0% found this document useful (0 votes)

257 views23 pagesEngineering Risk Analysis Guide

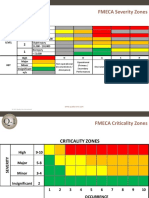

The document discusses risk analysis methods including failure mode and effects analysis (FMEA). It describes defining system functions, identifying failure modes and their causes, and determining failure effects. The FMEA process involves analyzing these factors at different levels of a complex system from components to overall functions.

Uploaded by

Minhaj RafiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

257 views23 pagesEngineering Risk Analysis Guide

The document discusses risk analysis methods including failure mode and effects analysis (FMEA). It describes defining system functions, identifying failure modes and their causes, and determining failure effects. The FMEA process involves analyzing these factors at different levels of a complex system from components to overall functions.

Uploaded by

Minhaj RafiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd