Professional Documents

Culture Documents

M 01 Repol

Uploaded by

albertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M 01 Repol

Uploaded by

albertoCopyright:

Available Formats

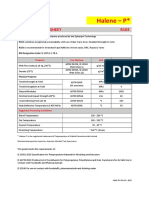

HOMOPOLYMER

AS12000N FOR MELT BLOWN NON-WOVEN

Repol AS12000N is an ultra-high melt flow, narrow molecular weight distribution polypropylene

homopolymer made from Spheripol Technology in Spheribeed form. This is a Unique technology

which allows to manufacture Polymer in Spheribeed form in the reactor and avoids extrusion &

Pelletization with better thermal stability.

High Melt Flow and Narrow MWD helps in optimum processing / line speeds and can be melt blown

in to ultra-fine denier fibers. This grade can be used on Standalone Melt Blown and can be also used

on Spun & Melt Blown Composite Lines

Typical Characteristics

Property Test Method Unit Typical Value*

Melt Flow Rate (230 oC/2.16 kg)$ ASTM D1238 gm/10 min 1200

Density ASTM D792 g/cc. 0.90

Melting Temperature ASTM D3418 O

C 161 - 165

* Typical values, not to be taken as specification.

$ Melt Flow rate is tested as per ASTM D1238 – Method C, The Value indicated is an Aim Value only and range is in accordance with ASTM

D 4101 – 17.

Typical Processing Conditions

Extrusion Temperature: 260 – 290 °C

Note: Processing parameters mentioned above are for reference only and not to be considered as specifications. They may vary based on

the product to be manufactured.

Applications

Melt blown nonwoven fabrics for Absorption & Filtration, Hygiene & Medical Disposables, Masks,

Wipes and others.

Reliance Industries Limited, Product Application & Research Centre (PARC), Vadodara Manufacturing Division, P. O. Petrochemicals, V i l la g e K o ya l i, District Vadodara: Pin 391346,

Gujrat, India. E-mail: polymer_patsupport@ril.com Website: www.ril.com

Updated as of January 2021

Regulatory Information

The product complies with Indian Standard IS 10910 on “Specification for polypropylene and its

copolymers for safe use in contact with foodstuffs, pharmaceuticals and drinking water. It also

conforms to IS 16738:2018 on positive list of constituents for polypropylene, polyethylene and their

copolymers for its safe use in contact with foodstuffs and pharmaceuticals. The grade and the

additives incorporated in it also comply with the FDA:CFR Title 21,177.1520, Olefin polymers

Storage Recommendations

Bags should be stored in dry / closed conditions at temperatures below 50°C and protected from UV

/ direct sunlight

DISCLAIMER

The information contained herein may include typical properties and processing parameters of the grade or its typical

performances when used in respective applications. The values given above are based on analysis of representative

samples and not the actual product supplied. It is the customer’s responsibility to inspect and test our grades in order to

satisfy itself as to the suitability of the products for customers’ particular application. The customer is solely responsible

for all determinations regarding any use of material or product and any process in its area of interest. RIL assumes no

obligation or liability for any loss, damage or injury directly or indirectly suffered or incurred as a result of using any of the

information or product given in this document. The information and data presented herein is true and accurate to the best

of our knowledge. No warranty or guarantee expressed or implied, is made regarding performance or otherwise. This

information and data may not be considered as a suggestion to use our products without taking into account existing

patents, or legal provisions or regulations, whether national or international. The user of any information and/or data is

advised to obtain the latest details from any of the offices of the company or its authorized agents, as the information

and/or data is subject to change based on the research and development work undertaken by the company.

Reliance Industries Limited, Product Application & Research Centre (PARC), Vadodara Manufacturing Division, P. O. Petrochemicals, V i l la g e K o ya l i, District Vadodara: Pin 391346,

Gujrat, India. E-mail: polymer_patsupport@ril.com Website: www.ril.com

Updated as of January 2021

You might also like

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlFrom EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- Rlene SpecificationDocument2 pagesRlene SpecificationjaintarunNo ratings yet

- H030SGDocument2 pagesH030SGLaxman AhirNo ratings yet

- Reliance Ldpe Heavy Duty Non Slip 0 5 Mfi J22fa002eDocument2 pagesReliance Ldpe Heavy Duty Non Slip 0 5 Mfi J22fa002eakshayNo ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- TDS J1020xa20Document2 pagesTDS J1020xa20akshayNo ratings yet

- Linear Low Density Polyethylene: Film Extrusion GradeDocument2 pagesLinear Low Density Polyethylene: Film Extrusion GradeAnugya RastogiNo ratings yet

- Im B120MADocument1 pageIm B120MAPrashant MalikNo ratings yet

- TWO H Chem LTD.: Nova-P Nova-PDocument2 pagesTWO H Chem LTD.: Nova-P Nova-PKingsley BaptistaNo ratings yet

- Topilene J700N ENDocument1 pageTopilene J700N ENJoni Sie MssNo ratings yet

- Topilene R200P PDFDocument2 pagesTopilene R200P PDFAli MNo ratings yet

- Topilene R200PDocument2 pagesTopilene R200PNguyễn Hồng NamNo ratings yet

- Polypropylene Random Copolymer: Technical Data SheetDocument2 pagesPolypropylene Random Copolymer: Technical Data SheetEmmylouCasanovaNo ratings yet

- Topilene R200P PDFDocument2 pagesTopilene R200P PDFEmmylouCasanovaNo ratings yet

- R200P Data SheetDocument2 pagesR200P Data SheetPRIME STEEL RE-ROLLING MILLSNo ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- Product Data Sheet: Sumitomo Polyethylene LdpeDocument2 pagesProduct Data Sheet: Sumitomo Polyethylene LdpeMd Abdul SalamNo ratings yet

- Abp-2030 Tds-Iso-EngDocument2 pagesAbp-2030 Tds-Iso-Engkatolokchok100% (2)

- Topilene J640Document1 pageTopilene J640EmmylouCasanovaNo ratings yet

- TC54Document1 pageTC54tushar.sasaneNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Technical Data Sheet - ISO PE LYONDELLDocument3 pagesTechnical Data Sheet - ISO PE LYONDELLNur AzizahNo ratings yet

- Topilene J800Document1 pageTopilene J800KevinGarciaNo ratings yet

- Bindex E-188 Speciality Polymer: Technical Data SheetDocument2 pagesBindex E-188 Speciality Polymer: Technical Data SheetfNo ratings yet

- TDS PP 306 Hi10ho 03Document2 pagesTDS PP 306 Hi10ho 03indahNo ratings yet

- Indorama - PP HPIG110 PP Homopolymer Grade For Injection MouldingDocument2 pagesIndorama - PP HPIG110 PP Homopolymer Grade For Injection MouldingAnonymous pQ3FRKTNo ratings yet

- Haldia PP Raffia - R103 DatasheetDocument2 pagesHaldia PP Raffia - R103 DatasheetNarender RawatNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Indorama - PP HPIG250 PP Homopolymer Grade For Injection MouldingDocument2 pagesIndorama - PP HPIG250 PP Homopolymer Grade For Injection MouldingAnonymous pQ3FRKTNo ratings yet

- Technical Data Sheet: Powder PropertiesDocument2 pagesTechnical Data Sheet: Powder PropertiesJoshNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- Nghi Son Refinery And Petrochemical Llc: Công Ty Tnhh Lọc Hóa Dầu Nghi SơnDocument1 pageNghi Son Refinery And Petrochemical Llc: Công Ty Tnhh Lọc Hóa Dầu Nghi SơnJimmy NguyenNo ratings yet

- PDS M365Document2 pagesPDS M365prabhunmayNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- TDS - Platinum Phase PP D100Document2 pagesTDS - Platinum Phase PP D100LIM YE HENGNo ratings yet

