Professional Documents

Culture Documents

Tannin Note

Tannin Note

Uploaded by

sivaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tannin Note

Tannin Note

Uploaded by

sivaCopyright:

Available Formats

INTRODUCTION:

Internal treatment of water inside the boiler is essential whether or not the feedwater has

been pretreated. Internal treatment compliments external treatment and is required

regardless of whether the impurities entering the boiler with the feedwater are large or small

in quantity. In some cases feedwater supply needs to be only filtered without the need for any

other external treatment. Internal treatment can constitute the sole treatment when boilers

operate at low pressure, large amounts of condensed steam are used for feedwater, or the raw

water available is of good quality. However, in moderate or high-pressure boilers, External

treatment of the make-up water is mandatory for good results. With today’s boilers having

higher heat transfer rates, even a small deposit can cause tube failure or wasted fuel.

Internal water treatment program aims at the following:

1. To react with incoming feedwater hardness and prevent it from precipitating on the

boiler metal as scale

2. To condition any suspended matter such as hardness sludge in the boiler and make it

nonadherent to the boiler metal

3. To provide antifoam protection to permit a reasonable concentration of dissolved and

suspended solids in the boiler water without foaming

4. To eliminate oxygen from the feedwater

5. To provide enough alkalinity to prevent boiler corrosion

6. To prevent scaling and protect against corrosion in the steam-condensate systems.

Various technologies are available for Boiler water treatment . For the low pressure boilers the

popular technologies are the Phosphate / Sodium sulphite based programs , whilst at Wex we

have a host of technologies to offer for boilers and especially for low pressure boilers we have

stabilised tannins also among the offreings . A comparision of the technologies is done herewith

along with description of the stabilised tannIn product CHEMSOL 9221.

Advantages of the CHEMSOL 9221 Technology:

CHEMSOL 9221 , a Tannin technological product offers dual corrosion protection

mechanism since they not only remove the oxygen by chemisorption ,but also form a

corrosion resistant tannate film on the boiler steel.

CHEMSOL 9221 is brown in colour so is easier to detect and test .

They are particularly suitable for low or variable feed water temperatures and very good

at protecting idle and intermittently used boilers.

CHEMSOL 9221 is a very good dispersants and even oil dispersants in case of oil slips.

They cut down foaming and carryover and are effective for a wider range of TDS in the

boilers.

Suitable for low pressure boilers , they are excellent sludge conditioners.

They don’t add to the boiler TDS so reduces the need for blow down and saves energy.

Methodology of its workings:

Chemisorbs Oxygen Molecules

And forms protective film over

the wet metal surface.

Target Market : For Boilers with feed hardness less then 10 ppm and low pressure boilers

Dis-Advantage of Tannin Technology:

They add colour to blowdown waters.

They are suitable for low pressure boilers

Caution Note:

In case of accidental hardness slippage , compliment the CHEMSOL 9221 program with

CHEMSOL 9065 @ 5 ppm dose, accompanied by blow downs for control on boiler water

hardness , max limit of 300 ppm.

For long shutdowns of boilers kindly give double blowdowns before boiler stoppage and

fill the boiler with fresh treated waters.

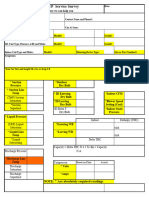

Residuals of Tannin in Boiler: 100 to 150 ppm Tan

Method of Testing:

TAN TEST KIT method using TN1 AND TN2 reagents.

Take 20 ml sample

Add TN1 ( indicator powder ) about 5 milligrams ( approx.) or one small scoop.

Add TN2 Solution till pink colour persist for about 10 seconds.

TAN ppm is = Drops *10.

