Professional Documents

Culture Documents

The Effect of Lubricants On The Stiffness of Sewing Threads

The Effect of Lubricants On The Stiffness of Sewing Threads

Uploaded by

RITIKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Effect of Lubricants On The Stiffness of Sewing Threads

The Effect of Lubricants On The Stiffness of Sewing Threads

Uploaded by

RITIKCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/289069083

The effects of lubricants on the stiffness of sewing threads

Article in TEKSTİL VE KONFEKSİYON · July 2011

CITATIONS READS

3 1,183

4 authors, including:

Ayca Gurarda Binnaz Meric Kaplangiray

Uludag University Uludag University

28 PUBLICATIONS 283 CITATIONS 23 PUBLICATIONS 325 CITATIONS

SEE PROFILE SEE PROFILE

Mehmet Kanik

Uludag University

45 PUBLICATIONS 321 CITATIONS

SEE PROFILE

All content following this page was uploaded by Mehmet Kanik on 06 April 2020.

The user has requested enhancement of the downloaded file.

(REFEREED RESEARCH)

THE EFFECTS OF LUBRICANTS ON THE STIFFNESS

OF SEWING THREADS

YAĞLAMA MADDELERİNİN DİKİŞ İPLİKLERİNİN EĞİLME

DAYANIMI ÜZERİNE ETKİLERİ

Ayça GÜRARDA * , Binnaz MERİÇ KAPLANGİRAY, Mehmet KANIK, Esra YÜKSELTAN

Uludag University Textile Engineering Department, Bursa, Turkey

Received: 10.12.2010 Accepted: 16.05.2011

ABSTRACT

This paper reports an experimental investigation into the effects of lubricants on the stiffness of sewing threads. In this work, three

types of sewing threads, polyester-spun, core-spun (polyester/polyester) and core-spun (polyester/cotton) having the same ticket number

at different colours (white, grey and black) were used. Three different lubricant types and lubricant feeding rates (0,5-1-2 g/min) were

applied to these sewing threads. Therefore 81 different sewing threads were obtained.

The aim of this study is to see the effects of the lubricants on the stiffness of sewing thread. Sewing threads with very high bending

length and flexural rigidity values may lead to sewing problems like seam pucker as they too stiff to be manipulated and controlled. To

investigate the stiffness of a sewing thread bending length must be obtained. In this work a stiffness tester was used to measure the

bending length of sewing thread.

In this study, it was found when lubricant feeding rate increase on the sewing thread bending length and stiffness decreased. It was

also found lubricant type is very important on the stiffness of sewing thread.

Key Words: Sewing thread, Lubricant feeding rate, Lubricant amount, Stiffness, Bending length.

ÖZET

Bu araştırma, yağlama maddelerinin dikiş ipliklerinin eğilme dayanımı üzerine etkilerini deneysel olarak sunmaktadır. Bu

çalışmada, aynı etiket numarasında ve farklı renklerde (beyaz, gri ve siyah) polyester, core-spun (polyester/pamuk) ve core-spun

(polyester/polyester) olmak üzere 3 tip dikiş ipliği kullanılmıştır. Bu dikiş ipliklerine 3 değişik yağ tipi ve 3 değişik yağ besleme oranı

(0,5-1-2 g/min) uygulanmıştır. Böylece 81 değişik tip dikiş ipliği elde edilmiştir.

Bu çalışmanın amacı, dikiş ipliklerinin eğilme dayanımı üzerine yağların etkisini görmektir. Yüksek eğilme uzunluğu ve eğilme

rijtliğine sahip dikiş iplikleri sert olmalarından dolayı kullanılması ve kontrolü zor olduğundan dikiş büzülmesi gibi dikiş problemlerine

sebep olmaktadır. Dikiş ipliğinin eğilme dayanımı için eğilme uzunluğu bulunmalıdır. Bu çalışmada, dikiş ipliklerinin eğilme

uzunluğunun ölçümünde, eğilme dayanımı test cihazı kullanılmıştır. Burada, yağ besleme oranı arttığı zaman dikiş ipliği eğilme

uzunluğu ve eğilme dayanımı azalmaktadır. Aynı zamanda dikiş ipliklerinin eğilme dayanımı üzerine yağ tipi de çok önemlidir.

Anahtar Kelimeler: Dikiş ipliği, Yağ besleme oranı, Yağ miktarı, Eğilme dayanımı, Eğilme uzunluğu.

*

Corresponding author: Ayça Gürarda, aycagur@uludag.edu.tr, Tel: + 90 224 29420 60

1. INTRODUCTION friction between the thread-needle and The physical and mechanical

fabric being-sewn. Sewing thread properties of sewing threads related to

In apparel industry, the sewing finishes have a significant influence on seam apperance, their combined effect

process is one of the critical processes threads frictional properties. The is not clear and hence sewing threads

in the determination of productivity and lubricant must provide low and can not be compared in terms of their

quality of the finish garment (1,2). controlled level of friction and be overall performance.

