Professional Documents

Culture Documents

3329 Sta Advice Notes No4 - Tolerances Part 2

3329 Sta Advice Notes No4 - Tolerances Part 2

Uploaded by

algalespamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3329 Sta Advice Notes No4 - Tolerances Part 2

3329 Sta Advice Notes No4 - Tolerances Part 2

Uploaded by

algalespamCopyright:

Available Formats

STA advice notes

STA ADVICE NOTES

STRUCTURAL

Recommended construction tolerances TIMBER ASSOCIATION

Building solutions in timber

for timber structures

No. 4 - January 2014

Part 3 - Timber frame wall panel tolerances

Introduction

Timber framed buildings are prefabricated to a high level of quality within controlled factory conditions and delivered to site for assembly into a structure which can achieve

excellent levels of accuracy.

STA membership requires that all manufacturers operate a minimum standard of quality control which ensures the continuation of high standard within the industry.

Scope of this advice note

This advice note provides a summary of the industry acceptable maximum tolerances of erected timber frame

at the time of handover. This document does not cover manufacturing tolerances of prefabricated panels out of

the factory that are delivered to the site; such tolerances are covered by the manufacturer’s quality procedures

This is Part 3 of the recommended tolerances for timber frame site construction. Other parts in this series are:

Part 1 Foundation tolerances

Part 2 Sole plate tolerances

Part 3 Timber frame wall panel erection tolerances (this document)

Part 4 Roof tolerances

Part 5 Floor tolerances

1 RECOMMENDED CONSTRUCTION TOLERANCES PART 3 - WALL PANEL TOLERANCES

STA ADVICE NOTES

STRUCTURAL

TIMBER ASSOCIATION

Building solutions in timber

Timber frame assembled wall panel erection tolerances

The tolerances given are for the erected walls and floors which are made up of the separate prefabricated wall panels. The tolerances of the prefabricated panels is not covered

by this advice note.

These tolerances express permitted deviations of timber frame wall panels measured relative to the wall panels immediately adjacent to the component under consideration.

All data at time of handover.

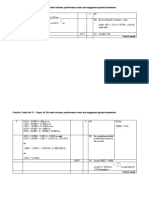

Assembled wall panels

Vertical step

Horizontal step

Plan view

Elevation view

Alignment

Internal horizontal building face of the panel on plan shall be a maximum of step of 5mm with an average of no more than 3mm to any one panel.

Steps to the vertical level - either top or bottom of a panel shall be to the top or bottom shall be reviewed to consider the impact on floor/ roof and follow on floor

levels. Gaps above 2mm in height and above 300mm long shall have a rigid full bearing packer inserted. Maximum steps shall be ±5mm before investigations are

undertaken and adjustment works considered.

Deviation from line on plan along a wall at any one horizontal line Distance (m) +/- Tolerance (mm)

=√ (4×d) + 1 or 5mm whichever is the greater 3 5

T is tolerance in mm subject to a minimum of 5mm and 5 6

d is the distance under consideration in metres 10 8

15 9

20 10

25 11

30 12

Table 1: 40 14

Acceptable tolerances

for wall panel erection 50 16

Plumb of assembled panels

± 10mm in storey height up to 3m (refer also to the tolerance for overall building height)

± (Height in mm) / 300) above 3m (for single storey structures)

Gaps between assembled panels

Maximum 5mm gap between vertical fixed panel junctions

To achieve air-tightness, all gaps should be sealed with a suitable foam filler, unless a site installed membrane or other air-tight barrier is to be

fitted to the internal face of the external wall panels on site

2 RECOMMENDED CONSTRUCTION TOLERANCES PART 3 - WALL PANEL TOLERANCES

STA ADVICE NOTES

STRUCTURAL

TIMBER ASSOCIATION

Building solutions in timber

Appropriate references

BS5606:1990: Guide to accuracy in Building Figure 4 (of the BS)

• Verticality in timber columns (up to 3m high) = 10mm

BS EN 1995-1-1:2004 Clause 10.2

The deviation from straightness measure midway between the supports should, for columns and beams where lateral instability can occur, or members in frames, be limited

to 1/300 times the length of solid timber. The limitations on bow in most strength grading rules are inadequate for the selection of material for these members and particular

attention should therefore be paid to their straightness.

Overall building tolerances

Note: This advice note deals with the overall building tolerances as opposed to individual components.

Height of structural frames Horizontal datum line tolerance of the timber frame from

the first lift agreed datum at time of handover. **

The height tolerance +10mm per floor and up to 10mm difference between

structural floor levels with maximum accumulative total values at the time of

hand over as given in Figure 1. 5 to 7 storey level

Values in Figure 1 are from a datum line which is based on the level of the

+50mm/-0mm

first lift agreed level. All values presented are erected values at the time

from datum*

of hand over by the erector and does not include settlement shrinkage or

swelling. Note that it is the contractors responsibility to consider frame

protection after hand over.

3 to 4 storey level

Fig 1: Acceptable maximum accumulative height level tolerance +30mm/-0mm

of the timber frame from the first lift agreed datum from datum*

Note: The maximum over the full height but maximum between any floor

to floor is +10mm. E.g. If the 2nd floor is +0mm from datum then 3rd floor

can be +10mm

Note: For clarity the height tolerance is the distance between horizontal 1 storey

levels. +10mm/-0

from datum

2 storey

+15mm/-0

from datum

DATUM

3 RECOMMENDED CONSTRUCTION TOLERANCES PART 3 - WALL PANEL TOLERANCES

STA ADVICE NOTES

STRUCTURAL

TIMBER ASSOCIATION

Building solutions in timber

Vertical datum line tolerances (plumb) of external

timber frame walls

Variance is measured to an agreed theoretical vertical datum which takes account of the number of storeys constructed.

Out of plumb - storey to storey tolerances to agreed vertical datum line

Vertical datum line

5 to 6 storey level

±25mm from vertical datum1

Maximum deviation for any floor step to

the floor below shall be ±10mm but

accumulate values to be no greater than

the relevant storey tolerance values

3 to 4 storey level

±20mm from vertical datum1

1 to 2 storey level

±10mm from vertical datum1

Note1: Maximum step at any

floor/wall junction ±10mm

Vertical datum line

Fig 2: Acceptable vertical datum line tolerance (standard storey height buildings up to 3m height)

4 RECOMMENDED CONSTRUCTION TOLERANCES PART 3 - WALL PANEL TOLERANCES

STA ADVICE NOTES

STRUCTURAL

TIMBER ASSOCIATION

Building solutions in timber

0mm +10mm +10mm

+10mm +0mm 0mm

Timber frame wall

Timber frame wall

Timber frame wall

0mm -5mm +10mm

Fig 3: Diagramatic representation of vertical datum line tolerances

Adjustment of the cladding and cavity width to suit

horizontal frame tolerances

Where timber frame is erected out of tolerance agreement on action to take is to be carried out between the timber frame company and the main contractor. Vertical out of

alignment is likely to require a variation in the cavity width for the external cladding taking due account of the fixings and cavity barrier design changes needed.

The proposed cladding cavity is to be reviewed by the Main Contractor and cladding engineer prior to commencement of the cladding construction and after the timber frame

has been checked for line and level.

Masonry clad structures should have the “splash course” below DPC left down until the frame is completed. The clear cavity between the masonry and the sheathing should

be minimum 50mm ±10mm.

For masonry the exact position of the wall below DPC can then be determined by plumbing down the building and the cavity width adjusted to suit any deviations in the timber

frame sole plate or wall position. The length and type of cavity wall ties should be reviewed if tolerances are higher than initially considered. The brick coursing shall be agreed

prior to starting masonry to take account of agreed opening cill and head levels taking due account of the differential movement values at each level.

For lightweight cladding a best fit line should be established before fixing battens which should be packed to the agreed line.

The tolerances in this document represent a good level of accuracy compared to other material codes. Higher levels of accuracy for cladding finishes can be easily attained

by the correct use of packers and variable batten depths. It is important that the tolerances outlined in this document are communicated to the cladding contractor to enable

appropriate allowance for any cladding alignment adjustment work to be made.

Structural Timber Association t: 01259 272140

The e-Centre f: 01259 272141

Cooperage Way e: office@structuraltimber.co.uk STRUCTURAL

Alloa w: www.structuraltimber.co.uk TIMBER ASSOCIATION

FK10 3LP Building solutions in timber

5 RECOMMENDED CONSTRUCTION TOLERANCES PART 3 - WALL PANEL TOLERANCES

You might also like

- TR 34 4th EditionDocument15 pagesTR 34 4th EditionRamarao CH100% (1)

- Masonry Structures Changes To As 3700 2018 Fact Sheet For Builders PDFDocument2 pagesMasonry Structures Changes To As 3700 2018 Fact Sheet For Builders PDFalexNo ratings yet

- Architectural Precast Concrete Sealant and Joint GuideDocument36 pagesArchitectural Precast Concrete Sealant and Joint GuideCarlo Dizon100% (1)

- MA45 Masonry Handbook PDFDocument30 pagesMA45 Masonry Handbook PDFRemington SalayaNo ratings yet

- American Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsDocument32 pagesAmerican Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsMohammad Humayun KabirNo ratings yet

- Masonry Concrete Masonry HandbookDocument31 pagesMasonry Concrete Masonry HandbookNguyễn Hoàng Bảo100% (2)

- Branz Advisory Trower PartitionsDocument6 pagesBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Black Scholes ExampleDocument3 pagesBlack Scholes ExamplechubbyqcayNo ratings yet

- Advice Notes No4 - Tolerances Part 1Document4 pagesAdvice Notes No4 - Tolerances Part 1algalespamNo ratings yet

- Sole Plate TolerancesDocument10 pagesSole Plate TolerancesLiam DevineNo ratings yet

- Brick Masonry DesignDocument34 pagesBrick Masonry DesignWan Rids50% (2)

- Comflor 60 80 Span Tables 2011Document12 pagesComflor 60 80 Span Tables 2011Nguyễn TrườngNo ratings yet

- Tekdek IT5 Specification SheetDocument2 pagesTekdek IT5 Specification SheethenrygeesNo ratings yet

- Preliminary Design Rules of ThumbDocument11 pagesPreliminary Design Rules of Thumbnimal1234No ratings yet

- Joint DetailsDocument2 pagesJoint Detailsmusibo911No ratings yet

- Trimo 2967 Trimo Assembly SNVDocument14 pagesTrimo 2967 Trimo Assembly SNVBogdan RuxandaNo ratings yet

- 11 Wall TiesDocument28 pages11 Wall TiesDuncan Lillistone100% (1)

- Impact Resistance of Ceramic Tiles & FlooringDocument12 pagesImpact Resistance of Ceramic Tiles & FlooringGanesh BhisteNo ratings yet

- Masonry Su PDFDocument32 pagesMasonry Su PDFDanusha EgodawatteNo ratings yet

- Safdeck Specification Sheet - KenyaDocument3 pagesSafdeck Specification Sheet - KenyagraceNo ratings yet

- Concrete Masonry Handbook, WallingDocument30 pagesConcrete Masonry Handbook, WallingCharisma D. Sumalinog100% (2)

- 3 Installation - TpoDocument22 pages3 Installation - TpoDoni IrawanNo ratings yet

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDocument4 pagesNcma Tek: Segmental Retaining Wall Units TEK 2-4BJorge Luis Arevalo LopezNo ratings yet

- Masonry ManualDocument114 pagesMasonry Manualdpdqh0No ratings yet

- STEPOC 150dpiDocument6 pagesSTEPOC 150dpinick8081No ratings yet

- STRL Design Rules of Thumb PDFDocument11 pagesSTRL Design Rules of Thumb PDFsakti prasanna sahuNo ratings yet

- Name of Work: Rennovation of Roof in ICHR Building, Bangalore. SH:Provision For Replacing Mangalore Tiles and Wooden Planks and WaterproofingDocument21 pagesName of Work: Rennovation of Roof in ICHR Building, Bangalore. SH:Provision For Replacing Mangalore Tiles and Wooden Planks and WaterproofingManasNo ratings yet

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDocument4 pagesNcma Tek: Segmental Retaining Wall Units TEK 2-4BjerryNo ratings yet

