Professional Documents

Culture Documents

Brochure Vertical 2020

Brochure Vertical 2020

Uploaded by

Pinku Maiti0 ratings0% found this document useful (0 votes)

4 views4 pagesOriginal Title

Brochure vertical 2020

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views4 pagesBrochure Vertical 2020

Brochure Vertical 2020

Uploaded by

Pinku MaitiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

MILLING MACHINES

ated ee eel [l=]

www.bhambar.in

ae

BHAMBAR ENGINEERS (Regd.)

ee ene in li =o)

SALIENT FEATURES:

» High rigidity of structure and drives.

» Convenient Design.

» Separate drive forthe spindle and the table movements

» Single lever control of feeds & rapid traverse,

» Wide range of spindle speeds & feeds with high upper limits.

Castings high tensile strength, graded & superior quality

High rates of rapid table traverse while the spindle is running or

atrest

» Large longitudinal & traverse movements of table.

» Long lasting interchangeable spare parts.

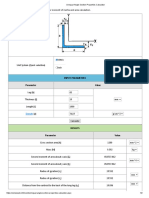

‘SPECIFICATION CHART FOR HYDRAULIC FEED MILLING MACHINES(in mm)

ne Type To

Thue Se "100300

‘Se New CD. mes

XTrmerse Lorgutea) 500 (48) 150 ye

‘raves Cress Travers) | 200 (Manas) 0 Maru)

Ziere(Vened Teese) 300 =

“abo Loas Capacty 200 Kors seo Kone

Spice Tae Sancard Is040 18000

Sie Spends Farge (4 TODAS) 945100 RPA

Feedage Hyctaue Vale rule ttle

Pape uk use

7 ile Sree Moo HP @RORPUS| | SHP|GEORPM'S)

Singin Feed Auta Frieder actor 2HEGUOREY | 24 (RY

Hydraulic Milling Machine patmencunaqien = [cae a

for High-Production

opto Wight (ms) 1950 70

BB.XBER Vertical iting Machines ae heavy metal removal machines. tic usd or surface facing operations ofany components wit facing cuter The construction of Vertical

Miliog machine very toboepn view of ough & tough working conditions Thehead can swivel both sides 90 degrees. The al gated vertical ling machine have XYZ as

auto foods & Raps. These machines re normally used in tool reams of Forgingindusry, Auto Parts industry, Defence workshops, Engineering Colleges, hand toolsindustris ee

“The hydraulic feed vertial milling machine swed todo maze production & terete ae better than conventional gearbox type and manuslmiling machines, The SHAMBAR,

Branches its pediy ong term experience to mansfacture accurate & quality milingmachines fam past S decades. We always welcome he persoraltles whore inoreted

toprocure aqualyatreasonableprces.

SPECIFICATIONS FOR ALL GEARED X-Y-Z AXIS AUTO FEED N RAPID

VERTICAL MILLING MACHINES

Crs Cr) cl vg VM4B TH) rd) v7 8

no

Working Surface 1200x300 | 1250x300 1450x350 1650x360 | 1900x400 | 2100x450 | 2300x500

Swivel 245° 245° 345° 245° Fix Fix Fix

TSlot Nos. /Size an 37 37 3n7 a7 5/20 5/20

FSlot Centre 70 70 80 90 100 90 95

Table Loading Capacity (Kgms) 200 300 500 800 1100 1600 2500

X-Longitudinal Travel 550 700 800 900 1100 1200 1900

Y-Cross Travel 180 220 ze 325 400 450 550

Vertical Travel

No. Of Feeds

Range of Longitudinal Feed/min rea ive 400 an ie ica me 400 Oh

Range of Cross Feed / in 18260 | 1810400 | 18t0400 | t8t0400 | 1810400 | 1810400 | 18to400

Range of Vertical Feed / min 6120 351090 351099 35t090 | 351090 | 35t090 4t090

No. Of Rapid Feeds 1 2 2 2 2 2 2

Longitudinal Rapid Feeds J min 00 900,150. 900,150 900.1500. | 900.1500 900.1500 700, 900

Gross Rapid Feeds / min 00 900,1500 | 900,1500 | 900,1500 | 900,1500 | 900.1500 | 700, 900

