Professional Documents

Culture Documents

Nedox

Uploaded by

Mithun Kumar BeheraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nedox

Uploaded by

Mithun Kumar BeheraCopyright:

Available Formats

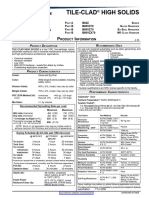

BENEFITS

• Dramatically increase surface

Nedox ®

hardness

“Synergistic” Surface Enhancement Coatings Protect

• Resist corrosion, chemicals, and

acids

Most Metals– Including Aluminum – Against Wear,

• Prevent abrasive wear and galling Corrosion, Sticking and Galling

• Self-lubricating for extended wear

• Provide superior mold release

• Meets and exceeds requirements All types of metal parts, including those made of aluminum, are treated

for ASTM B656 and ASTM B733 with NEDOX to create a harder-than-steel, self-lubricating surface that

• Permanently dry-lubricated for resists corrosion, friction, sticking, galling, and static buildup, and exhibits

very low COF superior mold release as well.

• Many meet FDA and The General Magnaplate-applied process improves parts made of less

USDA codes durable and/or less costly metals by adding physical properties that permit

• Speed cleanup and sanitation them to outperform and outwear even chrome and stainless steel. Because

maintenance NEDOX-treated surfaces are superior in performance to the base metal

• Eliminate sticking and product itself or to any of the individual components used in the enhancement

“hang-up” process, NEDOX coatings are considered “synergistic.”

• Ideal for cryogenic uses down to

–250°F (–157°C) ENGINEERING DATA AND PERFORMANCE

• Prevent galvanic corrosion with CHARACTERISTICS

incompatible metals

Wear resistance. Hardness is up to Rc 68 (940 Vickers scale) — better than

• Won’t chip, peel or flake off like hard chrome plate. There is no degradation of fatigue strength. NEDOX

“paint-ons”

coatings also eliminate the likelihood of galling or seizing.

• NASA material #20386*

Corrosion resistance. NEDOX “synergistic” coatings are superior in

• ITAR and REACH compliant corrosion resistance to chromium or standard electrolytic-nickel plated

coatings. A 0.001” coating shows little or no corrosion after 14 months of

continuous exposure to atmosphere and salt water. Good resistance to

most common chemicals. Certain coatings show no effect after 90 days

immersion in pH 3.0 – 9.5 solutions. Some NEDOX coatings are especially

resistant to phosphate-free bleach used in washdown solutions in food

processing and packaging operations. NEDOX coatings on aluminum also

provide resistance to a wide range of chemicals.

Nuclear Applications. Nedox is well suited for use in reactors that are

used for uranium enrichment. In the process that creates fissionable

Uranium 235 from Uranium 238, uranium hexafluoride (UF6) is produced

GENERAL MAGNAPLATE CORPORATION 1-800-441-6173 | info@magnaplate.com | www.magnaplate.com

in a gaseous diffusion process. The UF6 was found to be one of the

TYPICAL APPLICATIONS most active chemicals known, almost acting as a universal solvent. The

components in Nedox are shown to have excellent chemical resistance to

• Aircraft

UF6.

• Aerospace

• Chemical processing equipment EQUILIBRIUM WEAR RATES*

• Electronic equipment

• Food processing

• Heat sinks

• Meters (gas & electric)

• Molds (release agents)

• Packaging equipment

• Pharmaceutical processing

• Pumps

• Sealing equipment

• Textile manufacturing

• Valves

* Weight loss = mg per 10,000 cycles - CS10 wheel

using Taber Abrasion per ASTM D 4060

Friction. Surface is smooth and slippery. In some cases, the static friction

decreases with an increase in load. NEDOX eliminates “stick-slip” and

undesirable vibration of higher break-away friction.

NEDOX FRICTION CHART

Material vs. Material COF Static COF Kinetic

Steel Aluminum 0.47 0.38

Steel NEDOX SF-2 0.30 0.26

NEDOX SF-2 NEDOX SF-2 0.18 0.12

Feeder auger used in handling ultrafine Teflon* NEDOX SF-2 0.10 0.09

powders for the non-woven industry.

NEDOX provides the release necessary to *Teflon is a registered trademark of DuPont

keep the powders from sticking and caking.

Temperature. Exhibits high strength, toughness and self-lubricity down to

–250°F (–157°C). Exhibits flexibility down to –110°F (–79°C). 850°F (454°C)

is the maximum continuous operating temperature.

GENERAL MAGNAPLATE CORPORATION 1-800-441-6173 | info@magnaplate.com | www.magnaplate.com

Thermal coefficients. Typical Coefficient of Thermal Expansion: 7.22

x 10–6 in/in/1°F. (13 x 10–6 in/in/1°C). Typical Coefficient of Thermal

Conductivity: .0105 – .0135 Cal-cm/sec/°C.

SALT SPRAY TEST

A cookie manufacturer eliminates frequent

production downtime to change batter-

clogged cookie molds and also reduces

mold replacement by treating brass molds

with an FDA/USDA compliant NEDOX

coating. Other food processors solve mold

release, cleanup and sanitation problems

by specifying NEDOX for molds, extrusion

pistons and dies, filling nozzles, rollers,

trays, kettles, and blades.

Hours of exposure in 5% NaCl until first

appearance of corrosion spots per ASTM B-117

Versatility. With few exceptions, NEDOX coatings can be applied to parts

of any configuration, any weight, virtually any size or thickness, and almost

any metal (including aluminum). Precise control of coating thickness

permits use on machine threads and similar close-tolerances.

FDA and USDA compliance. Compliance with FDA and USDA codes

makes many NEDOX coatings particularly advantageous for food and

pharmaceutical applications. These non-stick coatings eliminate the

potential growth of mold and bacteria by creating a dense, non-porous

surface. They are used extensively on processing, packaging and handling

equipment to prevent product residue from clinging to machinery and add

the benefits of quicker equipment cleanup and sanitation maintenance.

Non-stick release properties. Very few solid substances, even adhesives,

adhesive-backed products or glues, will permanently adhere to the

proprietary polymer-impregnated surface of a NEDOX coated part. Most

substances, such as plastics, rubber or slurries, release easily. Some

A NEDOX coating on the steel portions

extremely tacky materials may exhibit mild temporary adhesion.

and a TUFRAM® coating on the aluminum

portions solved galvanic corrosion and Thickness. Typical normal surface deposition is 0.0002” – 0.002” (±10%)

erosion problems encountered on their and is based upon thickness requirement and coating formulation. (See

combination steel/aluminum molds used section describing NEDOX FAMILY OF “SYNERGISTIC” COATINGS).

to injection blow-mold PET bottles. The

coatings also prevented corrosion created

by condensation on both metals.

GENERAL MAGNAPLATE CORPORATION 1-800-441-6173 | info@magnaplate.com | www.magnaplate.com

NEDOX vs. chromium plating. High-efficiency NEDOX coatings provide

optimum uniformity and do not build up on high current density areas (see

diagrams below). Thus, costly and labor-intensive secondary machining

and secondary finishing steps can be completely eliminated. An added

feature is the ductility of NEDOX which allows a 180° Bend-Test without

flaking or chipping.

The poor efficiency of chromium plating systems (10% – 14% under

optimum conditions, even less with some configurations), when

complicated by high and low current density areas, can lead to extremely

Actuators on the International Space

uneven deposition rates and leave large variations in the coating thickness.

Station (ISS) project are coated with NEDOX Uneven deposition of chrome also results in a very brittle coating.

SF-2 to give them superior lubricity and a

hardness of up to Rc 65. (NASA material

Nedox Chromium Plating

#20386). The ISS is a partnership in space

between the USA, Europe, Canada, Japan, Low “CD” Effect High “CD” Effect

and Russia.

Anti-static electrical properties. The proprietary polymeric impregnation

usually imparts dielectric resistance, a low dissipation factor, and very

high surface resistivity over a wide range of frequencies. However, special

techniques developed by Magnaplate’s R&D Group permit NEDOX to be

made conductive enough to be used as an anti-static coating.

NEDOX was used on these lipstick mold Non-wetting. Since our proprietary polymer-impregnated surfaces are both

parts to ease cleanup of residues left from oleophobic and hydrophobic, they resist wetting by most liquids. Hence,

the molding process. The smooth NEDOX clean-up is faster, easier and more thorough. In many cases, parts become

surface increased product quality and

self-cleaning. Maintenance time and labor are greatly reduced. Droplet

appearance by minimizing pinholes and

blemishes on the lipstick. exhibit excellent performance.

Value-added coatings permit substitution of carbon steel or aluminum for

expensive metals. In order to reduce bottomline costs, innovative design

engineers today are utilizing Magnaplate “synergistic” coatings such as

NEDOX to permit substitution of aluminum and low-cost steels for more

expensive metals such as stainless steel.

Stainless costs about five times more than carbon steel. Yet in many

applications, a carbon steel part that has been protected by the proper

type of NEDOX coating will have the corrosion resistance of stainless steel

and can be used in place of the stainless part. Similarly, other lower cost

ferrous alloys can be specified in a wide range of applications where higher

Guide plates used in pharmaceutical form/ cost substrate materials are currently used.

fill seal machine. NEDOX prevents product NEDOX-coated aluminum, too, has become a popular choice of design

hang-up, keeping flow rates steady.

engineers, as well as of plant and materials engineers.

GENERAL MAGNAPLATE CORPORATION 1-800-441-6173 | info@magnaplate.com | www.magnaplate.com

NEDOX FAMILY OF “SYNERGISTIC” COATINGS

Superior corrosion resistance offering release up to 850F. Compliant wtih

10K3

USDA and FDA codes

Hardness (up to Rc 65) combined with lubricity. USDA/FDA compliant,

SF-2

CFIA approved. NASA material #20386*.

SF-2R Same as SF-2, but with superior mold release. USDA/FDA compliant.

Resists bleach washdown solutions and lactic acid from dairy equipment.

SF-2SB

USDA/FDA compliant.

Maximum wear resistance. Hardness up to an equivalent of Rc 68.

CR+

Maximum salt spray resistance.

Designed to provide adequate wear protection and improved corrosion

CR

properties over CR+ with higher COF

Combines release properties of 615 with the wear properties of SF-2.

SLK

USDA/FDA compliant.

A variety of seal bars are coated with Excellent mold release for plastics, urethane epoxies and rubber. Black

NEDOX to increase wearlife and prevent MR-3 (U-4)

color. Recommended for UV curing.

packaging films from sticking during heat

sealing operations. Special combination of proprietary polymers and dry-lubricants. Low

FM-5

coefficient of friction after burnishing.

Excellent for resistance to wear and corrosion. Hardness of coating can be

NH-1

varied based upon specific requirements.

Hardness of coating can be varied for excellent corrosion and chemical

NH-2

resistance.

NH-1SB Same as NH-1, with superior corrosion resistance to chlorinated solvents.

Wide range of NEDOX surface enhancement coatings offers design

flexibility. During the multiple steps of the NEDOX process, there are a

number of variables that can be controlled to produce different surface

enhancement characteristics.

Through experience and research, the exact control required to produce

the desired results of a specific coating type has been refined. There are

many different types of coatings within the NEDOX family off “synergistic”

coatings. Each one has unique characteristics to meet application needs or

can be modified to achieve special performance requirements.

These metering valves, which regulate

the flow of oil in a jet engine, received the

non-binding surface it needed with a

NEDOX coating.

GENERAL MAGNAPLATE CORPORATION 1-800-441-6173 | info@magnaplate.com | www.magnaplate.com

You might also like

- Archimedes: 287 B.C. - 212 B.CDocument32 pagesArchimedes: 287 B.C. - 212 B.CVladislav CoteleaNo ratings yet

- PPG Amercoat 370 Data SheetDocument3 pagesPPG Amercoat 370 Data SheetAchraf Boudaya0% (1)

- Zecor PDFDocument7 pagesZecor PDFjavoidea696526100% (1)

- GB - T 8163-2018Document8 pagesGB - T 8163-2018Dung HDNo ratings yet

- Sulfur Recovery Units (SRU)Document5 pagesSulfur Recovery Units (SRU)Splish SplashNo ratings yet

- Effects of ElectricityDocument19 pagesEffects of Electricitynhold vNo ratings yet

- 8BT2 - Installation and Operating InstructionsDocument96 pages8BT2 - Installation and Operating Instructionsalanetn100% (1)

- Steel Ladle Calderys Brochure A4Document22 pagesSteel Ladle Calderys Brochure A4Mitone Diaz100% (1)

- Science 9 Exemplar-Melc 5Document8 pagesScience 9 Exemplar-Melc 5Thartson Oliveros MagdadaroNo ratings yet

- Eurocode Conference 2023 Mandara Eurocode 9Document25 pagesEurocode Conference 2023 Mandara Eurocode 9Rodolfo BlanchiettiNo ratings yet

- Statement of Purpose SampleDocument2 pagesStatement of Purpose SamplePouya DarvishNo ratings yet

- Xylan CoatingDocument3 pagesXylan Coatingsidhesh870% (1)

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- NEDOX - "Synergistic" Surface Enhancement CoatingsDocument5 pagesNEDOX - "Synergistic" Surface Enhancement CoatingsXto PeregrinNo ratings yet

- 4010 TDS EnglishDocument1 page4010 TDS EnglishJose Luis Ramirez RamirezNo ratings yet

- Shell Gadus S2 OG 40: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 OG 40: Performance, Features & BenefitsAmanNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Epoxy CatalogueDocument21 pagesEpoxy CatalogueChinthamani PandiNo ratings yet

- Basf-Ucrete Ud 200 - TdsDocument3 pagesBasf-Ucrete Ud 200 - TdsAbdul ZailaniNo ratings yet

- Tesco: Biodegradable Hydraulic Oil BIO 68Document2 pagesTesco: Biodegradable Hydraulic Oil BIO 68lucas ronaldo coronel mendozaNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- DOWSIL™ 3-1965 Conformal Coating: Features & BenefitsDocument3 pagesDOWSIL™ 3-1965 Conformal Coating: Features & Benefitsquang trinhNo ratings yet

- Product Data Sheet: Product Description Technical SpecificationDocument1 pageProduct Data Sheet: Product Description Technical SpecificationKamalakar SastryNo ratings yet

- Sikagard 62 - InglesDocument9 pagesSikagard 62 - InglesMisael GómezNo ratings yet

- Revista MP Diciembre 2022Document68 pagesRevista MP Diciembre 2022María Vaquero TxapartegiNo ratings yet

- 1233-1235 Product InfoDocument2 pages1233-1235 Product InfoJeisson HolguinNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Nitoproof 600 Standard PDFDocument4 pagesNitoproof 600 Standard PDFManojKumawatRjNo ratings yet

- Acrylic Binders For Water-Borne Industrial CoatingsDocument12 pagesAcrylic Binders For Water-Borne Industrial CoatingsLong An DoNo ratings yet

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderNo ratings yet

- Tech Uddeholm-Vancron ENDocument11 pagesTech Uddeholm-Vancron ENsobheysaidNo ratings yet

- 739 Plastic AdhesiveDocument4 pages739 Plastic AdhesivevkmsNo ratings yet

- Teknomastic 80 Primer 8803-00 Tds enDocument6 pagesTeknomastic 80 Primer 8803-00 Tds en8q5tgtfn7tNo ratings yet

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocument2 pagesZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNo ratings yet

- Steel PuttyDocument1 pageSteel PuttySiva SubramaniNo ratings yet

- Mascoat DTI PDSDocument7 pagesMascoat DTI PDSAnnas QahharNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- Cepsa Arga SyntDocument1 pageCepsa Arga SyntRamonNo ratings yet

- Fusion Bond Epoxt Coating BrochureDocument12 pagesFusion Bond Epoxt Coating Brochure4uengineerNo ratings yet

- Polibrid 705: Technical DataDocument2 pagesPolibrid 705: Technical DataSky MoonNo ratings yet

- Chemlok 217 Adhesive: Lord Technical Data Lord Technical DataDocument2 pagesChemlok 217 Adhesive: Lord Technical Data Lord Technical DataNeeraj BhallaNo ratings yet

- DSI - PT - Sistemas Postensado Cable NoAdherenteDocument16 pagesDSI - PT - Sistemas Postensado Cable NoAdherenteManuel RoblesNo ratings yet

- RC-2200 Rubber Compound Specification SheetDocument1 pageRC-2200 Rubber Compound Specification SheetRoosta_ManNo ratings yet

- Shell Gadus S2 OG 85Document2 pagesShell Gadus S2 OG 85Anonymous oAbjbl4HNo ratings yet

- Protecting Plant Piping From CUI With Water RepellencyDocument2 pagesProtecting Plant Piping From CUI With Water RepellencySergey KichenkoNo ratings yet

- Duremax GPE: General Purpose Epoxy CoatingDocument4 pagesDuremax GPE: General Purpose Epoxy CoatinglivefreakNo ratings yet

- DOWSIL 791 Weatherproofing Sealant Product Data 1799967Document4 pagesDOWSIL 791 Weatherproofing Sealant Product Data 1799967Research DevelopmentNo ratings yet

- Hempadur Zinc SeriesDocument2 pagesHempadur Zinc SerieskylegazeNo ratings yet

- Conformal Coating On Printed Circuit BoardsDocument7 pagesConformal Coating On Printed Circuit BoardspmazkoNo ratings yet

- 01 - TDS - Concresive ZRDocument2 pages01 - TDS - Concresive ZRaahtagoNo ratings yet

- Chevron Aries TDSDocument2 pagesChevron Aries TDSprimmughalNo ratings yet

- New Anti-Corrosion Coating For Rare Earth Magnets: WWW - Emcoatingsuk.co - UkDocument2 pagesNew Anti-Corrosion Coating For Rare Earth Magnets: WWW - Emcoatingsuk.co - UkRoberto RevinsacNo ratings yet

- Coating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryDocument43 pagesCoating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryLarasanto LarasantoNo ratings yet

- Devol PlasticsDocument8 pagesDevol Plasticsabns899004No ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- SilcoTek Coating Overview Brochure WebDocument6 pagesSilcoTek Coating Overview Brochure WebIker MelladoNo ratings yet

- PDS Shell GadusDocument2 pagesPDS Shell GadusTaufik BinasrNo ratings yet

- DS - Pipe Sections NOV07Document2 pagesDS - Pipe Sections NOV07pdiconpNo ratings yet

- AG 7740 Tankguard SF Euk GBDocument11 pagesAG 7740 Tankguard SF Euk GBChandran NairNo ratings yet

- Tankguard 412: Technical Data Sheet Application GuideDocument1 pageTankguard 412: Technical Data Sheet Application GuideTamerTamerNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Delta Protekt KL120Document1 pageDelta Protekt KL120GavinNo ratings yet

- Dowsil 790 Silicone Building SealantDocument4 pagesDowsil 790 Silicone Building SealantChris ChanonaNo ratings yet

- Bondloc B270 Studlock TDSDocument2 pagesBondloc B270 Studlock TDSsean jukesNo ratings yet

