Professional Documents

Culture Documents

Silabus Kecil IBT 2022

Uploaded by

Agung Rizki PradanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silabus Kecil IBT 2022

Uploaded by

Agung Rizki PradanaCopyright:

Available Formats

SYLLABUS BIMBINGAN TEKNIS KUALIFIKASI NSPEKTUR BEJANA TEKAN MIGAS

OBJECTIVES 8. Fabrication

a. Overview

Participants of this course will learn about: c. Local Regulations

b. Drawing Review

• Describe the role of the Authorized Pressure Vessel > UU No.1 of 1970 c. Inspection

Inspector > UU No. 22 of 2001 d. PWHT

• Evaluate Quality Control Programs > PP No. 11 of 1979 e. Inspector Duties

• Use Design Calculations from ASME Code > Permen ESDM No.32 of 2021 f. Manufacturer Duties

• Evaluate Impact Testing Results 2. Material g. Standard Hydrotest

• Recognize material requirements a. General Requirements h. Marking and Reporting

• Recognize welding requirements b. Requirements Governing Permitted Materials i. Pressure Relief Device

• Recognize manufacturer process development and c. Requirements for Welding Material j. QC Systems

controls d. Material Specifications 9. Damage Mechanism

• Evaluate nondestructive examination (NDE) methods e. Material Selection a. Fundamental of Corrosion

• Assess pressure relief devices 3. Cylindrical shell b. API RP 571 for Inspector

• Perform inspections and tests a. Material Requirements 10. PV inspection Code

• Explain markings and data reports b. Minimum Thickness Requirements a. Overview of API 510

• Responsibility c. Corrosion Allowance in Design Equations b. Scope

• Determining CML on existing vessel 4. Head c. References

• Evaluating the pressure existing vessel a. Types of formed head d. Definitions

b. Unstayed Flat Heads and covers e. Owner-User Inspection Organization

5. Join f. Inspection, Examination and Press. Practices

OUTLINES g. Interval/Frequency and extent of Inspection

a. Join Category

1. Introduction b. Radiography h. Inspection Data Evaluation, Analysis, and Recording

a. Overview of Pressure Vessel c. Join Efficiency i. Repair, Alteration, and Re-Rating PV

b. Codes and Standards d. Compensation j. Alternative Rules for E&P PV

> ASME II e. Minimum requirements for welds 11. Welding

> ASME V 6. Ligaments a. Overview and Definitions

> ASME VIII a. Ligament efficiency b. General Requirements

> ASME IX b. Types of ligaments c. Welding Procedure Qualifications

> API 510 c. Spacing and patterns d. Welding Data

> API RP 571 d. Solving for pitch e. Standard Welding Procedure Specifications

> API 572 7. Impact Test 12. Non-Destructive Examination

> API 576 a. Material a. Basic Principles

> API 577 b. Design Temperature b. Code Requirements

RESEARCH

c. Requirements for PWHT

POSTER

1

d. Governing Thickness

You might also like

- Api 570 PreDocument3 pagesApi 570 PreBhargava NaiduNo ratings yet

- 570 Renewal Quiz SolutionsDocument14 pages570 Renewal Quiz SolutionsLeenmack100% (5)

- The Welding Procedure and Its QualificationDocument51 pagesThe Welding Procedure and Its QualificationYousef Adel HassanenNo ratings yet

- Med SchoolDocument12 pagesMed SchoolCheryl ChangNo ratings yet

- API 510 PC 20 31 Aug05 Bench MarkDocument4 pagesAPI 510 PC 20 31 Aug05 Bench MarknikafiqNo ratings yet

- API 570 Recertification Quiz - Questions and Answers (Updated January 2022)Document13 pagesAPI 570 Recertification Quiz - Questions and Answers (Updated January 2022)Amani Reid100% (4)

- Leadership Development PresentationDocument30 pagesLeadership Development PresentationNoorJehan Arif50% (2)

- Multilingualism, Politics, and FilipinismDocument24 pagesMultilingualism, Politics, and FilipinismJhasmine Jam Albos100% (1)

- Dimensional Control ProcedureDocument12 pagesDimensional Control ProcedureBethel NdifonNo ratings yet

- Hydrotest Ansi b31.3 2017Document13 pagesHydrotest Ansi b31.3 2017Bangkit SusiloNo ratings yet

- API 510 Pressure Vessel Inspector Certification Preparation CourseDocument4 pagesAPI 510 Pressure Vessel Inspector Certification Preparation CoursejbsantoNo ratings yet

- Lexile MapDocument1 pageLexile MapDNo ratings yet

- API 570 in Service Inspection Piping System 1643295114Document32 pagesAPI 570 in Service Inspection Piping System 1643295114DeepakNo ratings yet

- 1 API 570 Bench Mark Quiz 1 55Document56 pages1 API 570 Bench Mark Quiz 1 55rodholfho100% (1)

- Array Cli PDFDocument398 pagesArray Cli PDFsanna agarwalNo ratings yet

- C Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsDocument10 pagesC Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsElankumaran Periakaruppan100% (1)

- Workbook Module 01Document3 pagesWorkbook Module 01kyeong cheol leeNo ratings yet

- Boxt Field Quality PlanDocument86 pagesBoxt Field Quality PlanHariom GuptaNo ratings yet

- Api 510 Close Book (Sec Viii & 510) - 17Document12 pagesApi 510 Close Book (Sec Viii & 510) - 17walid walid100% (1)

- Datasheet Anchor FlangeDocument1 pageDatasheet Anchor FlangeHafiz Ashadi100% (1)

- CMRT Practice QuestionsDocument2 pagesCMRT Practice Questionslinbaba123100% (2)

- API 570-Final Model Exam-Closed Book Without AnswersDocument9 pagesAPI 570-Final Model Exam-Closed Book Without AnswersbananaNo ratings yet

- WPS Steps of MakingDocument51 pagesWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- API 510 Mid Session Closed0Document10 pagesAPI 510 Mid Session Closed0مبشر أحمد100% (2)

- C8516-CLT-QMT-0003 Rev.00Inspection Checklist For Concreting WorksDocument2 pagesC8516-CLT-QMT-0003 Rev.00Inspection Checklist For Concreting WorksJabinNo ratings yet

- SCTE ISBE BTCS Broadband TelecomCenter Specialist Certification Competencies FINAL 2017 PDFDocument31 pagesSCTE ISBE BTCS Broadband TelecomCenter Specialist Certification Competencies FINAL 2017 PDFHamdi GharsalliNo ratings yet

- Sis Book1Document99 pagesSis Book1Hamza AlamNo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Final Exam (Closed) : Professional Training and ConsultationDocument12 pagesFinal Exam (Closed) : Professional Training and ConsultationGeorge KudiaborNo ratings yet

- Method Statement For Installation of DBsDocument11 pagesMethod Statement For Installation of DBstristan guarinoNo ratings yet

- Volume 1 API 510 ExamDocument34 pagesVolume 1 API 510 ExamMohammad Danish67% (3)

- June 2018 API RP 577 Practice QuestionsDocument4 pagesJune 2018 API RP 577 Practice QuestionsMahmoud Alwasif100% (2)

- API 570 Exam ClosedDocument12 pagesAPI 570 Exam ClosedMisbah ur Rehman100% (1)

- QuizletDocument31 pagesQuizletbananaNo ratings yet

- Bench Mark Quiz: API 510 PreparatoryDocument5 pagesBench Mark Quiz: API 510 PreparatoryRajkumar ArikumarNo ratings yet

- Regulatory Engineering Quality Assurance ManualDocument3 pagesRegulatory Engineering Quality Assurance Manualshelvin.swamyNo ratings yet

- 2 API 570 Info PDFDocument4 pages2 API 570 Info PDFاحمد حسنNo ratings yet

- Manual Testing: 1. Black Box 2. White Box 3. Grey Box DocumentationDocument1 pageManual Testing: 1. Black Box 2. White Box 3. Grey Box DocumentationRonit GuptaNo ratings yet

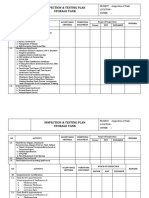

- Form ITP Storage TankDocument4 pagesForm ITP Storage Tanksuratno 25No ratings yet

- ANSI - TIA - 568C Cat 6Document6 pagesANSI - TIA - 568C Cat 6Mayra Gon HalonNo ratings yet

- CHAPTER-2 Duties & Reponsibilities Welding Term and DefinitionsDocument8 pagesCHAPTER-2 Duties & Reponsibilities Welding Term and Definitionsshahid khanNo ratings yet

- NIST Calibration Program Calibration Services Users Guide SP 250 AppendixDocument69 pagesNIST Calibration Program Calibration Services Users Guide SP 250 Appendixjepri purwantoNo ratings yet

- AC25 562 1B - Dynamic Evaluation of Seat Restraint System PDFDocument104 pagesAC25 562 1B - Dynamic Evaluation of Seat Restraint System PDFffontanaNo ratings yet

- 4 API 653 AST Inspector CourseDocument4 pages4 API 653 AST Inspector CourseshaajiNo ratings yet

- Civil Aviation Safety & Engineering Academy Makassar: Learning ActivityDocument2 pagesCivil Aviation Safety & Engineering Academy Makassar: Learning ActivityNur InayahNo ratings yet

- Jash Engineering LTD.: Quality Assurance PlanDocument3 pagesJash Engineering LTD.: Quality Assurance PlanShree ConstructionNo ratings yet

- Upcoming Changes To API 653 2021Document6 pagesUpcoming Changes To API 653 2021Cherie JohnsonNo ratings yet

- API 510 Question Bank Sets G I 2Document30 pagesAPI 510 Question Bank Sets G I 2Nayeem UllahNo ratings yet

- PSM Knowledge Review 2 KeyDocument1 pagePSM Knowledge Review 2 KeyAlfiNo ratings yet

- Alliance Protocols 2Document1 pageAlliance Protocols 2alamNo ratings yet

- Brochure API 570 (150129) PDFDocument4 pagesBrochure API 570 (150129) PDFMakhfud Edy100% (1)

- Daily - Exam - 5A - Closed and AnswerDocument6 pagesDaily - Exam - 5A - Closed and AnswerGeorge KudiaborNo ratings yet

- PMT-MS-018 Rev.00 - Method of Statement For Chpping and Coring WworksDocument4 pagesPMT-MS-018 Rev.00 - Method of Statement For Chpping and Coring Wworksromeo arazaNo ratings yet

- Lecture 6Document14 pagesLecture 6Kakashi 12No ratings yet

- Lockhart 653Document7 pagesLockhart 653oluninjaaNo ratings yet

- Qap PDFDocument3 pagesQap PDFRavi BhadaniNo ratings yet

- API 510 PC 20 31 Aug05 Bench MarkDocument5 pagesAPI 510 PC 20 31 Aug05 Bench MarkCss SfaxienNo ratings yet

- AIM SyllabusDocument2 pagesAIM Syllabusvivekpatel786543No ratings yet

- Model DE Electronically Controlled Diesel Fuel Injection Pump Operation and Instruction ManualDocument60 pagesModel DE Electronically Controlled Diesel Fuel Injection Pump Operation and Instruction ManualjiovanniNo ratings yet

- Bitstream 24603Document7 pagesBitstream 24603mohammad293No ratings yet

- ReviewerDocument6 pagesReviewerJaylord FernandoNo ratings yet

- API 510 PC 05mar05 Bench MarkDocument5 pagesAPI 510 PC 05mar05 Bench MarkKommula Narayana SwamyNo ratings yet

