Professional Documents

Culture Documents

Blasting SupportPlacing Blasting Mats 2016 Version

Blasting SupportPlacing Blasting Mats 2016 Version

Uploaded by

Abdul Aziz Mohammed0 ratings0% found this document useful (0 votes)

4 views3 pagesOriginal Title

Blasting-SupportPlacing-Blasting-Mats-2016-Version

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views3 pagesBlasting SupportPlacing Blasting Mats 2016 Version

Blasting SupportPlacing Blasting Mats 2016 Version

Uploaded by

Abdul Aziz MohammedCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

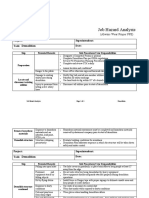

Job Hazard Analysis

(Always wear proper PPE)

Project: Superintendent:

Task: Blasting Support / Placing Blasting Mats Date:

Step Potential Hazards Safe Procedures/ Crew Responsibilities

• Designate a Competent Person: Blaster MUST direct placement of mats

• Review P3 (Preparation Planning Procedures) and Hazard Analysis with crew

• Complete and review STA’s daily

Preparation

• Assess location and conditions*

*If work is to be performed in a travel way, complete and follow Job Hazard

Analysis for ‘Work in Travel Way’

Uncontrolled explosion • Meet requirements of OSHA 1926, Subpart U, including:

• Use proper warning signs and blasting signals

• No smoking within 50 feet of explosives

• Do not transport blasting caps and explosives in same vehicle

• Vehicles for transporting explosives are properly marked

Review basic

• Explosives in transport vehicle shall not be left unattended

drilling and

• Blasting caps and explosives are stored in separate magazines

blasting

requirements • No drilling or excavating within 50 feet of a loaded hole

with Blaster • Following each blast, blaster inspects to determine if all charges have fired before

employees return to blast area

• Unexploded charges must be found and re-fired before drilling or mechanical

excavation is started within 50 feet of a misfire

• Sargent Corp employees shall not assist in locating a misfire

• No drilling in a hole that has previously contained explosives

Job Hazard Analysis Page 1 of 3 Blasting Support/Placing Blasting Mats

Project: Superintendent:

Task: Blasting Support / Placing Blasting Mats Date:

Step Potential Hazards Safe Procedures/ Crew Responsibilities

Rollover of machine placing • Determine the size and weight of mats in advance to be sure that the

mats machine used is properly rated to lift and set mats

• Use an experienced operator who understands and follows the

excavator’s load charts

• Set machine up for its most efficient lifting capacity

Damage to blast wire • Follow Blaster’s directions when setting and placing mats

• Do not set or remove mats if the Blaster is not present

Overhead electrical or • Follow 10’ overhead clearance rule

telephone lines

Rigging failure • Use rigging that is properly sized for the load

Set mats for Blaster • Rigging must be positively attached to the excavator

Remove mats • Inspect rigging prior to use

Store mats Personnel being hit by mats • Maintain a safe distance from machine and mats at all times

or machinery

Hit by debris falling out of • Inspect mats for debris before/after blast

mats while being moved • Maintain a safe distance from machine and mats at all times

Damage to machine and • Establish proper site traffic control plan

personnel due to fly rock or • Vacate blast area per Blaster’s signals

explosion • Move a safe distance from blast zone

• After “all clear” signal, wait until Blaster has inspected to determine that

all charges have fired before entering and continuing work in blast area

• NEVER use an excavator to dig up/locate a misfire

Job Hazard Analysis Page 2 of 3 Blasting Support/Placing Blasting Mats

Other Steps (if any): Other Hazards: Other Safe Procedures:

Job Hazard Analysis Page 3 of 3 Blasting Support/Placing Blasting Mats

You might also like

- Safety and Operability (SAFOP) Study ManualDocument52 pagesSafety and Operability (SAFOP) Study Manualokemma80% (15)

- Excavator Safety Training Slides FINALDocument40 pagesExcavator Safety Training Slides FINALJu Li Tan100% (4)

- Appointment - S16.1 CEO - 2021Document2 pagesAppointment - S16.1 CEO - 2021bombi100% (2)

- Jsa Welding and Sleeve InstallationDocument5 pagesJsa Welding and Sleeve Installationshinto Lawrence100% (2)

