Professional Documents

Culture Documents

Military Vehicles Archive Compendium Vol.5 M4 Sherman

Uploaded by

Nickiedeposie0 ratings0% found this document useful (0 votes)

61 views100 pagesMilitary Vehicles Archive Compendium Vol.5 M4 Sherman

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMilitary Vehicles Archive Compendium Vol.5 M4 Sherman

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

61 views100 pagesMilitary Vehicles Archive Compendium Vol.5 M4 Sherman

Uploaded by

NickiedeposieMilitary Vehicles Archive Compendium Vol.5 M4 Sherman

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 100

OR ET

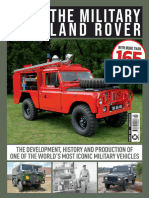

ar ary i WITH MORE THAN

IMAGES!

Amonthly round-up of the latest news

buying and selling reports, auction, working

classics and restorations direct to your inbox.

Sign up to the

today and receive a

for Heritage

Machines products and

special editions!

VISIT HERITAGEMACHINES.COM

AND SIGN-UP ON THE HOMEPAGE TODAY!

RG

Ua THe

Seo

(© The distinctive dust of the War & Peace

arena and the equally distinctive cast hull

fof the Maal and with the longer barrelled

"76mm gun. (Simon Thomson)

4 USTANK DESIGN 1917-42

How the US Army's M2 and

M3 medium tanks led to the

development of the Sherman

12. SHERMAN

The US Army shifts production

from the M3 Grant to the

Ma Sherman

24 M4

Despite its designation, the

Mé was not actually the

first Sherman variant into

production

32 (MAI

September 1941, and Lima

Locomotive Works starts to

build the cast-hull Sherman

42 M4A2

The radial engine is replaced

by GM Detroit Diesel power...

twice!

HTS

‘© With its ubberised-canvas screen, the

‘duplex drive (00) Sherman was developed

toallow Shermans to svim ashore d

the opening stages of the Normandy

landings.

50 M443

‘The US Army's preferred

variant uses Ford's mighty

GAA VB petrol engine

66 M44

30 cylinders...the

extraordinary Chrysler multi-

bank powered Sherman,

72 M4A5, M4A6

The mysterious Canadian

M4A8, and the Caterpillar

diesel-engined M4A6

76 OTHER APPLICATIONS

The Sherman's reliability,

combined with the numbers

produced, led to a host of

adaptations and

‘modifications

82 M4-BASED ENGINEER TANKS

ARVs, bridge-layers,fascine

carriers, demolition tanks and

prime movers

roeed

f@ The shape ofthe Sherman quickly

became iconic and images of Shermans

were pressed into service whenever a

{generic tank was required, as in this poster

for the US War Manpower Commission,

«© With its huge V8 petrol engine, the Ford

Motor Company/'s MaN4 was the US Army's

favoured variant. (Ford Motor Company)

86 M4 IN COMBAT

‘The Sherman in front-line

service

98 THE LAST WORD

‘What becomes of obsolete.

and battle-damaged tanks?

(MILITARY VEHICLES ARCHIVE | 3

US TANK DESIGN 1917-42

USE

DESIGN 1917-42

aC Owes e Pea CE Maat rel ae Talo te RCoR aly

ree) etaat a eee ees lal

Before we can look at the M4 Sherman in any detail, we, firstly, have to consider how little

experience the United States had at the time in producing tanks. Between 1920 and 1935, total

Us tank production was just 33 vehicles. Admittedly the figure rose to 1000 in the five years

between 1935 and 1940, but, it was at this point that the US Army came to the conclusion that

the M2 medium tank, which it had been planned would provide a cornerstone for the newly-

formed Armored Force, was effectively obsolete on the battlefield before it had even been put

into production. Not only was its 37mm gun no match for the SOmm or 75mm weapons being

fitted to German tanks, but it was also inadequately armoured... and, few were impressed by

there being seven machine guns!

|

|

|

i

i

x

spite much brave talk, itwas much longer. Tanks were going tobe German tanks on an equal footing. A

clear that the USA was not going urgently required and, clearly, even minimum 75mm gun was required,

tobe able to ignore what was the improved, standardised M2A1 foreing the Ordnance Department to

going on in Europe for very was not going tobe able to take on the go back to the drawing board.

4 | MILITARY VEHICLES ARCHIVE

US TANK DESIGN 1917-42

(© M2AI marked as belonging to the 67th Infantry Regiment; the photograph was taken in 1940 during US Third Army manoeuvres.

1 From a total order of 126 M2Al tanks, some 94 were constructed between November

1940 and August 194, They were used solely fr training purposes.

In June 1940 a document was

issued that spelt out the desirable

characteristies of a much-improved

tank that would replace the M2A1

with the minimum of automotive

changes. And, within little more than

nine weeks a full-sized wooden mock-

up, of what was now being described

as the Mg medium tank, was

presented to the Tank Committee,

and ultimately to the British Tank

Commission who considered this to

bea ‘eruiser tank... describing it as

‘fast and well armed, but relatively

lightly armoured’.

Like the M2Ax that had so nearly

gone before, power was supplied by a

Wright R-075 nine-cylinder air-cooled

radial engine, producing 4oobhp

(ookW) from a capacity of 15,980ce

(675in®), and coupled to the front

sprockets via a Mack-built five-speed

transmission. The lower part ofthe

hull was similar to the M2A1, with the

(MILITARY VEHICLES ARCHIVE. | 5

US TANK DESIGN 1917-42

«Pilot model forthe M3 photographed at Aberdeen Proving

Ground in March 1941

{© “Youll believe a tank ean fy’

running gear on each side consisting

of three pairs of rubber-tyred road

wheels assembled as six bogies, and

with each of the bogies suspended on

vertical volute springs.

‘The g7mm main gun of the M2A1

had indeed been replaced by a 75mm

(© Grant-based canal defence light (COL) constructed on the MAI

variant. A dummy gun was normally mounted in the turret.

mKe BS

‘weapon but, unfortunately, no US-

Duilt turret was available that could

carry this gun and still retain a full

‘360° of rotation, There was little

choice but to mount the gun in a

sponson on the right-hand side of

the hull which restricted the rotation

toa total of go. just 15° in either

direction. A standard turret was also

fitted on top of the hull, equipped with

a 37mm gun and, on top of this turret

was a second, smaller turret that both,

carried a .goin anti-aircraft gun and

acted as a commander's cupola.

6 | MILITARY VEHICLES ARCHIVE

US TANK DESIGN 1917-42

(© US Army MS Lee kicking up the dust during training. Although the turret is of cast construction, the hulls riveted; note that the

‘37mm gun has not yet been fitted,

«© Before its expansion, the shipping and heavy repairs department shared space with

the MS production line at Deteolt Tank Arsenal. (Chvysier Corporation)

It would be ungracious to point out

that the arrangement of turrets was

considered far from ideal: the limited

traverse of the main gun meant that,

it was often necessary to manoeuvre

the entire tank to make an accurate

shot. But, perhaps, worse still, the

combination of a small rotating

turret with a commander's eupola

‘mounted on top, gave an overall

height of 123in (3125mm), compared

toa figure of 98-104in (2500-

2650mm) for the equivalent German

Panzerkampfwagen IL ot IV. No

surprise then that the Mg presented a

‘very easy target.

However, such was the demand

for tanks by the British Army, who

had been forced to leave behind large

‘numbers of armoured vehicles in

France in May 1940, that production

of the Mg was authorised without

further delay, with the tanks being

jurchased by the War Office on a

‘cash-and-carry’ basis. This allowed

the British to ask for changes to the

(MILITARY VEHICLES ARCHIVE. | 7

US TANK DESIGN 1917-42

‘© During demonstrations of Chrysler's frst tank on ‘presentation day’ in 194, the test diver deliberately snapped a telephone pole.

(Chiyslee Corporation)

design, meaning that two different

versions were put into production,

the US Army's version was described

as the ‘General Lee’, named for the

Confederate leader Robert E. Lee,

whilst the British version, which was

fitted with a redesigned turret that

lacked the small rotating anti-aircraft

turret or commander's cupola, was

described as the ‘General Grant’ in

recognition of Ulysses S. Grant. These

names were subsequently adopted by

the US Army, but the word ‘General

was soon abandoned.

‘The detailed design work was

completed by February 19.41,

with the first example shipped to

Aberdeen Proving Ground in May

1941. Testing of the pilot models

started almost immediately, in

front of what were described as ‘US

8 | MILITARY VEHICLES ARCHIVE

US TANK DESIGN 1917-42

‘© Production line for the M3 Lee atthe Detroit Tank Arsenal. (Chrysler Corporation)

Army officers, Office of Production

Management (OPM) officials

and British representatives’ and

production was in hand by August

1941, with an initial total of 20 tanks

shipped to the British Army, now

under the Lend-Lease arrangements.