What garment manufacturers can do capable of masking the different basic

to improve the quality of garments is to The physical and mechanical properties

surface properties of threads (3).

use better sewing threads, improved of sewing threads related to seam

machinery, better garment design and Although there is some understanding apperance include linear density,

better trained personel. The use of of the effect of individual thread irregularity, tensile, bending and

better sewing thread would appear to properties on seam apperance, their frictional properties and dimensional

be easiest, least expensive option (4). combined effect is not clear and hence stability (3). The bending properties of

sewing threads can not be compared sewing threads were important for

The forces that are developed in the seam pucker on garments. If the

in terms of their overall performance.

sewing thread are mostly due to the sewing thread stiffness higher than

272 TEKSTİL ve KONFEKSİYON 3/2011

fabric stiffness seam pucker were fiber movement during bending. After the lubricants were applied to the

occur on the garments (5). However, increase in flexural rigidity is sewing threads on the winding

more marked in rotor yarns than in machine under controlled lubricant

The simple cantilever is a common

ring-spun yarns. Moreover, increased feeding rates, the amount of lubricant

method to measure the bending rigidity

twist factor normally increases flexural on the sewing threads were measured.

of fabrics. However, the small

rigidity (8). Mesdan Oil Exraction Apparatus

dimension and untwisting of the free

(Code 273B) was used to measure for

end of yarn are the major difficulties in To investigate the stiffness of a sewing

quick determination of lubricant

the simple cantilever method. A two thread bending length and flexural

percent content of thread.

support beam system was used to rigidity must be obtained.

measure the bending rigidity of yarn As described at Turkish Standart 2250

(6). 2. MATERIALS AND METHODS “Textile Glass- Determination of

Stiffness of Rovings” and ISO

Owing to the helical paths taken by the Three types of sewing threads,

3375:2009, suspension of a test piece

fibers in the yarn, they are both bent polyester-spun, polyester/polyester

of threads, 500 mm long, at its centre

and twisted when the yarn is bent. The core-spun (poly/poly) and poliester/

over a hook with specified dimensions

yarn bending rigidity depends on the cotton core-spun (poly/cotton) having

and measurement of the separation of

bending and torsional rigidity of its the same ticket number at different

the two hanging ends of the test

constituent fibers, the arrangement colours (white, grey and black) were

specimen at a standart distance of 60

due to twist, and the geometric used. Three different lubricant types

mm below the suspension point (9).

parameters such as helix angle. The and lubricant feeding rates (0,5-1-2

yarn bending rigidity can be predicted g/min) were applied to these sewing A suitable sewing thread stiffness

using the tensile modulus and shear threads. Therefore 81 different sewing tester is shown in Figure 1.

modulus of its constituent fibers, yarn threads were obtained.

helix angle and yarn radius. SPSS was used for all statistical

Tenacity and elongation values of procedures. The results were evaluated

One of the yarn’s mechanical sewing threads were measured in a by analysis of variance (anova) and

properties, the bending property, is not Instron Strength Tester. Student-Newman-Keuls (SNK) test. All

only closely connected with the fabric’s test results were assessed at

physical properties, such as crimp, Lubricant was applied to these sewing

significant levels of α ≤ 0.05.

skew and curl but also with its threads under controlled conditions

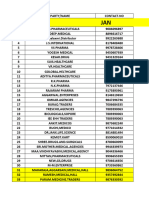

formability, such as drape, crease with the OMR winding machine. Table 6 shows the results of the SNK

recovery and tailorability (7). Lubricant feeding rates were set up tests. The numbers in brackets

with Graf lubrication system. The indicate the significant level of the

Yarn flexural rigidity was estimated by properties of lubricants were in Table factors for the properties in Table 6.

the ring loop method. Some chemical 1. The properties of sewing threads Therefore, all numbers in brackets are

treatments cause an increase in before lubricant application were in 1 for colour indicating that colour did

flexural rigidity regardless of the yarn Table 2 and the properties of sewing not have effect on bending length. The

structure. The swelling of fibres during thread after lubrication were in Table number in bracket is 3 for poly/cotton

enzymatic scouring and bleaching 3, 4 and 5. indicating that poly/cotton thread type

might increase the compactness of the had significant effect on bending

structure, resulting in lesser freedom of length.

Table 1. Properties of lubricants used

Viscosity Application temperature

Lubricant name Chemical structure

(mPas) (°C)

Polisiloksan+parafin Cold

Ruco-Fil SCI 500-1000

(without water) (25 °C)

Cold

Ruco-Fil SNV Polisiloksan 350

(25 °C)

Polisiloksan+parafin Hot

Ruco-Fil SCW 1000-3000

(without water) (80 °C)

Table 2. Properties of sewing threads before lubricant application

Yarn Type Colour Yarn Count Ticket Twist Tenacity Elongation Bending

(dtex) Number (T/m) (N/tex) (%) Length (cm)

White 130x2 120 781 (Z) 0.377 14.44 1.5

Polyester-spun Black 130x2 120 780 (Z) 0.353 14.82 1.48

Grey 130x2 120 774(Z) 0.406 14.98 1.56

Core-spun White 125x2 120 981(Z) 0.514 20.77 1.76

(poly /poly) Black 125x2 120 1004(Z) 0.49 20.22 1.86

Grey 125x2 120 997(Z) 0.512 21.60 1.9

White 123x2 120 1096(Z) 0.423 20.81 1.96

Core-spun Black 123x2 120 1081(Z) 0.422 20.31 2

(poly/cot) Grey 123x2 120 1105(Z) 0.411 19.82 1.92

TEKSTİL ve KONFEKSİYON 3/2011 273

Figure 1. The yarn stiffness tester (9)

