Professional Documents

Culture Documents

Catalog - Castolin HVOF Powders

Catalog - Castolin HVOF Powders

Uploaded by

Ngo BinhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalog - Castolin HVOF Powders

Catalog - Castolin HVOF Powders

Uploaded by

Ngo BinhCopyright:

Available Formats

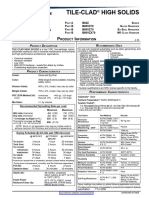

HVOF POWDERS

Powders for CJK5 HP - HVOF System &

other range of HVOF systems

• All HVOF coatings offer good resistance to abrasion / erosion

• Hard, dense coatings with excellent corrosion resistance

• May be used with some non-HVOF application systems

• Consistant particle size distribution

19300 HV

19300 HV A low carbon, austenitic stainless steel powder which produces coatings

which are resistant to high temperature oxidation (430°C / 800°F). Each lot of

TECHNICAL DATA:

powder is subjected to extensive quality checks to ensure a consistent particle Typical hardness: 90 HRB

size distribution. The coating takes on uniform cylindrical compressive loads with Nominal size distribution :

Excellent machinability & Controlled permeability.

US Mesh µm %w/w

.

+230 +63 1 max

- 625 - 20 3 max

TYPICAL APPLICATIONS: Chemistry : C < 0.1 , Ni 12.0 , Cr

16.0 , Mo 2.5 , Si 1.0 , Fe Bal.

An austenitic stainless steel alloy alloy designed for HVOF thermal spray systems

that provides good resistance to a variety of atmospheric conditions. Used on

pistons, valves, chemical processing parts, etc..

19400 HV

19400 HV is a high chromium, iron base powder with key features such as Good

wear properties, Good machinability, Controlled permeability. Each lot of powder

TECHNICAL DATA:

is subjected to extensive quality checks to ensure a consistent particle size Typical hardness: HRC 35

distribution. Nominal size distribution :

US Mesh µm %w/w

+230 +63 1 max

TYPICAL APPLICATIONS: - 625 - 20 3 max

A high chromium, martensitic alloy designed for HVOF process that provides a Chemistry : C 0.2 , Ni 2.0 , Cr 16.0

Fe Bal.

wear resistant coating. Used on pistons and pump parts, etc.. The alloy is not

recommended for applications requiring high impact properties.

55116 HVOF

55116 is a gas atomized Type 316L stainless steel powder designed specifically for

application via thermal spraying. Optimum coating results will be achieved using TECHNICAL DATA:

HVOF. 55 116 powder may also be applied using high energy, low velocity combustion

or plasma NTA systems. The powder is essentially spherical in shape. The HVOF Micro hardness: 375 DPH 300g

Hardness / R15N: 73 (HRC 27

coatings produced are suitable for a wide range of applications requiring resistance converted)

to corrosion, cavitation and erosion .

Nominal size distribution :

Service Temperature: 1000° F / 538° C (Max)

US Mesh µm %w/w

+230 +63 1 max

TYPICAL APPLICATIONS:

- 625 - 20 5 max

Pump impellers and plungers , Seal rings , Cylinder liners , Dimensional restoration , Chemistry : C< 0.1 , Ni 12.0 , Cr

Turbine buckets and nozzles 16.0 , Mo 2.5 , Si 1.0 , Fe Bal.

55125 HVOF

55125 HVOF is a gas atomized Ni Cr alloy powder designed specifically for applications

by Thermal spraying. Optimum coating results will be achieved using HVOF process.

Each lot of powder is subjected to extensive quality checks to insure a consistent

TECHNICAL DATA:

particle size distribution. The chemical composition is comparable to AWS A5.14 Hardness / R15N: 78 (HRC 35)

class ERNiCrMo-3. The HVOF coatings produced are suitable for a wide range of

applications requiring resistance to alkaline , acidic and aqueous salt environments. Method of manufacture:

Gas atomized

Coatings of 55125 are oxidation resistant up to a temperature of 1600°F (871°C). .