A total of 666 had been completed

by the end of March 1942, and the

Mg saw its first action with the

British Desert Rats in Egypt in May,

where Chrysler described it as ‘the

tank which whipped Rommel’.

Although it was soon to be

superseded by the Sherman, the

British continued to use Mgs against

the Japanese in south-east Asia until

aslate as 1945. Whereas, in the US

‘Army, the Mg was almost exclusively

reserved for erew training, with any

real action restricted to the Tunisian

campaign in November 1942.

(MILITARY VEHICLES ARCHIVE | 9

US TANK DESIGN 1917-42

January 1942 using a welded upper

hall in place of the riveted or east.

construction used in the M3 and.

‘Mgt. This not only simplified

production, but also improved the

ballistic properties of the hull. The

later M3Ag, also entering production

in January 1942, was an attempt at

getting around a shortage of radial

engines by fitting a pair of GM 6-71,

diesels into the welded hull of the

‘MgA2, whilst the MgAs saw these

same engines being used in a riveted

hull. Finally, the MgA4, introduced in

June 1942, used the original riveted

hull, but with the complex Chrysler

30-eylinder multi-bank engine in

place of the radial.

However, even before design

work on the Mg was completed,

‘The first Mg variant came when the and flying around the interior causing a new tank, to be designated T6

‘Ondnance Committee authorised the injury to the crew and damaging during development and then as

use ofa one-piece cast upper hull that interior fittings. The cast hull variant M4 when put into production, was

‘eliminated the dangers of rivets; these was designated M3A1, with production being planned. The M4 was to use

1¢ Ms Loe photographed in action,

had previously been used to assemble beginning in February 1942. ‘a modified version of the proven

the plates of the hull, breaking loose Next came the MgA2 which was Mg chassis, and would mount a

under the impact of ineoming rounds put into limited production in 75mm main gun in a fully-rotating,

turret, thus eliminating the sponson-

‘mounted gun, It was hoped that the

use ofa similar chassis and choice

of power units would enable the

‘M4 to simply replace the Mg on

production lines with the minimum

of downtime.

Pat Ware

Author and series editor

CO a

ie

‘© REME demonstrates how to change the Wright radial engine ofthe MS Grant using an

Austin KS gantry crane.

10. | MILITARY VEHICLES ARCHIVE

US TANK DESIGN 1917-42

«© Restored M3 Grant in the distinctive, But Believed by many people tobe erroneous,

‘camouflage scheme used in the Western Desert

MILITARY VEHICLES ARCHIVE | 11

SHERMAN

Sa

The US Army shifts production from the

M3 Grant to the M4 Sherman

Entering production in February 1942, the US-designed M4 medium tank was quickly

dubbed the ‘Sherman’ by the British both in recognition of the US civil war General William.

Tecumseh Sherman, and in order to avoid confusion with other similarly named machinery.

It was certainly not the best Allied tank of WW2, that title arguably belongs to the Soviet T-34

or the IS-2 Stalin. However, it was one of the most numerous tanks of the war, with a total of

almost 50,000 examples constructed before production ended in July 1945. And whilst we are

criticising the Sherman, it would not have won any prizes for either its firepower or levels of

armoured protection either, but it was an extremely reliable and easily-maintained machine

which was able to turn the tide in the Allies’ favour almost anywhere that it was deployed.

jork on what was initially

described as the 6 medium

tank ~ later to be known as

the M4 Sherman = started in

the spring of 1941 when Rock Island

Arsenal presented five alternative

proposals, differing mainly by the

type of main gun.

‘The first mounted a 75mm short-

barrelled Mz gun with double

counterweights on the muzzle ~ th

counterweights were necessary to

allow the gyrostabiliser to operate

correctly ~ whilst production tanks

were fitted with the Mg version of

the 75mm gun. Although it was

approaching 45 years old, originally

being based on the French canon de

75 modele 1897, and now with much

higher velocity, the 75mm Mg tank

sun was still considered to be the

‘minimum that would be required

to achieve parity with the German

‘medium tanks.

‘The Mg gun remained the

standard fitment for the Sherman

until February 1944 when itstarted

to be replaced by the high-velocity

‘76mm Mi gun, now with a maximum

elevation of 35°, rather than the 25°

of the original M3 weapon. The 76mm,

gun required the use of a new turret,

in order to accommodate the recoil;

this was borrowed from the soon to

(© Mock-up for TS medium tank at Aberdeen Proving Ground...later to become known as

the Ma Sherman.

be cancelled medium tanks T20 and

‘Tag. The Soviet Red Army believed

that this gun made the Sherman more

effective in anti-tank encounters.

‘The second proposal was fitted with

a pair of 37mm M6 guns and one

‘machine gun; option three carried

105mm howitzer, together with

a single machine gun; the fourth

‘was fitted with three o.50in anti-

aircraft machine guns; whilst the

final iteration mounted a British

6-pounder (57mm) high-velocity gun

and a co-axial machine gun

Inall eases, the commander's

cupola from the Mg was retained,

complete with a co-axially mounted

0.g0in machine gun; there were also

three machine guns in the hull glacis

plate, two fixed and one in a rotating

ball mount.

‘The Ordnance Committee

recommended that a fall-size

‘wooden mock-up be produced

and this was completed during the

following month for the approval

of the Armored Force Board. Two

pilot models were then authorised

12 | MILITARY VEHICLES ARCHIVE

© 76 prototype photographed before the muzzle counterwoights were fitted.

“The first, which was constructed at

“Aberdeen Proving Ground, had the

distinctively-rounded cast hull, later

to become known as the M4Ax, and

‘mounted the M2.75mm gun. The

second, which was built by Rock

Island Arsenal, had a hull of welded

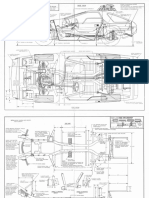

‘& LOADERS HATCH ON SHERMAN IC,

SHOWN IN CHAIN LINE.

construction, but was never fitted

with its designated turret.

‘The'T6 was approved and

standardised as the M4 medium tank

‘on 5 September 1941 and construction

‘of Mg and M4a1 pilot vehicles

tiated in November, with,

4 MOUNTING SHOW ON SHERMAN.

M.36.AL

M

8. ARE FITTEDWIT)

MOUNTING. (See SHEET 4

OVER AMMUNITION

(© Outtine drawing forthe M4,

SHERMAN

production scheduled to start in early

1942. Although this target was never

reached, the US authorities caleulated

that it would be necessary to construct

2000 tanks for every month of 1942.

Inevitably, modifications were

requested to the pilot model before

production was authorised, most

notably the elimination of the side

doors, which improved the ballistic

performance of the hull, and the

deletion of the commander's cupola

and machine gun, which saved a

‘modest amount of height, and, finally,

the removal ofthe two fixed machine

guns in the glacis plate,

tis interesting to note that the

Canadian Army’s Historical Section

claimed in their Report number

73:a survey of army research and

development, 1939-45, published

in 1955, that the Canadian Ram

tank, which was based on the hull

and automotive equipment of the

US Army's Mg, and which was built

at the Montreal Locomotive Works,

provided a prototype for the Mg

Sherman. This is not borne out by

(a ae

nes

=)) es

i

§

4

1g ove aan FENCES RovOED WHEN SANS AR FTTED)

1959

MILITARY VEHICLES ARCHIVE | 13

SHERMAN

‘© cast Sherman turrets atthe Ford Motor Company Highland Park plant. (Ford Motor

Compory)

PT

any other sources, although a Ram

‘was supplied to Aberdeen Proving

Ground for comparative trials against

the Mg... and it must be admitted that

there is some similarity between the

Ram and the Sherman,

Dubbed ‘General Sherman’ or

generally just ‘Sherman’ by the

British, seven basic variants were

eventually produced during the

production

ofthe vehicle,

(© Turret pistol port.

designated M4 through to M4A6,

Note that the numbered designations

do not represent either a logical

sequence of development, nor a

timeline... they are simply a means

of recording changing aspects of the

tank, such as the form of construction

or the power unit. Each variant was

also identified by a simple code by the

British Army, for example the M4A1

was designated Sherman I, the M4A2

was Sherman IIT, and so on.

© Mg or Sherman I: welded hull or

composite welded cast hull, with

‘one-piece cast nose, or three-

piece bolted nose; Wright or

Continental R-975 radial engine;

‘75mm or 105mm gun.

© -M4At or Sherman I: cast hull

with one-piece cast nose, or three-

piece bolted nose; Wright or

Continental R-975 radial engine;

‘75mm or 76mm gun.

© M4Ar: Canadian-built Grizzly;

cast hull with three-piece bolted

nose; Wright or Continental R-975,

radial engine; 75mm gun.

© -M4A2 or Sherman III: welded null

with one-piece cast nose, or three-

piece bolted nose; General Motors

6-71 twin diesel engines; 75mm,

‘76mm or 105mm gun.

© -M4Ag or Sherman IV: welded

bull, with one-piece cast nose;

Ford GAA V8 petrol engine;

75mm, 76mm or 15mm gun,

© M4AgB2: up-armoured welded

hall, with one-piece cast nose;

heavier turret; Ford GAA V8 petrol

engine; 75mm, or 76mm gun.

© M4A4 or Sherman V: welded hull

14 | MILITARY VEHICLES ARCHIVE

SHERMAN

with three-piece bolted nose;

Chrysler A-57 multi-bank petrol

engit ym gun,

‘M4As or Sherman VI: this,

designation was reserved for the

Canadian Ram Mk II tank, but

was never used.

‘M4A6 or Sherman VII: welded.

hull with one-piece cast nose;

Caterpillar RD-1820 radial multi-

fuel diesel engine; 75mm gun.

Engine, transmission and

final drive

‘The chosen power unit for the

prototypes and for the initial

production run was the Wright

R-975 Whirlwind, or its licence-built

equivalent from Continental Motors.

‘The R-975 was a nine-cylinder

air-cooled radial engine producing

40obhp (300kW) gross from

15,945¢¢ (973in’). The engine was

generally considered to be reliable

but had a short life of only around

000 miles (1600km) when excessive

piston-ring wear was said to cause

‘chronic oiling up’

Other power units were also used,

and, at one time, in order to maintain

eet

Pee eae

Fight, the machine gunners seat

een eet

anne

Ce er

MILITARY VEHICLES ARCHIVE | 15

SHERMAN

(© commanders cupola,

Duele

ener

production at a sufficient rate, the

Sherman was being constructed

with engines from Ford, GM Detroit

Diesel, Chrysler and Caterpillar; of

these, only the Ford GAA had been

specifically designed as a tank engine.

In the nose of the tank, coupled by a

Jong propeller shaft, was a five-speed

‘manual gearbox with synchromesh

on all gears except first and reverse,

together with a Cletrac controlled

differential unit that provided the

‘means to steer the vehicle. Final drive

to the tracks was made via 13 teeth

con the front sprockets. The complete

transmission unit was manufactured

by six different companies ~ including

GM Buick, Caterpiller Tractor, Detroit

‘Tank Arsenal, Ford Motor Company,

Towa Transmission Company and

Reed Roller Bit Company.

‘Suspension

Early examples of the M4, M4A1,

M4A2, and M4Ag variants were fitted

with what was deseribed as the vertical

volute-spring suspension system

(VVSS), which used two springs fitted

vertically to each of six bogie units.

Although the WSS suspension was

Spero ROLLER

said to be reliable, it became apparent

that the increases in weight were

starting to have a negative effect on.

the ride, and, from late 1944, the

‘much improved horizontal volute-

spring (HVSS) suspension was fitted,

indicated by the addition of E8 or Y

asa suffix to the basic designation, for

example M4A4E8 or Sherman VY. The

HYSS suspension allowed the use of

wider tracks, reducing the likelihood of

throwing a track, and offering a more

stable ride across country. M44 and

‘M4A6 variants used only the WVSS

suspension,

16 | MILITARY VEHICLES ARCHIVE

pre

ADJUSTING SCREW

towie

DJUSTING SCREW

(© Turret traversing gear.

‘The rear idler sprockets were

adjustable to allow the track tension

to be altered, and three steel rollers

supported the upper run of the track,

Tracks

‘The track pitch of the Sherman was

6in (152mm); short-hulled vehicles,

POWER TRAVERSING

CONTROL HANDLE

PLOT VALVE CAP

RIVE SHAFT

‘COUPLING

RAPD 141

were fited with 79 shoes, whilst

the longer hulls had 83, Some of

the Canadian M4As Grizzlies had

a shorter track pitch that required

special drive sprocket. As regards

the track shoes themselves, a variety

of patterns were fitted during

the production life ofthe vel

SHERMAN

including smooth rubber, rubber

chevron, steel parallel bar, and steel

chevron types, with both dry and

rubber-bushed pins employed.

Main guns

Four different main guns were

‘mounted in the Sherman during its

first five years of lif; see also table

(on page 23 for details of authorised

ammunition rounds.

First came the short-barrelled

‘75mm Mz which was carried in

mount Mgq or M341, and was fitted

with twin counterweights at the

‘muzzle end of the barrel. The barrel

Jength was 91.75in (2330mm), which

givesa length-to-calibre figure of gia

(L/31.1). This gun was fitted to just

the first two M4As tanks to come out

of the Lima Locomotive Works and

‘was considered to be a temporary

measure whilst work on the 75mm

‘Mg was completed.

‘Next was the 75mm Mg, the barrel

fon which measured up at 118.38in

(Goo7mm), giving length-to-calibre

value of 40.1 (1/4021), and which

dispensed with the counterweights. The

same M4 or M3441 mount was used.

By late 1942, it was obvious that

the 75mm gun was not sufficiently

powerful to take on the heavier German

tanks and that the Sherman needed a

new main gun. Accordingly, from late

1943, the 75mm Mg was replaced by

the 76mm Ma gun, firstly with a barrel

Jength of 163,75in (4159mm) givinga

Jength-to-calibre figure of L/57. The

Darrel was soon reduced in length to

148:75in (778mm) giving a length-to-

calibre of L/52; versions were produced

Doth with and without a muzzle brake

counterweight, Ithad been hoped that

allofthe 75mm Shermans could be

replaced by those mounting the new

‘76mm gun but, unfortunately, there

‘were never sufficient 76mm guns

available,

‘The 7mm gun offered

improvements in range and

penetrating power, but the Sherman

‘was still ata disadvantage when

compared to the heavier German

tanks and, in January 1943, it was

decided that a Sherman that carried a

British 17-pounder (gin, 76mm) high-

MILITARY VEHICLES ARCHIVE | 17

18 | MILITARY VEHICLES ARCHIVE

SHERMAN

the Tank took a hint from

fer

MILITARY VEHICLES ARCHIVE | 19

SHERMAN

۩ The use of bolted-on grousers increased the width of the Sherman's rather narrow

tracks and thus reduced the ground pressure,

velocity gun would be a formidable

‘weapon. Based on an existing anti-

tank weapon, the 17-pounder had a

barrel length of 165in (4191mm) and a

length-to-calibre figure of L/55.

twas not easy to make sufficient

space for the gun in the turret but, with

the barrel rotated through 90° so that

the breech was side loaded, the recoil

‘mechanism modified, and the radio

‘moved into an armoured box outside

the turret, it was shown to be possible.

Dubbed Firefly ~ although some

evidence from the period suggests that

twas originally called Mayfly ~ the

British Tank Board requested that

some 2100 Shermans be converted to

the Firefly configuration, Work started,

in December 1943, with about 700

available by late July 1944. A total of

somewhere between 2100 and 2350

examples were converted, with the last

example delivered in May 1945.

‘The fourth Sherman main gun

was the 105mm Mq howitzer, a

‘modification of the gun fitted to

the towed M2A1 howitzer. Trials

had started in November 1942

using a short-barrelled weapon, but

production was not put in hand until

1944. The barrel length was 1o1in

(2565mm), giving a length-to-calibre

value of L/24.5.

Communications equipment

Radio equipment in the Mg series

consisted of US Signal Corps SCR-

508, SCR-528, SCR-538 or SCR-

608B FM sets, or the AM AN/VRC-:

command tanks were fitted with SCI

506, SCR-245 or SCR-193 radios.

British and Canadian Army tanks

were equipped with Number 19 or

‘Number 29 sets.

Production

‘Mass production started at Lima

Locomotive Works in February 1942,

with the Pressed Steel Car Company

coming on stream a month or so later.

‘The first examples to be produced

were actually of the cast-hull M4At

configuration.

