Professional Documents

Culture Documents

Fulton-Work-Instruction_WRK-2022-02_Fulton-Boiler-Blowdown-Process

Fulton-Work-Instruction_WRK-2022-02_Fulton-Boiler-Blowdown-Process

Uploaded by

kikokiko KarimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fulton-Work-Instruction_WRK-2022-02_Fulton-Boiler-Blowdown-Process

Fulton-Work-Instruction_WRK-2022-02_Fulton-Boiler-Blowdown-Process

Uploaded by

kikokiko KarimCopyright:

Available Formats

WORK INSTRUCTION

SUBJECT: APPLIES TO: WRK-2022-02

Fulton Boiler Blowdown Process Fulton Steam Boilers

OCTOBER 31, 2022

TO ALL FULTON REPRESENTATIVES: Once the blowdown tank is flooded, it should remain

flooded. In the event the blowdown tank is drained,

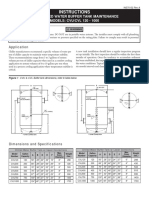

During installation the temperature sensor for the it will need to be re-filled prior to preforming a boiler

cooling valve will need to be installed in the correct blowdown.

location on the blowdown tank.

BOILER BLOWDOWN:

NOTE: Fulton recommends the boiler(s) be blown down

at low pressure (10psig or less) whenever possible. If

this is not practical, the boiler may be blowdown at

operating pressure, however additional flash steam

will be generated. It will also be more critical to control

the volume and duration of the blowdown to prevent

discharging additional water and/or prevent damage

to any equipment.

c Temperature Sensor

Prior to starting to blowdown a boiler, verify the Bottom Boiler Blowdown:

following valve positions and tank level.

The valves that will be used are the quick opening

and slow opening valves on the boiler bottom

1. The drain valve on the blowdown tank should

blowdown connection(s). Some boiler models have

be fully closed

(2) two bottom blowdown openings.

2. Cold water valve to the cooling kit should be

To complete a bottom blowdown, every connection

fully opened

on the bottom of the boiler should be blown down

3. Set the above cooling valve so that adequate individually each blowdown instance. Typical bottom

cooling water flows to keep the drain water blowdown frequency is once every 8 hours, but may

temperature below 140°F or below the required be modified based on water chemistry requirements.

temperature of the local jurisdiction if different The typical bottom blowdown valves are pictured

below with the fast opening ball valve and slow

4. Verify blowdown tank is flooded via sight glass opening Y-valve. (Cont’d page 2)

(if provided)

5. Auxiliary cooling line valve closed

6. Low level drain valve closed

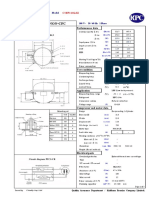

Slow Opening Valve

7. Boiler fast and slow opening bottom blowdown Fast Opening Valve

valves are closed

8. Boiler water column blowdown valve is closed

9. Boiler sight glass blowdown valve is closed

Fulton recommends that bottom blowdown be WATER COLUMN BLOWDOWN:

completed at least once per day. The blowdown

NOTE: Be sure that the water column is properly piped

should last ten seconds and have a drop in the boiler per the IOM to an adequate drain prior to completing the

sight glass level of 1-2” in height. blowdown procedure.

When completing a bottom blowdown, the valves

should be opened slowly and carefully. If possible, Probe-Type Water Column Blowdown:

the boiler should be blown down at lower firing rates.

The water column is be blown down once every 8

Blowdown valves are to be tightly closed after each

hours of operation and a minimum of once per day.

blowdown is completed.

To blowdown the Fulton

To complete a bottom blowdown, please follow the water column, the “Water

instructions below. Some Fulton boilers have two Column Valve” is opened

bottom blowdown openings; this process is to be for a minimum period of

completed for each opening to satisfy the blowdown 5 seconds or until the low

requirements. Also check to be sure that proper water cutoff causes the

cooling water is available and turned on. burner to cycle.

Sight

For other types of water Glass

10. Check to see that all bottom blowdown valves Valve

columns, please refer

are fully closed

to the installation and

11. Open the quick opening blowdown valve operation manual for the

Water

(nearest to the boiler) column for the blowdown Column

procedure. The frequency Valve

12. Open the slow opening valve of blowdown is still to be

– The boiler water level should drop 1-2” over once every 8 hours with a

the (10) ten second bottom blowdown minimum of once per day.

13. Allow the boiler to blowdown to occur for Water Column Sight Glass Blowdown:

the above specified amount of time or as

specified by your water treatment consultant; NOTE: Be sure that the sight glass is properly piped per

the IOM to an adequate drain prior to completing the

some instances will require multiple bottom

blowdown procedure.

blowdowns depending on operation duration

and water chemistry

Blowdown of the water column sight glass is to be

14. Close the slow opening valve once every 8 hours and a minimum of once per day.

To blowdown the sigh glass, the “Sight Glass Valve”

15. Close the quick opening valve is opened for 5 seconds. If the water in the sight

glass is dirty, repeat blowdown of “Sight Glass Valve”

16. Open the slow opening valve again to drain

and “Water Column Valve” until water is clean.

the line in between the slow and quick

opening valves Best regards,

The Fulton Team

17. Close the slow opening valve and double check

that all valves are shut off tightly

NOTE: Never pump the quick opening valve to blowdown

the boiler. Such action could cause water hammer and

damage piping and valves. It could also cause personal

injury. Never leave an open blowdown valve unattended.

©2022 Fulton Management Services, Inc. - All Rights Reserved PHONE: (315) 298-5121 FAX: (315) 298-6390 www.fulton.com

This bulletin is confidential and intended for internal Representative Use Only. No part of this

bulletin is to be reproduced or made public without the express written consent of Fulton. WRK-2022-02

You might also like

- FlexCon HDPE Flyers 2021Document4 pagesFlexCon HDPE Flyers 2021Lloyd CruzetNo ratings yet

- Stress Analysis of Guide Rails of Elevators: Hayder F. Neamah Wisam H. AliDocument13 pagesStress Analysis of Guide Rails of Elevators: Hayder F. Neamah Wisam H. Alikikokiko KarimNo ratings yet

- Well Control EquiptDocument115 pagesWell Control EquiptGhavban David100% (3)

- Mechanical Steam TrapsDocument6 pagesMechanical Steam TrapspramodtryNo ratings yet

- AQ9 Boiler PDFDocument26 pagesAQ9 Boiler PDFВиталий РунцивNo ratings yet

- BoilerDocument7 pagesBoilerAlexander LakraNo ratings yet

- Procedure For Alkali BoiloutDocument9 pagesProcedure For Alkali BoiloutBapu612345No ratings yet

- Microcontrollers TextbookDocument649 pagesMicrocontrollers TextbookCodiNo ratings yet

- Upgrading SAP S4HANA Why How and Best PracticesDocument89 pagesUpgrading SAP S4HANA Why How and Best PracticesmahfoudNo ratings yet

- 750-326 Blowdown Separator 11 2015Document10 pages750-326 Blowdown Separator 11 2015osamaNo ratings yet

- Y203 EN2 01 Motion Drives Catalogue 2004Document328 pagesY203 EN2 01 Motion Drives Catalogue 2004dangkhuyenmai100% (1)

- Blow-Down Procedure For Marine Boilers PDFDocument7 pagesBlow-Down Procedure For Marine Boilers PDFRejoGevargheseRajanNo ratings yet

- Operation and Installation Manual: Prds - Prs - DSH SystemsDocument125 pagesOperation and Installation Manual: Prds - Prs - DSH Systemskikokiko Karim100% (2)

- Wireman, Terry - Developing Performance Indicators For Managing Maintenance Second Edition-Industrial Press (2005) PDFDocument272 pagesWireman, Terry - Developing Performance Indicators For Managing Maintenance Second Edition-Industrial Press (2005) PDFPedrogomes6No ratings yet

- Experiment 1: Steam Boiler Operation and Boiler MountingDocument4 pagesExperiment 1: Steam Boiler Operation and Boiler Mountingsarjenputra07No ratings yet

- Daily Boiler Blowdown Instructions 1.5-3 H.P. Parker Gas Fired BoilerDocument2 pagesDaily Boiler Blowdown Instructions 1.5-3 H.P. Parker Gas Fired BoilerKarthik AnandanNo ratings yet

- 1998-02 Water HeatersDocument2 pages1998-02 Water HeatersMike PerryNo ratings yet

- Section11 ROUTINE OPERATION.Document37 pagesSection11 ROUTINE OPERATION.Mithilesh YadavNo ratings yet

- Marine BoilerDocument31 pagesMarine BoilerydwkpteagmNo ratings yet

- Instruction Manual 12340Document10 pagesInstruction Manual 12340Oțeleanu BogdanNo ratings yet

- BOILER MOUNTINGS ADocument17 pagesBOILER MOUNTINGS Ahafiz aiman100% (1)

- Safer Boiler OperationDocument2 pagesSafer Boiler OperationUmangtarangNo ratings yet

- Instructions: For Chilled Water Buffer Tank Maintenance MODELS: CVU/CVL 120 - 1000Document2 pagesInstructions: For Chilled Water Buffer Tank Maintenance MODELS: CVU/CVL 120 - 1000Vũ Đình QuangNo ratings yet

- Fabdock Operating Manual 2019Document8 pagesFabdock Operating Manual 2019Kyle McCormackNo ratings yet

- Birla MEEP Op ManualDocument43 pagesBirla MEEP Op ManualAshok ChettiyarNo ratings yet

- Lesson 4. Boiler MountingsDocument4 pagesLesson 4. Boiler MountingsalexdenychenkoNo ratings yet

- Service Manual: Purewatercooler Model Pwc-500/1000/1010/1500Document38 pagesService Manual: Purewatercooler Model Pwc-500/1000/1010/1500Vel MuruganNo ratings yet

- Start/stop of The Boiler: 1 GeneralDocument4 pagesStart/stop of The Boiler: 1 GeneralphuocNo ratings yet

- Guide 2 Safer BoilerDocument2 pagesGuide 2 Safer BoilerTharanyaanandNo ratings yet

- Section-3 Hydraulic Test: ISGEC John ThompsonDocument4 pagesSection-3 Hydraulic Test: ISGEC John ThompsonMithilesh YadavNo ratings yet

- Troubleshooting Guide: Start Up ConditionsDocument4 pagesTroubleshooting Guide: Start Up ConditionsShouzab AbbasNo ratings yet

- Applied ThermodynamicsDocument19 pagesApplied ThermodynamicsAayush PandeyNo ratings yet

- Operation and Maintenance: Start/stop of BoilerDocument24 pagesOperation and Maintenance: Start/stop of BoilerAlexander BaziotisNo ratings yet

- TH PBLDocument11 pagesTH PBLAlbert FredriekNo ratings yet

- 104 BdivDocument2 pages104 BdivClara FelitaNo ratings yet

- Section13 EMERGENCIESDocument7 pagesSection13 EMERGENCIESMithilesh YadavNo ratings yet

- Section 3 - Hydraulic Test: 3.1 PurposeDocument3 pagesSection 3 - Hydraulic Test: 3.1 PurposeJITIN ARORANo ratings yet

- Lesson 5. Blow Down ProcedureDocument3 pagesLesson 5. Blow Down ProcedureАртем БабенкоNo ratings yet

- Notice Mitigeur Douche FrenchTripleControlIssue2COMBINATIONDocument39 pagesNotice Mitigeur Douche FrenchTripleControlIssue2COMBINATIONPascal ArenouNo ratings yet

- Bringing A Boiler On-Line From Cold AR PWIR KS - V3 170816Document5 pagesBringing A Boiler On-Line From Cold AR PWIR KS - V3 170816cadhoaNo ratings yet

- Ai Boiler Routine Maintenance Guide: AmerecDocument10 pagesAi Boiler Routine Maintenance Guide: Amerecأبو نبيل سلامNo ratings yet

- Ss 03037Document6 pagesSs 03037Necati Yunus OrbayNo ratings yet

- Boiler Mountings: School of Maritime Studies Vels University ThalamburDocument3 pagesBoiler Mountings: School of Maritime Studies Vels University ThalamburAayush AgrawalNo ratings yet

- Descaling Plate Heat ExchangersDocument2 pagesDescaling Plate Heat ExchangersrishimaranNo ratings yet

- Delayed Float ValvesDocument6 pagesDelayed Float ValvesferasbushnaqNo ratings yet

- Tank Blanketing: A Versatile Tool For Tank ProtectionDocument21 pagesTank Blanketing: A Versatile Tool For Tank ProtectionAnonymous Wd2KONNo ratings yet

- Tech Boiler Operation and Maintenance 20111025Document3 pagesTech Boiler Operation and Maintenance 20111025Fana AkalNo ratings yet

- Cryogenic Dewar Maintenance: Bell Jar GasketDocument4 pagesCryogenic Dewar Maintenance: Bell Jar GasketPaslab UjfiNo ratings yet

- Tech Sheet 128Document1 pageTech Sheet 128Sriram RamanujamNo ratings yet

- Vol.06 02 EDocument2 pagesVol.06 02 EZhengwei YinNo ratings yet

- Cold Weather Startup & Winter Opn Best PracticeDocument4 pagesCold Weather Startup & Winter Opn Best Practicerongomes69yahoo.com.sgNo ratings yet

- Boiler DevicesDocument4 pagesBoiler DevicesMohamed DorboukNo ratings yet

- Boiler Safety Valves PDFDocument2 pagesBoiler Safety Valves PDFripalNo ratings yet

- Jw-Direct-Vent-Expation Tank RequireDocument1 pageJw-Direct-Vent-Expation Tank Requirebuisson-21No ratings yet

- Boiler Safety Systems and InstrumentsDocument6 pagesBoiler Safety Systems and InstrumentsАртем БабенкоNo ratings yet

- F51 450 FP AccessoriesDocument4 pagesF51 450 FP AccessoriesFayez Al-ahmadiNo ratings yet

- Technical Instructions: Form TI410-5 v3Document8 pagesTechnical Instructions: Form TI410-5 v3薛泽绵No ratings yet

- Pilot Float Valve 45fwrDocument5 pagesPilot Float Valve 45fwrripcurlzNo ratings yet

- Desalt DPU-36-C Series: Titanium Plate Type Fresh Water GeneratorDocument4 pagesDesalt DPU-36-C Series: Titanium Plate Type Fresh Water GeneratorDwi Tri CahyonoNo ratings yet

- FPS P SummaryDocument3 pagesFPS P SummaryGreen MichaelsNo ratings yet

- Flood BackDocument3 pagesFlood BackChris Doncillo DondonNo ratings yet

- Singer Valve 106 206 F Type 4 IOM Operation GuideDocument4 pagesSinger Valve 106 206 F Type 4 IOM Operation GuideSijo JoyNo ratings yet

- Fittings and MountingsDocument14 pagesFittings and Mountingssandeep kumarNo ratings yet

- Why Check Valves SlamDocument2 pagesWhy Check Valves SlamBramJanssen76No ratings yet

- 5.apparatus: Unit Construction For Film & Dropwise Condensation Unit (Model: HE 163)Document4 pages5.apparatus: Unit Construction For Film & Dropwise Condensation Unit (Model: HE 163)Hafizi Naim IsmailNo ratings yet

- 1SBL137001R1310-af09-30-10-13Document7 pages1SBL137001R1310-af09-30-10-13kikokiko KarimNo ratings yet

- SizesDocument1 pageSizeskikokiko KarimNo ratings yet

- BDV_ENDocument2 pagesBDV_ENkikokiko KarimNo ratings yet

- NOL-G100-125-150MANUAL(3)Document42 pagesNOL-G100-125-150MANUAL(3)kikokiko KarimNo ratings yet

- UFTAS-WPSDocument3 pagesUFTAS-WPSkikokiko KarimNo ratings yet

- 2CDS211001R0104-sh201-c10Document4 pages2CDS211001R0104-sh201-c10kikokiko KarimNo ratings yet

- SLD_mergedDocument14 pagesSLD_mergedkikokiko KarimNo ratings yet

- 1SAM350000R1011-ms132-16Document8 pages1SAM350000R1011-ms132-16kikokiko KarimNo ratings yet

- 6-RPU-RPTDocument1 page6-RPU-RPTkikokiko KarimNo ratings yet

- 2CDS253001R0404-s203-c40 (1)Document7 pages2CDS253001R0404-s203-c40 (1)kikokiko KarimNo ratings yet

- Target SectorsDocument4 pagesTarget Sectorskikokiko KarimNo ratings yet

- Three Way ValveDocument3 pagesThree Way Valvekikokiko KarimNo ratings yet

- Mechanical System BOQDocument11 pagesMechanical System BOQkikokiko KarimNo ratings yet

- Pressure Drop For Storage Calofier Model BV1KDocument1 pagePressure Drop For Storage Calofier Model BV1Kkikokiko KarimNo ratings yet

- CRHY4 : Consolidated Statement of Accounts Consolidated Statement of AccountsDocument3 pagesCRHY4 : Consolidated Statement of Accounts Consolidated Statement of Accountskikokiko KarimNo ratings yet

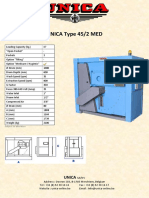

- UNICA Type 45/2 MEDDocument13 pagesUNICA Type 45/2 MEDkikokiko KarimNo ratings yet

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Document1 pageFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimNo ratings yet

- Water Specialist WS1TT Drawings and Service Manual: 2nd Tank Connection PortDocument36 pagesWater Specialist WS1TT Drawings and Service Manual: 2nd Tank Connection Portkikokiko KarimNo ratings yet

- Simpro - Task 2-1 - : Guide Rail Optimization by IsightDocument24 pagesSimpro - Task 2-1 - : Guide Rail Optimization by Isightkikokiko KarimNo ratings yet

- Wiring DiagramDocument21 pagesWiring Diagramkikokiko KarimNo ratings yet

- BiometricsDocument51 pagesBiometricsRishik Gupta (Riskytemp)No ratings yet

- Nee2102 Experiment Report 5Document13 pagesNee2102 Experiment Report 5Lynndon VillamorNo ratings yet

- C-BF 110L0Z PDFDocument3 pagesC-BF 110L0Z PDFWardi SupriadiNo ratings yet

- Asus SOSTAC AnalysisDocument4 pagesAsus SOSTAC AnalysisCalix CasanovaNo ratings yet

- 17 J MST 88 2023 131 138 1671Document8 pages17 J MST 88 2023 131 138 1671k3proNo ratings yet

- Modern Technology PDFDocument5 pagesModern Technology PDFhanna991No ratings yet

- ZUGFeRD-2.1.1 - Specification - TADocument117 pagesZUGFeRD-2.1.1 - Specification - TAgerstenblunaNo ratings yet

- Math K 12 Enduring Understandings and Essential QuestionsDocument2 pagesMath K 12 Enduring Understandings and Essential QuestionsMark neil a. GalutNo ratings yet

- Operation Manual: Riso Collator Tc7100Document48 pagesOperation Manual: Riso Collator Tc7100Arturo AparicioNo ratings yet

- SK-600I - Operator's Manual v1.0 (En)Document68 pagesSK-600I - Operator's Manual v1.0 (En)Zákány ZoltánNo ratings yet

- 100 Empresas para Se Trabalhar RemotamenteDocument3 pages100 Empresas para Se Trabalhar RemotamenteGUILHERME RODRIGO DE FARIANo ratings yet

- How To Do A Literature Review Harvard StyleDocument5 pagesHow To Do A Literature Review Harvard Stylesjcuwurif100% (1)

- Chemlab 1.Document3 pagesChemlab 1.jamila_aceberos33% (3)

- Form 1. Lac ProfileDocument2 pagesForm 1. Lac ProfileJohn QuidulitNo ratings yet

- 1371 4834 1 PB PDFDocument9 pages1371 4834 1 PB PDFArdy Moses SitanggangNo ratings yet

- Senior Five Applied Mathematics Paper2 Time: 3hours: Instruction: Answer All QuestionsDocument3 pagesSenior Five Applied Mathematics Paper2 Time: 3hours: Instruction: Answer All QuestionsJava JimmyNo ratings yet

- Working Principle of Four Stroke Si EngineDocument3 pagesWorking Principle of Four Stroke Si EngineajubabuNo ratings yet

- HPHT PVT Analysis: ApplicationsDocument2 pagesHPHT PVT Analysis: ApplicationsJesseNo ratings yet

- Tutorial 6Document2 pagesTutorial 6harshit khandelwalNo ratings yet

- EER v9Document72 pagesEER v9NURTURE - Heal & Grow Dr. Anjali BhimajiyaniNo ratings yet

- Form 3 SPPD CV Resource PersonDocument3 pagesForm 3 SPPD CV Resource PersonP Olarte ESNo ratings yet

- Performance of Trainer Kits Sorting Station Based On PLC, HMI and SCADADocument4 pagesPerformance of Trainer Kits Sorting Station Based On PLC, HMI and SCADArullyhimawan.tmmjNo ratings yet

- Engineering Report - Chemical Anchor Suspended Glass Pemasangan Angkur Samping (H 5 M, 2 FTRS M10 + FIS VS)Document10 pagesEngineering Report - Chemical Anchor Suspended Glass Pemasangan Angkur Samping (H 5 M, 2 FTRS M10 + FIS VS)Febrinaldo HidayahNo ratings yet

- Khawar Nehal Resume IT Manager 11 June 2023-1Document25 pagesKhawar Nehal Resume IT Manager 11 June 2023-1khawar.nehalNo ratings yet

- b28370 (307 712) PDFDocument406 pagesb28370 (307 712) PDFPatrick Moreira AlcantaraNo ratings yet