Nominal size distribution:

-53 + 20 microns

TYPICAL APPLICATIONS: Chemistry : Cr 21.5 , Mo 9.0 , C

Pollution control equipment , Pump shafts , Paper mill digesters , High temperature < 0.10 , Fe 3.0 , Nb + Ta 3.6% , Ni

balance

environments , Chemical process equipment , Dimensional restoration of Alloy 625

Turbine shafts

Stronger, with Castolin Eutectic www.castolin.com

55396 HVOF

55396 HVOF is a water atomized Ni Cr B Si alloy powder designed specifically for

applications by HVOF process . Each lot of powder is subjected to extensive quality

TECHNICAL DATA:

checks to insure a consistent particle size distribution. Coatings of 55396 may be used Hardness: R 51N: 87 - 88 (HRC

in as sprayed conditions or subsequently fused condition . The fusing will densify 54 - 56)

the coating and will provide a metallurgical bond with the base metal. The coatings Method of manufacture :

produced are hard , dense and will exhibit high bond strengths to a wide variety Water atomized

of base metals. 55396 offers an excellent resistance to abrasion and hard particle

Nominal size distribution:

erosion. -63 + 20 microns

TYPICAL APPLICATIONS: Chemistry : Cr 15.5 , Si 3.8 , B 3.2 ,

C 0.07 , Fe 3.5 , Ni balance

Pump shafts , Compressor rods , Wear rings , Cr Plating replacement applications ,

Seals , Brick dies

55575 N HVOF

55575N HVOF is an agglomerated and sintered Chromium carbide – Nickel chromium

alloy powder designed specifically for HVOF process. The powder is essentially

TECHNICAL DATA:

spherical in shape. The coatings produced are hard , dense and will exhibit high bond Hardness: R 51N: 87 - 88 (HRC

strength to a wide range of base metals. Exceptional resistance to fretting, abrasion, 53 - 57)

oxidation and high temperature corrosion are achieved. Method of manufacture:

Agglomerated & Sintered

Nominal size distribution:

-45 + 15 microns

TYPICAL APPLICATIONS: Chemistry : Chromium carbide

75% + Nickel Chromium 25%

Marine and truck diesel valve stems , Hydraulic cylinders , Chrome plating

Replacement applications , Compressor rods , Ball valves , Sucker rods

55583 N HVOF

55583N HVOF is an agglomerated and sintered Tungsten carbide – Cobalt powder TECHNICAL DATA:

designed specifically for HVOF process. The powder is essentially spherical in shape.

The coatings produced are hard, dense and will exhibit high bond strength to a Hardness: R 51N: 90 - 92 (HRC

59 - 65)

wide range of base metals. The powder is essentially spherical in shape. Exceptional

resistance to low stress abrasion , fretting wear and erosion are achieved Method of manufacture:

Agglomerated & Sintered

Nominal size distribution:

-45 + 15 microns

Chemistry : Tungsten carbide

TYPICAL APPLICATIONS: 83% , Cobalt 17%

Compressor shafts , Hydraulic cylinders , Oil field apparatus , Induced draft fan

blades , Pump seals , Compressor rods

55586 N HVOF

55586N HVOF is an agglomerated and sintered Tungsten carbide – Cobalt

powder designed specifically for HVOF process. The powder is essentially

spherical in shape. The coatings produced are hard, dense and will exhibit

TECHNICAL DATA:

high bond strength to a wide range of base metals. Exceptional resistance to Hardness: R 51N: 90 - 93 (HRC

low stress abrasion , fretting wear and corrosion / erosion can be achieved. 59 - 67)

The addition of Chromium matrix improves resistance to corrosion and Method of manufacture:

increases thermal stability as compared with WC-12Co or WC-17 Co powders. Agglomerated & Sintered

Nominal size distribution:

-45 + 15 microns

TYPICAL APPLICATIONS: Chemistry :Tungsten carbide

86%, Cobalt 10%, Chromium 4%

Compressor shafts , Impellers , Splined and bearing mandrels , Induced draft fan

blades , Oifield apparatus , Pump seals , Paper rolls

Stronger, with Castolin Eutectic www.castolin.com

55588 N HVOF

55588N HVOF is an agglomerated and sintered Tungsten carbide – Cobalt powder

designed specifically for HVOF process. The coatings produced are hard , dense

TECHNICAL DATA:

and will exhibit high bond strength to a wide range of base metals. The powder is Hardness: R 51N: 90 - 93 (HRC

essentially spherical in shape. Exceptional resistance to low stress abrasion, fretting 59 - 67)

wear and hard particle erosion can be achieved. Each lot of powder is subjected to Method of manufacture :

extensive quality checks to insure a consistent particle size distribution. Agglomerated & Sintered

Nominal size distribution:

-45 + 15 microns

TYPICAL APPLICATIONS:

Chemistry : Tungsten carbide

Knife blades , Capstans and pulleys , Oil field apparatus, Exhaust fan blades , Pump 88% , Cobalt 12%

seals , Extrusion dies.

55590 N HVOF

55590N HVOF is an agglomerated and sintered tungsten carbide – Nickel powder

designed specifically for HVOF process. The use of Nickel matrix improves corrosion

TECHNICAL DATA:

resistance as compared with WC 12 Co coatings. In addition, the absence of Cobalt Hardness: R 51N: 90 - 93 (HRC

renders coatings of 55590 suitable for suitable nuclear applications. The coatings 59 - 67)

produced are hard, dense and will exhibit high bond strength to a wide range of Method of manufacture:

base metals. Exceptional resistance to low stress abrasion, fretting wear and hard Agglomerated & Sintered

particle erosion can be achieved.

Nominal size distribution:

-45 + 15 microns

Chemistry : Tungsten carbide

TYPICAL APPLICATIONS: 90% , Nickel 10%

Knife blades , Turbine components , Oil field apparatus , Exhaust fan blades , Pump

seals , Extrusion dies

55606 HVOF

55606 HVOF is a self fluxing Nickel based highly alloyed powder. Coatings of 55606 can TECHNICAL DATA:

be used in as sprayed condition or subsequently be fused depending on application

needs. The fusion will densify the coating and will produce a metallurgically Hardness: R 51N: 85 - 88 (HRC

50 - 54)

bonded coating. The coatings produced are hard, dense and will exhibit high bond

strength to a wide range of base metals. Method of manufacture:

Water atomized

Nominal size distribution:

-53 + 15 microns

Chemistry : Cr 18.0 , Mo 13.0 , Si

TYPICAL APPLICATIONS: 4.5 , B 2.8 , Cu 2.5 , Ni bal

Waste incineration , Pulp and paper , Sleeves , Chemical industries , Boiler tubes ,

Mixer blades , Extruder screws , Shafts

OTHER HVOF POWDERS & BLENDS

PRODUCT DESCRIPTION PRODUCT DESCRIPTION

5252 HV Ni Si B (HRC 39) 55395 Ni Cr Si B (HRC 50)

5237 HV Ni Si B (HRC 25) 55396 WC WC - Co+ Ni Cr Si B

18997 HV Fe Ti Mo Ni W V 55580 Cr3C2 / 20 % Ni Cr

55122 Ni-21 Cr-13 Mo-3 W-4 Fe (C22) 55592 90% WC - 8 Co

55123 Fe - 32 Ni 55606 WC WC - Co - Cr + Ni Cr Si B Mo Cu

55317 Ni Cr Si B Mo Cu HRC 60) 55506 Cobalt 6 type

Eutectic Canada Inc. Castolin Eutectic Ireland Castolin Eutectic ( SEA ) Pte Ltd

920 Rue André-Liné Magna Business Park, 36 Magna Ave, Citywest, 50 Tuas Avenue 11 , # 01-04 Tuas Lot , Singapore 639107 .