3. RESULTS AND DISCUSSION length was higher than core-spun Lubricant types have significant effects

(poly/poly) and polyester-spun sewing on the sewing threads, too. The

3.1. Bending Length Results threads. Lubricant feeding rates and bending length values were higher on

The SNK results at Table 6 show that lubricant types are also have the sewing threads with SCI and SNV

no significant effects of the colours of significant effects on the bending lubricant types than the sewing threads

the sewing threads after lubricant length. The bending length values with SCW lubricant. Hot application

application on the bending length. But were higher on the sewing threads with with SCW lubricant makes the threads

the yarn structure has significant 0.5 lubricant feeding rate than the more softness than the cold application

effects on bending length. Core-spun sewing threads with 1 and 2 lubricant with SCI and SNV lubricants. At figure

(poly/cotton) sewing thread bending feeding rates. High lubricant feeding 2, 3 and 4 we can see these results,

rates make the sewing threads soft. too.

Table 3. Properties of polyester-spun sewing threads after lubrication

Lubricant Lubricant Feeding Colour Lubricant Bending Length Thread Tenacity Thread

Type Rate(g/min) Amount (%) (cm) (N/tex) Elongation (%)

White 3.05 1.54 0.346 13.77

0.5 Grey 4.2 1.52 0.404 14.64

Black 3.1 1.62 0.346 14.96

White 8.1 1.68 0.346 13.4

Ruco-Fil SCI 1 Grey 6.1 1.72 0.384 14.21

Black 6.3 1.78 0.362 14.47

White 14.8 2.02 0.348 13.58

2 Grey 14.4 1.84 0.381 14.52

Black 14.1 1.64 0.382 14.76

White 4 1.9 0.377 14.69

0.5 Grey 3.95 1.92 0.417 15

Black 4 1.6 0.364 15.09

White 9.8 1.76 0.386 14.25

Ruco-Fil SNV 1 Grey 8.8 1.86 0.37 13.98

Black 9.3 1.7 0.382 15.23

White 17.9 1.82 0.36 13.84

2 Grey 16 1.84 0.4 14.64

Black 14.4 1.7 0.354 14.61

White 3.5 1.9 0.35 13.87

0.5 Grey 4.15 1.48 0.414 15.17

Black 3.35 1.5 0.356 15.15

White 9.35 1.48 0.348 13.96

Ruco-Fil SCW 1 Grey 9.6 1.52 0.341 14.01

Black 9 1.46 0.386 15.27

White 16.75 1.46 0.380 14.64

2 Grey 16.3 1.52 0.372 14.52

Black 14.65 1.48 0.355 15.16

274 TEKSTİL ve KONFEKSİYON 3/2011

Table 4. Properties of core-spun (poly/poly) sewing thread after lubrication

Lubricant Lubricant Feeding Colour Lubricant Bending Length Thread Tenacity Thread

Type Rate(g/min) Amount (%) (cm) (N/tex) Elongation (%)

White 3.55 1.68 0.51 20.73

0.5 Grey 3.55 1.8 0.506 20.14

Black 3.75 1.88 0.510 21.56

White 6.9 1.96 0.518 20.29

Ruco-Fil SCI 1 Grey 7.2 1.76 0.512 21.11

Black 7.9 1.88 0.516 21.07

White 13.3 1.68 0.512 19.69

2 Grey 13.4 1.68 0.514 20.19

Black 13.95 1.82 0.50 20.98

White 3.95 1.82 0.504 20.49

0.5 Grey 3.85 1.8 0.520 16.75

Black 3.65 1.92 0.496 21.68

White 9.75 1.78 0.520 21.04

Ruco-Fil SNV 1 Grey 9.4 1.78 0.524 20.37

Black 9.1 1.86 0.496 21.44

White 15.1 1.84 0.507 20.17

Grey 15.2 1.76 0.516 20.05

Black 16.7 1.84 0.511 21.44

White 3.7 1.82 0.504 20.55

0.5 Grey 3.1 1.92 0.512 21.73

Black 4.4 1.84 0.504 21.58

White 8.55 1.9 0.500 20.57

Ruco-Fil SCW 1 Grey 9.05 1.9 0.518 21.08

Black 8.3 1.88 0.503 21.90

White 16.2 1.78 0.496 20.57

2 Grey 13.8 1.72 0.515 21.24

Black 14.25 1.84 0.477 21.32

Table 5. Properties of core-spun (poly/cotton) sewing thread after lubrication

Lubricant Type Lubricant Colour Lubricant Bending Length Thread Tenacity Thread

Feeding Amount (%) (cm) (N/tex) Elongation (%)

Rate(g/min)

