Professional Documents

Culture Documents

Culvert and Multi Plate Installation 2016 Verison

Uploaded by

Jæy Jåý0 ratings0% found this document useful (0 votes)

16 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views3 pagesCulvert and Multi Plate Installation 2016 Verison

Uploaded by

Jæy JåýCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Job Hazard Analysis

(Always Wear Proper PPE)

Project: Superintendent:

Task: Culvert and Multi Plate Installation Date:

Step Potential Hazards Safe Procedures/Crew Responsibilities

• Designate a Competent Person or persons

• Review P3 (Preparation Planning Procedures) and Hazard Analysis with crew

Preparation

• Complete and review STA’s daily

• Assess location and conditions*

Proper layout • Review plans and specs; discuss with electrician

Damage to existing • Notify Dig Safe and all non-member utilities prior to start

Mark and locate utility lines or personnel • Follow 18” rule for locating utilities: Use hand tools to dig within 18” of the

existing utilities during location process marked line until the utility is exposed.

Overhead utility lines • Follow the 10’ overhead clearance rule

• Have electric lines de-energized or covered if you need to be closer than 10’

Excavate for culvert Cave-in of trench or test • Use proper sloping or shoring while locating utilities and placing conduit

and backfill after pit • Do not enter trench until it is properly sloped or shored

installation Rocks and dirt rolling • Spoils pile must be at least 2’ from edge of excavation

into trench or test pit • Keep trench or test pit area clean of all debris

Tools or supplies falling • Keep tools and supplies well away from the edge

into trench or test pit • Good housekeeping around excavation

Job Hazard Analysis Page 1 of 3 Culvert and Multi Plate Installation

Project: Superintendent:

Task: Culvert and Multi Plate Installation Date:

Step Potential Hazards Safe Procedures/Crew Responsibilities

Person falling or • Good housekeeping around excavation

tripping into trench or • Berm and barricade excavation

test pit • Keep non-essential personnel away from the hole

• Use a quality ladder of sufficient size to access holes over 4’ deep

Excavation and • Never walk on edges or spreaders of trench boxes

backfill continued Water in the trench • Divert or otherwise control surface water flows

• Dewater trench before installing culvert **

Personnel struck by • Maintain eye contact with excavator operator and truck drivers

trucks, machines, or • Maintain a safe distance from excavation operation

excavation • All personnel should be out of trench when backfilling

Cuts from sharp metal • Eliminate or mark any sharp or jagged edges

on ends of pipe • Wear gloves when working with metals

Cuts to hands from • Use proper wrench or sockets for task and wear gloves

slipping when

tightening bolts

Assemble and install Noise hazards • Always wear ear protection when operating impact guns or cutting culvert or

culvert or multi- multi-plate with power saw

plate Electrical shock from • Keep equipment and culvert at least 10’ from overhead wires

power source • Ground generator and use GFCIs

Pinched or crushed by • Assemble on level surface and trig pipe

rolling pipe

Rigging failure • Use proper rigging and inspect prior to each use

• Use tag lines to control suspended loads

• Maintain arm’s length from suspended load at all times

• Never put any body part under any suspended load

Job Hazard Analysis Page 2 of 3 Culvert and Multi Plate Installation

Project: Superintendent:

Task: Culvert and Multi Plate Installation Date:

Step Potential Hazards Safe Procedures/Crew Responsibilities

Being struck by pipe or • Never stand under a suspended load

Assemble and install machine • Maintain eye contact and safe distance from machinery

culvert or multi-

plate continued Injury from pry tools • Be sure all pry tools are properly anchored prior to prying and have a good

slipping footing

Other Steps (if any): Other hazards: Other safe procedures:

*1) If work is to be performed in a travel way, complete and follow Work in

Travel Way Job Hazard Analysis

2) If Hazardous Materials are encountered, cease work, secure work area

and notify Superintendent and/or appropriate personnel immediately

** If water is present, complete and follow Dewatering JHA

Job Hazard Analysis Page 3 of 3 Culvert and Multi Plate Installation

You might also like

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- JSA-RMC Pump ConcreteingDocument6 pagesJSA-RMC Pump ConcreteingRakeshkasarla100% (2)

- Method Statement of Gantry Crane Dismantling - DIFD 20-09-18Document8 pagesMethod Statement of Gantry Crane Dismantling - DIFD 20-09-18mechajay2002No ratings yet

- Revised List of Maharashtra HospitalsDocument16 pagesRevised List of Maharashtra Hospitalsdummy data100% (1)

- Ainsworth, The One-Year-Old Task of The Strange SituationDocument20 pagesAinsworth, The One-Year-Old Task of The Strange SituationliliaNo ratings yet

- Open Cholecystectomy ReportDocument7 pagesOpen Cholecystectomy ReportjosephcloudNo ratings yet

- Retaining Walls Slope Protection 2016 VersionDocument3 pagesRetaining Walls Slope Protection 2016 VersionsubNo ratings yet

- Demolition 2016 VersionDocument3 pagesDemolition 2016 VersionArun Koshy AlexanderNo ratings yet

- JHA Crushing OperationsDocument3 pagesJHA Crushing Operationsabdullah ashrafNo ratings yet

- Job Hazard Analysis DemolishDocument4 pagesJob Hazard Analysis Demolishyajid bustomiNo ratings yet

- Silt Fence Installation 2016 VersionDocument2 pagesSilt Fence Installation 2016 VersionMIAN MATEENNo ratings yet

- Dewatering 2016 VersionDocument2 pagesDewatering 2016 VersionAmeerHamzaWarraichNo ratings yet

- Essential Standard 1 - ExcavationsDocument8 pagesEssential Standard 1 - ExcavationsDarren O HanlonNo ratings yet

- DOCS AND FILES-19128068-v1-DIT Min Const Safety Expectations Second Edition Aug 2022Document1 pageDOCS AND FILES-19128068-v1-DIT Min Const Safety Expectations Second Edition Aug 2022Nuragus HariyadiNo ratings yet

- Inverts Brick Masonry 2016 VersionDocument2 pagesInverts Brick Masonry 2016 VersionTrần Bảo AnNo ratings yet

- RiggingDocument2 pagesRiggingpruncu.alianmNo ratings yet

- Health and Safety FCX-HS32Document8 pagesHealth and Safety FCX-HS32berry trisnamuktiNo ratings yet

- Ehv SWP Form Tower AssemblyDocument4 pagesEhv SWP Form Tower AssemblySn AhsanNo ratings yet

- Use Personnel Lift Aerial Lift 06 2015 1Document2 pagesUse Personnel Lift Aerial Lift 06 2015 1Margielyn CaoileNo ratings yet

- Ehv SWP Form Tower ErectionDocument4 pagesEhv SWP Form Tower ErectionSn AhsanNo ratings yet

- Capstan (OSRV) SOPDocument7 pagesCapstan (OSRV) SOPakbar muslimNo ratings yet

- Sample Swms Heights Mobile ScaffoldDocument7 pagesSample Swms Heights Mobile ScaffoldAnonymous BzGb2fnfENo ratings yet

- Crane and Rigging Policy: Potential Fatal Risks PolicyDocument3 pagesCrane and Rigging Policy: Potential Fatal Risks PolicyAlex Sandro Borges PereiraNo ratings yet

- JSA Any OprationDocument12 pagesJSA Any Oprationn.aboshhewaNo ratings yet

- Norseman Directional Drilling Safe Work PracticeDocument6 pagesNorseman Directional Drilling Safe Work PracticeZYS ConstructionNo ratings yet

- Working at Height Risk Assessment Mar 21Document2 pagesWorking at Height Risk Assessment Mar 21tariq1987No ratings yet

- Safety Orientation For Excavation WorkersDocument8 pagesSafety Orientation For Excavation WorkersHaroonAbdulRahimNo ratings yet