- For Further Information, Please Contact:: Railway FactoriesDocument2 pagesFor Further Information, Please Contact:: Railway FactoriesAndreas KamwankaNo ratings yet

- Bostik Paneltack HM Dekton Tds en 2020Document5 pagesBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaNo ratings yet

- TAPPI TIP-0402-21 Ultrasonic Performance Technician ..Document8 pagesTAPPI TIP-0402-21 Ultrasonic Performance Technician ..a_parrat100% (1)

- Advantages of Steel Fibre Reinforced Con PDFDocument5 pagesAdvantages of Steel Fibre Reinforced Con PDFAce NovoNo ratings yet

- Ficha Técnica - ArmourJoint PDFDocument2 pagesFicha Técnica - ArmourJoint PDFDiego BarretoNo ratings yet

- Steel Stud Installation GuideDocument6 pagesSteel Stud Installation GuidePrinz MarkNo ratings yet

- HiRib Design PrincipleDocument9 pagesHiRib Design PrinciplesanilNo ratings yet

- Guideline Notes Deck - Guide PDFDocument20 pagesGuideline Notes Deck - Guide PDFPrapakaranNo ratings yet

- Rules of ThumbDocument14 pagesRules of ThumbAntoniette Samantha Nacion100% (1)

- Steel Stud Installation GuideDocument6 pagesSteel Stud Installation GuiderfadeNo ratings yet

- Typical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BDocument4 pagesTypical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BfostbarrNo ratings yet

- Top - Top. Joint TreatmentsDocument9 pagesTop - Top. Joint Treatmentseng laythNo ratings yet

- T Proc Notices Notices 040 K Notice Doc 35762 449071606Document5 pagesT Proc Notices Notices 040 K Notice Doc 35762 449071606jaafar abdullahNo ratings yet

- Rib and Timber Infill LoadsDocument2 pagesRib and Timber Infill LoadsKesavan DhuraiNo ratings yet

- Masonry SuDocument32 pagesMasonry SuÔzØnè BęržëŕkNo ratings yet

- Experiment-1 Eng Mech & Civil Eng.Document5 pagesExperiment-1 Eng Mech & Civil Eng.Riya JaiswalNo ratings yet

- solidworks ขั้นพื้นฐานDocument74 pagessolidworks ขั้นพื้นฐานChonTicha'No ratings yet

- SL No Description Unit Quantity Remarks Total Amount Excluding Taxes - Rate (INR) Amount (INR)Document18 pagesSL No Description Unit Quantity Remarks Total Amount Excluding Taxes - Rate (INR) Amount (INR)Chaitanya IdateNo ratings yet

- Modeling and Analysis of The Building: 3.1. GeneralDocument19 pagesModeling and Analysis of The Building: 3.1. GeneralShaik ZuberNo ratings yet

- TECON TP60 Formwork A4Document18 pagesTECON TP60 Formwork A4Luis Carlos Sánchez ArreguiNo ratings yet

- Bracing WebDocument1 pageBracing WebDavid O'MearaNo ratings yet

- Emprical and Rational DesignDocument6 pagesEmprical and Rational DesignCalvin יעקב CopelingNo ratings yet

- Tek 10-03 PDFDocument8 pagesTek 10-03 PDFJUAN JOSE LariosNo ratings yet

- Advanced Reinforced Concrete Analysis and Design (2008) - Book. Eng. Mohammed Osama YousefDocument51 pagesAdvanced Reinforced Concrete Analysis and Design (2008) - Book. Eng. Mohammed Osama YousefJulio Humberto Díaz RondánNo ratings yet

- Particleboard Flooring BrochureDocument8 pagesParticleboard Flooring Brochurehojese4775No ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Hughes, Structure and Interpretation of Quantum MechanicsDocument382 pagesHughes, Structure and Interpretation of Quantum MechanicsRogério P. Severo100% (1)

- 3-MS Examples PDFDocument59 pages3-MS Examples PDFlexuanminhk54lochoaNo ratings yet

- 08 Practice Tests Set 17 - Paper 2H-3H Mark SchemeDocument15 pages08 Practice Tests Set 17 - Paper 2H-3H Mark SchemeKenneth SorraNo ratings yet