White 3.15 1.98 0.425 20.59

0.5 Grey 3.35 1.92 0.422 20.13

Black 3.25 1.84 0.423 20.47

White 8 1.9 0.433 20.39

Ruco-Fil SCI 1 Grey 7.8 1.96 0.410 19.33

Black 7.05 1.84 0.426 20.10

White 14.25 1.66 0.427 20.52

2 Grey 14.6 1.84 0.411 19.75

Black 13.6 1.88 0.422 20.17

White 3.6 1.94 0.423 20.33

0.5 Grey 4.1 1.96 0.421 20.10

Black 4.25 1.84 0.422 19.82

White 9.25 1.92 0.426 20.26

Ruco-Fil SNV 1 Grey 8.9 1.78 0.424 20.05

Black 9.05 1.78 0.423 20.01

White 16.75 1.78 0.418 19.88

2 Grey 16.5 1.76 0.422 20.08

Black 16.05 1.86 0.422 19.47

White 4.1 1.96 0.432 21.26

0.5 Grey 4.35 1.9 0.427 20.64

Black 3.3 1.9 0.423 20.7

White 8.5 1.86 0.416 19.84

Ruco-Fil SCW 1 Grey 8.65 1.86 0.414 19.82

Black 9.05 1.78 0.423 20.38

White 15.84 1.84 0.424 21.12

2 Grey 14.6 1.84 0.407 20.20

Black 12.5 1.84 0.418 20.10

TEKSTİL ve KONFEKSİYON 3/2011 275

Table 6. The Student-Newman-Keuls test results of sewing threads after lubrication

Factor Bending Length Thread Tenacity Thread

(cm) (N/tex) Elongation (%)

Thread Polyspun 1.6644 (1) .3710 (1) 14.4919 (1)

Type Polycotton 1.8600 (3) .4222 (2) 20.2275 (2)

polypoly 1.8259 (2) .5089 (3) 20.8866 (3)

Colour Black 1.7741 (1) .4301 (1) 18.8707 (2)

Grey 1.7859 (1) .4460 (2) 18.4230 (1)

White 1.7904 (1) .4315 (1) 18.3123 (1)

Lubricant 2.00 1.7622 (1) .4323 (1) 18.4288 (1)

Feeding Rate 1.00 1.7904 (2) .4338 (1) 18.4444 (1)

0.50 1.7978 (2) .4361 (1) 18.7327 (2)

Lubricant SCW 1.7393 (1) .4307 (1) 18.7570 (2)

Type SCI 1.7919 (2) .4337 (1) 18.3687 (1)

SNV 1.8193 (2) .4377 (2) 18.4802 (1)

2,5

Bending Length (cm)

1,5

Polyspun,SCI

1 Polyspun,SNV

Polyspun,SCW

0,5

0

0,5 1 2

Lubricant Feeding Rate (g/min)

Figure 2. Bending length values of white poly spun sewing threads with SCI, SNV and SCW lubricants at different lubricant feeding rates

2

1,95

1,9

Bending Length (cm)

1,85

1,8

1,75 Polypoly,SCI

1,7 Polypoly,SNV

1,65 Polypoly,SCW

1,6

1,55

1,5

0,5 1 2

Lubricant Feeding Rate (g/min)

Figure 3. Bending length values of white core-spun (poly/poly) sewing threads with SCI, SNV and SCW lubricants at different lubricant

feeding rates

276 TEKSTİL ve KONFEKSİYON 3/2011

2

1,95

Bending Length (cm)

1,9

1,85

1,8

1,75 Polycot,SCI

1,7 Polycot,SNV

1,65 Polycot,SCW

1,6

1,55

1,5

0,5 1 2

Lubricant Feeding Rate (g/min)

Figure 4. Bending length values of white core-spun (poly/cotton) sewing threads with SCI, SNV and SCW lubricants at different lubricant

feeding rates

3.2. Lubricant Amount Results lubricants and Ruco-SNV silicone When lubricant feeding rate 2 g/min at

based lubricant for our sewing threads. Graf lubrication system, poly spun and

Parafin wax is an essential constitutent poly-cotton sewing thread lubricant

of the lubricants used for many sewing Figure 5, 6 and 7 show that significant amount higher than poly-poly sewing

thread, but silicone compounds are effects of the thread type and lubricant thread.

most frequently used because their feeding rate on the lubricant amount. In

frictional properties unaffected by heat. this study, it was found when lubricant Sewing threads stiffness were

In this study we used Ruco-SCI and feeding rate increased on the sewing decreased when the amount of

Ruco-SCW silicone-parafin based thread lubricant amount increased too. lubricant were increased.

16

Lubricant Amount (%)

14

12

10

8 Polyspun,SCI

6 Polypoly,SCI

4

Polycot,SCI

2

0

0,5 1 2

Lubricant Feeding Rate (g/m in)

Figure 5. Lubricant amounts of white poly-spun sewing threads with SCI lubricant at different lubricant feeding rates

18

16

Lubricant Amount

14

12

10

(%)

Polyspun,SNV

8

6 Polypoly,SNV

4 Polycot,SNV

2

0

0,5 1 2

Lubricant Feeding Rate (g/m in)

Figure 6. Lubricant amounts of white poly-spun sewing threads with SNV lubricant at different lubricant feeding rates

TEKSTİL ve KONFEKSİYON 3/2011 277

18

16

Lubricant Amount (%)

14

12

10 Polyspun,SCW

8 Polypoly,SCW

6 Polycot,SCW

4

2

0

0,5 1 2

Lubricant Feeding Rate (g/min)

Figure 7. Lubricant amounts of white poly-spun sewing threads with SCW lubricant at different lubricant feeding rates

3.3.Tenacity and Elongation Results

The SNK results at Table 6 and Figure 8, 9 and 10 show that significant effects of the thread type of the sewing thread after

lubricant application on the tenacity and elongation. There was no significant effect of lubricant feeding rate of the sewing

threads after lubrication application on the tenacity and elongation. Core-spun (poly/poly) sewing thread tenacity and

elongation values were higher than core-spun (poly/cot) and polyester-spun sewing threads.