- ErEbcqpwLhsp1uYp - zrFdQAEnSUWuEj8v-OSHA 10 Construction - Module 10 - Study GuideDocument6 pagesErEbcqpwLhsp1uYp - zrFdQAEnSUWuEj8v-OSHA 10 Construction - Module 10 - Study GuideBelkacem BouazzaNo ratings yet

- Struck byDocument24 pagesStruck byzazoNo ratings yet

- Module 3Document117 pagesModule 3usmanNo ratings yet

- Working at Height Rev 4Document71 pagesWorking at Height Rev 4Adrian Seng100% (2)

- Safe Lifting and Rigging TrainingDocument84 pagesSafe Lifting and Rigging Trainingfaroz khan100% (1)

- CCRP - IP-20N ManualDocument281 pagesCCRP - IP-20N ManualelchevaraNo ratings yet

- Manual de Instalacion CeragonDocument257 pagesManual de Instalacion Ceragonsebastian sernaNo ratings yet

- Weekly Safety Training ExcavationDocument19 pagesWeekly Safety Training Excavationbsltcs65No ratings yet

- HSE-BMS-019 Excavations SafetyDocument34 pagesHSE-BMS-019 Excavations Safetykhan jadoonNo ratings yet

- Module 3Document114 pagesModule 3Vimal SankarNo ratings yet

- Excavation Trench SafetyDocument31 pagesExcavation Trench SafetyBipin Babu100% (1)

- JSA - Crane Setuppdf PDFDocument12 pagesJSA - Crane Setuppdf PDFChoko ChokriNo ratings yet

- Working Around Heavy Equipment: TBT NoDocument1 pageWorking Around Heavy Equipment: TBT NoRaynus ArhinNo ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- 5 Heavy Equipment Safety Rev.Document56 pages5 Heavy Equipment Safety Rev.Marc Louie S. SanchezNo ratings yet

- Ehv SWP Form Scaffolding RemovalDocument2 pagesEhv SWP Form Scaffolding RemovalSn AhsanNo ratings yet

- Liftingoperationsafetyppt 230220111908 487c851eDocument39 pagesLiftingoperationsafetyppt 230220111908 487c851emamuNo ratings yet

- R2 RC Installation ManualDocument10 pagesR2 RC Installation ManualMaan Valencia - RevillaNo ratings yet

- Crane SafetyDocument8 pagesCrane SafetyRaghu Dev Hosur100% (1)

- Formwork Placing Concrete PDFDocument1 pageFormwork Placing Concrete PDFdavidNo ratings yet

- Excavating, Trenching and ShoringDocument7 pagesExcavating, Trenching and ShoringocernnNo ratings yet

- Ehv SWP Form SpaceringDocument3 pagesEhv SWP Form SpaceringSn AhsanNo ratings yet

- WAH & ExcavationDocument23 pagesWAH & ExcavationFawwaz RidzuanNo ratings yet

- Method Statement Risk AssessmentDocument4 pagesMethod Statement Risk Assessmentjundesilva169No ratings yet

- Material Handling by CraneDocument16 pagesMaterial Handling by Cranenitin369100% (1)

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Solutions For Tree Care HazardsDocument2 pagesSolutions For Tree Care HazardsTerex14253No ratings yet

- Aerial LiftsDocument2 pagesAerial LiftsHous BoukadoNo ratings yet

- Work at Heigths BPDocument11 pagesWork at Heigths BPElias LemusNo ratings yet

- Chapter 3-3.5. (Shoring Design)Document51 pagesChapter 3-3.5. (Shoring Design)akhjazrNo ratings yet

- Interstitial Safety TrainingDocument28 pagesInterstitial Safety TrainingSham AranNo ratings yet

- Risk Mitigation Plan 1Document25 pagesRisk Mitigation Plan 1Omar BahakimNo ratings yet

