings yet

- Formulation and Evaluation of Floating Microspheres of Metformin HydrochlorideDocument10 pagesFormulation and Evaluation of Floating Microspheres of Metformin HydrochlorideBaru Chandrasekhar RaoNo ratings yet

- A Rapid Filtration Method For Harvesting Cell Cultture Grown in Cellbag Bio ReactorsDocument4 pagesA Rapid Filtration Method For Harvesting Cell Cultture Grown in Cellbag Bio ReactorsfreefreederNo ratings yet

- Braskem CP 741 Blow Molding PolypropyleneDocument2 pagesBraskem CP 741 Blow Molding PolypropyleneRonaldo CamargoNo ratings yet

- Tehnički List - KIMITECH EP INDocument5 pagesTehnički List - KIMITECH EP INMARKO MATUHANo ratings yet

- Composites Fibre CoconutDocument9 pagesComposites Fibre CoconutmajmateusNo ratings yet

- Vegetable Oil-Based Epoxy Resins and Their Composites With Bio-Based Hardener: A Short ReviewDocument17 pagesVegetable Oil-Based Epoxy Resins and Their Composites With Bio-Based Hardener: A Short ReviewbelkhamasNo ratings yet

- CH 18 Lecture PresentationDocument127 pagesCH 18 Lecture PresentationMaski03No ratings yet

- 2.6.a-Reshaping Our LivesDocument14 pages2.6.a-Reshaping Our Livestwinkledreampoppies50% (2)

- Dyeing of Acrylic FibresDocument19 pagesDyeing of Acrylic FibresHugo Eduardo Ipiales Mesa100% (1)

- Alat-Alat Kedokteran Umum Harga (RP) Satuan Jumlah I Uks Kit Terdiri DariDocument4 pagesAlat-Alat Kedokteran Umum Harga (RP) Satuan Jumlah I Uks Kit Terdiri DaripkmpsNo ratings yet

- Quiz Cer Poly CompDocument6 pagesQuiz Cer Poly CompJae Hacuculaiy SamoreNo ratings yet

- VW2.8.1 en 2009-12-01Document17 pagesVW2.8.1 en 2009-12-01mehmet ustunNo ratings yet

- Epofine 179-1: Finehard 906-1Document4 pagesEpofine 179-1: Finehard 906-1Karishma PrabhuNo ratings yet

- General Properties of Elastomers Summary ChartDocument1 pageGeneral Properties of Elastomers Summary ChartvenkatramanNo ratings yet

- 811 Win-2019 APDocument34 pages811 Win-2019 APAakif AnjumNo ratings yet

- Ud 019Document5 pagesUd 019Hasibul Ehsan KhanNo ratings yet

- THE CELL Concept MapDocument3 pagesTHE CELL Concept MapDae PelayoNo ratings yet

- PROTEASYL Mark Pres ENDocument2 pagesPROTEASYL Mark Pres ENTruong Thi Thuy TrangNo ratings yet

- Amazon Cafe.9015.1474873367Document14 pagesAmazon Cafe.9015.1474873367AsmZziz OoNo ratings yet

- Reactive SIliconesDocument80 pagesReactive SIliconesJesus ChaNo ratings yet

- Jan. 1, 1963 W. E. Kaskel 3,071.498: 77oawaDocument8 pagesJan. 1, 1963 W. E. Kaskel 3,071.498: 77oawaricva_rjNo ratings yet

- Chapter 1213Document13 pagesChapter 1213Dinda Anggunianti UtamiNo ratings yet

- Chieftain Master CatalogDocument48 pagesChieftain Master CatalogRoi OportoNo ratings yet

- Acrylic: Alur Proses Pembuatan Serat AcrylicDocument7 pagesAcrylic: Alur Proses Pembuatan Serat AcrylicFathimatuz ZahroNo ratings yet

- Shade Card BEZATHRENDocument9 pagesShade Card BEZATHRENFatih SezenNo ratings yet

- Amino Acids Peptides and ProteinsDocument71 pagesAmino Acids Peptides and ProteinsMike AbellanaNo ratings yet

- Intraocular Lens Glistenings PDFDocument2 pagesIntraocular Lens Glistenings PDFAndreea L. MihalceaNo ratings yet

- Production of RubberDocument15 pagesProduction of Rubbertariq fareedNo ratings yet

- CH 13Document93 pagesCH 13Rose Ann AlcantaraNo ratings yet