- CG4352 GM1927 03a Gas Mig Braze Weld Quality Verification ProcedureDocument10 pagesCG4352 GM1927 03a Gas Mig Braze Weld Quality Verification ProcedureBruna VitalNo ratings yet

- BS 65-1991 Clay PipesDocument26 pagesBS 65-1991 Clay PipesP_DaviesNo ratings yet

- Qap Reciever TanksDocument6 pagesQap Reciever Tanksyamunaengg2011No ratings yet

- Lotus Sametime 3DDocument23 pagesLotus Sametime 3DsvrbchaudhariNo ratings yet

- Ocb 283Document4 pagesOcb 283Vishnu NairNo ratings yet

- Training Program Proposal (Group Dynamics)Document7 pagesTraining Program Proposal (Group Dynamics)Josh PoloNo ratings yet

- Exporting Blender Models To ThreeJS and WebGLDocument5 pagesExporting Blender Models To ThreeJS and WebGLGerman BautistaNo ratings yet

- Chi Square Test - Apr 24 2015Document30 pagesChi Square Test - Apr 24 2015Sneha Arora100% (1)

- Feagin and Cobas Language Oppression and Resistance The Case of Middle Class Latinos in The UDocument22 pagesFeagin and Cobas Language Oppression and Resistance The Case of Middle Class Latinos in The UOscar Fluxus DiazNo ratings yet

- Review Effective Marketing Strategy For Umkm Coffee Shop in The Face of PandemiDocument10 pagesReview Effective Marketing Strategy For Umkm Coffee Shop in The Face of PandemiAn Nissa Ar RauufiNo ratings yet

- Erp Sap Cours PDFDocument2 pagesErp Sap Cours PDFMattNo ratings yet

- RRLDocument3 pagesRRLTyrone BautistaNo ratings yet

- Topic 4 - What Makes A Person SuccessfulDocument1 pageTopic 4 - What Makes A Person SuccessfulKNguyen HuynhNo ratings yet

- Lab - Binomial GeogebraDocument2 pagesLab - Binomial Geogebraapi-488084761No ratings yet

- Rhetorical Analysis EssayDocument2 pagesRhetorical Analysis Essayapi-453444499No ratings yet

- Natural Disasters - Prediction Before Prevention The Catastrophe Theory - The Background To Georheology - DR Andrew M. DavieDocument6 pagesNatural Disasters - Prediction Before Prevention The Catastrophe Theory - The Background To Georheology - DR Andrew M. DavieChromaticghost2100% (1)

- Chapter 3Document23 pagesChapter 3ratu erlindaNo ratings yet

- Is Human Nature Fundamentally Selfish or AltruisticDocument5 pagesIs Human Nature Fundamentally Selfish or Altruistic文光No ratings yet

- Instant Download Language of Medicine 11th Edition Chabner Test Bank PDF Full ChapterDocument32 pagesInstant Download Language of Medicine 11th Edition Chabner Test Bank PDF Full Chapterthuyhai3a656100% (7)

- RIPARODocument1 pageRIPAROPEA CHRISTINE AZURIASNo ratings yet

- How To Write A Composition PDFDocument2 pagesHow To Write A Composition PDFAbeeha RajpootNo ratings yet

- Fronteira Infosys: Venue: Dates: Course FacilitiesDocument2 pagesFronteira Infosys: Venue: Dates: Course Facilitiesapi-26281459No ratings yet

- LogcatDocument3,139 pagesLogcatvatsavai swathiNo ratings yet

- Star UmlDocument9 pagesStar UmlAchintya JhaNo ratings yet

- Full Download Test Bank For Canadian Organizational Behaviour 8th Edition Mcshane PDF Full ChapterDocument36 pagesFull Download Test Bank For Canadian Organizational Behaviour 8th Edition Mcshane PDF Full Chapterpeelefisc7vnzww100% (17)

- Nef Adv End-Of-course TestDocument7 pagesNef Adv End-Of-course TestIlya PNo ratings yet

- Quantitative 11Document9 pagesQuantitative 11Gayatri PatelNo ratings yet