Professional Documents

Culture Documents

Pressure Drop

Pressure Drop

Uploaded by

Konrad SzwedoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Drop

Pressure Drop

Uploaded by

Konrad SzwedoCopyright:

Available Formats

Pressure Drop vs.

Particulate Loading

920 & 920R Series Accessible Coalescent Oil Separators

Approximate %

Pressure Drop Action*

of Filter Loaded

<5 psid – 0.34 bar 50%

<7 psid – 0.48 bar 60%

<10 psid – 069 bar 70% 70%

<12 psid – 0.83 bar 75% Change Filter

<15 psid – 1.03 bar 80% Change Filter

<20 to 25 psid – 1.4 to 1.7 bar 85% Change Filter

<30 to 40 psid – 2.1 to 2.8 bar 90% Filter O-ring could dislodge

<60 to 80 psid – 4.1 to 5.5 bar 95% Filter could rupture

*For systems with a hermetic oil separator (i.e., 900 Series) the filter is not replaceable. The whole oil separator must be

removed and replaced with either a new 900 Series separator or a new 920 or 920R Series oil separator.

The above figures are for design conditions given in the Temprite catalog with normal oil loading.

System design conditions such as pipe sizing, other discharge line components, piping layout,

under-sized oil separators, higher density oils, high oil levels or liquid loading may cause a higher

than normal pressure drop.

The above figures area for Medium Temp R-22 systems with 150-300 SSU or 32-48 cST viscosity

mineral oil. Higher density oils such as 450 SSU or 68 cST will have a slightly higher pressure

drop. For other conditions see below:

For High Temp: multiply by 1.36

For Low Temp: multiply by 0.49

For R-404A (HP-62) with 22-32 cST viscosity POE oil: multiply by 0.86

For R-507 (AZ-50) with 22-32 cST viscosity POE oil: multiply by 0.875

Pressure drop can compound at

exponential rates. That’s why it’s

important to keep the 920 and 920R

Series Standard Filter clean and free of

debris and solid contaminants.

© Copyright 2013 Temprite. All rights reserved,

You might also like

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- DESIGN OF SIEVE PLATE ColumnDocument5 pagesDESIGN OF SIEVE PLATE ColumnVirendra Bhagat100% (1)

- Seal Oil System of Generator in Thermal Power PlantDocument39 pagesSeal Oil System of Generator in Thermal Power PlantHari Prasad100% (6)

- Petroleum Production Engineering PDFDocument20 pagesPetroleum Production Engineering PDFKarwan Ibrahim100% (4)

- 2 - ATPL Questions AGK1 - Aiframe - SystemsDocument38 pages2 - ATPL Questions AGK1 - Aiframe - SystemsTanvir Hasan100% (1)

- Spakester 9260 - and - Spakester 1192 1Document1 pageSpakester 9260 - and - Spakester 1192 1Menoddin shaikhNo ratings yet

- Transformer Oil Specifications: BY Central Insulating Oil Testing LaboratoryDocument17 pagesTransformer Oil Specifications: BY Central Insulating Oil Testing LaboratoryRonak ThakkarNo ratings yet

- 3.oil Tests (Dec2010)Document87 pages3.oil Tests (Dec2010)Lionel MessiNo ratings yet

- Oil Revised)Document78 pagesOil Revised)shhansikaNo ratings yet

- High GOR Environmentl - SPE Format - Rev1Document30 pagesHigh GOR Environmentl - SPE Format - Rev1SrewaBenshebilNo ratings yet

- Marine Diesel (Xi Weeks) : Departemen Teknik Sistem Perkapalan ITS SurabayaDocument23 pagesMarine Diesel (Xi Weeks) : Departemen Teknik Sistem Perkapalan ITS SurabayaRazaq PayapoNo ratings yet

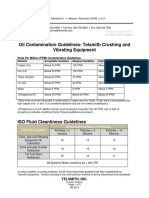

- Oil Contamination GuidelinesDocument2 pagesOil Contamination Guidelinescarlos martinezNo ratings yet

- DynamosDocument15 pagesDynamosAlanNo ratings yet

- AIRpipe ISO 8573 1 SheetDocument2 pagesAIRpipe ISO 8573 1 SheetJosh WhiteNo ratings yet

- VP-2215-1 VaPure® Vapor Compression Still - Paul Mueller CompanyDocument6 pagesVP-2215-1 VaPure® Vapor Compression Still - Paul Mueller CompanyChrisNo ratings yet

- Tds 1111108 enDocument3 pagesTds 1111108 enAntonio AaaaNo ratings yet

- WP 10 Maintenance (Compatibility Mode)Document41 pagesWP 10 Maintenance (Compatibility Mode)Ade KurniawanNo ratings yet

- Technical Information Kroil Basela CP Oils For Air and Inert Gases CompressorsDocument1 pageTechnical Information Kroil Basela CP Oils For Air and Inert Gases CompressorsDavid Lortes LiñaresNo ratings yet

