Professional Documents

Culture Documents

SOP For Using The Oxyhydrogen Torch

Uploaded by

Abdulrahman Jradi0 ratings0% found this document useful (0 votes)

74 views3 pagesSop Oxyhydrogen Torch

Original Title

o150 Sop Oxyhydrogen Torch

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSop Oxyhydrogen Torch

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views3 pagesSOP For Using The Oxyhydrogen Torch

Uploaded by

Abdulrahman JradiSop Oxyhydrogen Torch

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

SOP for using the oxyhydrogen torch

Before using the torch prospective users must be trained by capability person or capability

person

Wear face shield (welding face shield or welding glasses and ordinary face shield)

Check that fume hood is on

Check that all valves for both O 2 and H2 are closed (gas cylinders, regulators and torch).

Open for H2-gas flow

1) Open main valve on H2-gas cylinder.

2) Check the pressure of first gauge on the H 2-regulator (minimum allowed cylinder

pressure 30 kPa/cm2).

3) Open slightly main reduction valve on the regulator (turn clockwise). Check pressure

of the second gauge on the regulator (max allowed pressure 1.5 kPa/cm 2).

Ignite flame on torch

1) Open the hydrogen valve on the torch, and ignite fire by match or lighter.

2) Adjust hydrogen flow to obtain an orange flame.

3) Open carefully the oxygen valve on the torch and adjust flow to blue colour for use.

Open for O -gas flow

2

1) Open main valve on O2-gas cylinder.

2) Open slightly the valve (counter clockwise), and check the increase in pressure of first

and second gauges on the regulator. Max operating pressure for second gauge is 5

bar.

Adjust flame on torch for a short break (max 5 minutes)

1) Close oxygen valve on the torch

2) Adjust hydrogen flow on the torch to give an orange flame

3) Reset H2/O2 flame (after break) by carefully open oxygen valve on the torch and

adjust flow to give blue colour.

Close H2/O2 gas flow at end of experiment

1) Close main valves on O2- and H2-gas cylinders. The remaining gases in the lines will be

treated in steps 2-5 below.

2) Burn remaining H2-gas in the line until the pressure of both first and second gauges

on the H2 cylinder decreases to zero. Close H2 valve on the torch.

3) Release remaining O2-gas until pressure of both first and second gauges on the O2

cylinder becomes zero.

4) Close all valves on both H2 and O2 lines and assure both gas cylinders are in closed

position. Do not over-tighten needle values.

Last updated: March 20, 2012; CIT, AOS

Remember to tidy workspace after use

Report any problems or concerns to Christopher I. Thomas (Ø-138) or Anja O. Sjåstad (Ø-

130)

Last updated: March 20, 2012; CIT, AOS

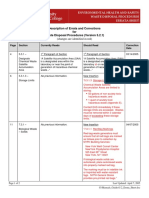

SAFE JOB ANALYSIS (SJA)

Name of unit: Department of Chemistry

This SJA concerns: hydrogen torch in room Ø150

Date: 1/11-2010, Agnieszka Gorzkowska-Sobas, Hiroshi Okamoto, Helmer Fjellvåg

Date: 20/3-2012: Christopher Ian Thomas, Anja O. Sjåstad

Subtask Possible cause of undesired event Precautions to be taken

Hydrogen gas Flammability/Ignitability Turn on fume hood

Hydrogen gas must be

always burned out.

Sealing quartz Damage to the eyes Do not look at melting part

of quartz by naked eye

Damage to the face Use face-shield for

protection

Skin burns Keep tidy work place, and

maintain good

housekeeping

Explosion Think about possible over

pressure during sealing

treatment

Assure H2 gas cylinder

have at least 30kPa/cm2

when starting up

experiment

Last updated: March 20, 2012; CIT, AOS

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Acetylene MSDS Provides Safety Info for Welding GasDocument4 pagesAcetylene MSDS Provides Safety Info for Welding Gassami1243No ratings yet

- Tomco2 Fire Systems Manual SectionsDocument140 pagesTomco2 Fire Systems Manual Sectionszfrl100% (1)