Vertical Rapid Feeds / min 225,965 225,365 225,965 | 225,965 | 225,265 165, 250

A

Spindle Taper iso4a- |'iso40 | tso4o— | tso40 | 180.40 18050 | 18050

No. of Spindle Speeds Gut2 | 9ut2 | 9ut2 | Dt But Qu12 | G02

Range of Spindle Speeds (RPM) | 45-1120. | 45-1120 45-1120 45-1120 | 45-1120 45-1120 45-1120

Distance from Spindle to Table 325 48 475 525 575 625 700

Distance Spindle Gentre to Column | 250 300 350 400 500 600 650

Vertical Head Titt 90° 390° 290° 290° 190° 90° 290°

‘Manual Quill Travel 95 95 95 95 95 95 100

Main Motor SHP SHP SHP SHP cnr | 7.5HPowrm | 10HP 10H?

Feed Motor 15HP | HP 2HP 2HP 2HPranw | 3HPaaany | SHP

Coolant Pump (Optional) inp | Ose O1HP 01H O.1HP o.HP one

PEST

Overall Length 1700 1850 2000 2100 2500 2700 2800

Width 4500 1600 1750 1950 2500 2600 2700

Height 1800 2080 2200 2300 2400 2700 2800

Net Weight © 1800 2800 3400 3800 4500 5600 7000

Gross Weight 2200 3200 3900 4300 5000 6100 8200

Note : As per our objective for continual improvements the details in illustrations and specifications are subject to change without prior notice.

User have option to select the spindle speed among 9 or 12 before placing the order

STANDARD ACCESSORIES

Electric Motors

Control Panel

Jack Handle

Draw Bar ital Read Out oreo tachment

OPTIONAL ACCESSORIES Z

Dividing Head Machine Lamp

Rotary Table Horizontal Attachment

Bellows Milling Machine Vice

Coolant Pump pigital Read Out (ORO)

Splash Guard Collet Adopter & Collets

A SHORT PREVIEW ue OUR FACTORY (INFRASTRUCTURE)

8.5 kms from

Samrala

Ludhiana City Focal Point

Railway Junction Chow

Bharat

Nagar Chowk

at

sepued

<

Gi

Giaspura Nein Flyoy,Skmirom

watt . Loahiana

iy. Crossing 7

From

ein Side

Jom rosa

BHAMBAR ENGINEERS (Regd.) —

1208, GT. Road, Dhandari khurd, Ludhiana-141 010 (Punjab) INDIA

Ph : +91-161-2510183 Telefax : +91-161-2510002 Mobile : +91-98141-95888

Email: info@bhambar.in, bhambar@hotmail.com Website : www.bhambar.in

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TowerDocument1 pageTowerPinku MaitiNo ratings yet

- Mock Test Paper Answer SheetDocument4 pagesMock Test Paper Answer SheetPinku MaitiNo ratings yet

- Tensile Testing of Metals Proficiency Testing Program Round 4Document39 pagesTensile Testing of Metals Proficiency Testing Program Round 4Pinku MaitiNo ratings yet

- Mock Test Paper MCQDocument6 pagesMock Test Paper MCQPinku MaitiNo ratings yet

- Inspection and Test Plan (Towers & Fasteners) : DescriptionDocument84 pagesInspection and Test Plan (Towers & Fasteners) : DescriptionPinku MaitiNo ratings yet

- 2 - General Technical SpecificationsDocument24 pages2 - General Technical SpecificationsPinku MaitiNo ratings yet

- 1 - General Technical RequirementsDocument36 pages1 - General Technical RequirementsPinku MaitiNo ratings yet

- Unequal Angle Section Properties CalculatorDocument3 pagesUnequal Angle Section Properties CalculatorPinku MaitiNo ratings yet

- Equal Angle Section Properties CalculatorDocument2 pagesEqual Angle Section Properties CalculatorPinku Maiti100% (1)

- Unequal Angle Section Properties CalculatorDocument4 pagesUnequal Angle Section Properties CalculatorPinku MaitiNo ratings yet

- GTTPL Technical Specifications Full EpcDocument10 pagesGTTPL Technical Specifications Full EpcPinku MaitiNo ratings yet

- Account Statement From 18 Dec 2020 To 18 Jun 2021Document12 pagesAccount Statement From 18 Dec 2020 To 18 Jun 2021Pinku MaitiNo ratings yet