- Purification: Reinigen Luft Technology India Pvt. LTDDocument49 pagesPurification: Reinigen Luft Technology India Pvt. LTDAuspice QatarNo ratings yet

- Pompe Ulei Tip RSADocument4 pagesPompe Ulei Tip RSALucian UrsuNo ratings yet

- Industry Product OverviewDocument6 pagesIndustry Product Overviewphool singhNo ratings yet

- Re2540-Blf 171201Document2 pagesRe2540-Blf 171201LưuVănViếtNo ratings yet

- 200-DR Datasheet PDFDocument4 pages200-DR Datasheet PDFKumarRam100% (2)

- NIC Components NCF SeriesDocument3 pagesNIC Components NCF SeriesNICCompNo ratings yet

- Oil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetDocument4 pagesOil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetJhonNo ratings yet

- Tds 1145100 enDocument2 pagesTds 1145100 enwaelNo ratings yet

- PDS - GulfSea PE Cooloil SeriesDocument2 pagesPDS - GulfSea PE Cooloil SeriesObydur RahmanNo ratings yet

- Gassense Ndir SensorDocument7 pagesGassense Ndir SensorSửa Thiết BịNo ratings yet

- Transformeroilanalysisanditsconditionmonitoring 190204061858Document45 pagesTransformeroilanalysisanditsconditionmonitoring 190204061858MAHMOUD MOHAMEDNo ratings yet

- CLP 0190 Basinçli Hava Fi̇ltresi̇ Sarmak-BeaDocument12 pagesCLP 0190 Basinçli Hava Fi̇ltresi̇ Sarmak-Beamustafa çetinkayaNo ratings yet

- Transformer General InformationDocument8 pagesTransformer General InformationNiven MoodleyNo ratings yet

- Flow Meter 2.04.5Document24 pagesFlow Meter 2.04.5Sitto JosephNo ratings yet

- Signet 2536 Rotor-X Paddlewheel Flow SensorsDocument6 pagesSignet 2536 Rotor-X Paddlewheel Flow SensorsMETHOR SERVICE GROUPNo ratings yet

- Owgels Godcare Oxygen Concentrator 10lpmDocument6 pagesOwgels Godcare Oxygen Concentrator 10lpmamit261287No ratings yet

- Filtros HXN8GDocument16 pagesFiltros HXN8GAdan PachecoNo ratings yet

- Form-Crude Oil Assay Type-ADocument3 pagesForm-Crude Oil Assay Type-AAndri PutraNo ratings yet

- LennRO LBW S 2 EN 2018 Rev01Document3 pagesLennRO LBW S 2 EN 2018 Rev01sanusiibrahimNo ratings yet

- Oil-X FabricatedDocument4 pagesOil-X FabricatedMohsen ParpinchiNo ratings yet

- 27e9f1d3-c2a9-443a-b033-5cecf47738caDocument3 pages27e9f1d3-c2a9-443a-b033-5cecf47738caahmetNo ratings yet

- r5, Hy-Optima 740, Technical Data SheetDocument1 pager5, Hy-Optima 740, Technical Data SheetSeanKuoNo ratings yet

- Aircraft Leg DocumentsDocument77 pagesAircraft Leg DocumentsNio Zi FengNo ratings yet

- RA 90 221 Rexroth Environmentally Acceptable Hydraulic Fluids PDFDocument8 pagesRA 90 221 Rexroth Environmentally Acceptable Hydraulic Fluids PDFeng13No ratings yet

- DN Turbine OilDocument2 pagesDN Turbine OilPrapat SabsinthaweelapNo ratings yet

- Refining of Crude Oil For Liquid Fuels Production - NPTELDocument23 pagesRefining of Crude Oil For Liquid Fuels Production - NPTELSATHISH YENIBERANo ratings yet

- Insulating Oils: by Santosh.N Engineer/HosurDocument19 pagesInsulating Oils: by Santosh.N Engineer/Hosursantoshnarinoi241No ratings yet

- Tech Info Herculesus PDFDocument37 pagesTech Info Herculesus PDFRafhael Tapia ZunigaNo ratings yet

- Nevastane SLDocument4 pagesNevastane SLronnysiguasNo ratings yet

- Sulzer Brochure CPE en LDocument19 pagesSulzer Brochure CPE en Lphantuan080213No ratings yet

- Repsol DXR 8 - 1 v1 15w40Document1 pageRepsol DXR 8 - 1 v1 15w40thrharsrgNo ratings yet

- BT 0832 Rethane FWP SB 672 - InglêsDocument2 pagesBT 0832 Rethane FWP SB 672 - InglêsProtection Representacoes Valter HugoNo ratings yet

- Selection Guide: Pressure Test / Calibration PumpsDocument1 pageSelection Guide: Pressure Test / Calibration PumpsNitish VazeNo ratings yet

- Air Compressor Lubricant: SOS-D1-100Document2 pagesAir Compressor Lubricant: SOS-D1-100Orlando GalvanNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBudi SetiawanNo ratings yet

- Gassense Ndir Sensor ManualDocument11 pagesGassense Ndir Sensor ManualSửa Thiết BịNo ratings yet