- SCBA Safety ChecksDocument3 pagesSCBA Safety ChecksAkhil Raj BNo ratings yet

- Standard Operating Procedure: 1) Synthesis With Gaseous Ammonia 2) Condensing Ammonia 3) Quenching/Evaporating AmmoniaDocument6 pagesStandard Operating Procedure: 1) Synthesis With Gaseous Ammonia 2) Condensing Ammonia 3) Quenching/Evaporating AmmoniagouthamsaiNo ratings yet

- Aircraft Air Conditioning Pressurisation Week 2Document16 pagesAircraft Air Conditioning Pressurisation Week 2JohanNo ratings yet

- R717 PDFDocument2 pagesR717 PDFOtto OttoNo ratings yet

- NSC Welding and Gas CuttingDocument80 pagesNSC Welding and Gas CuttingBharath CjNo ratings yet

- JHA Welding HazardsDocument6 pagesJHA Welding HazardsakhilakaNo ratings yet

- Brochure Siex-Co2 Fixed-Stations Eng WebDocument8 pagesBrochure Siex-Co2 Fixed-Stations Eng WebAhmed El Sayed SalamaNo ratings yet

- HPCL Madurai Welding Safety Work ProcedureDocument2 pagesHPCL Madurai Welding Safety Work Procedureanon_106345234100% (1)

- Shrinkfast™ 998Document27 pagesShrinkfast™ 998Wilson RodriguezNo ratings yet

- Oxy-Acetylene Welding SafetyDocument4 pagesOxy-Acetylene Welding SafetyBajaj NitinNo ratings yet

- MATERIAL SAFETY DATA SHEET for TANKLEEN cleaning productDocument6 pagesMATERIAL SAFETY DATA SHEET for TANKLEEN cleaning productJezrell JaravataNo ratings yet

- O2 PSA Design NotesDocument3 pagesO2 PSA Design NotesTushar AgarwalNo ratings yet

- Technical Data Sheet for Epoxy Mastic CoatingDocument5 pagesTechnical Data Sheet for Epoxy Mastic CoatingRamlialianNo ratings yet

- AcetyleneDocument9 pagesAcetylenegkmlalNo ratings yet

- Muki Z 2001: Technical Data SheetDocument5 pagesMuki Z 2001: Technical Data SheetIan PerdanaNo ratings yet

- Service RSVP Post Weld Heat TreatDocument2 pagesService RSVP Post Weld Heat Treat1339979No ratings yet

- Hempadur 15553 two-component epoxy primerDocument2 pagesHempadur 15553 two-component epoxy primerachusanachuNo ratings yet

- Liquefied Petroleum Gas (Lpgas) : Safety Data SheetDocument8 pagesLiquefied Petroleum Gas (Lpgas) : Safety Data Sheetnuke apriyaniNo ratings yet

- Material Safety Data Sheet: SeacleanDocument6 pagesMaterial Safety Data Sheet: SeacleanJezrell JaravataNo ratings yet

- Study and Analysis of A Cryogenic Pressure Vessel Design For The StorageDocument9 pagesStudy and Analysis of A Cryogenic Pressure Vessel Design For The StorageSandeep PaulNo ratings yet

- Muki Z 2001Document5 pagesMuki Z 2001CESAR CHAVEZNo ratings yet

- Technical Data Sheet for Epoxy Mastic CoatingDocument5 pagesTechnical Data Sheet for Epoxy Mastic CoatingJayasurya PaluriNo ratings yet

- CO2 Manual (English)Document25 pagesCO2 Manual (English)vaibhav_mechanical100% (2)

- Cellcom - Obsh Asa2 (N)Document1 pageCellcom - Obsh Asa2 (N)CristianNo ratings yet

- Pulsfog K-10 SP - K-10 Standard - K-10/O: Operating Instructions Portable Thermal FoggerDocument16 pagesPulsfog K-10 SP - K-10 Standard - K-10/O: Operating Instructions Portable Thermal FoggerMohamed MonerNo ratings yet

- Carbon Dioxide MSDS SummaryDocument4 pagesCarbon Dioxide MSDS SummaryAndri PrastianNo ratings yet

- MSDS 004-ArgonDocument4 pagesMSDS 004-Argonhendrik subagioNo ratings yet

- Instruction Manual: Kosangas LPG Sdn. BHDDocument10 pagesInstruction Manual: Kosangas LPG Sdn. BHDahmad hafizNo ratings yet

- Echo Yodel Heat Radiation-Report 3035780 01Document29 pagesEcho Yodel Heat Radiation-Report 3035780 01Mortadha Al-YahyaNo ratings yet

- Hempadur 15553Document2 pagesHempadur 15553EngTamerNo ratings yet

- Oxy-fuel burner and pressure vessel experiment safety guideDocument14 pagesOxy-fuel burner and pressure vessel experiment safety guideMohamad Abou DaherNo ratings yet

- IG-01 (Argon)- Safe, Effective, Environment-friendly Fire SuppressionDocument8 pagesIG-01 (Argon)- Safe, Effective, Environment-friendly Fire SuppressionBang IzwanNo ratings yet

- CFN05 ThereductionofcopperoxideDocument5 pagesCFN05 Thereductionofcopperoxidechikohoraarnold268No ratings yet

- Varnishes For Electric EquipmentsDocument2 pagesVarnishes For Electric EquipmentsAnonymous KeBaAOY3T100% (1)

- SWP Welder Oxy-Fuel Gas AS563Document2 pagesSWP Welder Oxy-Fuel Gas AS563Abdulrahman JradiNo ratings yet

- Adiabatic CompressionDocument10 pagesAdiabatic CompressionVan SotNo ratings yet

- Nickel Cadmium Battery MsdsDocument2 pagesNickel Cadmium Battery MsdsSuns Wahjoedhi100% (2)

- Automatic CO2 Fire SuppressionDocument18 pagesAutomatic CO2 Fire SuppressionomarNo ratings yet

- AA-6800-6650 IM VerFocrDocument329 pagesAA-6800-6650 IM VerFocrJozef Uhrovcik100% (2)

- Tankguard Zinc Jotun PaintDocument5 pagesTankguard Zinc Jotun PaintGurdeep Sungh AroraNo ratings yet

- Tankguard Flexline Technical Data SheetDocument5 pagesTankguard Flexline Technical Data Sheetraza.slietNo ratings yet

- SOP Ozone GeneratorDocument6 pagesSOP Ozone Generatorاحمد عبدالكريم الحماديNo ratings yet

- AQT Test ProcedureDocument6 pagesAQT Test Proceduretabish_khattakNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- AcetyleneDocument2 pagesAcetyleneuyvukd3No ratings yet

- Manual Operacion Aas 100 SeriesDocument104 pagesManual Operacion Aas 100 Seriesdéborah_rosalesNo ratings yet

- Material Safety Data Sheet: AcetyleneDocument1 pageMaterial Safety Data Sheet: AcetyleneNuri Estiana AnggrainiNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Oxy-Fuel Gas WeldingDocument2 pages(Your Business Name Here) - Safe Work Procedure Oxy-Fuel Gas WeldingSafety DeptNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Section 8 Boilout.Document7 pagesSection 8 Boilout.Mithilesh Yadav100% (1)

- User Com 5Document16 pagesUser Com 5Clint FosterNo ratings yet

- On-Vehicle Inspection: - RadiatorDocument2 pagesOn-Vehicle Inspection: - RadiatorsalusfrankNo ratings yet

- Compare Cooling Effect of Different Working Fluid PDFDocument5 pagesCompare Cooling Effect of Different Working Fluid PDFMuhammad HassanNo ratings yet

- The Oxyacetylene Process: Safe Practice and Accident AvoidanceDocument6 pagesThe Oxyacetylene Process: Safe Practice and Accident AvoidanceAsan IbrahimNo ratings yet

- MSDS - AcetyleneDocument5 pagesMSDS - AcetyleneNishanthNJNo ratings yet

- VOCs: Sources, Health Effects, and Measurement of Volatile Organic CompoundsDocument2 pagesVOCs: Sources, Health Effects, and Measurement of Volatile Organic CompoundsAbdulrahman JradiNo ratings yet

- Fire Extinguisher TrainingDocument30 pagesFire Extinguisher TrainingenvsandyNo ratings yet

- DR Khalid Process and Procedures of Industrial Energy AuditDocument36 pagesDR Khalid Process and Procedures of Industrial Energy AuditEstrelita DominguezNo ratings yet

- Carbon Footprint CalculationDocument13 pagesCarbon Footprint CalculationAbdulrahman Jradi100% (1)