- Indorama - Copo NGC040IU PP Copolymer Grade For Injection MouldingDocument2 pagesIndorama - Copo NGC040IU PP Copolymer Grade For Injection MouldingAnonymous pQ3FRKTNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Lldpe Jl210: Application / Use CaseDocument2 pagesLldpe Jl210: Application / Use CaselyesNo ratings yet

- RCE111NPDocument3 pagesRCE111NPdignityymartNo ratings yet

- Technical Data Sheet - PE Granules-BasellDocument3 pagesTechnical Data Sheet - PE Granules-Basellbtv.mylepham.208No ratings yet

- TDS - NSRP All Grades UpdatedDocument4 pagesTDS - NSRP All Grades UpdatedJimmy Nguyen100% (2)

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- Bindex E-190 Speciality Polymers: Technical Data SheetDocument2 pagesBindex E-190 Speciality Polymers: Technical Data SheetfNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- TDS - Encor 2750 - 01-12Document2 pagesTDS - Encor 2750 - 01-12APEX SONNo ratings yet

- Ficha Tecnica NordelDocument2 pagesFicha Tecnica NordelStephany HernándezNo ratings yet

- TDS Emeraude Ldpe Lf2021e - V 2.3Document1 pageTDS Emeraude Ldpe Lf2021e - V 2.3Gabriela Lopez MunozNo ratings yet

- MOLYKOTE L-1668FM Synthetic Blend Vacuum Pump Oil 80-8456A-01 PDFDocument2 pagesMOLYKOTE L-1668FM Synthetic Blend Vacuum Pump Oil 80-8456A-01 PDFFajar EkoNo ratings yet

- HC402BFDocument2 pagesHC402BFgovindNo ratings yet

- Indian Oil Corporation Limited: RemarksDocument1 pageIndian Oil Corporation Limited: RemarksNAGRAJ RAMANNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- HD5403AA - New - Revision September 2020Document2 pagesHD5403AA - New - Revision September 2020AthonioMourinhoNo ratings yet

- Experimental Investigation of Properties of Polypropylene and Non-Woven Spunbond FabricDocument7 pagesExperimental Investigation of Properties of Polypropylene and Non-Woven Spunbond FabricalbertoNo ratings yet

- RSC Advances: PaperDocument9 pagesRSC Advances: PaperalbertoNo ratings yet

- Meltblown Technology For Production of Polymeric Micro/nano Fibers: A ReviewDocument73 pagesMeltblown Technology For Production of Polymeric Micro/nano Fibers: A ReviewalbertoNo ratings yet

- DTY Voltage Regulator Big Type With PWMDocument5 pagesDTY Voltage Regulator Big Type With PWMalbertoNo ratings yet

- P O L Y P R O P Y L E N E: Reliance Industries LimitedDocument1 pageP O L Y P R O P Y L E N E: Reliance Industries LimitedalbertoNo ratings yet

- SurgicalGowns JITPrintDocument18 pagesSurgicalGowns JITPrintalbertoNo ratings yet

- Overview and Analysis of The Meltblown Process and ParametersDocument25 pagesOverview and Analysis of The Meltblown Process and ParametersalbertoNo ratings yet

- Experimental and Numerical Simulation Study of An Air Drawing Model of Polyethylene Terephthalate (PET) Polymer and Model of Air Jet Flow Field in The Spunbonding Nonwoven ProcessDocument8 pagesExperimental and Numerical Simulation Study of An Air Drawing Model of Polyethylene Terephthalate (PET) Polymer and Model of Air Jet Flow Field in The Spunbonding Nonwoven ProcessalbertoNo ratings yet

- Classification of DGR For Transport by AirDocument5 pagesClassification of DGR For Transport by AirPaolo CeruttiNo ratings yet

- Consolidation Step by Step GuideDocument36 pagesConsolidation Step by Step GuideKrishna100% (3)

- Inheritance 3Document5 pagesInheritance 3Adarsh SinghNo ratings yet

- 4570 Error CodeDocument3 pages4570 Error CodeNadeesha NishaniNo ratings yet

- Public Health Engineering Department (PHED) : Government of RajasthanDocument18 pagesPublic Health Engineering Department (PHED) : Government of RajasthanRajesh GangwalNo ratings yet

- Standard of Flange in Different Field and CountriesDocument2 pagesStandard of Flange in Different Field and CountriesJaime LopezNo ratings yet

- An Analysis of Software Requirements Specification Characteristics in Regulated EnvironmentsDocument15 pagesAn Analysis of Software Requirements Specification Characteristics in Regulated EnvironmentsAnonymous rVWvjCRLGNo ratings yet

- 217plus - Buscar Con GoogleDocument2 pages217plus - Buscar Con GooglebibbiblosNo ratings yet

- Zu 9001 Mud Pump en Rev00Document731 pagesZu 9001 Mud Pump en Rev00Noureddine AdjNo ratings yet

- Katalog Kabel en HRD SGDocument1 pageKatalog Kabel en HRD SGAlda MariusNo ratings yet

- DCS Configurationand Its ComponentsDocument37 pagesDCS Configurationand Its Componentsaks5884No ratings yet

- Phu Dong Premier ApartmentDocument146 pagesPhu Dong Premier ApartmentMan EbookNo ratings yet

- Gas Turbine Engine Construction: Intake and DuctsDocument49 pagesGas Turbine Engine Construction: Intake and DuctsIdrisNo ratings yet

- L - 9 Ah - SSBLF I (6.5)Document7 pagesL - 9 Ah - SSBLF I (6.5)Arjun SharmaNo ratings yet

- Zimbra OS Admin GuideDocument188 pagesZimbra OS Admin GuideCarlitos CustodioNo ratings yet

- Alhamdulillah: Delivering Interactive SolutionsDocument9 pagesAlhamdulillah: Delivering Interactive SolutionsAfroz SiddiqueNo ratings yet

- Pipe Support Metric 2011 (High Resolution) PP 189 & 190 Corrected PDFDocument291 pagesPipe Support Metric 2011 (High Resolution) PP 189 & 190 Corrected PDFdzungNo ratings yet

- Sanyo MDF-U74V + VC Instruction-32414072Document42 pagesSanyo MDF-U74V + VC Instruction-32414072Diggy2No ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- TIJ Cartridge Care and Maintenance-ZDocument3 pagesTIJ Cartridge Care and Maintenance-ZCloudcst SoteloNo ratings yet

- BS en 13445-3 (2009)Document17 pagesBS en 13445-3 (2009)Pedro_csNo ratings yet

- Workflow Abap Ad-Hoc AssignmentDocument13 pagesWorkflow Abap Ad-Hoc AssignmentSrinivasan SriNo ratings yet

- Sierra MC Series 2014Document4 pagesSierra MC Series 2014MrJohnGaltshrugsNo ratings yet

- Alpha RT PDFDocument8 pagesAlpha RT PDFHugo GranadosNo ratings yet

- Brochure TPS 3200 4000 5000Document2 pagesBrochure TPS 3200 4000 5000MRC WeldingNo ratings yet

- APQP Matrix Pedal Yl1 at IsgDocument11 pagesAPQP Matrix Pedal Yl1 at Isgkaran singh100% (2)

- Csa Xe 3 13s Asr 920 Book1g 10G Ports PDFDocument16 pagesCsa Xe 3 13s Asr 920 Book1g 10G Ports PDFSyed JailanyNo ratings yet

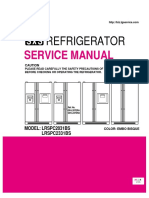

- Manual de Servicio SXD Refrigerator LGDocument113 pagesManual de Servicio SXD Refrigerator LGfredy guevara oNo ratings yet

- Soil Dynamics in TillageDocument14 pagesSoil Dynamics in Tillagerevange2112No ratings yet

- PCM Cayenne Telephone Manual USDocument183 pagesPCM Cayenne Telephone Manual USMantasPuskoriusNo ratings yet