Since the M3 75mm gun was not

ready for production immediately, the

first two tanks produced retained the

short-barrelled Mz gun. One of these

tanks was shipped to Britain where

it was named ‘Michael’ in honour of

Michael Dewar, head of the British

‘Tank Mission, and in November 1942,

‘was put on display at Horse Guards

Parade. The other, still wearing the

British census number T-25189,

‘was taken over by the US Ordnance

Department for testing.

20 | MILITARY VEHICLES ARCHIVE

SHERMAN

COU

By the time production of the Mg Canadian company, as follows: and M4A2; total production, 1245

came to an end, ten US manufacturers @ American Locomotive Company; examples

had been involved, representing Mg and MqA2; total production, Chrysler Detroit Tank Arsenal;

‘virtually all of the major automotive 2300 examples M4, M4Ag, M4A4 and M4At

companies, together with one © Baldwin Locomotive Wo total produetion, 17,947 examples

MILITARY VEHICLES ARCHIVE | 21

SHERMAN

«© British Army training booklet covering the Sherman

© Federal Machine & Welder;

‘MaA2; total production, 540

examples

© Ford Motor Company; M4a3;

total production, 1690 examples

© GM Fisher Tank Arsenal (Grand

Blanc); M4A2 and M4Ag; total

production, 11,358 examples

¢ Lima Locomotive Works; M41:

total production, 1655 examples

‘© Montreal Locomotive Works;

M4As; total production, 188

examples

maments systern,

© Pacific Car & Foundry; Maas;

total production, 926 examples

© Pressed Steel Car Company;

‘M4, MaAt and MqA2; total

production, 8147 examples

© Pullman-Standard Car Company;

‘Mg and M42; total production,

3426 examples

Between them, these companies

produced a total of 49,422 Shermans

uring five years of production and a

total of 88,410 tanks altogether. By

contrast, Britain manufactured some

27,019 tanks between July 1939 and

May 1945, whilst tank produetion in

Germany, between the years 1940

and 1945, totalled just 22,050 units.

In Japan, the total number of tanks

produced between between 1931 and

1945 was 6450.

I’salso worth mentioning that

Chrysler Detroit Tank Arsenal and the

GM Fisher Tank Arsenal, who, with

respective totals of 17,947 and 11,358

tanks, were not only responsible for

the bulk of Mq production, but were

also labouring against the inevitable

difficulties of working in brand-new

purpose-built manufacturing facilities.

And, what is more, the changeover

from the Mg to the M4 at the Chrysler

Detroit Tank Arsenal was made during

a period when the facility was also

being expanded by some 50%.

Refurbishment

Chrysler, Federal Machine & Welder

and GM Fisher Tank Arsenal were

all involved in the refurbishment of a

total of some 2145 early production

Shermans which were either shipped

to Britain under the Lend-Lease

arrangements or were allocated to

the foreign aid programme. Others

involved in the refurbishment work,

covering a total of 5880 tanks, were

International Harvester and the

Montreal Locomotive Works, as well

as the Chester, Evansville, Lima and

Richmond Tank Depots.

‘The refurbishment work involved

stripping the tank as far as was feasibly

possible, before rebuilding with new or

refurbished components as necessary;

late production features were also

incorporated wherever possible.

‘THE POST-WAR YEARS

‘Many Shermans remained in service

‘well into the post-war years with

European and Middle Eastern

nations. At the same time, there is

scarcely a military museum worthy of

‘the name that doesn’t have a Sherman

on display... there are also many

in private hands, and dozens have

been retained as memorials around.

‘the world, meaning that, today, the

Sherman has become something of a

classic amongst tank aficionados,

22 | MILITARY VEHICLES ARCHIVE

SHERMAN

CCT See UTC

Type of round CE

ees eent esis) 5 :

(neta eene reset eee eer) 5

oaetas entree Ren nea con 5

‘Armour-piercing discarding sabot (APDS)

antes ene Poe eee

oneMas ene meaner a ca)

Pr

eal

eee)

Pees tcesal

Hyper-velocity armour piercing (HVAP) a

Hyper-velocity armour piercing, with tracer (HVAP-T)

eee ee ae ee eee Renee ace)

teens

reece o

reer sie It)

‘Smoke, coloured (green, red, violet, yellow)

Seen eee ental

‘Smoke, sulphur trioxide in chlorosulphonic acid (FS)

Eames eno)

See ee oes)

Seen et tee tue)

STU TCO a a

Reet Pete

7 Maat fae ae Pee

Penne nee ed

ror pm S ey

Peete)

rr rs

Creer coo 40173039) mer)

cee

eee ores

ere 1690)

care z eee

Lima Locomotive Works 1655

Montreal Locomotive Works mv

eee Ea

eee tena Ered

Peers)

eae

ee Cr ee ee ed

Grand total of M4 Sherman production: USA, 49,234; Canada, 168

MILITARY VEHICLES ARCHIVE | 23

RU RU eee a ie

PTC U a!

Me Sere atc)

Production of the first variant in the M4 family - the welded-steel hulled ‘Sherman I, as it was

designated by the British Army - was started at the Pressed Steel Car Company in July 1942, a

month or so after production of the M4Al had been initiated at the Lima Locomotive Works.

Pressed Steel went on to construct a total of 1000 examples, but the M4- was also produced

by American Locomotive, who manufactured 2150 vehicles, as well as by Baldwin Locomotive

(1233), Chrysler Detroit Tank Arsenal (3317), and Pullman-Standard (689). Production was

considered to be complete by 1944, with the Detroit Tank Arsenal being the last plant to

manufacture the M4.

«© Restored welded-hull 44 showing some battle damage on the front left-hand quarter, (Simon Thomson)

the M4 and the M4A differed _variants. Unfortunately, there were

only in the form of construction _ few foundries in the USA capable of

used for the upper hull: where casting items as large as tank hulls

the Mg was of mixed cast, and so it was hoped that the adoption

and welded construction, the hull ‘of welded construction would both

of the M4A1 was exclusively cast. speed-up the manufacturing process

Other than this, there was very and reduce bottlenecks in produetion,

litte difference between the two This method of construction also had.

the added advantage of increasing

internal space in the hull, thus

allowing stowage for 97 rounds of.

75mm ammunition, compared to the

90 rounds carried by the M41 with

its east upper hull

‘The hull of the Mg was thoroughly

conventional, and was divided

24 | MILITARY VEHICLES ARCHIVE

(© This s one ofa series of cards issued by the US Army during WW2 describing various items of military equipment.

(© Nose-on view of the welded-hull M4, inthis instance in service with the British Army;

note how the triangles painted onta either side of the turret appear to change its shape.

into three separate spaces: the

driving compartment, the fighting,

compartment, which included the

turret, and the engine compartment.

‘The upper parts were formed from

rolled homogenous steel, welded

together to provide a protective

fighting compartment box that was

2in (5omm) thick to the front, and

Yin (8mm) tothe sides. Where the

‘Mg had often been erewed by six men,

the M4 was designed to be manned by

five men, consisting of commander,

gunner, loader, driver, and co-driver/

‘machine-gunner. Folding and rotating

upholstered seats were provided for

the crew members, the driver's and co-

driver's seats being height adjustable.

‘The nose of the lower hull was of

cast steel, and originally consisted of

three separate pieces bolted together.

Late production versions from the

Chrysler Detroit Tank Arsenal had

ther a one-piece nose, which was

apparently nicknamed Mary Ann

~ it seems that some love-starved

production-line personnel thought

that the castings had a slightly

MILITARY VEHICLES ARCHIVE | 25

.© View down into the engine compartment showing the Wright/Continental radial.

feminine shape — or else had a

composite rolled/cast nose. On this

latter version, which was described as

the ‘Sherman 1 hybrid’ by the British,

the cast section extended from the

differential housing to the forward

edge of the turret ring,

‘Access to the hull was made via.

twin hatch doors in the turret, or by

‘means of twin hatches in the glacis

plate; there was also an escape hatch

in the floor. The engine was accessed

‘via twin side-hung doors at the rear or

by using the large hatch in the upper

rear deck.

‘As regards ammunition for the

‘main gun, some 97 rounds were

stored inside the hull, with many

in racks placed against the interior

surfaces of the side sponsons,

and under the turret basket floor.

Unfortunately, battle experience

subsequently showed that the

ammunition stored in these racks

was liable to ignite if the armour was

penetrated, sometimes sufficiently

violently for the turret to be lifted

lear of the hull. In an effort to

get over this problem, Sherman

variants produced after 1944 stored

the ammunition in liquid-protected

racks. The M4 retained the dry

storage racks but had plates of

supplementary appliqué armour,

in (25mm) thick, welded in an

appropriate position on the outside

of the hull, and later to the front-

facing areas of the turret. Additional

armour was also welded to the front

of the driver's hood. These armour

patches were incorporated into

production as well as being applied

retrospectively to tanks that were

already in service.

‘The turret, which was identical to

that fitted to the MgA1, was also of

cast-steel construction and offered a

‘maximum thickness of gin (75mm)

to the front, and 2in (50mm) to the

sides and the rear. Periscopes were

provided for both the driver and

the commander. Regardless of the

main gun, the turret was fitted with

hydraulic traversing gear with a

back-up manual system; the original

traversing gear, which was well-

liked for its smooth operation, was

supplied by the Oilgear Company,

‘but the pressures of production

eventually saw Logansport and

Westinghouse becoming involved,

‘with traversing gear from the latter

operated electrically

26 | MILITARY VEHICLES ARCHIVE

ra eoMiNtiew mat

oe eae

of Le era

Fe oa oo aad

CORI es

? Exivaus

Seeieg Eo rue ee

Ma oo ey

ORDER.1-3-5-7-9

isey lee

pa

Power was provided by a rear-

‘mounted Whirlwind R975 air-cooled

nine-eylinder four-stroke radial

engine, originally designed for use

in aircraft; the engine was de-rated

for this application, producing

4oobhp (gookW) gross from 15,945¢¢

(o7in®). Early production tanks used

the EC2 version of the power unit,

constructed by Wright Aeronautical

of Patterson, New Jersey, but this

was subsequently superseded by the

C1 version produced by Continental

‘Motors based in Muskegon, Michigan.

‘The engine, which was both tall and

narrow, was tilted to reduce the

apparent height as far as possible, and

‘occupied the space behind the fighting

compartment, from which it was

separated by a fire-proof bulkhead. A

long propeller shaft, running under

the floor, connected the engine toa

{© One of 1641 examples of the Mé fitted with the loSmm howitzer; designated Sherman 18 dry twin-plate clutch, together with

(or IBY by the British Army; the latter also fitted with HVSS suspension. (US Signal Cores) five-speed manually-shifted gearbox,

MILITARY VEHICLES ARCHIVE | 27

eet pment - De eee

the latter built by Mack Motors. The drive the front sprockets. vas installed in the rear of the hull,

differential unit was bolted inside the A Homelite Model HRUH-28, producing 50h at goV (1500W).

nose casting, and was arranged to petrol-engined auxiliary generator This generator was designed to keep

28 | MILITARY VEHICLES ARCHIVE

(© Restored M4 with a coating of artificial snow in homage to the Battle ofthe Bulge.

MILITARY VEHICLES ARCHIVE | 29

‘© Although the standard Sherman crew was five men, the tank could also be operated

without the co-drver.

the batteries charged whilst the main

engine was not running, as well as

supplementing the engine-driven

generator when necessary.

Most M4 variants were fitted with

the original vertical volute-spring

suspension system (VWSS) that

had been carried over from the Mg

‘medium tank, with 12 wheels in six

bogies, each having a track return

roller. This was redesigned in mid-

1942 with rear-mounted track-return

rollers to reduce the incidence of

spring failure, and, atthe same time,

the diameter of the volute springs

‘was increased from 7in (78mm) to

8in (20gmm). The new suspension

‘was fitted to tanks from January 1943

the more effective heavier-duty

horizontal volute-spring suspension

system (HVSS) was fitted to the final

‘841 examples of the 105mm gun-

equipped Mq variant. Track pitch was

6in (152mm), with a total of 158 shoes

giving a contact length measured on

the ground of 147in (3734mm). The

track itself was either of chevron or

parallel-bar steel construction, or

of steel construction, with rubber

chevron inserts,

‘The main gun was the 75mm

medium-velocity M3 with a

‘maximum firing rate of 20 rounds a

minute, and designed to be manually

loaded. The gun was initially carried

in the M34 mount, with a maximum.

gun shield thickness of 3¥ain

(8mm), but later, the modified

‘Mgqa1 mount was used which had

a wider mantlet to protect both the

telescope on one side of the main

gun, and the .30 calibre machine gun

on the other. Both direct and indirect

sighting systems were fitted,

‘The later 76mm gun that appeared

on subsequent Shermans was never

fitted to the M4, and anyway was

considered by some to be of dubious

value. However, from 1943 on, a

total of 1641 examples of the M4, all

of them constructed by the Chrysler

Detroit Tank Arsenal, were equipped

with the 105mm Mq howitzer in

mount Mg4 or M34as, the latter with

widened mantlet. The gun used

separate bagged charges and had a

‘maximum firing rate of three rounds

a minute, but there was no powered

traverse for the turret. These M4

105mm tanks were designated as

Sherman IB and IBY by the British,

the later with the HVSS suspension.

Production

By the time production of the M4

variant ended in January 1944,

the total number of M4 Shermans

produced amounted to 6748 examples,

with the 75mm gun, of which

somewhere around 1600 were of the

composite type with the rolled/cast

nose; 1641 examples were fitted with,

the 105mm howitzer.

SEE RR Te OTM TE Ra Uta

Pees er

fee

ian

[7s a

ieee

Peri!

eee

Eee

fee

ia)

r=)

rere

Ma with

een eae

5

Speen cd

30 | MILITARY VEHICLES ARCHIVE

Sab TAF

Manufacturer: American Locomotive, Schenectady, New York; Baldwin Locomotive, Eddystone,

eeu eu a eee CU eee eae eee kena ee

FeuneyVeaed neues ee Kec iaken ee Iet

erect

Total number produced: 6748.

renee ees

Engine: Wright R975-EC2, or Continental R975-Ci; 15 94Scc (973in}); nine-cylinder radial, air-cooled,

bore and stroke, 127x140mm; 80 octane petrol; compression ratio, 5:7:}; overhead valves; power

enter steele saree ated

Seems enweals Meee

eee Reset ct eee ee teen SS

examples, horizontal volute-spring suspension (HVS).

Sere ana ene Messen eee

sarees

eid

SO rene a ee ce OD

(13-25mm).

Turret: gun shield, 33in (89mm); rotor shield, 2in (Simm); front, 3in (76mm); sides, 2in (Simm); rear,

Pane eer mA =a

Appliqué armour patches, in (25mm) thick, were welded to the sides of the hull, adjacent to the fuel

pee ne eae aa eases

oe)

Rene ees ee

Eyes ny

Length, 232in (5893mm); width, 103in (2616mm); height, over turret hatch, 108in (2743mm),

presario}

Weight: unstowed, 62,800 lb (28,545kg); combat ready, 66,900 Ib (31,545ka).

Pensa ean)

Length, 244in (618mm); width, 105in (267mm); height, over cupola, Niéin (2546mm).

Grea ame

Ieee aeRO CE ees

The apparent increase in length for those tanks that were equipped with the 105mm gun was simply

Dene een Cur eRe cae ene eee

versus 10lin (2565mm) for the 105mm, resulting in a front overhang._

cen)

Pesaran an ee See ee SS

Rein een aon

enka eect)

Ren et etd

Ninian aia eee

MILITARY VEHICLES ARCHIVE | 31

M4Al

September 1941, and Lima Locomotive Works

TRC RUT Stl)

Production of the cast-hull M4AI, known by the British Army as the Sherman Il, started

in February 1942 at the Lima Locomotive Works in Lima, Ohio. Initially, the company was

contracted to the British Ministry of Supply under direct ‘cash-and-carry’ rules, but all

subsequent contracts for British Army Shermans were made under the US Lend-Lease Act

which had been signed into law in March 1941.

{© The distinctive shape of the hul ofthe Mal is easly recognised: note the side-mounted doors on ths ealy production vehicle which

were almost immediately eliminated,

the first two tanks built by Lima

‘were considered to be pilot

models and used the early T6

upper hull casting with the side

access apertures welded up, and had

spoked road wheels, carried over

from the Mg. Forall subsequent

production, the road wheels were

solid dises, the side doors were

eliminated altogether, modifications

were made to the gun rotor shield,

and changes were made to improve

ventilation, particularly to clear gun

fumes from the interior.

