Professional Documents

Culture Documents

JRC Magnetrons Replacement Procedure

JRC Magnetrons Replacement Procedure

Uploaded by

mscsaryaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JRC Magnetrons Replacement Procedure

JRC Magnetrons Replacement Procedure

Uploaded by

mscsaryaCopyright:

Available Formats

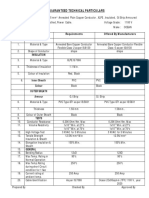

[Required Tools]

The tools shown in the following table are required for replacement work.

Table Required Tools

No Name Size Appearance

1 Non-magnetic Phillips Size #2, Size #3

screwdriver

2 Open-end wrench*1 Width across flats

13 mm (for M8 screws)

3 Socket wrench*1 Width across flats

13 mm (for M8 screws)

*1 Either the wrench (adjustable wrench) or socket wrench is mandatory. (mounting/removing

the cover, etc.)

Before beginning work, turn Off the safety switch of the Scanner unit.

Before conducting replacement work, turn Off the circuit breaker for the power supply of the

display unit.

Exercise care not to lose bolts, screws and other parts removed from the Scanner unit, as they

will be used again in later steps.

Step 1 Turn Off the safety switch (to the lower side) and remove the cover.

The safety switch is located on the rear (stern) side of the scanner unit. Open the cover for the

safety switch and turn it Off (to the lower side). Remove the cover on the left (port) side.

Bow side

Turn Off the safety switch.

4-9 Chapter 4 Replacement procedure

Remove the eight

hexagonal screws.

Example: Port side cover removal

Step 2 Remove the screws holding the magnetron cables.

Measure the voltage between pin 1 and pin 3 of CPA-264 (modulation circuit) J2101 by using a

multimeter (1000 V DC or more), check that there is no remaining electric charge in the modulation

high-voltage circuit board. Remove the two screws (M4) holding the magnetron cables (both

yellow and green).

Magnetron

Remove the green cable.

Remove the yellow cable.

Remove the two screws.

Chapter 4 Replacement procedure 4-10

Step 3 Remove the fixture holding the magnetron.

Remove the eight screws (M6) to remove the fixture holding the magnetron. The screws cannot

be removed from the fixture, so loosen the all eight screws and remove the magnetron together

with the fixture.

Remove the magnetron.

Remove the yellow cable.

Loosen the eight screws.

The magnetron is held by a hook, but be careful not to let it fall.

Use a non-magnetic screwdriver. If the magnetron comes into contact with any metal (tool),

its performance may deteriorate.

Step 4 Install the new magnetron.

Install the new magnetron together with the fixture and tighten the screws to hold the cables.

Follow the removal procedure in the reverse order.

Do not forget to tighten the bolts or screws, and make sure that the cables are connected.

4-11 Chapter 4 Replacement procedure

Step 5 Operation check

After you have completed the replacement work, turn On the safety switch and follow the

procedure below to check the operation.

1. Turn On the Display unit for the radar. Allow sufficient time for the radar to be

preheated (about 20 to 30 minutes/bring the radar unit to STBY mode).

2. Start transmission from the short pulse range and gradually change it to the long

pulse range. Open the service engineer menu to perform tuning adjustment.

Check the magnetron current on the test menu during the time and if

operation becomes unstable, bring the radar unit back to STBY mode

and restart transmission after allowing for an interval of 5 to 10

minutes.

3. Transmit radio waves in long pulse range mode for about 15 minutes and reopen the

service engineer menu to perform tuning adjustment.

Adjust the setting in the service engineer menu until the tuning indication bar on the

display unit reaches the 8th calibration marking. Check in the test menu that the

magnetron current is between the 6th and 9th calibration markings.

4. Finally, initialize the transmission time in the service engineer menu.

This completes magnetron replacement.

Chapter 4 Replacement procedure 4-12

You might also like

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Risk Management Plan SampleDocument13 pagesRisk Management Plan SampleRonna GasconNo ratings yet

- 2D201-079E - N - Aquilion16PC ConsoleDocument138 pages2D201-079E - N - Aquilion16PC ConsoleSwami Meera100% (3)

- User Instructions For R1100S Gear Switch IndicatorDocument17 pagesUser Instructions For R1100S Gear Switch Indicatorbuzzz57No ratings yet

- Notes For Lunar Light Empowerment: HealingDocument2 pagesNotes For Lunar Light Empowerment: Healingt t (torico)No ratings yet

- X-Band Radar FURUNO FAR 2827 Magnetron ReplacementDocument14 pagesX-Band Radar FURUNO FAR 2827 Magnetron ReplacementPătrașcu Mircea-GabrielNo ratings yet