- Catalog EPSEA 6th Generation Ultra-Cool Refrigerated Air DryerDocument9 pagesCatalog EPSEA 6th Generation Ultra-Cool Refrigerated Air DryerRedd ReddNo ratings yet

- Chapter 3 Stripping at The Wellhead An in Gathering StationsDocument22 pagesChapter 3 Stripping at The Wellhead An in Gathering Stationsali AbbasNo ratings yet

- Fluid Control Contamination HandbookDocument32 pagesFluid Control Contamination HandbookEzomar UzcáteguiNo ratings yet

- Start - Up Instructions:: Parameter Working Rate Maximum RateDocument1 pageStart - Up Instructions:: Parameter Working Rate Maximum RateMilton PeñaNo ratings yet

- Paroil S EnglishDocument2 pagesParoil S EnglishКонстантин ГетьманNo ratings yet

- Servo Marine 10 & 20Document1 pageServo Marine 10 & 20DriptoNo ratings yet

- Everest 170 Synthetic Refrigeration Lubricant: Data SheetDocument3 pagesEverest 170 Synthetic Refrigeration Lubricant: Data SheetPhan Thiện HảoNo ratings yet

- Ne CADDDocument4 pagesNe CADDLoganBohannon100% (1)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Edoc - Pub - 248602254 Shell Dep List PDFDocument25 pagesEdoc - Pub - 248602254 Shell Dep List PDFShubhodeep SarkarNo ratings yet

- ES - LineSize User ManualDocument7 pagesES - LineSize User ManualvuongNo ratings yet

- Operating Principle of The Filter: Primary Filtration StepsDocument7 pagesOperating Principle of The Filter: Primary Filtration StepsTawanda Nyambiya100% (1)

- SSP 665 Audi A8 Type 4N New Air Conditioning Features and Introduction of Refrigerant R744Document36 pagesSSP 665 Audi A8 Type 4N New Air Conditioning Features and Introduction of Refrigerant R744ylk1No ratings yet

- CIAC - 3 - Operation & MaintenanceDocument15 pagesCIAC - 3 - Operation & Maintenanceleonardoacastro9886No ratings yet

- Bourdon Pressure GaugeDocument5 pagesBourdon Pressure GaugeMustafa Ani100% (1)

- Exhaust Restriction G3500Document4 pagesExhaust Restriction G3500Jose FavaNo ratings yet

- Gas Detector Bump Test Record Log Sheet: Bump Test Result Test Date Time Pass Fail Retest Pass Retest Fail Tester NameDocument2 pagesGas Detector Bump Test Record Log Sheet: Bump Test Result Test Date Time Pass Fail Retest Pass Retest Fail Tester NameAndry Kurnia100% (2)

- Experiment 4 (Re No.)Document21 pagesExperiment 4 (Re No.)Mervin PerezNo ratings yet

- CHE 411 Exam 1-2008Document1 pageCHE 411 Exam 1-2008aleeyakamalNo ratings yet

- Oil-WATER Distributions in Large Diameter Horizontal PipelinesDocument8 pagesOil-WATER Distributions in Large Diameter Horizontal PipelinesBMCANo ratings yet

- Water Supply in High Rise BuildingsDocument8 pagesWater Supply in High Rise BuildingsVaishnavi Parmar100% (1)

- Che323 Note Cooling Tower 3Document130 pagesChe323 Note Cooling Tower 3ifiokNo ratings yet

- Lab 5 Enthalpy of VaporizationDocument4 pagesLab 5 Enthalpy of VaporizationFrolian MichaelNo ratings yet

- Especificaciones Del Gas - TG5Document2 pagesEspecificaciones Del Gas - TG5Lizbeth EstradaNo ratings yet

- Chapter 5 Upthrust in Fluids Archimedes'Document30 pagesChapter 5 Upthrust in Fluids Archimedes'Hardik M ProNo ratings yet

- R-22 FinalDocument58 pagesR-22 FinalAmit Katiyar100% (1)

- Regulators Cobra RegulatorDocument4 pagesRegulators Cobra RegulatorBogdan TabasNo ratings yet

- Mechanical Field Trip Report 2022Document16 pagesMechanical Field Trip Report 2022RichardNo ratings yet

- Flashback Arrestor TestingDocument1 pageFlashback Arrestor TestingmashanghNo ratings yet

- Gas-Liquid SeparatorsDocument27 pagesGas-Liquid Separatorshisoka55No ratings yet

- Alat KesehatanDocument6 pagesAlat Kesehatanerik verawatiNo ratings yet

- Onsite PlanDocument10 pagesOnsite PlanHiren Maheta100% (1)

- Liquid Oxygen SystemDocument9 pagesLiquid Oxygen SystemMotaz H OthmanNo ratings yet

- 3700-AC P2 Operacion y PartesDocument80 pages3700-AC P2 Operacion y PartesParedes Miler100% (4)

- Rigorous Method For Fire CaseDocument4 pagesRigorous Method For Fire CaseFlorin Daniel AnghelNo ratings yet