You might also like

- Lucas CAV DPA Injection Pump Instruction BookDocument8 pagesLucas CAV DPA Injection Pump Instruction BookRicardo Jorge Horta Pequeno83% (12)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Kadix Clima Manual Baxi Duo Tec MP 35-110 Engl PDFDocument5 pagesKadix Clima Manual Baxi Duo Tec MP 35-110 Engl PDFVasil PascuNo ratings yet

- Water Treatment - EngineerTraining2021fffDocument49 pagesWater Treatment - EngineerTraining2021fffRakeshKrishnanNo ratings yet

- Tank Lining Brochure Corp 20140320Document7 pagesTank Lining Brochure Corp 20140320manuel25286262No ratings yet

- Chemphos 111Document6 pagesChemphos 111Himanshu AgrawalNo ratings yet

- Neutralizing AmineDocument3 pagesNeutralizing AmineJefanny JaouhariNo ratings yet

- Wet Lay Up in BoilerDocument5 pagesWet Lay Up in BoilersprotkarNo ratings yet

- Water Treatment & Quality For Boiler Less Than 40 Bar To Prevent Boiler FailuresDocument17 pagesWater Treatment & Quality For Boiler Less Than 40 Bar To Prevent Boiler Failureszerocool86No ratings yet

- Boiler ChemicalsDocument7 pagesBoiler ChemicalsTayaChandranNo ratings yet

- Total Boiler SystemDocument11 pagesTotal Boiler SystemWaleed EmaraNo ratings yet

- Pressurised Deaerator Solutions-Sales BrochureDocument4 pagesPressurised Deaerator Solutions-Sales BrochureYury LorenzNo ratings yet

- Different Systems For Boiler Feed Water TreatmentDocument30 pagesDifferent Systems For Boiler Feed Water TreatmentsudirmanNo ratings yet

- Boiler Chemicals Untuk Pabrik CPO PDFDocument7 pagesBoiler Chemicals Untuk Pabrik CPO PDFMuhammad Abdurrokhim ANo ratings yet

- Recommended Procedure For Alkali Boil OutDocument3 pagesRecommended Procedure For Alkali Boil OutretrogradesNo ratings yet

- Coro CleanDocument18 pagesCoro Cleanlaminar ersNo ratings yet

- Hydrogen Embrittlement in Boilers - LenntechDocument2 pagesHydrogen Embrittlement in Boilers - Lenntechseif elsaieNo ratings yet

- Desiccants PDFDocument9 pagesDesiccants PDFjesus_manrique2753No ratings yet

- Water Chemistry Guidelines For High Pressure Boilers: PUB - NO. 2003Document12 pagesWater Chemistry Guidelines For High Pressure Boilers: PUB - NO. 2003गुंजन सिन्हाNo ratings yet

- Quench Tower 2Document16 pagesQuench Tower 2achillesntroy100% (2)

- Experimental Study On Heat Recovery From Continuous Blow Down Water and Reduced Feed Water Consumption by Utilizing It in CFBC BoilerDocument5 pagesExperimental Study On Heat Recovery From Continuous Blow Down Water and Reduced Feed Water Consumption by Utilizing It in CFBC BoilerIan B. YtomNo ratings yet

- 3.10 Water For The BoilerDocument12 pages3.10 Water For The BoilerJhonathan AlejandroNo ratings yet

- Primary-Secondary-Tertiary Pumping PDFDocument32 pagesPrimary-Secondary-Tertiary Pumping PDFMinh TranNo ratings yet

- Industrial Water and Waste Water ManagementDocument15 pagesIndustrial Water and Waste Water ManagementsagarNo ratings yet

- Bonderite® 958-EnDocument9 pagesBonderite® 958-EnGabriel BrăbanNo ratings yet

- Boiler Preservation NalcoDocument4 pagesBoiler Preservation NalcoSushil Kumar71% (7)

- Aquacare - Boiler Water TreatmentDocument14 pagesAquacare - Boiler Water TreatmentjewettwaterNo ratings yet

- Storage and Handling of NEODOL AlcoholsDocument7 pagesStorage and Handling of NEODOL AlcoholsGonzalo Zoé VázquezNo ratings yet

- DNCGDocument5 pagesDNCGMurugan VellaichamyNo ratings yet

- Consider New Steam System Corr Prot Refineries HydProcMar2014Document9 pagesConsider New Steam System Corr Prot Refineries HydProcMar2014Anonymous nw5AXJqjdNo ratings yet

- Diethyl Hydroxyl AmineDocument6 pagesDiethyl Hydroxyl AminemnasiroleslamiNo ratings yet

- Boiler Water TestDocument8 pagesBoiler Water TestMohammad Jahid AlamNo ratings yet

- AMMONIA Syn Gas Drying With Z4-01Document4 pagesAMMONIA Syn Gas Drying With Z4-01raghu4594No ratings yet

- PhosphateDocument4 pagesPhosphatechinmay sundar dashNo ratings yet

- Design and Operation Considerations For Condensate Polishing - T5S5O3-paper PDFDocument17 pagesDesign and Operation Considerations For Condensate Polishing - T5S5O3-paper PDFNhhVuNo ratings yet

- 0372 0375 Vol A1 t02 Water ChemistryDocument71 pages0372 0375 Vol A1 t02 Water ChemistrySandeep MishraNo ratings yet

- Boiler WaterDocument1 pageBoiler WaterdeviancemNo ratings yet

- ConSep Carbon Regeneration KilnDocument2 pagesConSep Carbon Regeneration KilnNelsonNo ratings yet

- Boiler Blowdown and Refuse LossesDocument14 pagesBoiler Blowdown and Refuse LossesknsaravanaNo ratings yet

- Pentomuls: Water-In-Oil EmulsionDocument12 pagesPentomuls: Water-In-Oil EmulsionVivek SinghNo ratings yet

- Blowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...Document7 pagesBlowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...حسين مهديNo ratings yet

- TDS CS. 1-062 Rev04-1Document2 pagesTDS CS. 1-062 Rev04-1DIANNo ratings yet

- Bright Nickel ProcessDocument10 pagesBright Nickel Processshanmukha MechanicalNo ratings yet

- Polyamine Boiler Treatment Technology: A Discussion in Question & Answer FormatDocument4 pagesPolyamine Boiler Treatment Technology: A Discussion in Question & Answer FormatIrina AlexandraNo ratings yet

- Divinylbenzene Storage, Handling and SafetyDocument19 pagesDivinylbenzene Storage, Handling and SafetyMehul DeshpandeNo ratings yet

- Appendix F Treatment Control of Feed Boiler Feed Water20100129Document3 pagesAppendix F Treatment Control of Feed Boiler Feed Water20100129ReyNo ratings yet

- SUB: A Report About Shree Renuka Sugars Ltd. 15MW Power Plant in A View To Increase It's Cycle EfficiencyDocument5 pagesSUB: A Report About Shree Renuka Sugars Ltd. 15MW Power Plant in A View To Increase It's Cycle EfficiencyMurthy VvnNo ratings yet

- Basf Masterglenium Sky 920 Tds PDFDocument4 pagesBasf Masterglenium Sky 920 Tds PDFvikasNo ratings yet

- Alkali Boil Out ProcedureDocument7 pagesAlkali Boil Out Procedureismail karmanaNo ratings yet

- Efficient Operation & Maintenance of Boilers: Organised byDocument26 pagesEfficient Operation & Maintenance of Boilers: Organised byfayek shakranNo ratings yet

- Rtps Unit # 7 Boiler Water ChemistryDocument16 pagesRtps Unit # 7 Boiler Water ChemistryharimadhavareddyNo ratings yet

- DeaeratorDocument3 pagesDeaeratorpawangwlNo ratings yet

- Topsoe Steam Reforming CatDocument6 pagesTopsoe Steam Reforming CatKhairul HadiNo ratings yet

- Neutralizing Amines: Boiler Water Operator Training NotesDocument4 pagesNeutralizing Amines: Boiler Water Operator Training NotesSheikh SahabNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Gasoline and Oil Stoves, "New Process" and "Standard." 1901From EverandGasoline and Oil Stoves, "New Process" and "Standard." 1901No ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- Second Law Analysis of A Waste Heat Recovery BasedDocument9 pagesSecond Law Analysis of A Waste Heat Recovery Basedyahska1305No ratings yet

- Overview of NTPC PDFDocument40 pagesOverview of NTPC PDFRahul Kedia100% (1)

- Refrigeration and Air-Conditioning Exit Exam QuestionDocument9 pagesRefrigeration and Air-Conditioning Exit Exam QuestionKiraNo ratings yet

- FinalDocument7 pagesFinalMuralee Dharan PillaiNo ratings yet

- Catalogue Pres DeaeratorDocument2 pagesCatalogue Pres Deaeratorمحمد عصامNo ratings yet

- ManualDocument4 pagesManualfongNo ratings yet

- Rencana Power Energize 11 Feb 21 Rev.2Document11 pagesRencana Power Energize 11 Feb 21 Rev.2Ari Puji HidayatullahNo ratings yet

- Course Handout TEE 504Document2 pagesCourse Handout TEE 504Anonymous HyOfbJ6No ratings yet

- 锅炉一次风机启动操作票 Operation Ticket for PA Fan StartupDocument4 pages锅炉一次风机启动操作票 Operation Ticket for PA Fan StartupOcto Goldwin TambaNo ratings yet

- Performance Analysis of MPPT Charge Controller WitDocument6 pagesPerformance Analysis of MPPT Charge Controller WitMunkh-Erdene TseveenNo ratings yet

- Flange Valves: Flange Mounted Pressure ControlsDocument64 pagesFlange Valves: Flange Mounted Pressure ControlsDanielEscobarMontecinosNo ratings yet

- Central Electricity Authority Go&Dwing Operation Performance Monitoring DivisionDocument4 pagesCentral Electricity Authority Go&Dwing Operation Performance Monitoring DivisionData CentrumNo ratings yet

- Sihi Pompa LPG API 610Document1 pageSihi Pompa LPG API 610Andry RimanovNo ratings yet

- 4.8 Appendix-3h Color CodeDocument4 pages4.8 Appendix-3h Color CodeSubrata DasNo ratings yet

- Faizan Rasool: ObjectiveDocument4 pagesFaizan Rasool: ObjectiveFaizan RasoolNo ratings yet

- Power Cycles PDFDocument5 pagesPower Cycles PDFcarlverano0428No ratings yet

- DS 02995Document2 pagesDS 02995Giovanni ValentinoNo ratings yet

- Ac HP Critical Readings SurveyDocument1 pageAc HP Critical Readings SurveyEko WinantoNo ratings yet

- BE-Aerospace-Filter Replacement of Air ChillerDocument3 pagesBE-Aerospace-Filter Replacement of Air ChillerJason JiaNo ratings yet

- Alpha ESS Storion Battery Based Solar PV SolutionsDocument6 pagesAlpha ESS Storion Battery Based Solar PV SolutionsaraNo ratings yet

- Seer 23 Ciac Inverter BDocument1 pageSeer 23 Ciac Inverter BHugo OnoroNo ratings yet

- Physics Investigatory Project: Solar CarsDocument9 pagesPhysics Investigatory Project: Solar CarsDhanushreeNo ratings yet

- Report On Steam TurbineDocument18 pagesReport On Steam TurbineAmit PareekNo ratings yet

- Methods To Increase The Efficiency of Production and Purification Istallations of Renewable MethanolDocument16 pagesMethods To Increase The Efficiency of Production and Purification Istallations of Renewable MethanolMelinda FischerNo ratings yet

- SOP For Using The Oxyhydrogen TorchDocument3 pagesSOP For Using The Oxyhydrogen TorchAbdulrahman JradiNo ratings yet

- Any Company Any Street 21 54321 Any Town Tel.: +49 123 456-0 Fax: +49 123 456-100 E-Mail: Info@any-Company - de Internet: WWW - Any-Company - deDocument2 pagesAny Company Any Street 21 54321 Any Town Tel.: +49 123 456-0 Fax: +49 123 456-100 E-Mail: Info@any-Company - de Internet: WWW - Any-Company - dejohncharter122No ratings yet

- LNG CoDocument6 pagesLNG ColubangjarumNo ratings yet

- Types of Burners and Combustion Systems - HEATER TREATER IMPORTANTDocument5 pagesTypes of Burners and Combustion Systems - HEATER TREATER IMPORTANTadewunmi olufemiNo ratings yet