Granby, Quebec J2J 1E2 Dublin 24, Ireland Email : salesadmin@eutectic.com.sg

Canada Tel : +65 6862 6008 Fax :+65 6862 6012

www.castolin.com

You might also like

- Thermal Spray Coatings-CRC Press (2021)Document367 pagesThermal Spray Coatings-CRC Press (2021)Ngo Binh100% (1)

- Mil STD 193LDocument47 pagesMil STD 193LSon NguyenNo ratings yet

- 3coated SteelDocument20 pages3coated Steelalifakash1605No ratings yet

- ASTM Grades PDFDocument0 pagesASTM Grades PDFRaj KamalNo ratings yet

- Caterpillar Hardware CatalogDocument6 pagesCaterpillar Hardware Catalogesther100% (53)

- Cement Mill - Ball Mill DynamicsDocument36 pagesCement Mill - Ball Mill DynamicsRohit Manglik100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Advances in Thermal Spray Technology - 2020 - 190Document190 pagesAdvances in Thermal Spray Technology - 2020 - 190Ngo BinhNo ratings yet

- Brochure-Metatech Thermal Spray PVT LTDDocument12 pagesBrochure-Metatech Thermal Spray PVT LTDbadesharamkNo ratings yet

- Astm A234 A234m - 20252Document9 pagesAstm A234 A234m - 20252OscarBoneNo ratings yet

- Carter Ogl 1000 M PDFDocument1 pageCarter Ogl 1000 M PDFAnibal RiosNo ratings yet

- Thermal Spray Manual - A Practical Reference Guide-American Welding Society (AWS) (1996)Document183 pagesThermal Spray Manual - A Practical Reference Guide-American Welding Society (AWS) (1996)Ngo BinhNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Tech Uddeholm Ramax HH ENDocument8 pagesTech Uddeholm Ramax HH ENwrh9rqr22vNo ratings yet

- Ramax Hh-Eng P 1604 E6Document8 pagesRamax Hh-Eng P 1604 E6venkithankamNo ratings yet

- Fosroc Nukote BLDocument4 pagesFosroc Nukote BLm.elsanee.cubicNo ratings yet

- Tech Uddeholm Vanax en PDFDocument8 pagesTech Uddeholm Vanax en PDFRuang Sudut OfficialNo ratings yet

- Armorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsDocument4 pagesArmorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsOswaldo SantoyoNo ratings yet

- Data 9018 B3 LDocument2 pagesData 9018 B3 LAntonio Torres (Volcomtony)No ratings yet

- Product Description Sheet Silver Grade Anti-Seize Lubricant: Maintenance, Repair & Operations, December 1998Document2 pagesProduct Description Sheet Silver Grade Anti-Seize Lubricant: Maintenance, Repair & Operations, December 1998Toddy SamuelNo ratings yet

- High Performance Lubricants: Molykote HP-870 GreaseDocument2 pagesHigh Performance Lubricants: Molykote HP-870 GreaseBruno FranNo ratings yet

- Humiseal 1B31 English TdsDocument2 pagesHumiseal 1B31 English TdsLee HitchensNo ratings yet

- EuTronic Arc Spray 595ASDocument2 pagesEuTronic Arc Spray 595ASEdwinNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Cepsa Fundicol Hfu: Lubricants For Industrial UseDocument1 pageCepsa Fundicol Hfu: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- Humiseal 1R32 Conformal Coating English TdsDocument2 pagesHumiseal 1R32 Conformal Coating English TdsLee HitchensNo ratings yet

- Thermal Spray WiresDocument4 pagesThermal Spray WiresSHUBH Engeeniaring worksNo ratings yet

- 3M Scotchkote Epoxy Primer GP 120+Document2 pages3M Scotchkote Epoxy Primer GP 120+satya ranjanNo ratings yet

- Firetex FX5120 PDFDocument2 pagesFiretex FX5120 PDFArturo QuispeNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Tranself Type B 80w 90Document1 pageTranself Type B 80w 90ironiteNo ratings yet