- JSA For Excavation WorksDocument4 pagesJSA For Excavation WorksKelly Bates100% (12)

- New York State Vehicle and Traffic LawDocument1 pageNew York State Vehicle and Traffic Lawnoname1254No ratings yet

- JSA-RMC Pump ConcreteingDocument6 pagesJSA-RMC Pump ConcreteingRakeshkasarla100% (2)

- Hydro Jetting and Sludge RemovalDocument18 pagesHydro Jetting and Sludge Removalmarvin100% (1)

- JSA Transformer Installations, Testing, Commissioning.Document6 pagesJSA Transformer Installations, Testing, Commissioning.Kiran Bhatt75% (4)

- JHA Sample PDFDocument2 pagesJHA Sample PDFT.DAVID DHASNo ratings yet

- Small Unit Leaders Operational Planning GuideFrom EverandSmall Unit Leaders Operational Planning GuideRating: 5 out of 5 stars5/5 (1)

- Action Plan in SDRRMDocument3 pagesAction Plan in SDRRMRuben80% (25)

- DeCarlo Vs NFL Original LawsuitDocument32 pagesDeCarlo Vs NFL Original LawsuitRobert LeeNo ratings yet

- OPERATION AND PROGRAMMING MANUAL - RMS Washers PDFDocument80 pagesOPERATION AND PROGRAMMING MANUAL - RMS Washers PDFJuan Manuel LopezNo ratings yet

- Culvert and Multi Plate Installation 2016 VerisonDocument3 pagesCulvert and Multi Plate Installation 2016 VerisonJæy JåýNo ratings yet

- Screening and Crushing Operations 2016 VersionDocument3 pagesScreening and Crushing Operations 2016 Versionmohamedkeita0880No ratings yet

- Sample Swms Heights Mobile ScaffoldDocument7 pagesSample Swms Heights Mobile ScaffoldAnonymous BzGb2fnfENo ratings yet

- Demolition 2016 VersionDocument3 pagesDemolition 2016 VersionArun Koshy AlexanderNo ratings yet

- Job Hazard Analysis DemolishDocument4 pagesJob Hazard Analysis Demolishyajid bustomiNo ratings yet

- Ehv SWP Form SpaceringDocument3 pagesEhv SWP Form SpaceringSn AhsanNo ratings yet

- Ehv SWP Form Tower AssemblyDocument4 pagesEhv SWP Form Tower AssemblySn AhsanNo ratings yet

- Dewatering 2016 VersionDocument2 pagesDewatering 2016 VersionAmeerHamzaWarraichNo ratings yet

- Ehv SWP Form Tower ErectionDocument4 pagesEhv SWP Form Tower ErectionSn AhsanNo ratings yet

- Retaining Walls Slope Protection 2016 VersionDocument3 pagesRetaining Walls Slope Protection 2016 VersionsubNo ratings yet

- JHA Crushing OperationsDocument3 pagesJHA Crushing Operationsabdullah ashrafNo ratings yet

- Silt Fence Installation 2016 VersionDocument2 pagesSilt Fence Installation 2016 VersionMIAN MATEENNo ratings yet

- Health and Safety FCX-HS32Document8 pagesHealth and Safety FCX-HS32berry trisnamuktiNo ratings yet

- Ehv SWP Form Scaffolding RemovalDocument2 pagesEhv SWP Form Scaffolding RemovalSn AhsanNo ratings yet

- Inverts Brick Masonry 2016 VersionDocument2 pagesInverts Brick Masonry 2016 VersionTrần Bảo AnNo ratings yet

- DOCS AND FILES-19128068-v1-DIT Min Const Safety Expectations Second Edition Aug 2022Document1 pageDOCS AND FILES-19128068-v1-DIT Min Const Safety Expectations Second Edition Aug 2022Nuragus HariyadiNo ratings yet

- Shifting and Loading Unloading of MaterialDocument4 pagesShifting and Loading Unloading of MaterialAdilMunirNo ratings yet

- Crane and Rigging Policy: Potential Fatal Risks PolicyDocument3 pagesCrane and Rigging Policy: Potential Fatal Risks PolicyAlex Sandro Borges PereiraNo ratings yet