- Excavation For ConstructionDocument57 pagesExcavation For ConstructionSaddiqNo ratings yet

- Work at HeightDocument65 pagesWork at HeightdaddyanataNo ratings yet

- Ajr.09.2772 Grading Neuroforaminal StenosisDocument4 pagesAjr.09.2772 Grading Neuroforaminal StenosisOscar NogueraNo ratings yet

- Perioperative Care For CABG PatientsDocument32 pagesPerioperative Care For CABG PatientsAya EyadNo ratings yet

- Hippocrates OathDocument6 pagesHippocrates OathSundary FlhorenzaNo ratings yet

- Wes Jackson PM PMP OhioDocument10 pagesWes Jackson PM PMP Ohioraj jdsNo ratings yet

- Cooling Tower (Genius)Document7 pagesCooling Tower (Genius)JeghiNo ratings yet

- Certification "Products Made of Compostable Materials" Procedure No. 3355757Document3 pagesCertification "Products Made of Compostable Materials" Procedure No. 3355757Rei BymsNo ratings yet

- Mini Project 2Document9 pagesMini Project 2gunjan_pattnayak2007No ratings yet

- ExamDocument10 pagesExamjohn ivan100% (1)

- NCP On DiabetesDocument2 pagesNCP On DiabetesShumaila AlviNo ratings yet

- TFALL CaseStudy-Chandni+Chopra 072020+Document5 pagesTFALL CaseStudy-Chandni+Chopra 072020+Luis Gustavo Heredia VasquezNo ratings yet

- The Superhero LifestyleDocument9 pagesThe Superhero LifestyleDerp Blood0% (3)

- Technical Publication: Direction 2296441-100 Revision 06 Ge Medical Systems Lightspeed 3.X - Schematics and BoardsDocument380 pagesTechnical Publication: Direction 2296441-100 Revision 06 Ge Medical Systems Lightspeed 3.X - Schematics and BoardsJairo Manzaneda100% (2)

- Posi LokDocument24 pagesPosi LokMarcel Baque100% (1)

- Edgie A. Tenerife BSHM 1108: Page 1 of 4Document4 pagesEdgie A. Tenerife BSHM 1108: Page 1 of 4Edgie TenerifeNo ratings yet

- UM-1D User ManualDocument30 pagesUM-1D User ManualAhmedBalaoutaNo ratings yet

- Buddahism ReportDocument36 pagesBuddahism Reportlaica andalNo ratings yet

- Sedation and Analgesia in Critically Ill Neurologic PatientsDocument24 pagesSedation and Analgesia in Critically Ill Neurologic PatientsrazaksoedNo ratings yet

- SM FBD 70Document72 pagesSM FBD 70LebahMadu100% (1)

- Aseptic TechniquesDocument3 pagesAseptic TechniquesMacy MarianNo ratings yet

- Project PlanDocument55 pagesProject PlanAlfredo SbNo ratings yet

- Chapter - 7 Materials HandlingDocument14 pagesChapter - 7 Materials HandlingTanaya KambliNo ratings yet

- 13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaDocument9 pages13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaArick Frendi AndriyanNo ratings yet

- Ecg Quick Guide PDFDocument7 pagesEcg Quick Guide PDFansarijavedNo ratings yet

- Mobil Delvac 1 ESP 5W-40Document3 pagesMobil Delvac 1 ESP 5W-40RachitNo ratings yet

- Understanding Senior Citizens Outlook of Death Sample FormatDocument14 pagesUnderstanding Senior Citizens Outlook of Death Sample FormatThea QuibuyenNo ratings yet

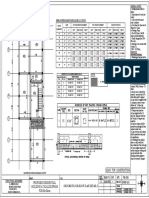

- G.f.roof Beam & Slab DetailDocument1 pageG.f.roof Beam & Slab Detailahmad anasNo ratings yet

- Narrative ReporDocument3 pagesNarrative ReporMARK LUKE ULITNo ratings yet