Professional Documents

Culture Documents

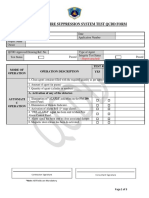

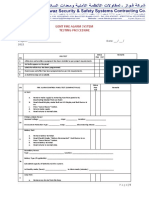

Acceptance Test Checklist

Acceptance Test Checklist

Uploaded by

Fernando KatayamaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acceptance Test Checklist

Acceptance Test Checklist

Uploaded by

Fernando KatayamaCopyright:

Available Formats

Courtesy of Automatic Fire Alarm Association, Inc.— www.afaa.

org — (844) 438-2322

Acceptance Test Checklist

(This is only a guide, and does not replace the Record of Completion)

Property Name: _____________________________ Date: _______________________________

Address: __________________________________ Co. performing test ___________________

__________________________________________ AHJ witnessing test ___________________

Y N I. NOTIFICATION OF TESTING Y N

Fire Department Dispatch 7. Restore normal power.

Building Occupants Power indicator on.

Monitoring Facility if monitored off-premises Audible and visual trouble indicators off.

(after verification of acceptable call back)

8. Battery verification.

Y N II. CONTROL UNIT TEST

Batteries dated.

1. Location of Record (As-Built) Drawings.

___________________________________ Batteries same rating (or larger) as battery

calculations in Record of Completion.

Zone indicators labeled properly?

Battery location recorded at control (if located

Smoke detector protecting the control unit? remote from control).

(If not in a constantly attended area)

(Use heat detector if ambient conditions do not 9. Contractor disconnects battery lead.

allow use of smoke detector)

Audible and Visual trouble indicators on.

2. Panel in normal condition.

Reconnect batteries.

Power indicator on.

10. Contractor initiates an alarm from any device

No trouble or alarm indicators on. in the system.

3. Operate the lamp test switch. Alarm sounds .

All indicators on. Proper identification of actuated device.

4. Check for ground fault indication – contractor 11. Operate alarm silence switch.

to connect a jumper from an initiating or

signaling line circuit to ground [conduit, system Alarms silence.

cabinet, etc.].

Zone light or display stays on.

Ground fault indicator on (if applicable).

12. Contractor initiates another alarm from a

5. Contractor trips main breaker to disconnect AC device on a different initiating device circuit.

power.

Alarms resound.

Location of breaker is indicated at control unit.

13. Reset devices and operate system reset

Power indicator off. switch.

Audible and Visual trouble indicators on. System resets.

6. Operate trouble silence switch. Trouble indicators activate until alarm silence

switch is returned to normal.

Audible trouble sounder silences.

Visual trouble indicator stays on.

III. FIELD DEVICE TESTS DEVICE TESTS

A. Inspector should witness field testing of

devices by contractor. Y N Manual Fire Alarm Boxes (Pull Stations)

B. Person at control is to notify inspector of alarm

indication. 1. Actuate a pull station.

C. All devices must be tested for alarm or

supervisory function and indication verified at Alarms sound.

the control unit and all remote annunciators.

D. 10% of devices must be tested for supervision Zoning identification verified.

and trouble indication verified at the control

unit and all remote annunciators. 2. Repeat for each manual pull station in the

system.

CIRCUIT SUPERVISION TESTS

Smoke Detectors

Y N CLASS “A” WIRING- 1. Actuate a smoke detector using smoke or

aerosol acceptable to the manufacturer. Do not

1. Remove an initiating device (pull station, test with magnets.

smoke detector, etc.) and disconnect both

incoming wires (there should be 4 wires Alarms sound.

connected to the device).

Zoning identification verified.

Audible and visual trouble indicators on.

2. Reset system.

2. Actuate the device.

System returns to normal standby condition.

Alarms sound.

3. Repeat smoke test for each smoke detector in

Zoning identification verified. system.

3. Reset station and system.

Air Sampling Smoke Detectors

4. Replace those two wires and disconnect the

two outgoing wires. 1. Follow the manufacturers recommended test

methods.

5. Actuate the device.

Non-Restorable Fixed Temperature

Alarms sound. Heat Detector

6. Reconnect wires, re-install the device and 1. Remove the device from it’s mounting plate

reset system. and short across the alarm contacts.

7. Repeat wiring supervision test for 10% of all Alarms sound.

initiating devices in system.

Zoning identification verified.

CLASS “B” WIRING -

2. Replace device.

1. Remove an initiating device (pull station,

smoke detector, etc.) and open the circuit by 3. Repeat for each non-restorable heat detector

disconnecting one wire (there should be 4 in system.

wires connected to the device – except if end

of line device, then 2 wires and end of line

resistor). Restorable Fixed Temperature Heat

Note: Removing the smoke detector from it’s Detector

base will open the circuit.

1. Heat test using a hair dryer or approved heat

Audible and visual trouble indicators on. detector tester.

2. Reconnect the wire and reinstall the device or Alarms sound.

place smoke detector back in it’s base.

3. Repeat wiring supervision test for 10% of all Zoning identification verified.

initiating devices in system.

Y N Y N Flame Detectors

2. Acceptance/Re-acceptance Tests – Repeat

tests for each restorable heat detector in 1. Follow the manufacturers recommended test

system. methods.

3. Periodic Tests – Test 20% of restorable fixed

temperature heat detectors. Be sure to log Waterflow Switches

which detectors have been tested.

1. Open the Inspector’s Test Valve and flow

water.

Rate of Rise Heat Detector

Alarms sound within 90 seconds. (Time should

1. Heat test using a hair dryer or approved heat be no shorter than 30 seconds to avoid

detector tester. possible nuisance alarms due to pressure

variations, surges, etc.)

Alarms sound.

2. Repeat for each waterflow switch in system.

Zoning identification verified.

Pressure-type Waterflow Device (Alarm)

2. Repeat for each rate-of-rise heat detector in

system. 1. Operate the alarm test bypass connection.

Rate Compensation Heat Detector Alarms sound.

1. Heat test using a hair dryer or approved heat 2. Repeat for each pressure-type waterflow

detector tester. switch in system.

Alarms sound. High or Low Pressure Switch

Zoning identification verified. (Supervisory)

2. Repeat for each rate compensation heat 1. Operate the switch.

detector in system.

Supervisory signal is received when pressure

increases or decreases by 10 PSI.

Restorable Line-Type Heat Detector

Restoration of signal is received when

1. Heat test using a hair dryer or approved heat pressure is back within 10 PSI of required

detector tester. pressure.

Alarms sound. 2. Repeat for each supervisory pressure switch in

system.

Zoning identification verified.

Room Temperature Switch

2. Repeat for each restorable heat detector in

system. (Supervisory)

1. Operate the switch.

Non-Restorable Line-Type Heat

Detector Supervisory signal is received when

temperature is decreased to 400 F.

1. Short across the conductors at the end of the

heat detector cable. Restoration of signal is received when

temperature is returned to above 400 F.

Alarms sound. 2. Repeat for each room temperature switch in

system.

Zoning identification verified.

2. Repeat for each non-restorable line-type heat

detector in system.

Y N Water Temperature Switch Y N Other Supervisory Switches

(Supervisory) Type of Device ____________________

1. Operate the switch. 1. Operate device as appropriate for the type of

device.

Supervisory signal is received when

temperature is decreased to 400 F. Supervisory signal received.

Restoration of signal is received when 2. Return device to normal position.

temperature is returned to above 400 F.

Supervisory signal restores.

2. Repeat for each water temperature switch in

the system. 3. Repeat for all other supervisory switches in

system.