Unfortunately, although the first

‘two tanks were completed during

September 1941, the chosen M3

‘75mm gun was not available at this

time, which meant that these two

tanks retained the short-barrelled

‘Mz gun that had been used on early

"To mock-ups. This gun can be easily

identified by the counterweight

clamped around the muzzle,

Additional armaments included two

in Browning machine guns in

the lower front area of the hull, one

32 | MILITARY VEHICLES ARCHIVE

‘© Production Mal from which the side doors have been eliminated

(© 6A in action, (US Signal Corps)

M4Al

cof which was eliminated in March

1942. The 75mm Mz was quickly

superseded by the 75mm M3 gun,

and then, in 1944, this was replaced

by the high-velocity 76mm Mi gun

in a larger, improved turret that had

an integral counterweight. When

equipped with the 76mm gun, the

‘MaA1 was identified as the Sherman

IIA by the British,

But, back to September 1941... the

first production M4A1 was retained in

the USA for testing purposes, and the

second was shipped to Britain where

twas put on display’on a plinth in

Horse Guards Parade, as the first

American-built tank to be delivered

to the British Army. Assigned the War

Office registration number T25190

(ater renumbered T74195), this

first tank was named ‘Michael’, in

honour of Michael Dewar, a British

industrialist who had led the mission

to have tanks constructed in the

MILITARY VEHICLES ARCHIVE | 33

M4Al

(© uly 1964, and an MAA passes a knocked-out German Panzer Mk V on the road near Ponsacco, Pisa, (US Signal Corps)

34 | MILITARY VEHICLES ARCHIVE

4d withthe T28 turret and 7émm main gun. (Simon Thomson)

Army. The Prime

Minister, Winston Churchill, was

photographed inspecting the tank on

Horse Guards Parade, even climbing

inside, albeit with some difficulty.

Nevertheless, he was sufficiently

impressed to have said to Roosevelt

about a month later... “Give us as

‘many Sherman tanks as you can

spare, and ship them to the Middle

Bast as quickly as possible. And,

indeed, the first Shermans arrived

in Egypt in September 1942, going

into combat for the first time against

German armour at the Second Battle

of El Alamein on 23 October.

‘The Lima Locomotive Works

continued production of the M4Ax

until September 1943 by which time

the company had built 1655 tanks,

and had refurbished a further 60.

In March 1942, the Pressed Steel

Car Company was second on the

ist of manufacturers of the Maas,

eventually producing a total of 8147

tanks at its Pittsburgh works. Finally,

€ Underside view of the MAA Sherman asit crests rce..a perfect shot atthe in June 1942, produetion was started

Sherman's least well protected area atthe Pacific Car & Foundry works in

MILITARY VEHICLES ARCHIVE | 35

M4Al

‘© 6281 Firefly atthe South African National Museum of Miltary History in Johannesburg.

Renton, Washington, where a total of

(926 examples were built.

Regardless of the manufacturer, the

upper areas of the M4A1 consisted

of a massive, one-piece casting with

a distinctive rounded ‘turtle’ shape,

which some users (wrongly) came

sco 8

to believe was ballistically inferior

to the welded ull. Late production,

hulls were modified to increase the

size of the driver's escape hatch, but

the upper hull is the only significant

area of difference between the Mg

and the M4A1. Despite the differences

eae

in construction, the hulls of cast and

‘welded Shermans offered the same

levels of protection, and were equally

‘vulnerable to the guns of the heavier

German tanks.

‘The lower hulls of M4Ais produced

by Lima and Pacific Car & Foundry

36 | MILITARY VEHICLES ARCHIVE

M4Al

(© Based on the Sin M7 gun of the MO tank destroyer, late production examples of the 7émm gun were fitted with @ muzzle break to

Ceflect bias to the sides and the rear, thus reducing the recoil. (Simon Thamson)

(© tes lfficul to tell what is going on here, but the crew ofthis M4Al 7mm saemn to be carving out an equipment check. (US Signal Corns)

MILITARY VEHICLES ARCHIVE | 37

M4Al

‘© 61481 76mm produced by the Pressed Steel Car Company; note the one-piece cast nose. The photograph is dated May 1944,

were of welded construction, whilst

those produced by the Pressed Steel

Car Company before the Spring of

1943 were riveted,

Like that of the Mq, the hull of the

‘M4A1 was designed to accommodate

a crew of five, consisting of

commander, gunner, loader, driver,

and co-driver/machine gunner, and

‘was divided into three spaces: the

driving compartment, the fighting

compartment, which included the

turret, and the engine compartment;

the engine compartment was

separated by a steel firewall. The

engine and the other automotive

equipment was the same as had been

used in the M4. For example, the

rear-mounted Wright or Continental

R975 nine-cylinder radial was

identical, and there was the same type

of five-speed transmission, coupled

to the differential, and driving the

front sprockets. In 1943, in response

38 | MILITARY VEHICLES ARCHIVE

(© 6A with three-piece cast nose.

to shortages of the original power

unit, the US Ordnance Department

produced what was designated the

‘MaE7 by trial-fitting a Ford GAA

petrol engine into an M4As hull

Regardless of whether or not the

conversion was a success, there was

no further production.

Originally, the suspension and track

design also followed the same lines

as that fitted to the M4. However,

in March 1944, the US Ordnance

Committee approved the use of a

new, more durable horizontal volute-

spring suspension system (HVSS)

that gave a better ride, was less prone

to bogging down in mud or sand, and

inimised the possibility of throwing

a track. M4A1 tanks that were fitted

with the new suspension, together

with wide tracks designed to improve

mobility, were identified as M4A1E8

(or Sherman IIAY).

‘The original 75mm gun was fitted

with a gyrostabiliser operating in the

levation mode, and the US Army's

standard armour-piercing capped

(APC) rounds could penetrate 27sin

(68mm) of armour ata distance of

1640ft (500m), reducing to 2¥sin

(Gomm) at 328oft (1000m). Other

standard rounds included white

phosphorus (WP), high explosive

(HIE), and smoke. The maximum

rate of fire was caleulated to be 20

rounds a minute, but this was rarely

achieved. The 76mm gun, together

‘with the larger T2g turret, started to

appear on new tanks in the summer of

1944. Rounds available included high-

explosive, armour-piercing capped,

tracer (APC-T), and high-velocity

‘armour-piereing, tracer (HVAP-T),

the latter, capable of piercing 6in

(150mm) of armour at 3280ft

(000m), was apparently saved for

‘Tigers and Panthers,

‘As regards performance, the

M4A1 had a top speed of 21-24mph

(34-39km/h), which was directly

comparable to the Panzer III and the

subsequent Panzer IV. Of course,

in tank warfare, speed is only rarely

significant, and the Sherman's great

advantage was that it was available in

far larger numbers than the Panzer

and was probably more reliable. But,

make no mistake, it was generally,

Doth out-gunned and out-armoured.

Tn 1944, in an attempt at

improving the Sherman's armour-

piercing capabilities, somewhere

around 2250 tanks, not all of them

MaAts, were retro-fitted with the

(British) Ordnance quick-firing

high-velocity 17-pounder (gin,

76.2mm) gun and were dubbed

“Firefly. Unfortunately, although

the Firefly has been described as

‘the only tank worth having in

Normandy’, the armour was not

improved which meant that a Firefly

had a chance of taking out a German

tank at a distance, but it was no

better equipped for closer tank-on-

MILITARY VEHICLES ARCHIVE | 39

M4Al

(@ 64018-based MSI Super Sherman of the Israeli Defence Force; the main gun isa French 105mm weapon. (Simon Thomson)

tank action. Those tanks that were 75mm gun, and 3426 with the 76mm

converted from M4A1 Sherman I weapon (although some sources

configuration, were identified by the __ suggest that this latter figure should

British as Sherman IIC Firefly. bbe 3396). A further 188 examples

of what was, effectively, the M4,

Production using the same hull design as that

By the time production ended in produced by Pressed Steel, were

December 1943, the total number _uilt by the Montreal Locomoti

of M4A1 tanks produced was 9707. Works in Canada, starting in August

Ofthese, 6281 were armed with the 1943 under the name Grizzly; the

programme was terminated in mid-

January 1944.

‘The second tank off the Lima

production line, ‘Michael, has,

survived to this day and, although the

‘Mz gun was subsequently replaced

by the standard Mg, this is the oldest

Sherman tank still in existence. It

can be seen at The Tank Museum in

Bovington, Dorset.