- FibersDocument238 pagesFibersdejayzNo ratings yet

- IEE Lab ManualDocument28 pagesIEE Lab ManualUppum Mulakam FansNo ratings yet

- Procedure For Changing S Band Magnetron JRC JMA 9132Document2 pagesProcedure For Changing S Band Magnetron JRC JMA 9132Zhengwei YinNo ratings yet

- SOP of TRU MonitoringDocument10 pagesSOP of TRU MonitoringYogesh SainiNo ratings yet

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- E9 The Synchronous MotorDocument10 pagesE9 The Synchronous Motorlucas100% (1)

- Portable X-Ray Unit: 1. Manufacture Company InformationDocument17 pagesPortable X-Ray Unit: 1. Manufacture Company Informationcomphome100% (2)

- OWS New PLCDocument1 pageOWS New PLCmscsaryaNo ratings yet

- FireCR Flash Service ManualDocument22 pagesFireCR Flash Service ManualCesur Akyol100% (2)

- Folland Real Analysis Solution Chapter 3 Sign Measures and DifferentiationDocument10 pagesFolland Real Analysis Solution Chapter 3 Sign Measures and DifferentiationAlier Mony Bor50% (2)

- Jma-9000 7000 PDFDocument26 pagesJma-9000 7000 PDFMichael KarantziasNo ratings yet

- Erbe ICC-200 - Instruction ManualDocument8 pagesErbe ICC-200 - Instruction ManualFrancisco AvilaNo ratings yet

- PLX102 Maintenance ManualDocument8 pagesPLX102 Maintenance ManualJairo Manzaneda100% (4)

- TVL - Ia: Quarter 3 - Module 3Document11 pagesTVL - Ia: Quarter 3 - Module 3Chiarnie LopezNo ratings yet

- National Models of HRM: Europe and USADocument31 pagesNational Models of HRM: Europe and USAKwiz MichaelNo ratings yet

- MW Sharp R395eDocument23 pagesMW Sharp R395ejb100% (1)

- Adjustment Standards & ManitenanceDocument24 pagesAdjustment Standards & ManitenanceMd. Hanif SanketNo ratings yet

- Pem300D - Twin Photobeam Detectors: 1. Introduction & FeaturesDocument21 pagesPem300D - Twin Photobeam Detectors: 1. Introduction & FeaturesAdrian RavanNo ratings yet

- Manual Multimetru HT 112BDocument21 pagesManual Multimetru HT 112BAlin DanielNo ratings yet

- E2 Alternator Under LoadDocument8 pagesE2 Alternator Under LoadarjayNo ratings yet

- VaraDocument8 pagesVaraCesar Alfonso Saldivar MontoyaNo ratings yet

- Maintenance Manual For BBS-V800 202109Document15 pagesMaintenance Manual For BBS-V800 202109thaungmtNo ratings yet

- EXM3000 Installation SOPDocument8 pagesEXM3000 Installation SOPMuhammad Reza Fachlevi SitompulNo ratings yet

- Disassembly & ReassemblyDocument16 pagesDisassembly & ReassemblyleolamiaNo ratings yet

- Samsung MO1650xx Service ManualDocument29 pagesSamsung MO1650xx Service ManualBrent SmithNo ratings yet

- 93ZJ Secc 8J Turn Signals and Hazard Warning FlashesDocument4 pages93ZJ Secc 8J Turn Signals and Hazard Warning Flasheshelgith74No ratings yet

- Magnaflux UnitDocument28 pagesMagnaflux UnithamedmosadeqNo ratings yet

- Exp2 Two Slit Interference 1Document7 pagesExp2 Two Slit Interference 1Unik WadhwaniNo ratings yet

- Manual Takometro MegelliDocument21 pagesManual Takometro MegelliPablo Hernan Acuña25% (4)

- 42 799Document12 pages42 799scribdkhatnNo ratings yet

- ETCR1000C - 1000D ManualDocument16 pagesETCR1000C - 1000D ManualEnd Integridad Mecánica LegnaNo ratings yet

- Disassembly and Reassembly: 4-1 Replacement of Magnetron, Motor Assembly and LampDocument4 pagesDisassembly and Reassembly: 4-1 Replacement of Magnetron, Motor Assembly and LampKiran VeesamNo ratings yet

- MN 02004Document12 pagesMN 02004hyarub9No ratings yet

- Service Flash SMH9151 Mounting Bolt-Capacitor PDFDocument6 pagesService Flash SMH9151 Mounting Bolt-Capacitor PDFRox DiazNo ratings yet

- User 'S Manual Parts Book: SSU UN Nssttaarr M Maac CH Hiin Neerryy C CO O..,, LLTTD D.Document72 pagesUser 'S Manual Parts Book: SSU UN Nssttaarr M Maac CH Hiin Neerryy C CO O..,, LLTTD D.Luis Caba RamirezNo ratings yet

- Instruction Manual: Models 4370 R1800 RecorderDocument129 pagesInstruction Manual: Models 4370 R1800 RecordermihaiisvoranuNo ratings yet

- TVF2100NH - 09 008 432 1R2 PDFDocument39 pagesTVF2100NH - 09 008 432 1R2 PDFEfra Lan PeñaNo ratings yet

- Toshiba 32SW9UADocument50 pagesToshiba 32SW9UAXavier AxiakNo ratings yet

- Trinity Amelung KC4 - Service ManualDocument34 pagesTrinity Amelung KC4 - Service ManualNasser Anappara100% (1)

- Prestige - Medical - 2100 - Service - Manual Steam SterilizerDocument13 pagesPrestige - Medical - 2100 - Service - Manual Steam SterilizerGigi CostelusNo ratings yet

- TCL 21e12 PDFDocument14 pagesTCL 21e12 PDFeduscribd18No ratings yet

- Olympus BH 2 BHSP Manual PDFDocument22 pagesOlympus BH 2 BHSP Manual PDFRyan ArinditaNo ratings yet

- Replacement of Voltage Transformer 4MT3 at The Feeder 8djh36Document6 pagesReplacement of Voltage Transformer 4MT3 at The Feeder 8djh36Rodolfo VázquezNo ratings yet

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorDocument21 pagesOperator'S Manual Manuel de L'Utilisateur Manual Del OperadordonmathesNo ratings yet

- Honeywell Is2500lt Install GuideDocument2 pagesHoneywell Is2500lt Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- DF52 Manual Servicio Tecnico BDocument58 pagesDF52 Manual Servicio Tecnico BMauricio RomeroNo ratings yet

- 3 Disassembly M5370 M4370 EngDocument61 pages3 Disassembly M5370 M4370 Engpatricio godoyNo ratings yet

- Alfra Manuals 3462Document28 pagesAlfra Manuals 3462januszekNo ratings yet

- G-5500 Im Eng E12901004Document12 pagesG-5500 Im Eng E12901004ampetreNo ratings yet

- 【B】30240301001118-使用说明书-组串三相-SUN- (30-60) K-G03-德业英文-封面彩印-封面封底157g-内页70g铜版纸-142.5×210mm-G03-大屏-并联接电表-Ver 2.3-液晶0196Document67 pages【B】30240301001118-使用说明书-组串三相-SUN- (30-60) K-G03-德业英文-封面彩印-封面封底157g-内页70g铜版纸-142.5×210mm-G03-大屏-并联接电表-Ver 2.3-液晶0196Alhadi Marza PutraNo ratings yet

- Aq Logic SeriesDocument56 pagesAq Logic SeriesYahya AouraghNo ratings yet

- Title: Model Ut601: Operating ManualDocument26 pagesTitle: Model Ut601: Operating ManualScott TylerNo ratings yet

- Solar Pumping Inverter: Operation ManualDocument25 pagesSolar Pumping Inverter: Operation ManualdiegoNo ratings yet

- INS - MAN - Ultrasonic Interferometer - M-84 - S-NewDocument9 pagesINS - MAN - Ultrasonic Interferometer - M-84 - S-NewMrs. K.V. VaralakshmiNo ratings yet

- Aiwa Tvc2121Document43 pagesAiwa Tvc2121Safran NuhNo ratings yet

- Alignment Light AdjustmentDocument11 pagesAlignment Light AdjustmentNooruddin DeroNo ratings yet

- NDE 152 Lab 3-Wet Fluorescent Yoke and StationaryDocument2 pagesNDE 152 Lab 3-Wet Fluorescent Yoke and StationarydonciriusNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- 95 I - Inrush Blocking RelayDocument2 pages95 I - Inrush Blocking RelaymscsaryaNo ratings yet

- The Check Procedure For Insulation Resistance For ST WindingsDocument1 pageThe Check Procedure For Insulation Resistance For ST WindingsmscsaryaNo ratings yet

- Radpol Heat Shrink Tubes 2024Document34 pagesRadpol Heat Shrink Tubes 2024mscsaryaNo ratings yet

- MSC Corcovado IIIDocument1 pageMSC Corcovado IIImscsaryaNo ratings yet

- Ame - 4B (400af)Document1 pageAme - 4B (400af)mscsaryaNo ratings yet

- Ame SeriesDocument40 pagesAme SeriesmscsaryaNo ratings yet

- Bow Thruster Hydarulic LineDocument1 pageBow Thruster Hydarulic LinemscsaryaNo ratings yet

- ACB Draw Out ProcedureDocument10 pagesACB Draw Out ProceduremscsaryaNo ratings yet

- Bow ThrusterDocument2 pagesBow ThrustermscsaryaNo ratings yet

- Kyurdamir Ab Airfield SurveyDocument51 pagesKyurdamir Ab Airfield SurveySteve RichardsNo ratings yet

- Recycling of Plastics A Greener ApproachDocument21 pagesRecycling of Plastics A Greener ApproachSayyed AbulaasNo ratings yet

- What Is A Fruit: Suggestion: Access 'Vegetables" Select 'Tomato' Click 'Go'Document5 pagesWhat Is A Fruit: Suggestion: Access 'Vegetables" Select 'Tomato' Click 'Go'Al-juffrey Luis AmilhamjaNo ratings yet

- Club Swan 50Document19 pagesClub Swan 50Slaven IvanovicNo ratings yet

- Characteristics of SovereigntyDocument9 pagesCharacteristics of SovereigntyVera Mae RigorNo ratings yet

- Assertion, Denial and Some Cancellation Rules in Modal Logic - T. Williamson (1988)Document20 pagesAssertion, Denial and Some Cancellation Rules in Modal Logic - T. Williamson (1988)Andrea SabatiniNo ratings yet

- Final: Patient Name: Neetu 0009XC011564 Ref. DoctorDocument1 pageFinal: Patient Name: Neetu 0009XC011564 Ref. Doctorpiyush882676No ratings yet

- AR222S Week 1-5 BDocument83 pagesAR222S Week 1-5 BJOHANAH MICAH MARCOSNo ratings yet

- The Effect of Self-Efficacy To Mathematical Anxiety On Junior High School Students of YDM Learning Guidance Course MakassarDocument6 pagesThe Effect of Self-Efficacy To Mathematical Anxiety On Junior High School Students of YDM Learning Guidance Course MakassarNaillah SabaNo ratings yet

- Takserempak1fase 44pDocument120 pagesTakserempak1fase 44pEvan KanigaraNo ratings yet

- C1 UseDocument4 pagesC1 UseMichał JanickiNo ratings yet

- Existential Nihilism PDFDocument2 pagesExistential Nihilism PDFRosa0% (1)

- PowerRelays Selection GuideDocument24 pagesPowerRelays Selection GuidearturobatallasNo ratings yet

- Accounting Information Systems Controls Processes 3rd Edition Turner Solutions ManualDocument36 pagesAccounting Information Systems Controls Processes 3rd Edition Turner Solutions Manualnineteenaffytdu5k100% (28)

- 2C X 95CU POWER - Revised Datasheet Solar CableDocument1 page2C X 95CU POWER - Revised Datasheet Solar CableAashish MoyalNo ratings yet

- The Relationship Between Self-Esteem and Academic AchievementDocument16 pagesThe Relationship Between Self-Esteem and Academic AchievementARMIA ZAHEER / UPMNo ratings yet

- QEP 3.5 50Hz 1p: EngineDocument2 pagesQEP 3.5 50Hz 1p: EngineKen VikstromNo ratings yet

- Basic Data Cleaning With Microsoft Excel v1.1Document16 pagesBasic Data Cleaning With Microsoft Excel v1.1FazisfvttzNo ratings yet

- Malaria Diagnosis Specimen Collection and Smear PreparationDocument30 pagesMalaria Diagnosis Specimen Collection and Smear PreparationMegbaruNo ratings yet

- Case Study - CHL Golf 2019Document5 pagesCase Study - CHL Golf 2019Ayush rawalNo ratings yet

- PrimeTime AdvancedOCV WPDocument9 pagesPrimeTime AdvancedOCV WPPraful GaikwadNo ratings yet

- MATH 1210 Assignment 1 Solutions 16R-T1: Solution: For Any Integer NDocument7 pagesMATH 1210 Assignment 1 Solutions 16R-T1: Solution: For Any Integer Nneric cesarNo ratings yet

- The Effects of Infant Massage On Maternal PostpartumDocument6 pagesThe Effects of Infant Massage On Maternal PostpartumopanocayNo ratings yet

- BfgsDocument10 pagesBfgshusseinNo ratings yet

- Solving Linear Equations - FormulasDocument7 pagesSolving Linear Equations - FormulasMalhea VegeniaNo ratings yet