0,39

0,38

Tenacity (N/Tex)

0,37

0,36

Polyspun,SCI

0,35

Polyspun,SNV

0,34 Polyspun,SCW

0,33

0,32

0,5 1 2

Lubricant Feeding Rate (g/min)

Figure 8. Tenacity values of white poly spun sewing threads with SCI, SNV and SCW lubricants at different lubricant feeding rates

0,52

0,515

0,51

Tenacity (N/Tex)

0,505

0,5 Polypoly,SCI

0,495 Polypoly,SNV

0,49 Polypoly,SCW

0,485

0,48

0,5 1 2

Lubricant Feeding Rate (g/m in)

Figure 9. Tenacity values of white core-spun (poly/poly) sewing threads with SCI, SNV and SCW lubricants at different lubricant feeding rates

278 TEKSTİL ve KONFEKSİYON 3/2011

0,435

0,43

Tenacity (N/Tex)

0,425

0,42 Polycot,SCI

Polycot,SNV

0,415

Polycot,SCW

0,41

0,405

0,5 1 2

Lubricant Feeding Rate(g/min)

Figure 10. Tenacity values of white core-spun (poly/cotton) sewing threads with SCI, SNV and SCW lubricants at different lubricant feeding rates

4. CONCLUSION Core-spun (poly/cotton) sewing thread necessity to optimize the amount of

stiffness was higher than core-spun lubricant on the sewing threads. We

In this study, we investigated the (poly/poly) and polyester-spun sewing suggested poly spun sewing thread and

tenacity, elongation, bending length thread after lubricant application. SCW lubricant at 1 and 2 g/min

and lubrication amount of three main Moreover, core-spun (poly/poly) sewing lubricant feeding rates and % 14-16

types of sewing threads with different thread has higher tenacity and lubricant amount for optimum seam

lubricant feeding rates. elongation than core-spun(poly/cotton) performance. It is hoped that the results

The lubricants on the sewing threads and polyester- spun sewing thread after can be applicable in the apparel

affect the sewing thread stiffness, lubricant application. industries.

greatly. In this study, it was found Differences in the yarn structure ACKNOWLEDGEMENT

when lubricant feeding rate increased affected bending length. Sewing

on the sewing thread bending length threads with very high bending length We gratefully acknowledgement the

and stiffness decreased. It was also and flexural rigidity values may lead to support for this work by the Uludağ

found lubricant type is very important sewing problems like seam pucker as University (Project no: 2009/37). We

on the stiffness of sewing thread. The they too stiff to be manipulated and also grateful to Coats Textile Factory-

bending length and stiffness of the controlled. Lubricant application has Bursa/Turkey and its Quality Assurance

sewing thread decreased after affected friction force and stiffness of Manager Mr. Onur Yüksel.

application of SCW lubricant at 80 °C. the sewing thread. Therefore, there is

REFERENCES

1. Hui P. L., et al., 2007, “Application of Artifical Neural Networks to the Prediction of Sewing Performance of Fabrics”, International Journal of Clothing

Science and Technology, 19 (5), pp. 291-318.

2. Kaya S., Erdoğan Ç., 2008, “A Research About Factors Which Cause Quality Defects in Apparel Plants At the Sewing Department”, Tekstil ve Konfeksiyon,

Yıl :18 (2), s:135-141.

3. Eryürük H.S., Kalaoğlu F., 2010, “The Effects of Different Amounts of Lubricant Application on the Sewing Thread Performance Properties” Textile Research

Journal, Vol 80 (12), pp.1232-1242.

4. Fan I., Leeuwner W., 1998, “The Performance of Sewing Threads with Respect to Seam Apperance” The Journal of the Textile Institute, Vol.89, Nm 1, 1998,

pp.142-154.

5. Stylios G., Lloyd D.W.,1990, “ Prediction of Seam Pucker in Garments by Measuring Fabric Mechanical Properties and Geometric Relationship”,

International Journal of Clothing Science and Technology, Vol.2, Nm 1, pp.6-15.

6. Ghane M., et al., 2008, “Bending Rigidity of Yarn Using Two Support Beam System”, Fibers & Textiles in Eastern Europe, Vol. 16, No 3 (68), pp.30-32.

7. Park J.W. and Oh A. G., 2009, “Bending Rigidity of Yarns”, Textile Research Journal, Vol 76 (6), pp. 478-485.

8. Tyagi G.K., Gupta S.K., 2009, “Study on Cotton Ring and OE Rotor Yarns Characteristics: Part III-Effect of Enzymatic Wet Proccessing on Various

Characteristics”, Indian Journal of Fibre & Textile Research, Vol.34, pp. 41-46.

9. Turkish Standart (TS 2250), 1976, “ Textile Glass-Determination of Stiffness of Rovings”.

Bu araştırma, Bilim Kurulumuz tarafından incelendikten sonra, oylama ile saptanan iki hakemin görüşüne sunulmuştur. Her iki hakem

yaptıkları incelemeler sonucunda araştırmanın bilimselliği ve sunumu olarak “Hakem Onaylı Araştırma” vasfıyla yayımlanabileceğine

karar vermişlerdir.