See Rae Te eS [eas

oN

rn

aN

ano

Creer oan eee teeny

ec

eee te ener

ray Breet ay Re ote cee ca

dopte

eee eae

40 | MILITARY VEHICLES ARCHIVE

SEEN Ra TTB YY

Manufacturers: Lima Locomotive Works, Lima, Ohio; Pacific Car & Foundry, Renton, Washington; Pressed Stee!

ee eee ee

feete emer

ponte eee

enero

FSR ree ce Reems eee ea eo ee ge eee ee)

Bence ea eat ote eat eed

460bhp (345kW) gross, 350bhp (261kW) or 400bhp (SOOkW) net.

eee es

Sree ee eee ee

rete eee eects eset ease eo}

Perea ene ee iee

Errata

ron

FETE aa ana eM NE ate Ma oe LE AE

Turret: gun shield, 3in (76mm); rotor shield, 2in (Simm); front, Sin (7émm); sides, 2in (Simm); rear, 2in (Simm); top,

vest

in 1944, appliqué armour patches, lin (25mm) thick, were welded to the front corners of the turret to compensate

Cee Nae tae caer ee ne SR Coe en ee eee

Peas aee ee Ree eee ee aaa nee

nee

Peete eee ee ee ema)

ee eee eee

eee a eee a ieee en eae ee oe ee see cee ae D

Seen aed

eee ee Se a ee

Track width: (WWSS system) 16¥ain (42imm); (HVSS system) 23in (584mm).

Weight: unstowed, 62,700 Ib (28,500kg); combat ready, 66,801 Ib (50,364ka).

eee eae Ty

Pee Nes NS ea

Sree ee

er nen Mee NSE ce ne TEC)

Shee etna ee ee oe Ce ae ern?

Sena een ioe ae eae eo

the 76mm, resulting in a considerable front overhang.

ones

(ease Meee at ee ene

estate ence nea!

ent enon

fen en aad

Pinan eet)

MILITARY VEHICLES ARCHIVE | 41

M4A2

Design work on the third Sherman variant, the M4A2, or Sherman Ill to the British Army, started

in late 1941, with a pilot model available by April of the following year. Like the base model M4 -

which, it is worth mentioning, did not actually enter production until July 1942 - the M4A2 had a

hull of welded construction. In fact, it was the first US-designed tank to go into production that

was fabricated by welding rolled-steel plate.

‘© 61402, one of just 540 examples produced by Federal Machine & Welder; note the sand skirts.

‘owever, don’t imagine that

‘the ‘Aa’ sufix indicated that

this was, in any sense, a better

Sherman than its predecessors.

‘A shortage of Wright and Continental

radial engines meant that this was

essentially the same tank, but now

fitted witha pair of liquid-cooled

two-stroke diesel truck engines.

‘This allowed production lines to be

established at additional sites giving

a useful increase in the numbers of,

tanks able to be produced.

Production started in April 1942,

the same month that the pilot model

was completed, with construction

initially taking place at both the

newly-built GM Fisher Body Tank

Plant in Grand Blane, Michigan,

and at the Pullman-Standard Car

Manufacturing Company in Chicago.

‘The first M4A2 to come off the

production line at GM Fisher was

handed over to Aberdeen Proving

Ground for trials, where it was

eventually declared that there were

no downsides to the change of engine,

and that the diesel-engined M4A2

‘was ‘at Ieast as reliable’ as the radial-

engined Mq and M4Ax, whilst, at

the same time, it was slightly more

powerful. A dozen early producti

vehicles were subsequently evaluated

42 | MILITARY VEHICLES ARCHIVE

€@ ‘The naming of parts. line drawing taken from a British Army raining pamphlet dated 1945.1 Revolving turret hatch, 2 Turret seat,

3 Gunner's seat, 4 Commander's and loader’s seats, 5 Engine oll fiter, 6 Water header tank, 7 Air cleaners, & Radiator, 9 Water drain

tap control, 10 ler wheel, N! Water pump, 12Oil cooler, IS Air blower, V4 Starter motor, Is Transfer gear case, 16 Generator, 17 Clutch

idle lover and lockout assembly, 18 Clutch pedal, 19 Accelerator, 20 Gearbox, 21 Track-driving sprocket, 22 Steering levers, 23 Driver's

and hull gunners seats

MILITARY VEHICLES ARCHIVE | 43

1 Factory-fresh Detroit Diesel 6-71 diesel engine. Between them the two engines could produce 4IObhp (SO6KW) from a total of.

13962 (852in), (Generar Motors)

‘© Another view of the Federal Machine & Welder M&A2.

by the US Army 5" Armored Division

under the auspices of the Desert

Warfare Board, and a further six

vehicles were subjected to the same

series of trials in February 1943,

Despite the use of larger air cleaners

con these later vehicles, the diesel

engines proved to be sensitive to dust

resulting in reports of poor reliability.

‘The major difference between the

MqAz and what had gone before, lay

simply in the choice of power plant,

with the Wright radial engine of

the Mg and MqA1 variants replaced

by twin GM Detroit Diesel 6046D

supercharged two-stroke diesel

engines, with a maximum power

output of 4zobhp (306KW) from

a total of 13,962c¢ (853in’). Each

engine had its own clutch, although

both were controlled by a single

pedal, and the output shafts from

the clutches were coupled together

via a system of helical gears before

‘being connected via a propeller shaft

to the transmission, With somewhat

reduced performance, it was possible

to run the tank on just one engine by

locking out one of the clutches using a

control on the hand throttle bracket.

‘When compared to the M4A1,

any other differences were largely

confined to the hull. Like the original

‘Mg, the upper areas of the hull were

fabricated from a mix of rolled-steel

plate and steel castings, giving ita

distinctive ‘cheese box’ outline and

providing a little more interior space

than the M4Au, The nose of the lower

44 | MILITARY VEHICLES ARCHIVE

‘© Production line for the Detroit Diesel 6-7. (General Motors)

hull, which contained the differential,

originally consisted of three major

assemblies that were bolted together,

Dut in early 1944, this was superseded

by a one-piece casting which greatly

improved ballistie performance.

Very early vehicles had spoked road

wheels, although these were soon

superseded by solid dise wheels, and,

similarly, pilot and early production

‘models had the track-return rollers

‘mounted on top of the road-wheel

bogies. Following criticism of this

arrangement, this was quickly

superseded by the heavy-duty vertical

‘volute-spring suspension (VVSS)

system where the return rollers were

mounted on the trailing edge of the

bogie. As with M4A1 variant, later

models (M4A2E8, or Sherman IITAY)

‘were fitted with the horizontal volute-

spring suspension system (HVSS).

‘Small modifications were made to

the hull during the produetion life

of the vehicle. For example, during

1943, GM Fisher made small changes

to the varions cast components that

‘were welded to the glacis plate,

including the driver's hoods, and the

bow machine-gun port. An additional

escape hatch was incorporated into

the turret in December 1943, allowing

easier, or pethaps quicker, access

by the loader who no longer would

M4A2

have to wait for both the gunner and

the commander to exit before him.

Aretrofit kit was made available to

allow existing tanks to be modified. At

much the same time tanks built by the

GM Fisher were fitted with enlarged

driver’s hatches.

‘The original main gun for the

‘MaA2 was the 75mm M3, a low-

velocity gun that was capable of fring

various types of armour-piercing,

high-explosive and phosphorous

rounds at a maximum rate of 20

rounds a minute. In late 1943, the

original gun was replaced by the

improved 7omm M1 gun, firing

similar types of round, and mounted

MILITARY VEHICLES ARCHIVE | 45

NS OF TEETH

r

SHERMAN

TRANSFER RATIO,

CRANKSHAFT TO

DRIVESHAFT, 1137

25038",

99"

13.

I

tm.

ENGINE & TRANSMISSION,

{© Layout of the engines and transmission,

in a new turret designated T80. The

‘76mm gun was subsequently fitted

‘with a muzzle brake which saw the

designation change to M1AiC. Due to

difficulties with the mount, the new

gun was not accepted for service until

duly 1944.

‘The Sherman was easily penetrated

by nearly all ofthe Wehrmacht’s anti-

tank weapons, including the hand-

held Panzerfaust, and was no better

suited to tank-on-tank combat with

the Wehrmacht’ finest. However,

‘one area where the Sherman did

exhibit advantage over the German

opposition, particularly in Normandy

where the fighting tended to be at

lose range, was in its mechanical

simplicity and reliability, as well as

the speed at which the turret could

be traversed which often left, saya

Panther, struggling to find the target

“whilst the Sherman could get off

several shots during the same time.

Production

‘The lion's share of M4A2 production

came from the GM Fisher plant,

with a total of 7508; Pullman-

Standard were responsible for

46 | MILITARY VEHICLES ARCHIVE

M4A2

(© 61402 taking part ina victory parade. ‘© M482 Kangaroo photographed in Caen in 1944, (Library and

Archives of Canada)

—d eae POET ee

(© 61402 Kangaroa

MILITARY VEHICLES ARCHIVE | 47

‘Whom ordering further copies please quote AFVP/VP/3.

(SuperedesAFVP/VP/1),

SHERMAN III

VEHICLE TRAINING PAMPHLET

Without projudice to any Wer Office publication om this subject

tehich may be issued.

Produced, Published and Issued by

ABV, Publications Section,

AED. School,

Botingtin: Camp,

Dorset.

a further 2737 examples. The

‘M4Az subsequently also went into

production at four more plants:

American Locomotive, who built

150; Baldwin Locomotive, who built

19; Federal Machine & Welder, with

a total of 540; and Pressed Steel

who were responsible for 21,

‘The grand total of MqA2

production was 10,968, all of them

constructed between April 1942 and

May 1945. A total of 8053 were fitted.

with the medium-velocity 75mm gun,

and 2915 with the long- barrelled.

‘76mm gun (Sherman 111A), with all

but 21 of the latter being constructed

by GM Fisher,

M4A2 conversions

US Army Sherman M4Azs were

also used as the basis for the M32B2

armoured recovery vehicle as well

as for other specialised conversions.

Similarly, the British Army also

produced an armoured recovery

vehicle by removing the turrets

from a number of M4A2s (and other

Sherman variants) and fiting a

powerful mechanical winch and a

removable A-frame jib. And, between

October 1944 and April 1945, some 75

redundant M4A2s of the British Army

had their turrets and armaments

removed and were converted to

armoured personnel carriers (APC)

to accommodate ten men, plus a two-

‘man crew, in which guise they were

dubbed ‘Kangaroo’.

Alternative power unit

In 1943, an experimental M4A2,

designated M4A2E1, was produced by

GM as.a private project with a single

GM V8 diesel in place of the twin

6046D engines. Producing 600bhp

from around 24 litres, the engine was

developed from what was effectively

half of the sixteen-cylinder 16-1848

marine diesel. Despite acquitting

itself extremely well during trials at

Aberdeen Proving Ground between

May 1944 and March 1945, the tank

was not adopted for production.

eter ener

Below: British Army training pamphlet

eer eety

48 | MILITARY VEHICLES ARCHIVE

Deg SEE VEHICLES AND MAJOR PRODUCTION CHANGES

Peer Pease)

frei) 1943 Sees eee ee hE eer etl]

Goer

frees is een ee eae eee eee

er) 1943 M4A2 with spaced VVSS suspension and track grousers

Seer zea TTR UY

Re ee ere ee nee ce eed

a ee te ee eee oe eee ean

See at ee er ett ce e

rere

Sa da A

Er

Eo So

poner ete ee erect teeta ne ene ee ee eee a

ee eee eee eee ety eae ee een on ed

ao

Se aT

aE)

horizontal volute-spring suspension (HVSS).

Fee

Esmee

ood

EAA AE

See ee)

sete Ser

se ES a TN ANE

in 344, appliqué armour patches, ln (25mm) thick were welded tothe front corners ofthe turret to compensate for thinning oF

Se ee ee eee te et ee eet eee eee Sy

the sides ofthe hull, adjacent to the fuel tanks and the ammunition bins

Sane aE CET

oe

ert ta ann eee se hea

Poo)

eS RE Na A

EO NAN Co

Bae Se NA ST TEE

Poe eT

ea TES

ES NN ET

BS SN TT TSS

‘The apparent increase in fength for those tanks that were equipped with the 7émm gun was simply down to the dferences

eee teen anager

ete

oom

ES gt RI SC SST

Poa Ea

PoE ae ea)

aro

MILITARY VEHICLES ARCHIVE | 49

M4A3

The US Army's preferred va

GAA V8 petrol engine

Dee ele Mult: ae

With its welded hull, powerful V8 petrol engine, and latterly with the more-effective horizontal

volute-spring suspension (HVSS), the M4A3 was probably the best of the Sherman variants,

and, until 1944, was reserved strictly for the US Army. When compared to the German tanks,

and particularly those emerging in the later years of the war, the M4A3 was neither particularly

well armoured, nor was it well armed, but it was relatively cheap, it was easy to drive, and was

extremely reliable.

(0 The first Ford-produced M&AS. (Ford Motor Company)

he first example was constructed.

by the Ford Motor Company

and appeared in May 1942.

When Ford discontinued tank

production on 15 September 1943, the

‘M4Ag continued to be manufactured

at the Detroit Tank Arsenal as well

as at the GM Fisher Tank Arsenal,

with all three versions offering high

interchangeability of parts.

Regardless of the mamufaeturer,

all M4Ags were powered by Ford's

mighty GAA V8 petrol engine, which

produced 5oobhp (373KW) from a

capacity of 18,026ce (1100in'). The

GAA was based on an experimental

12-cylinder aircraft engine which Ford

hhad designed in 1940 asa private

venture at a cost of $2 million. When

subsequently ‘cut-down’ to eight

cylinders for use in tanks, the first

example of this engine ran on atest

bed for 85 hours without problems,

and was authorised by the US

Ordnance Committee for use in the

Sherman in January 1942.

‘Naturally aspirated, and breathing,

through a pair of huge Stromberg

carburettors, the GAA engine was

constructed around lightw

aluminium-alloy blocks and heads,

thus ensuring an excellent power-

to-weight ratio, and was fitted with

double overhead cams operating

four valves per cylinder. This was the

only engine to be fitted into any of,

50 | MILITARY VEHICLES ARCHIVE

M4A3

‘© Te chalk inscription on the hull declares that thi Sherman is the S0,000th combat vehicle to be shipped from Ford's Chester Tank

Depot (Ford Motor Company)

‘© Although passenger car production ceased in the USA from February 1942 to October 1945, nevertheless the major motor

‘manufacturers continued to advertise, reminding potential buyers that they were still in business. Here's one such advert from the

Ford Motor Company:

MILITARY VEHICLES ARCHIVE | 51

ure you'd be encouraged to climb on the machine these

52. | MILITARY VEHICLES ARCHIVE

M4A3

© Newy-built M&AS displayed outside Ford's Rouge River plant. (Ford Motor Company)

MILITARY VEHICLES ARCHIVE | 53

© Touching-up the paintwork at the end of the production process. The photograph was taken at Ford's Highland Park plant.

(ord Motor Company)

«© Early production example of the M&AS,

54 | MILITARY VEHICLES ARCHIVE

St ee eee

tener ei eae

© ear view of the M4ASEB with HVSS

suspension,

the Sherman variants that had been

specifically designed for use asa tank

engine and, in operation, proved

itself to be remarkably trouble-free,

as well as being easier to access for

‘maintenanee and repair. The use

of the GAA engine was said to have

increased the operational life of tank

engines from 100 to 400 hours

‘The first three M4Ag tanks to be

produced by Ford were taken to the

GM Proving Ground for extended

trials, the results of which called for

some minor modifications. One

production was underway, newly

completed tanks were subjected to

shakedown tests extending to 100

miles (162km), with the figure being

reduced to just 25 miles (gokm) in the

light of experience.

Ford also produced the armoured

plate for the hull. The hull differed

litte from that used for the M4A2,

although it was constructed from

fewer components which meant that

Jess welding was required, and all

MaAgs were fitted with a one-piece

cast nose. The reduced height of the

GAA engine when compared to the

radials used in the M4 and M4A1

variants, placed the drive-shaft

Jower down in the hull, and thus

allowed additional clearance under

the turret basket. Early examples

featured direct vision slots for the

driver, and dry ammunition stowage.

Unfortunately, when stowed in this

way, the ammunition proved to be

vulnerable to enemy fire and, from

1944, the ammunition was stowed in

racks on either side of the drive-shatt,

and was protected by 35 (imperial)

gallons (156 litres) of mixed glycerine

and water. This was described as,

‘wet ammunition stowage’, and was

MILITARY VEHICLES ARCHIVE | 55

g

s

3

=

5

2

(© MAS being put through

(Fe

MILITARY VEHICLES ARCHIVE | 57

vonicie

‘DATA

ACCELERATOR

«© Driver's position in the M43 withthe major controls identified.

indicated by the addition of a ‘W"

suffix to the model designation, for

example M4A3W.

‘The first M443 Shermans were fitted

with the heavy-duty vertical volute-

spring suspension system (VVSS). In

common with other variants, the later

M4AgE8, which was often described

as the ‘Easy Eight’ by Gls, and the

‘M4AgE9, which was also fitted with

‘duck-bill’ track grousers, both ran on

the superior horizontal volute-spring

suspension system (HVSS) enabling

the use of wider tracks that were less

prone to being thrown.

Like other Sherman variants, the

‘null was able to accommodate a crew

of five men, consisting of commander,

gunner, loader, driver, and co-driver/