- Ehv SWP Form Opgw SaggingDocument4 pagesEhv SWP Form Opgw SaggingSn AhsanNo ratings yet

- Hydraulic Excavators: Lifting With Slings: (Refer To Manufacturer's Manual)Document1 pageHydraulic Excavators: Lifting With Slings: (Refer To Manufacturer's Manual)bareekNo ratings yet

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- Working at Height Risk Assessment Mar 21Document2 pagesWorking at Height Risk Assessment Mar 21tariq1987No ratings yet

- Module 3Document114 pagesModule 3Vimal SankarNo ratings yet

- Osha FS-3759 PDFDocument3 pagesOsha FS-3759 PDFabdul khaderNo ratings yet

- RiggingDocument2 pagesRiggingpruncu.alianmNo ratings yet

- Guidance Blast ManagementVS2Document3 pagesGuidance Blast ManagementVS2osuwiraNo ratings yet

- Module 3Document117 pagesModule 3usmanNo ratings yet

- ErEbcqpwLhsp1uYp - zrFdQAEnSUWuEj8v-OSHA 10 Construction - Module 10 - Study GuideDocument6 pagesErEbcqpwLhsp1uYp - zrFdQAEnSUWuEj8v-OSHA 10 Construction - Module 10 - Study GuideBelkacem BouazzaNo ratings yet

- Procedure - HS011-Rotary-CoringDocument6 pagesProcedure - HS011-Rotary-CoringRasulNezNo ratings yet

- JSA For ExcavationsDocument3 pagesJSA For ExcavationsHSE fahadNo ratings yet

- 12 Life Saving RulesDocument15 pages12 Life Saving RulesVăn Trần ĐìnhNo ratings yet

- Handling of Misfires in MinesDocument4 pagesHandling of Misfires in Mineskanica maryNo ratings yet

- RA-SurveyingDocument7 pagesRA-SurveyingAbdul LatheefNo ratings yet

- SWP 02 - Use of Mobile ScaffoldDocument4 pagesSWP 02 - Use of Mobile ScaffoldGerald Wong NttNo ratings yet

- Concrete Bucket Safety2 PDFDocument3 pagesConcrete Bucket Safety2 PDFMuhammad Hamzah Habibburrahman100% (2)

- JSA-control Panel Final Reviwed AVCDocument5 pagesJSA-control Panel Final Reviwed AVCSubhash Chekka SEC 115KV ProjectNo ratings yet

- Craneblock WulDocument2 pagesCraneblock WulZachNo ratings yet

- Scaffolding Safety Procedure Awareness Session - Presentation MaterialDocument21 pagesScaffolding Safety Procedure Awareness Session - Presentation MaterialmjaseemksNo ratings yet

- Tilt-A-Door - Installation GuideDocument13 pagesTilt-A-Door - Installation GuideNhuVan NguyenNo ratings yet

- Safety Procedure For Pile TestDocument2 pagesSafety Procedure For Pile TestIsna MuthoharohNo ratings yet

- Use Personnel Lift Aerial Lift 06 2015 1Document2 pagesUse Personnel Lift Aerial Lift 06 2015 1Margielyn CaoileNo ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- Safe Lifting and Rigging TrainingDocument84 pagesSafe Lifting and Rigging Trainingfaroz khan100% (2)

- Hot Work and Modification PDFDocument19 pagesHot Work and Modification PDFmyo lwinNo ratings yet

- 1 Scaffolding Work PDFDocument16 pages1 Scaffolding Work PDFfadliNo ratings yet

- SRB-02-2011 - (Welding of Pipes) For Thrust BoringDocument4 pagesSRB-02-2011 - (Welding of Pipes) For Thrust BoringkkalviNo ratings yet

- Working On Slopes TrainingDocument37 pagesWorking On Slopes TrainingTim SharpNo ratings yet

- SWMS Work in A Confined SpaceDocument5 pagesSWMS Work in A Confined SpaceTamo Kim ChowNo ratings yet

- Lifting Hazards & Crane SafetyDocument26 pagesLifting Hazards & Crane SafetynincatNo ratings yet

- Lifting Operation Rev2Document29 pagesLifting Operation Rev2Chong Yun QingNo ratings yet