Water Level Switch (Supervisory)

Audible Notification Appliances -

1. Operate the switch. General Alarm

Pressure Tank – supervisory signal is received 1. Place system in alarm condition.

when water level increases or decreases 3

inches from the required level. 2. Using a Sound Level Meter, verify sound level

in all occupied spaces is 15 dBA above

Non-pressure Tank – supervisory signal is average ambient sound level or 5 dBA above

received when water levels falls 12 inches maximum sound level lasting more than 60

from the required level. seconds. (For sleeping rooms, 15 dBA over

average ambient, 5 dBA over maximum

Restoration of signals are received when water lasting more than 60 seconds or 75 dBA,

levels are returned to normal levels. whichever is greater.)

Gate Valve Supervisory Switch Emergency Voice/Alarm

Communications Systems

1. Turn valve toward closed position.

1. Verify alarm signal in selected areas (fire floor,

Supervisory signal within two revolutions. floor above, floor below, etc.)

2. Turn valve to full open position. 2. Manually place system in general alarm.

Supervisory signal restores. 3. Verify alarms sound throughout building.

3. Repeat for all gate valve supervisory switches 4. Verify each speaker zone for proper operation

in system. and identification.

Post Indicator Valve Supervisory 5. Verify evacuation tone signals are 15 dBA

Switch above average ambient sound level or 5 dBA

above maximum sound level lasting at least 60

1. Turn valve toward closed position. seconds.

Supervisory signal within two revolutions. 6. Verify clarity (intelligibility) of prerecorded

voice message.

2. Turn valve to full open position.

7. Verify clarity (intelligibility) of live voice signal.

Visible Notification Appliances

Supervisory signal restores.

1. Place system in alarm.

3. Repeat for all post indicator valve supervisory

switches in system. 2. Verify proper location and candela rating of

each strobe light in system.

Y N Two-way Telephone Communications

1. Using a fire phone portable handset or fire

warden station, verify proper operation from

each fire phone location.

2. Verify communications is still understandable

with 5 phone jacks plugged in 5 handsets off

hook.

Off-Premises Monitoring

Since Digital Alarm Communicator Transmitters

(DACTs) are the most popular type of off-premises

signaling, the following tests are concerned with

this type of signaling. If other methods are used,

follow the manufacturer’s and NFPA 72 Chapter 7

recommended test methods.

1. Disconnect one telephone line. DACT should

report a trouble condition within 4 minutes.

2. Reconnect first telephone line. System should

return to normal condition.

3. Disconnect second telephone line. DACT

should report a trouble condition within 4

minutes.

4. Turn DACT primary power breaker off.

Verify trouble condition.

5. Reconnect DACT primary power.

6. Disconnect DACT secondary power.

Verify trouble condition.

7. Reconnect DACT secondary power.

9. Call monitoring facility to verify receipt of

signals and have them place system back in

service.

You might also like

- Cobra Park Master R0390 R0290 R0190 Installation and Configuration Guide - Rev 1Document18 pagesCobra Park Master R0390 R0290 R0190 Installation and Configuration Guide - Rev 1SirLotus75% (4)

- Telecommunication Inspection ChecklistDocument4 pagesTelecommunication Inspection ChecklistAdhyartha Keraf100% (1)

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- Clean Agent Fire Suppression System Test QCDD FormDocument3 pagesClean Agent Fire Suppression System Test QCDD FormMahmoud HassanNo ratings yet

- 8-3 Rubber TireDocument22 pages8-3 Rubber TireFernando Katayama0% (1)

- Cat FiltersDocument96 pagesCat FiltersGaming Bebas100% (2)

- Hvac Watt Per Square Meter CalculationsDocument2 pagesHvac Watt Per Square Meter Calculationsmohammed_hatem96% (24)

- Fire Alarm Testing Procedure - Astra - Rev1Document5 pagesFire Alarm Testing Procedure - Astra - Rev1Mariano obilleNo ratings yet

- Fire Alarm System Commissioning ProcedureDocument3 pagesFire Alarm System Commissioning ProcedureNGASSAKI ATONGUI Christ HubertNo ratings yet

- FDAS System Maintenance AvescoDocument8 pagesFDAS System Maintenance AvescoRizalino BrazilNo ratings yet