- Monkeypox Symptoms, Transmission & PreventionDocument10 pagesMonkeypox Symptoms, Transmission & PreventionAbdulrahman JradiNo ratings yet

- 5.2 Waste Disposal ProceduresDocument80 pages5.2 Waste Disposal ProceduresAbdulrahman JradiNo ratings yet

- SSE Energy Solutions Carbon Footprint Calculator - 05.04.22Document531 pagesSSE Energy Solutions Carbon Footprint Calculator - 05.04.22Abdulrahman JradiNo ratings yet

- Monkeypox VirusDocument10 pagesMonkeypox VirusAbdulrahman JradiNo ratings yet

- presentationforHR10 22 14Document21 pagespresentationforHR10 22 14Abdulrahman JradiNo ratings yet

- What happens if a 50Hz motor is driven at 60HzDocument1 pageWhat happens if a 50Hz motor is driven at 60HzAbdulrahman JradiNo ratings yet

- Designing A 3D Jewelry ModelDocument4 pagesDesigning A 3D Jewelry ModelAbdulrahman JradiNo ratings yet

- Ehs Fire Safety2018Document47 pagesEhs Fire Safety2018Abdulrahman JradiNo ratings yet

- Halon extinguishers are used on Class B and C fires involving energized electrical equipmentDocument21 pagesHalon extinguishers are used on Class B and C fires involving energized electrical equipmentAbdulrahman JradiNo ratings yet

- UsapeinTongcumpou40881 114657 1 PBDocument9 pagesUsapeinTongcumpou40881 114657 1 PBAbdulrahman JradiNo ratings yet

- Is Monkeypox The Next Pandemic ?Document21 pagesIs Monkeypox The Next Pandemic ?Cyril LambayongNo ratings yet

- DBFO HA Carbon Calculation SpreadsheetDocument15 pagesDBFO HA Carbon Calculation SpreadsheetAbdulrahman JradiNo ratings yet

- CCTV Camera and Housing PREVENTIVE MAINTENANCEDocument2 pagesCCTV Camera and Housing PREVENTIVE MAINTENANCEAbdulrahman Jradi100% (1)

- Pandora Brilliance CFPDocument28 pagesPandora Brilliance CFPAbdulrahman JradiNo ratings yet

- UsapeinTongcumpou40881 114657 1 PBDocument9 pagesUsapeinTongcumpou40881 114657 1 PBAbdulrahman JradiNo ratings yet

- HWM FS Jewelry P2 RecommendationsDocument11 pagesHWM FS Jewelry P2 RecommendationsAbdulrahman JradiNo ratings yet

- Umicoregt List of Products enDocument55 pagesUmicoregt List of Products enAbdulrahman JradiNo ratings yet

- Removal of Pollutants from Industrial Wastewater using Fly AshDocument8 pagesRemoval of Pollutants from Industrial Wastewater using Fly AshAbdulrahman JradiNo ratings yet

- Greenhouse Gas Emission in Jewelry Industry: A Case Study of Silver Flat RingDocument8 pagesGreenhouse Gas Emission in Jewelry Industry: A Case Study of Silver Flat RingAbdulrahman JradiNo ratings yet

- CDP Submission 2009Document26 pagesCDP Submission 2009Abdulrahman JradiNo ratings yet

- TDS Scope of WorkDocument3 pagesTDS Scope of WorkAbdulrahman JradiNo ratings yet

- Deloitte Predictive-Maintenance PositionPaperDocument20 pagesDeloitte Predictive-Maintenance PositionPaperAbdulrahman JradiNo ratings yet

- Safety in The WarehouseDocument30 pagesSafety in The WarehouseAbdulrahman Jradi100% (1)

- Ugt-V - 2022.04.216Document3 pagesUgt-V - 2022.04.216Abdulrahman JradiNo ratings yet

- Keep This Area Clean SignDocument1 pageKeep This Area Clean SignAbdulrahman JradiNo ratings yet

- Produktblatt Auruna 215 en Screen 20190416Document2 pagesProduktblatt Auruna 215 en Screen 20190416Abdulrahman JradiNo ratings yet

- Intricacies of Designing Gas PipelinesDocument27 pagesIntricacies of Designing Gas PipelinesarunenggNo ratings yet