- Loctite 2432: Technical Data SheetDocument2 pagesLoctite 2432: Technical Data SheetFabio ParceroNo ratings yet

- DC 688 Technical Data SheetDocument3 pagesDC 688 Technical Data SheetHoang ThiNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Dr. A B Rajib Hazarika PHD FRAS AESDocument7 pagesDr. A B Rajib Hazarika PHD FRAS AESDrabrajib HazarikaNo ratings yet

- CE 2711 - Fluid Mechanics: Upaka Rathnayake 3 Floor - Engineering BuildingDocument26 pagesCE 2711 - Fluid Mechanics: Upaka Rathnayake 3 Floor - Engineering BuildingFearless HeroNo ratings yet

- Magic Milk Discrepant EventDocument11 pagesMagic Milk Discrepant Eventapi-579412994No ratings yet

- Chm1 Gases 1002 FDDocument14 pagesChm1 Gases 1002 FDaerkn skjksNo ratings yet

- Helium Refrigeration Plants - Linde EngineeringDocument2 pagesHelium Refrigeration Plants - Linde Engineeringait oubella marouaneNo ratings yet

- SC ISC TrainingDocument45 pagesSC ISC TrainingsuberorrNo ratings yet

- Cobre en Formulaciones de Pesticidas 922 - 05Document1 pageCobre en Formulaciones de Pesticidas 922 - 05quimicontayNo ratings yet

- 1 Atm 101.3 Kpa 1 Atm 760 MM HG or Torr: CH 13 and 14 Practice TestDocument11 pages1 Atm 101.3 Kpa 1 Atm 760 MM HG or Torr: CH 13 and 14 Practice Testيزن جانسيزNo ratings yet

- Certipur Certified Reference Material: Iron Standard Solution 1000 MG/L FeDocument1 pageCertipur Certified Reference Material: Iron Standard Solution 1000 MG/L Fefra80602No ratings yet

- Inorganic Biological Molecules - Water 0 MineralsDocument40 pagesInorganic Biological Molecules - Water 0 MineralsjonNo ratings yet

- Physics Lesson Notes On Heat and TemperatureDocument6 pagesPhysics Lesson Notes On Heat and TemperatureRoland TchanaNo ratings yet

- Humidity Conversion Formulas B210973EN-F PDFDocument17 pagesHumidity Conversion Formulas B210973EN-F PDFGyana MatiNo ratings yet

- Meeting Growing Alky LateDocument18 pagesMeeting Growing Alky LateChristianGuerreroNo ratings yet

- Daftar PustakaDocument2 pagesDaftar PustakawindaratlinNo ratings yet

- Horiba OCMA 310 DatasheetDocument4 pagesHoriba OCMA 310 DatasheetAnas AzzedineNo ratings yet

- Lesson 9-General Theory of RelativityDocument4 pagesLesson 9-General Theory of RelativityZarina SalesNo ratings yet

- P6. Hukum 1 TermodinamikaDocument6 pagesP6. Hukum 1 TermodinamikaAnis AnisaNo ratings yet

- The Systematic Identification of Organic CompoundsDocument6 pagesThe Systematic Identification of Organic CompoundsDwivelia Aftika0% (1)

- Comparation Glycerol Degradation by Microwave Heating and by Hydrothermal TreatmentDocument6 pagesComparation Glycerol Degradation by Microwave Heating and by Hydrothermal TreatmentzaedmohdNo ratings yet

- DLPFS2Document3 pagesDLPFS2Jessa LingaolingaoNo ratings yet

- 3BSM Group 3 General Tests For CarbohydratesDocument42 pages3BSM Group 3 General Tests For CarbohydratesJeanette RiosNo ratings yet

- Lecture 1. Kinematics of Flow By. Engr - Wendhel Q.LDocument9 pagesLecture 1. Kinematics of Flow By. Engr - Wendhel Q.Ljames PrincipeNo ratings yet