- Intelligent Photoelectric Smoke SensorsDocument2 pagesIntelligent Photoelectric Smoke Sensorsmubs73No ratings yet

- Aerosol System Functional Test QCDD FormDocument3 pagesAerosol System Functional Test QCDD FormMahmoud HassanNo ratings yet

- Communication SignalDocument16 pagesCommunication SignaltarlyNo ratings yet

- Leaksprotect User Manual: Leaksprotect Is A Wireless Leakage Detector That Noti Es Both in Case of A Leak andDocument11 pagesLeaksprotect User Manual: Leaksprotect Is A Wireless Leakage Detector That Noti Es Both in Case of A Leak andRadu AnastasescuNo ratings yet

- SECTION 16721 Fire Alarm SystemDocument8 pagesSECTION 16721 Fire Alarm Systemahmed fouadNo ratings yet

- Fire Alarm & Smoke Detection SystemsDocument9 pagesFire Alarm & Smoke Detection SystemsJalizco RuedaNo ratings yet

- Fire Alarm System MS (R1)Document7 pagesFire Alarm System MS (R1)mahroof mkuttyNo ratings yet

- Fire Alarm and Detection System ProcedureDocument7 pagesFire Alarm and Detection System ProcedureProjects aissol100% (1)

- SECTION 16721 Fire Detection and Alarm Systems: Building No. SC# Project NameDocument12 pagesSECTION 16721 Fire Detection and Alarm Systems: Building No. SC# Project NameSaeed VuNo ratings yet

- 5151 - Manual - I56-5151 DHCDocument2 pages5151 - Manual - I56-5151 DHCmeribout adelNo ratings yet

- Manual Usuario MD-2105RDocument1 pageManual Usuario MD-2105RJhonny PozoNo ratings yet

- MotionProtect Outdoor User Manual + Datasheet20211665145870466Document22 pagesMotionProtect Outdoor User Manual + Datasheet20211665145870466Ionut PavelNo ratings yet

- GO Switch, Seal Fail Relay PDFDocument2 pagesGO Switch, Seal Fail Relay PDFtotovasiNo ratings yet

- Moose Z900 ENDocument26 pagesMoose Z900 ENRichard RoperNo ratings yet

- Pir 900Document2 pagesPir 900albeda1No ratings yet

- Addressable Fire Alarm System TestDocument3 pagesAddressable Fire Alarm System TestSalim Bakhsh0% (1)

- Ire Alarm System Pre-Test and Acceptance Test ChecklistDocument2 pagesIre Alarm System Pre-Test and Acceptance Test ChecklisthNo ratings yet

- Manual para CuervoDocument2 pagesManual para Cuervof041793No ratings yet

- Vigilant VS1 and VS2 Operating Instructions PlacardDocument1 pageVigilant VS1 and VS2 Operating Instructions Placardj5f9c5hyspNo ratings yet

- 95-8790 - (X-Series-Flame-Detectors-with-Pulse-Output)Document16 pages95-8790 - (X-Series-Flame-Detectors-with-Pulse-Output)pabloperezmtz1No ratings yet

- Wet Chemical System Test QCDD FormDocument2 pagesWet Chemical System Test QCDD FormMahmoud HassanNo ratings yet

- Project MR Aamir Abdul LateefDocument8 pagesProject MR Aamir Abdul Lateeflatanyahusted33234No ratings yet

- 9101 Conventional Combination Heat Photoelectric Smoke Detector IssueDocument2 pages9101 Conventional Combination Heat Photoelectric Smoke Detector Issuenagulanmurugan_38134No ratings yet

- 3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetDocument2 pages3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetAlejandro coronelNo ratings yet

- Ar 222 2ND Exam 1Document12 pagesAr 222 2ND Exam 1princessharengarciaNo ratings yet

- Notifier SD 651 SD 651A Low Profie Plug in Smoke DetectorsDocument2 pagesNotifier SD 651 SD 651A Low Profie Plug in Smoke Detectorsด้วกส์ เอเชีย ไม่เคยเสียท่าใครNo ratings yet

- Fuente Fcps 24s6eDocument12 pagesFuente Fcps 24s6eGuido RuizNo ratings yet

- Testing and Commissioning of Fire Alarm SystemDocument10 pagesTesting and Commissioning of Fire Alarm SystemRobin Oidem CaniedoNo ratings yet

- Conventional Fire Alarm PanelDocument29 pagesConventional Fire Alarm Panelnastyn-1No ratings yet

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- sl-31028 Secuenciador AC3Document19 pagessl-31028 Secuenciador AC3Luis Alberto Huamán MalcaNo ratings yet

- Manual Programación Edwards Vigilant VS-2 Fire Alarm Control PanelDocument365 pagesManual Programación Edwards Vigilant VS-2 Fire Alarm Control Panelvizion2k4No ratings yet

- Manual Swan Quad CrowDocument2 pagesManual Swan Quad CrowApex PredatorNo ratings yet

- S W A N 1 0 0 0: Installation InstructionsDocument2 pagesS W A N 1 0 0 0: Installation InstructionsLuisAlbertoSaldañaRmzNo ratings yet

- C-9101 Conventional Combination Heat/Photoelectric Smoke DetectorDocument2 pagesC-9101 Conventional Combination Heat/Photoelectric Smoke DetectorHiteshgangeleNo ratings yet

- I-9102 Intelligent Photoelectric Smoke Detector Issue1.03Document2 pagesI-9102 Intelligent Photoelectric Smoke Detector Issue1.03Seagull MarineNo ratings yet

- Fire Alarm System Installation Inspection Checkllist PDFDocument4 pagesFire Alarm System Installation Inspection Checkllist PDFAhmed KhamisNo ratings yet

- Sec15 - Special SystemsDocument51 pagesSec15 - Special SystemsYusufNo ratings yet

- Pre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument2 pagesPre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- Method Statement: Fire Alarm SystemDocument7 pagesMethod Statement: Fire Alarm Systemមិន ខ្វល់No ratings yet

- SpecificationsDocument10 pagesSpecificationsvenkat0236No ratings yet

- 01 Tech. Spec Int. Fire Detection System 20230624Document15 pages01 Tech. Spec Int. Fire Detection System 20230624Jaydeep ParmarNo ratings yet

- Heat Detector Maintenance Testing ProcedureDocument2 pagesHeat Detector Maintenance Testing ProcedureAlvin MiraNo ratings yet

- Fire Alarm Panel Check ListDocument1 pageFire Alarm Panel Check Listfairoos aliNo ratings yet

- MPM 811 04 01Document2 pagesMPM 811 04 01Mousa PetrolNo ratings yet

- Owner Manual: Aqua New StylusDocument16 pagesOwner Manual: Aqua New StylussoldatechNo ratings yet

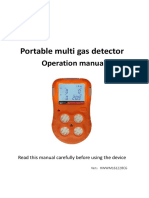

- Portable Multi Gas Detector: Operation ManualDocument24 pagesPortable Multi Gas Detector: Operation Manuallion GuveraNo ratings yet

- Service and Operation Manual: MTG-XX01 SERIES (13",19") CGA Open Frame Color MonitorsDocument11 pagesService and Operation Manual: MTG-XX01 SERIES (13",19") CGA Open Frame Color MonitorsVlade NaumovskiNo ratings yet

- Ja-60B Wireless Glass Break Detector: SpecificationDocument2 pagesJa-60B Wireless Glass Break Detector: SpecificationDragus IonelNo ratings yet

- 28 46 21 1x Fire Alarm SystemsDocument9 pages28 46 21 1x Fire Alarm SystemsindoramaNo ratings yet

- Fire Alarm Inspection Report Port QasimDocument8 pagesFire Alarm Inspection Report Port Qasimwarikhan1995No ratings yet

- Hd912 ManualDocument2 pagesHd912 ManualrhomadonaNo ratings yet

- Fire Detection and Alarm SystemDocument5 pagesFire Detection and Alarm SystemEric LopezNo ratings yet

- System Record of CompletionDocument31 pagesSystem Record of CompletionRaton121 RahmanNo ratings yet

- FM4000E - CI-146 Iss3 FM4000E InstallationDocument15 pagesFM4000E - CI-146 Iss3 FM4000E InstallationHans RughoonathNo ratings yet

- Fire Alarm FIADocument23 pagesFire Alarm FIAFernando KatayamaNo ratings yet

- br05805966k K Bidsub FpatsDocument8 pagesbr05805966k K Bidsub FpatsFernando KatayamaNo ratings yet

- 75F FacilisightDocument2 pages75F FacilisightFernando KatayamaNo ratings yet

- PS05805010K - B - JOCKEY Touch - Ver Jun 2015 - NS - 05-25-15Document1 pagePS05805010K - B - JOCKEY Touch - Ver Jun 2015 - NS - 05-25-15Fernando KatayamaNo ratings yet

- BS en 16282-7 2017 PDFDocument16 pagesBS en 16282-7 2017 PDFFernando KatayamaNo ratings yet

- Spare Parts - 05-01-23Document23 pagesSpare Parts - 05-01-23Fernando KatayamaNo ratings yet

- Experience. Innovation.: Roof Design For Fire Safety and Sound IsolationDocument30 pagesExperience. Innovation.: Roof Design For Fire Safety and Sound IsolationFernando KatayamaNo ratings yet

- Selecting Fire Protection Air CompressorsDocument2 pagesSelecting Fire Protection Air CompressorsFernando KatayamaNo ratings yet

- Diagrama Jockey FDJPDocument1 pageDiagrama Jockey FDJPFernando KatayamaNo ratings yet

- Ceiling Systems For High-Performing Health-Care FacilitiesDocument52 pagesCeiling Systems For High-Performing Health-Care FacilitiesFernando KatayamaNo ratings yet

- Smoke Propagation in Residential Buildings: Welcome and IntroductionDocument16 pagesSmoke Propagation in Residential Buildings: Welcome and IntroductionFernando KatayamaNo ratings yet

- Webinar Ce and MeDocument40 pagesWebinar Ce and MeFernando KatayamaNo ratings yet

- 01 Transportation Track Booming Technology in 2021 0331Document14 pages01 Transportation Track Booming Technology in 2021 0331Fernando KatayamaNo ratings yet

- Huawei 20201124 v2Document12 pagesHuawei 20201124 v2Fernando KatayamaNo ratings yet

- Emerging AI Trends: How AI and Its Applications Impact Healthcare IndustryDocument18 pagesEmerging AI Trends: How AI and Its Applications Impact Healthcare IndustryFernando KatayamaNo ratings yet

- 2 Mart Machine Keynote 2 The Future of Semiconductor Intelligent Equipment in The AIoT EraDocument15 pages2 Mart Machine Keynote 2 The Future of Semiconductor Intelligent Equipment in The AIoT EraFernando KatayamaNo ratings yet

- Revolutionize AI Solution Expansion With WISE PaaS AIFS - Advantech - Tony FuDocument19 pagesRevolutionize AI Solution Expansion With WISE PaaS AIFS - Advantech - Tony FuFernando KatayamaNo ratings yet

- Apollo Fire Safety in Healthcare Buildings UK CPDDocument1 pageApollo Fire Safety in Healthcare Buildings UK CPDFernando KatayamaNo ratings yet

- Cloud-Enabled Data Collect & Sensing IntelligenceDocument19 pagesCloud-Enabled Data Collect & Sensing IntelligenceFernando KatayamaNo ratings yet

- 52 IAG FAQ How To Update WebAccessDocument2 pages52 IAG FAQ How To Update WebAccessFernando KatayamaNo ratings yet

- Connecting To The Sustainable Future With 5G Wireless and M2M Gateway TechnologyDocument10 pagesConnecting To The Sustainable Future With 5G Wireless and M2M Gateway TechnologyFernando KatayamaNo ratings yet