- Scada Lab: Supervisory Control and Data AcquisitionDocument102 pagesScada Lab: Supervisory Control and Data AcquisitionpfalencarNo ratings yet

- Programming Assignment 6: Dynamic Programming 2Document4 pagesProgramming Assignment 6: Dynamic Programming 2Danh NguyenNo ratings yet

- GearsDocument57 pagesGearsعبدالاله العسيريNo ratings yet

- Linked List A5Document196 pagesLinked List A5蔡炅宸No ratings yet

- CSCE 3110 Data Structures & Algorithm Analysis: Rada MihalceaDocument30 pagesCSCE 3110 Data Structures & Algorithm Analysis: Rada MihalceaAnuja KhamitkarNo ratings yet

- The Low-Cost Vertical Axis Wind Turbine Project AnDocument13 pagesThe Low-Cost Vertical Axis Wind Turbine Project Anpomoc.pri.izradi.radaNo ratings yet

- Chapter 6 - : Statistical Process ControlDocument51 pagesChapter 6 - : Statistical Process ControlshihabNo ratings yet

- Swami Vivekananda SpeechDocument5 pagesSwami Vivekananda Speechdivya2390No ratings yet

- Laser Cutting From First Principles To The State of The ArtDocument6 pagesLaser Cutting From First Principles To The State of The ArtJing YinNo ratings yet

- Datasheet DSPIC33EP128MC204 70000657H-277982Document531 pagesDatasheet DSPIC33EP128MC204 70000657H-277982EduardoNo ratings yet

- Unit IvDocument20 pagesUnit IvArwaz KhanNo ratings yet

- Bostik Paneltack HM Dekton Tds en 2020Document5 pagesBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaNo ratings yet

- 90nm FSDocument2 pages90nm FSdanakamalakarNo ratings yet

- Gates, D.M. - Transpiration and Leaf Temperature - 1968 - Annurevpp19060168001235Document28 pagesGates, D.M. - Transpiration and Leaf Temperature - 1968 - Annurevpp19060168001235leandrodrigues14No ratings yet

- Automatic Voltage RegulatorDocument27 pagesAutomatic Voltage RegulatorHarpreet SharmaNo ratings yet

- Research Status Title Publication DateDocument8 pagesResearch Status Title Publication DateHarsheen SawhneyNo ratings yet

- Arvedi First Thin Slab Endless CastingDocument10 pagesArvedi First Thin Slab Endless CastingprasenjitsayantanNo ratings yet

- Efficacy of Miniscrew-Assisted Rapid Palatal Expansion (MARPE) in Late Adolescents and Adults A Systematic Review and Meta-AnalysisDocument11 pagesEfficacy of Miniscrew-Assisted Rapid Palatal Expansion (MARPE) in Late Adolescents and Adults A Systematic Review and Meta-Analysisaa bbNo ratings yet

- T Cell Concept in WCDMA PDFDocument8 pagesT Cell Concept in WCDMA PDFVusal SuleymanovNo ratings yet

- Usage of CFD in Automobile IndustryDocument28 pagesUsage of CFD in Automobile Industrygem_bhaveshNo ratings yet

- Mobilis Internship ReportDocument16 pagesMobilis Internship ReportAymEn SeKhri100% (1)

- Teletherapy MachinesDocument76 pagesTeletherapy MachinesKeynna KemNo ratings yet

- 3BCA010145R1701 A en General Purpose Interface Users Guide v4.0Document144 pages3BCA010145R1701 A en General Purpose Interface Users Guide v4.0Mario STNo ratings yet

- Resick2006 Article ACross-CulturalExaminationOfThDocument15 pagesResick2006 Article ACross-CulturalExaminationOfThspookywack4883No ratings yet

- Spontaneous Breakdown of Parity in A Class of Gauge TheoriesDocument31 pagesSpontaneous Breakdown of Parity in A Class of Gauge TheoriesFRANK BULA MARTINEZNo ratings yet

- External Weather Louvres: Type WGDocument30 pagesExternal Weather Louvres: Type WGSo DurstNo ratings yet