TEKSTİL ve KONFEKSİYON 3/2011 279

View publication stats

You might also like

- Ideas On Demand - A Crash Course On Creativ - Harrdas, MiliindDocument156 pagesIdeas On Demand - A Crash Course On Creativ - Harrdas, MiliindMyq100% (2)

- Argus: Tanker FreightDocument25 pagesArgus: Tanker FreightIvan OsipovNo ratings yet

- CONTRACT Job Order UtilityDocument3 pagesCONTRACT Job Order UtilityDus Tin100% (2)

- The Effects of Sewing Thread Properties On The Needle Thread Tension in An Industrial Sewing MachineDocument7 pagesThe Effects of Sewing Thread Properties On The Needle Thread Tension in An Industrial Sewing MachineRITIKNo ratings yet

- ملف رقم 3Document6 pagesملف رقم 3yosha3morshedNo ratings yet

- Nadu Param Bath 2016Document6 pagesNadu Param Bath 2016singhgirendra20001523No ratings yet

- Knitting Faults Causes and Remedies of Knit FabricsDocument14 pagesKnitting Faults Causes and Remedies of Knit FabricsRavi KumarNo ratings yet

- Knitting Faults Causesand Remediesof Knit FabricsDocument14 pagesKnitting Faults Causesand Remediesof Knit FabricsDivya SuryavanshiNo ratings yet

- Sew AbilityDocument5 pagesSew AbilityNitta MallikNo ratings yet

- Impact of Different Seam Types On SeamDocument5 pagesImpact of Different Seam Types On SeamEman El-metwalyNo ratings yet

- IJSR Article3Document6 pagesIJSR Article3Nawfal KettaniNo ratings yet

- Ijftr 43 (2) 164-172Document9 pagesIjftr 43 (2) 164-172anil beniwalNo ratings yet

- 93 M2 PDFDocument10 pages93 M2 PDFDoniNo ratings yet

- Effect of Knitted Structure On The Properties of Knitted FabricDocument5 pagesEffect of Knitted Structure On The Properties of Knitted FabricariefNo ratings yet

- Effect of Twist On Yarn PropertiesDocument6 pagesEffect of Twist On Yarn Propertiesali4300136No ratings yet

- Influence of Weave Design and Yarn Types On Mechanical and Surface Properties of Woven FabricDocument4 pagesInfluence of Weave Design and Yarn Types On Mechanical and Surface Properties of Woven FabricChinedu ObasiNo ratings yet

- Study On The Effect of Stitch Length On PhysicalDocument7 pagesStudy On The Effect of Stitch Length On PhysicalSudipto BeheraNo ratings yet

- Processing and Properties of Sewing Threads: Indian Journal of Textile Research August 2009Document10 pagesProcessing and Properties of Sewing Threads: Indian Journal of Textile Research August 2009Randhir Kumar GuptaNo ratings yet

- Characterization of Low Twist Yarn: Effect of Twist On Physical and Mechanical PropertiesDocument7 pagesCharacterization of Low Twist Yarn: Effect of Twist On Physical and Mechanical PropertiesMd. Humayun KabirNo ratings yet

- Improvement of Mode I Interlaminar Fracture Toughness of Stitched Glass/Epoxy CompositesDocument25 pagesImprovement of Mode I Interlaminar Fracture Toughness of Stitched Glass/Epoxy Compositesdharm94No ratings yet

- Effect of Different Types of Seam Stitch PDFDocument1 pageEffect of Different Types of Seam Stitch PDFsapna maheshwariNo ratings yet

- Manufacturing and Sewing Performance of Polyurethane and Polyurethane Silicone Coated FabricsDocument7 pagesManufacturing and Sewing Performance of Polyurethane and Polyurethane Silicone Coated FabricsAbhishek KumarNo ratings yet

- Effect of Speed Frame Drafting Systems On Quality of Ring YarnDocument6 pagesEffect of Speed Frame Drafting Systems On Quality of Ring YarnabhijitNo ratings yet

- Ijftr434393 401Document10 pagesIjftr434393 401jayanttiwariNo ratings yet

- A Comparative Study On Seam Performance of Cotton and Polyester Woven FabricsDocument13 pagesA Comparative Study On Seam Performance of Cotton and Polyester Woven FabricsAbhishek KumarNo ratings yet

- Study On Licker-In and Flat Speeds of Carding Machine and Its Effects On Quality of Cotton Spinning ProcessDocument17 pagesStudy On Licker-In and Flat Speeds of Carding Machine and Its Effects On Quality of Cotton Spinning ProcessSyah RezaNo ratings yet

- Optimizingthe Shrinkageand Bursting Strengthof Knitted Fabricsafter Resin FinishingDocument7 pagesOptimizingthe Shrinkageand Bursting Strengthof Knitted Fabricsafter Resin FinishingAyman SebaeiNo ratings yet

- A Study The Effect of Modifications in Compact Spinning Machine On The Yarn Quality PropertiesDocument10 pagesA Study The Effect of Modifications in Compact Spinning Machine On The Yarn Quality PropertiesVaibhav SinghNo ratings yet

- Effect of Sewing Speed On Seam Strength: January 2014Document8 pagesEffect of Sewing Speed On Seam Strength: January 2014AdamS RamadhanNo ratings yet

- Effect of Yarn Wetting On Some Physical Properties of Polyamide 6 False-Twist Textured YarnDocument8 pagesEffect of Yarn Wetting On Some Physical Properties of Polyamide 6 False-Twist Textured YarnFahima RashidNo ratings yet

- Effect of Some Splicing Variables Upon Strength CHDocument4 pagesEffect of Some Splicing Variables Upon Strength CHAssad FarooqNo ratings yet

- 01 NiromiDocument3 pages01 NiromiShanmugeshwari MuthiahNo ratings yet

- ملف رقم 4 ... حلاDocument12 pagesملف رقم 4 ... حلاyosha3morshedNo ratings yet

- Analysis of The Imperfection Index (Ipi) Value of Carded Yarn Produced by Using Different Diameter Spacers On The Ring Frame Spinning MachineDocument7 pagesAnalysis of The Imperfection Index (Ipi) Value of Carded Yarn Produced by Using Different Diameter Spacers On The Ring Frame Spinning MachineUtsho ParvezNo ratings yet

- Measurement of Seam Puckering and in Uence of Its Causes: IOSR Journal of Engineering April 2014Document8 pagesMeasurement of Seam Puckering and in Uence of Its Causes: IOSR Journal of Engineering April 2014Trangg BiNo ratings yet

- Effect of Yarn Count On Single Jersey Knitted Fabric PropertiesDocument5 pagesEffect of Yarn Count On Single Jersey Knitted Fabric PropertiesGOPINo ratings yet

- Seam Performance Evaluation of Plain Fabric UsingDocument9 pagesSeam Performance Evaluation of Plain Fabric UsingMd NurunnabiNo ratings yet

- Final Project Paper On The Smoothness of Stitch and Impact of Stitch Types On Seam StrengthDocument22 pagesFinal Project Paper On The Smoothness of Stitch and Impact of Stitch Types On Seam StrengthInnocent Shihab ShifatNo ratings yet

- Effects of Combed and Carded Yarn On Weft Knitted Finished Quality-MinDocument5 pagesEffects of Combed and Carded Yarn On Weft Knitted Finished Quality-MinNasrin AkterNo ratings yet

- Effect of Fiber PDFDocument4 pagesEffect of Fiber PDFAnil Suryawanshi0% (1)

- Ieie D 17 00025 - R1Document20 pagesIeie D 17 00025 - R1suchibrata rayNo ratings yet

- Improving Yarn Quality by Modification On Drafting Zone Settings of Draw FrameDocument11 pagesImproving Yarn Quality by Modification On Drafting Zone Settings of Draw FrameAbrõ WazirNo ratings yet

- Measurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaDocument7 pagesMeasurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Evaluation of Real Yarn Diameter - Processing, Dyeing & Finishing - FeaturesDocument7 pagesEvaluation of Real Yarn Diameter - Processing, Dyeing & Finishing - FeaturesTrinhTruongNo ratings yet

- Geometrical Model To Calculate The Consumption of Sewing Thread For 504 Over-Edge StitchDocument7 pagesGeometrical Model To Calculate The Consumption of Sewing Thread For 504 Over-Edge StitchBabar RamzanNo ratings yet

- 693 3926 1 PBDocument0 pages693 3926 1 PBM A HasanNo ratings yet

- Bursting Strengthof Knitted FabricsDocument7 pagesBursting Strengthof Knitted FabricsAyman SebaeiNo ratings yet

- Effect of Structural Parameters of Injected Slub Yarn On Its Tensile Properties and Abrasion ResistanceDocument9 pagesEffect of Structural Parameters of Injected Slub Yarn On Its Tensile Properties and Abrasion ResistanceDharmendra ChaudhryNo ratings yet

- 9927 28506 1 PBDocument14 pages9927 28506 1 PBSANGAVI TNo ratings yet

- Dimensional StabilityDocument10 pagesDimensional StabilityhawNo ratings yet

- Effect of Stitch Per Inch (SPI) and Yarn Count On Seam Strength of Twill FabricDocument7 pagesEffect of Stitch Per Inch (SPI) and Yarn Count On Seam Strength of Twill FabricAbhishek KumarNo ratings yet

- JSLTC SeamEfficDocument8 pagesJSLTC SeamEfficAlime Aslı İlleezNo ratings yet

- Bending and Compression Behaviour of Polyester Air-Jet-Textured and Cotton-Yarn FabricsDocument5 pagesBending and Compression Behaviour of Polyester Air-Jet-Textured and Cotton-Yarn Fabricsanil kapadiaNo ratings yet

- Study On Impacts of Spinning Process On Fiber CharacteristicsDocument6 pagesStudy On Impacts of Spinning Process On Fiber CharacteristicsNeelakandan DNo ratings yet

- Characterisation of Seam Strength & Seam Slippage On Cotton FabricDocument10 pagesCharacterisation of Seam Strength & Seam Slippage On Cotton FabricTuan Nguyen MinhNo ratings yet

- Ocholaand Mwasiagi 2012Document6 pagesOcholaand Mwasiagi 2012kahishasafwanasutaNo ratings yet

- Statistical Analysis of Yarn To Metal Frictional Coefficient of Cotton Spun Yarn Using Taguchi Design of ExperimentDocument9 pagesStatistical Analysis of Yarn To Metal Frictional Coefficient of Cotton Spun Yarn Using Taguchi Design of ExperimentMadhavKumar ThangavelNo ratings yet

- Spirality in Cotton Knit Fabrics Before and After Compacting Using Selected Yarn Count and Stitch LengthDocument8 pagesSpirality in Cotton Knit Fabrics Before and After Compacting Using Selected Yarn Count and Stitch Length2016rezashaNo ratings yet

- Calculating The Amount of Sewing Thread Consumption For Different Types of Fabrics and Stitch TypesDocument8 pagesCalculating The Amount of Sewing Thread Consumption For Different Types of Fabrics and Stitch TypesRaaz The ghostNo ratings yet

- Fabric Science-Ii: Assignment-3Document5 pagesFabric Science-Ii: Assignment-3nikitaNo ratings yet

- Effects of Different Count and Stitch Length On Spirality, Shrinkage and GSM of Knit FabricsDocument7 pagesEffects of Different Count and Stitch Length On Spirality, Shrinkage and GSM of Knit FabricsPUGAZHENDHI SNo ratings yet

- 7ITTC2018 Proceedings Book Sayfalar 231 240Document11 pages7ITTC2018 Proceedings Book Sayfalar 231 240ramiroNo ratings yet

- Part Disbursement Request FormDocument1 pagePart Disbursement Request Formravi100% (1)

- (VAT) in To: Clarifying (RR) No. The The Tax of (TaxDocument13 pages(VAT) in To: Clarifying (RR) No. The The Tax of (TaxShiela Marie Maraon100% (1)

- Nabl 400Document674 pagesNabl 400Ronak shahNo ratings yet

- April Sale SDocument13 pagesApril Sale Stechhealers37No ratings yet

- IB Econ Notes Chapter 2Document17 pagesIB Econ Notes Chapter 2Yiyun HanNo ratings yet

- Summative Test TleDocument18 pagesSummative Test TleGillyn Ruiz - AntonioNo ratings yet

- EMB 833 Assignment 1Document11 pagesEMB 833 Assignment 1Aliyu GafaarNo ratings yet

- Jumeirah Business Center by Al Fajer PropertiesDocument2 pagesJumeirah Business Center by Al Fajer PropertiesFrank DeligneNo ratings yet

- Lim Fire Research 03 2Document351 pagesLim Fire Research 03 2torNo ratings yet

- The Lincoln at Towne Square Apartments - Apartments in Plano, TXDocument3 pagesThe Lincoln at Towne Square Apartments - Apartments in Plano, TXSuraj KumarNo ratings yet

- Breakout Trading PDF Guide Content UpgradeDocument9 pagesBreakout Trading PDF Guide Content UpgradeHendra GunawanNo ratings yet

- Parkinmacro4 1300Document16 pagesParkinmacro4 1300Mr. JahirNo ratings yet

- Tender73391 PDFDocument266 pagesTender73391 PDFEr MogarkarNo ratings yet

- UntitledDocument3 pagesUntitledabdi abdiNo ratings yet

- Economics Project Lina 12A PDFDocument2 pagesEconomics Project Lina 12A PDFlina atyaniNo ratings yet

- 13 08 20 Final Capital Market ADDIS ABABA UNIVERSITYDocument2 pages13 08 20 Final Capital Market ADDIS ABABA UNIVERSITYchere100% (2)

- CrystalFX - User's ManualDocument16 pagesCrystalFX - User's ManualNerdyzinho OirotivNo ratings yet

- Company Profile - PT. Petrotec Air PowerDocument6 pagesCompany Profile - PT. Petrotec Air Poweriwan primus gultomNo ratings yet

- Customer Lifetime Value Calculator For Financial Institutions: Follow The Four Steps and Input Your CLV DataDocument29 pagesCustomer Lifetime Value Calculator For Financial Institutions: Follow The Four Steps and Input Your CLV DataPooja GuptaNo ratings yet

- New Chandigarh CaseDocument96 pagesNew Chandigarh CaseOjaswa PathakNo ratings yet

- Gym Membership Package G HotelDocument1 pageGym Membership Package G HotelOmar ShamsuddinNo ratings yet

- Invoice-27 MOA-4 Rekap PDFDocument1 pageInvoice-27 MOA-4 Rekap PDFdeeb1987No ratings yet

- ბუღალტერია - მ. ძოწენიძეDocument147 pagesბუღალტერია - მ. ძოწენიძეAlonzo MoselyNo ratings yet

- JSH - Module5 TH6 MPTH2Document5 pagesJSH - Module5 TH6 MPTH2Meishein FanerNo ratings yet

- Rebel SafetyGear Spec RE436BKDocument1 pageRebel SafetyGear Spec RE436BKGerson Sérgio MavieNo ratings yet

- JNTUA Managerial Economics - Financial Analysis Notes - R20Document52 pagesJNTUA Managerial Economics - Financial Analysis Notes - R20Pichuka VarshithaNo ratings yet

- Chapter 10 Marketing Exam AnswersDocument2 pagesChapter 10 Marketing Exam AnswersliaNo ratings yet