- 01 Energy and Environment - Keynote - ChingPo LinDocument23 pages01 Energy and Environment - Keynote - ChingPo LinFernando KatayamaNo ratings yet

- Hyundai HD 6 HD 72 HD 78 Circuit SchematicDocument10 pagesHyundai HD 6 HD 72 HD 78 Circuit Schematiccharles100% (50)

- Permit LOTODocument1 pagePermit LOTOsurya adi wijayaNo ratings yet

- S01 Hydraulic CartridgesDocument44 pagesS01 Hydraulic CartridgesESRANo ratings yet

- Installation / User Manual: Apsystems Yc600 MicroinverterDocument24 pagesInstallation / User Manual: Apsystems Yc600 MicroinverterCarlos BrancoNo ratings yet

- Module 4 Sheet 3.5 Installation of Peripherals Network Devices and Other IO DevicesDocument23 pagesModule 4 Sheet 3.5 Installation of Peripherals Network Devices and Other IO DevicesRalfh De GuzmanNo ratings yet

- Microscope Lab Key 1Document6 pagesMicroscope Lab Key 1cellestial_knightNo ratings yet

- Field Service - 1050,1050P, 1050e, 1050ep (Ver. 3.0 November 2006) PDFDocument854 pagesField Service - 1050,1050P, 1050e, 1050ep (Ver. 3.0 November 2006) PDFcopiartekNo ratings yet

- L150/C/D/E/F: Ground Engaging Tools / Wheel Loaders / Volvo Tooth SystemDocument2 pagesL150/C/D/E/F: Ground Engaging Tools / Wheel Loaders / Volvo Tooth SystemLucky OkoteNo ratings yet

- Cable Carrier CatalougeDocument146 pagesCable Carrier Catalougebachir diengNo ratings yet

- Manual HDCam6E130 2017-10-09Document13 pagesManual HDCam6E130 2017-10-09Serbanescu AndreiNo ratings yet

- Carlo Gavazzi Rev 10 2013Document252 pagesCarlo Gavazzi Rev 10 2013matoyNo ratings yet

- Pending Work List - AVSDocument1 pagePending Work List - AVSRamojeevaNo ratings yet

- Pump CalculationDocument5 pagesPump CalculationrkobeissiNo ratings yet

- Wiring Diagram Rear Control UnitDocument8 pagesWiring Diagram Rear Control UnitMcDimaDNo ratings yet

- 35MPa Cylinder ValveDocument12 pages35MPa Cylinder Valvechen guanghuaNo ratings yet

- ICTSMDocument11 pagesICTSMykjayashreeNo ratings yet

- Light MicroscopeDocument35 pagesLight MicroscopeDR VARSHA A SINGHNo ratings yet

- Erin-B6fm8d R0 enDocument4 pagesErin-B6fm8d R0 enMoises ReznikNo ratings yet

- Ficha Tecnica Inversor PVS - 50-60-TLDocument4 pagesFicha Tecnica Inversor PVS - 50-60-TLJair SaavedraNo ratings yet

- Roblan Sept 2015 - PVP MasterDocument11 pagesRoblan Sept 2015 - PVP MasterVEMATELNo ratings yet

- Wood LatheDocument22 pagesWood LatheDennisNo ratings yet

- Chapter 7 - Ai: ParagraphDocument4 pagesChapter 7 - Ai: Paragraphchiri003No ratings yet

- 420kV, 40 KA For 1 Sec. Triple Pole, Double Break, Motor Operated IsolatorDocument14 pages420kV, 40 KA For 1 Sec. Triple Pole, Double Break, Motor Operated Isolatorrajinikanth19100% (1)

- Caring For Your Laptop - zp190068Document15 pagesCaring For Your Laptop - zp190068cold storageNo ratings yet

- Quick Reference Guide PosterDocument1 pageQuick Reference Guide PosterXproNo ratings yet