Professional Documents

Culture Documents

Hardox 450 - Preheat Calculation

Uploaded by

Bien NguyenDuyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hardox 450 - Preheat Calculation

Uploaded by

Bien NguyenDuyCopyright:

Available Formats

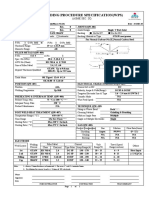

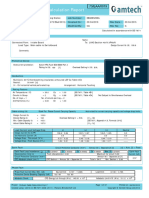

WPS Number PQR-0145

Base metal Hardox 450 to Hardox 450

HEAT INPUT CALCULATION GUIDELINE

Travel speed k [1] Heat Input - Welding process denoted

Process Amperage Voltage HI Min. HI max.

(mm/minutes) Factor

number 111, 121, 126, … according to BS EN

A_min. A_Max. V_Min. V_Max. Min. Max.

ISO 4063:2010 shall be applied k-factor (EN

Root 111 90 ~ 95 20 ~ 22 65 ~ 69 0.8 1.25 ~ 1.54

1011-1). AWS/ASME - welding processes will

Hot ~ ~ ~ - - ~ - multiple constant k-factor (k=1).

Fill ~ ~ ~ - - ~ - [2] Preheat - Preheat determination based on

Cap ~ ~ ~ - - ~ - base material CET and according to Annex C

of EN 1011-2:2001 (See C.3.2.1).

1. Heat-input calculation automaticly applied thermal effeciency according to EN 1011-2 for all processes number such 111, 121, …

2. Heat input calculation will apply k-factor is 1 for all processes under assgined AWS, such SMAW, FCAW, … [3] Cooling time t8/5 - calculation of cooling

3. Update and download at https://blog.duybien.com/2023/11/preheat-calculation.html

time t800/500 according to Annex D of EN

1011-2:2001 (See D.6).

[4] Input your data into the YELOW cell.

PREHEAT DETERMINATION

146 (see Annex C2 - EN1011-2)

Base metal

138.975 Deg. C %CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

%CET 0.39 %CET=C+(Mn+Mo)/10+(Cr+Cu)/20+Ni/40 %CEV 0.55

Thickness 1.17 Deg. C %C %Mn %Mo %Cr %Cu %Ni %V

d 30.0 mm 0.190 1.270 0.023 0.690 0.000 0.060 0

Hydrogen 8.90

HD 5.0

Heat Input -2.894775

Q 1.25 kJ/mm

Powered by https://duybien.com & https://wa.me/+84907354199

TWO DIMENSIONAL HEAT FLOW

Pre-heat HI Th'k Heat Flow Cooling Layers Q 1.34

T0 Q d F2 t8/5 (second) run(runs)

- 1 A 92

- 2 V 20

- 3 TS (mm/min.) 70

- 4 k 0.85

THREE DIMENSIONAL HEAT FLOW

Pre-heat HI Th'k Heat Flow Cooling Layers

T0 Q d F3 t8/5 (second) run(runs)

150 1.25 0.9 8.83 1 k-factors

- 2 121 1

- 3 135 0.85

- 4 111 0.85

Transition Plate Thickness [du] Thickness determination [d] Heat Flow

T0 Q du

150 1.25 18.4 30 Three dimension

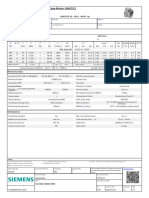

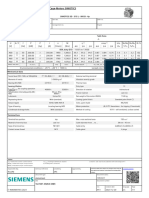

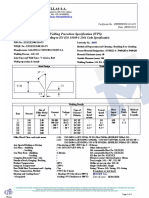

WPS Number PQR-0145

Base metal Hardox 450 to Hardox 450

HEAT INPUT CALCULATION GUIDELINE

Travel speed k [1] Heat Input - Welding process denoted

Process Amperage Voltage HI Min. HI max.

(mm/minutes) Factor

number 111, 121, 126, … according to BS EN

A_min. A_Max. V_Min. V_Max. Min. Max.

ISO 4063:2010 shall be applied k-factor (EN

Root 111 110 ~ 120 22 ~ 24 60 ~ 66 0.8 1.76 ~ 2.30

1011-1). AWS/ASME - welding processes will

Hot ~ ~ ~ - - ~ - multiple constant k-factor (k=1).

Fill ~ ~ ~ - - ~ - [2] Preheat - Preheat determination based on

Cap ~ ~ ~ - - ~ - base material CET and according to Annex C

of EN 1011-2:2001 (See C.3.2.1).

1. Heat-input calculation automaticly applied thermal effeciency according to EN 1011-2 for all processes number such 111, 121, …

2. Heat input calculation will apply k-factor is 1 for all processes under assgined AWS, such SMAW, FCAW, … [3] Cooling time t8/5 - calculation of cooling

3. Update and download at https://blog.duybien.com/2023/11/preheat-calculation.html

time t800/500 according to Annex D of EN

1011-2:2001 (See D.6).

[4] Input your data into the YELOW cell.

PREHEAT DETERMINATION

137 (see Annex C2 - EN1011-2)

Base metal

138.975 Deg. C %CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

%CET 0.39 %CET=C+(Mn+Mo)/10+(Cr+Cu)/20+Ni/40 %CEV 0.55

Thickness 1.17 Deg. C %C %Mn %Mo %Cr %Cu %Ni %V

d 30.0 mm 0.190 1.270 0.023 0.690 0.000 0.060 0

Hydrogen 8.90

HD 5.0

Heat Input -11.5791

Q 2.00 kJ/mm

Powered by https://duybien.com & https://wa.me/+84907354199

TWO DIMENSIONAL HEAT FLOW

Pre-heat HI Th'k Heat Flow Cooling Layers Q 1.99

T0 Q d F2 t8/5 (second) run(runs)

- 1 A 110

- 2 V 23

- 3 TS (mm/min.) 65

- 4 k 0.85

THREE DIMENSIONAL HEAT FLOW

Pre-heat HI Th'k Heat Flow Cooling Layers

T0 Q d F3 t8/5 (second) run(runs)

137 2 0.9 13.50 1 k-factors

- 2 121 1

- 3 135 0.85

- 4 111 0.85

Transition Plate Thickness [du] Thickness determination [d] Heat Flow

T0 Q du

137 2 22.9 30 Three dimension

You might also like

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Radiography Interpretation PDFDocument220 pagesRadiography Interpretation PDFVijay Kumar100% (1)

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Guidelines For Welding Cast IronDocument3 pagesGuidelines For Welding Cast IronNguyễn Thanh SơnNo ratings yet

- Pid InterviewDocument2 pagesPid InterviewShamshir Alam100% (1)

- Welding Domex SteelsDocument16 pagesWelding Domex Steelspozolab100% (1)

- I) Direct Reduced Iron: Production: March 2009Document29 pagesI) Direct Reduced Iron: Production: March 2009Jai Prakash Reddy100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- PWPS Structure 01. AWS D1.1 MCE (Lincoln Electric)Document2 pagesPWPS Structure 01. AWS D1.1 MCE (Lincoln Electric)eliskal bahar100% (1)

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Pipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionDocument2 pagesPipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionImmanuel SNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data Sheetapply19842371No ratings yet

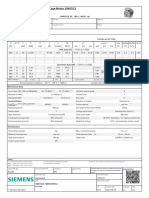

- 1LE1503-1DB43-4FK4 Datasheet enDocument1 page1LE1503-1DB43-4FK4 Datasheet enNicolas RossettoNo ratings yet

- S4030 600F111001FVDocument290 pagesS4030 600F111001FVШибко ЯрикNo ratings yet

- 1LE1504-3AB23-4AB4 Datasheet enDocument1 page1LE1504-3AB23-4AB4 Datasheet enOkke BoykeNo ratings yet

- 1LE1501-3AB53-4AB4 Datasheet enDocument1 page1LE1501-3AB53-4AB4 Datasheet enfarid.chira2No ratings yet