- W7 60 Slope Stability and Erosion Risk August2022Document53 pagesW7 60 Slope Stability and Erosion Risk August2022Abdul Aziz MohammedNo ratings yet

- Steep Slope ConstructionDocument16 pagesSteep Slope ConstructionAbdul Aziz MohammedNo ratings yet

- IIPP Campus Near Miss and Accident ReportDocument4 pagesIIPP Campus Near Miss and Accident ReportAbdul Aziz MohammedNo ratings yet

- Emergency EscapeDocument13 pagesEmergency EscapeAbdul Aziz MohammedNo ratings yet

- F3 McDonaldetal 0808Document6 pagesF3 McDonaldetal 0808Abdul Aziz MohammedNo ratings yet

- The Health and Safety (Safety Signs and Signals) Regulations 1996Document50 pagesThe Health and Safety (Safety Signs and Signals) Regulations 1996Mohamed NouzerNo ratings yet

- Traffic Signs: (The Philippines)Document65 pagesTraffic Signs: (The Philippines)Laidy Aizahlyn Indoc AngodNo ratings yet

- Safety Manager GuideDocument15 pagesSafety Manager GuideHaisam ZakariaNo ratings yet

- TRL - Overseas Road Note 17 PDFDocument27 pagesTRL - Overseas Road Note 17 PDFamintaka1025100% (1)

- Food Safety Director or Quality Assurance Manager or Quality AssDocument3 pagesFood Safety Director or Quality Assurance Manager or Quality Assapi-121348480No ratings yet

- SC1912 PDFDocument4 pagesSC1912 PDFA MahmoodNo ratings yet

- Safety Data Sheet: I.B.F® Tissue FixativeDocument9 pagesSafety Data Sheet: I.B.F® Tissue Fixativefitrisya luckyNo ratings yet

- Mushroom Good Agricultural Practices ProgramDocument23 pagesMushroom Good Agricultural Practices Programdchammer3171No ratings yet

- Aaaaaafile 2019 07 25 15 04 49Document24 pagesAaaaaafile 2019 07 25 15 04 49Hamza RizwanNo ratings yet

- Journal in Disaster Risk Reduction ManagementDocument11 pagesJournal in Disaster Risk Reduction ManagementEarl Mathew DangcalanNo ratings yet

- QA451Document242 pagesQA451Justice MachiwanaNo ratings yet

- FMECA - Cytotoxic DrugDocument6 pagesFMECA - Cytotoxic DrugRizqy AnandaNo ratings yet

- Msds PDFDocument4 pagesMsds PDFmisterpokeNo ratings yet

- MSDS IR Ultra Plus PDFDocument3 pagesMSDS IR Ultra Plus PDFUdit JainNo ratings yet

- Performance Monitoring and Coaching Journal: Republic of The Philippines Department of The Interior and Local GovernmentDocument14 pagesPerformance Monitoring and Coaching Journal: Republic of The Philippines Department of The Interior and Local GovernmentSanFabian Pangasinan Bfp RegionOneNo ratings yet

- Safety Instrumented System (SIS) HandbookDocument67 pagesSafety Instrumented System (SIS) HandbookDimas AgilNo ratings yet

- Iso TS 16733-2Document60 pagesIso TS 16733-2Matteo GiampieriNo ratings yet

- CHTerraGator 3244 ManualDocument560 pagesCHTerraGator 3244 ManualАндрей ГопкалоNo ratings yet

- 1111-Aa1 - Ga - 010122 - 080922Document4 pages1111-Aa1 - Ga - 010122 - 080922Tim Audit RSMNo ratings yet

- Brayco MSDS 2916907Document16 pagesBrayco MSDS 2916907RNo ratings yet

- Step7 - FM357-2Document822 pagesStep7 - FM357-2Sam eagle goodNo ratings yet

- Ankita Metals SopDocument10 pagesAnkita Metals SopDwitikrushna RoutNo ratings yet

- Electrical Wiring Diagram V414 M-32A M32B 7.5 2PCDocument532 pagesElectrical Wiring Diagram V414 M-32A M32B 7.5 2PCCreo ParametricNo ratings yet

- Nada PodDocument2 pagesNada PodzulfactNo ratings yet