- Essential Plumbing Components ExplainedDocument34 pagesEssential Plumbing Components ExplainedMorshed Bin Alam FervvezNo ratings yet

- Acid GasDocument37 pagesAcid Gaspleco4me100% (1)

- Test Gaseous State Questions:: Mrs Shallu Aggarwal Mobile #. 98786-08983Document3 pagesTest Gaseous State Questions:: Mrs Shallu Aggarwal Mobile #. 98786-08983Amna ShahzadNo ratings yet

- NGL Extraction TechnologiesDocument7 pagesNGL Extraction Technologiescbba2310% (1)

- Instrumentation Maintenance Measurements Training ManualDocument114 pagesInstrumentation Maintenance Measurements Training Manualbali100% (3)

- CE322 Standby Water SupplyDocument2 pagesCE322 Standby Water SupplyNickson KomsNo ratings yet

- ASTM Pipe Material Specifications ChartDocument14 pagesASTM Pipe Material Specifications ChartKim JungdaeNo ratings yet

- Water Sector in Dili Timor Leste - Field StudyDocument14 pagesWater Sector in Dili Timor Leste - Field StudyGaspar Da Costa XimenesNo ratings yet

- Line Sizing Spreadsheets-GeneralDocument8 pagesLine Sizing Spreadsheets-GeneralFavoriteNo ratings yet

- JC API Plans PosterDocument1 pageJC API Plans PosterDumitrescuNo ratings yet

- Guentner Subcooling EN PDFDocument18 pagesGuentner Subcooling EN PDFNotlim MarulandaNo ratings yet

- CE74.11 Watershed Hydrology COURSE DETAILSDocument2 pagesCE74.11 Watershed Hydrology COURSE DETAILSDanna ValdezNo ratings yet

- Properties of SteamDocument67 pagesProperties of SteamKhushank MNo ratings yet

- Humidity Conversion Formulas Technical Ebook B210973ENDocument16 pagesHumidity Conversion Formulas Technical Ebook B210973ENarjunchouhan.proNo ratings yet

- ID Studi Pencemaran Limbah Cair Dengan Parameter Bod5 Dan PH Di Pasar Ikan TradisioDocument10 pagesID Studi Pencemaran Limbah Cair Dengan Parameter Bod5 Dan PH Di Pasar Ikan TradisioHandoko AhmadNo ratings yet

- Orifice Sizing Instructions TablesDocument8 pagesOrifice Sizing Instructions TablesMatt AndersonNo ratings yet

- Flowmeter Demonstration Lab ReportDocument25 pagesFlowmeter Demonstration Lab ReportEZWANNo ratings yet

- DOC011Document4 pagesDOC011InggitNo ratings yet

- Richmond Jasper Barlis Problem Set No.3-GasesDocument11 pagesRichmond Jasper Barlis Problem Set No.3-GasesJasper BarlisNo ratings yet

- DIY Liquid Nitrogen Generator Using CryocoolerDocument2 pagesDIY Liquid Nitrogen Generator Using CryocoolerYasir AliNo ratings yet

- Pdvsa: Engineering Design ManualDocument5 pagesPdvsa: Engineering Design ManualkatheNo ratings yet

- Department of Petroleum Engineerng: 16 MarksDocument5 pagesDepartment of Petroleum Engineerng: 16 MarksPE9001 Aarthi100% (1)

- MEET310 - Refrigeration System - Group 1 PPT PresentationDocument38 pagesMEET310 - Refrigeration System - Group 1 PPT Presentationpipeds100% (2)

- Tutorial - Steam BasicsDocument2 pagesTutorial - Steam BasicsShazni AhamedNo ratings yet

- Spek Pompa 1Document14 pagesSpek Pompa 1vennyNo ratings yet

- Volumetric PropertiesDocument20 pagesVolumetric Propertiespk9zg2rxkgNo ratings yet

- Mouthpiece Flow OptimizationDocument2 pagesMouthpiece Flow OptimizationAbdul Rauf Noohani100% (2)

- Dairy TechnologyDocument20 pagesDairy TechnologyShweta SainiNo ratings yet

- W-4, Chap.3-Properties of Pure Substances-2Document31 pagesW-4, Chap.3-Properties of Pure Substances-2سيمو بشيريNo ratings yet