- Scope: Ferritic Heat-Resistant Steel TK 1.4762Document5 pagesScope: Ferritic Heat-Resistant Steel TK 1.4762Siis IngenieriaNo ratings yet

- 1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enDocument2 pages1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enrianandiyahooNo ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- Datasheet For Pressure Transmitter - Stg74S: (No. RP19-009)Document4 pagesDatasheet For Pressure Transmitter - Stg74S: (No. RP19-009)Dhananjay BhaldandNo ratings yet

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- 1le1503 3ab53 4ab4Document2 pages1le1503 3ab53 4ab4Whipman ArduinoNo ratings yet

- 1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZOmair FarooqNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- 1LE1003-1AA43-4FA4-Z B02 Datasheet enDocument2 pages1LE1003-1AA43-4FA4-Z B02 Datasheet enRefresh DrNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- Yff-Hc: SeriesDocument5 pagesYff-Hc: SeriesDhaval PatelNo ratings yet

- 1LE1503-1EA23-4AB4 Datasheet enDocument1 page1LE1503-1EA23-4AB4 Datasheet enpatilshailesh123No ratings yet

- NTE931 Integrated Circuit 3-Terminal Positive Voltage Regulator 5V, 3ADocument2 pagesNTE931 Integrated Circuit 3-Terminal Positive Voltage Regulator 5V, 3AWilfredo MolinaNo ratings yet

- 1LE1501 2DA03 4AA4 Datasheet enDocument1 page1LE1501 2DA03 4AA4 Datasheet enGismart 11No ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- 1NA1566-2AA30-0CC0-Z A65+K11+K97+L27: Data Sheet For Three-Phase Squirrel Cage Motor Simotics HV C Article Number OptionsDocument2 pages1NA1566-2AA30-0CC0-Z A65+K11+K97+L27: Data Sheet For Three-Phase Squirrel Cage Motor Simotics HV C Article Number OptionsDavid Nunez VeraNo ratings yet

- New Diode For TK From BoschDocument6 pagesNew Diode For TK From BoschSRIDHAREEE61No ratings yet

- 1LE1501-1EB43-4JA4 Datasheet enDocument1 page1LE1501-1EB43-4JA4 Datasheet enIbraheem AlfalahatNo ratings yet

- 1LE1003 0DA21 7AB4 Datasheet enDocument1 page1LE1003 0DA21 7AB4 Datasheet enkamal_arbabNo ratings yet

- J0231 LV TR - FINAL变压器2Document21 pagesJ0231 LV TR - FINAL变压器2SerhiiNo ratings yet

- 2.2 PED CertificateDocument5 pages2.2 PED CertificateAbhishek GoelNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 0EB02 2JA4Document2 pagesSilnik - Karta Katalogowa 1LE1002 0EB02 2JA4artur.sowaNo ratings yet

- DataBook CDXDocument15 pagesDataBook CDXLê Anh TuấnNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4nizarNo ratings yet

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- 2 HP Motor DS&GADocument2 pages2 HP Motor DS&GArituNo ratings yet

- Beddington To Rowdown - Cable Calculation Report - Croham Cooling Station - SHT 1Document57 pagesBeddington To Rowdown - Cable Calculation Report - Croham Cooling Station - SHT 1selva rajaNo ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division AhmednagarMohan BabuNo ratings yet

- Castel Magn O8Document14 pagesCastel Magn O8Daniel Fancis Amabran BarrientosNo ratings yet

- Datasheet M3BP315SMC6Document3 pagesDatasheet M3BP315SMC6Purchasing StanindoNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- Test Report 2.2 - Type Test (EN 10204) : 1 Rated Motor DataDocument9 pagesTest Report 2.2 - Type Test (EN 10204) : 1 Rated Motor DatazsmithNo ratings yet

- 1LE1002-1CB02-2AA4 Datasheet enDocument1 page1LE1002-1CB02-2AA4 Datasheet enLance AyoubNo ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division Ahmednagaranurag dhyaniNo ratings yet

- Datasheet 2SIE315M4CDocument1 pageDatasheet 2SIE315M4CGlen TuranganNo ratings yet

- 100 EDRS71M4 FG 2GD B KCC TF AL ProductData en DEDocument2 pages100 EDRS71M4 FG 2GD B KCC TF AL ProductData en DEMahesh Daxini ThakkerNo ratings yet

- WPS 141-121 P460QH To SameDocument2 pagesWPS 141-121 P460QH To SameakisdassasNo ratings yet

- Unisonic Technologies Co., LTD: NPN Silicon Bipolar Transistors For Low Frequency AmplificationDocument4 pagesUnisonic Technologies Co., LTD: NPN Silicon Bipolar Transistors For Low Frequency AmplificationSudais AkbarNo ratings yet

- (cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationDocument2 pages(cm3) (MM) (MM) (KG) (°C) : Compressor Applicationvictor parraNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Chapter 4_2Document56 pagesChapter 4_2Natnael workuNo ratings yet

- Dinesh New ProfileDocument3 pagesDinesh New ProfileDINESh patelNo ratings yet

- Electroless Plating28266Document17 pagesElectroless Plating28266fsarfrazNo ratings yet

- Product FolioDocument6 pagesProduct FolioVishnu DuttaNo ratings yet

- List of Welding Procedure Specification & Procedure Qualifications - Typical ConnectionDocument5 pagesList of Welding Procedure Specification & Procedure Qualifications - Typical ConnectionPrakash RajNo ratings yet

- DSM-0254.0 Pure Mo PowdersDocument4 pagesDSM-0254.0 Pure Mo PowdersApichitNo ratings yet

- 0803 - John Deere - Casting Repairing InstructionsDocument4 pages0803 - John Deere - Casting Repairing Instructionscrazy dNo ratings yet

- Pohon Industri Baja NasionalDocument1 pagePohon Industri Baja NasionalrossajnrNo ratings yet

- Assignment No. 2 in MDSPDocument14 pagesAssignment No. 2 in MDSPRex RebuyasNo ratings yet

- Ferrous MaterialsDocument73 pagesFerrous Materialsamrptl9010100% (1)

- Splice WashDocument4 pagesSplice WashJosue ToribioNo ratings yet

- Open End Wrench: Product Features ProfilesDocument3 pagesOpen End Wrench: Product Features ProfileskasanaNo ratings yet

- Superstrut Metal FramingDocument83 pagesSuperstrut Metal FramingAdam SonNo ratings yet

- Engine PC LS160 LS170 1 EUDocument82 pagesEngine PC LS160 LS170 1 EUsassine khouryNo ratings yet

- (PaperzoneVN - Com) - Paper Plane - by - AssembliDocument9 pages(PaperzoneVN - Com) - Paper Plane - by - AssembliBenedict CleonNo ratings yet

- Nitoflor Anti-Slip GransDocument2 pagesNitoflor Anti-Slip GransBalasubramanian AnanthNo ratings yet

- 1 110 Gauge Shutoff ValveDocument2 pages1 110 Gauge Shutoff ValveAinayya alfatimahNo ratings yet

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocument5 pagesAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedNo ratings yet

- Lndian Standard: Code of Practice For Oxy-Acetylene Welding For Structural Work in Mild (SteelDocument23 pagesLndian Standard: Code of Practice For Oxy-Acetylene Welding For Structural Work in Mild (SteelFrank StephensNo ratings yet

- Civil Engineering Materials 1st Edition Sivakugan Solutions ManualDocument7 pagesCivil Engineering Materials 1st Edition Sivakugan Solutions Manualbinhlinhh9ih100% (32)

- Smartcare Damp Block Sample TdsDocument2 pagesSmartcare Damp Block Sample TdsrudrabirNo ratings yet

- Aspen ELearning CatalogDocument128 pagesAspen ELearning Catalogshubham boteNo ratings yet

- Air Turbine Spindle (미국) - High Speed SpindleDocument24 pagesAir Turbine Spindle (미국) - High Speed SpindlekroczzangNo ratings yet

- Spec Automotive CustomerDocument2 pagesSpec Automotive CustomeryantoniNo ratings yet