- Aluminium Alloy 5083H116 Data SheetDocument1 pageAluminium Alloy 5083H116 Data SheetTarek MassimoNo ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- S3 V460DM 2 - TDSDocument2 pagesS3 V460DM 2 - TDSWawanDarmawanNo ratings yet

- Chronifer M-4108Document3 pagesChronifer M-4108IltefatNo ratings yet

- Interface Value GradesDocument16 pagesInterface Value Gradesvagner boldiNo ratings yet

- Kermetico HVAF Protective Coatings For Internal Diameters of Pipe Lines, Vessels and Industrial EquipmentDocument9 pagesKermetico HVAF Protective Coatings For Internal Diameters of Pipe Lines, Vessels and Industrial EquipmentycwbycwbNo ratings yet

- S.I.G Texter Catalogue PDFDocument12 pagesS.I.G Texter Catalogue PDFekrem0867100% (1)

- Hoja Tecnica - OmnilithDocument1 pageHoja Tecnica - OmnilithJhosbrield Pacheco ZegarraNo ratings yet

- Aeroshell Fluid 41Document2 pagesAeroshell Fluid 41S. MadaniNo ratings yet

- Enduro Maintenance Free ChainsDocument8 pagesEnduro Maintenance Free ChainstranhoanpdlNo ratings yet

- Technical Data Sheet: Heavy Duty GreaseDocument1 pageTechnical Data Sheet: Heavy Duty GreaseDon HowardNo ratings yet

- Ultrapaste Cu 12 SF - 2017 (E)Document1 pageUltrapaste Cu 12 SF - 2017 (E)HANIF AKBARNo ratings yet

- Nitoproof 600: Constructive SolutionsDocument22 pagesNitoproof 600: Constructive SolutionsMazen AlRefaaiNo ratings yet

- BECHEM High Lub LFB 2000 TDS enDocument1 pageBECHEM High Lub LFB 2000 TDS enluisvictorbariteNo ratings yet

- Flowfresh RT TDSDocument2 pagesFlowfresh RT TDSiqmalexcruzNo ratings yet

- Highland 74 HF Series Chem Temp Epoxy LinerDocument3 pagesHighland 74 HF Series Chem Temp Epoxy LinerJulian MorantesNo ratings yet

- SCC - Wax Wrap - OuterwrapsDocument4 pagesSCC - Wax Wrap - OuterwrapsEyoh EffiongNo ratings yet

- Industrial Enamel HS: Protective & Marine CoatingsDocument4 pagesIndustrial Enamel HS: Protective & Marine CoatingsAna CabreraNo ratings yet

- High Build Epoxy Coating For Pipelines: Product Data SheetDocument2 pagesHigh Build Epoxy Coating For Pipelines: Product Data Sheetdemi bajakanNo ratings yet

- Flowcrete Asia Flowshield CR May2020 TdsDocument2 pagesFlowcrete Asia Flowshield CR May2020 TdsQuoc AnNo ratings yet

- AW - Datasheet - ALLOY 20 CB 3Document2 pagesAW - Datasheet - ALLOY 20 CB 3.xNo ratings yet

- Whitmore Crush-Bac - PDS - EnglishDocument2 pagesWhitmore Crush-Bac - PDS - EnglishDon HowardNo ratings yet

- Eutectic 29029Document2 pagesEutectic 29029Imam SitumeangNo ratings yet

- MOLYKOTE HSC Plus Paste 71-0212H-01Document2 pagesMOLYKOTE HSC Plus Paste 71-0212H-01Vendy KurniawanNo ratings yet

- 503hoja-tecnica-MOLYKOTE® 44 MediumDocument2 pages503hoja-tecnica-MOLYKOTE® 44 MediumeariesilvapcNo ratings yet

- Adeco Lithium Grease 2: Technical Data SheetDocument1 pageAdeco Lithium Grease 2: Technical Data SheetVelibor KaranovicNo ratings yet

- Refra EnergíaDocument6 pagesRefra EnergíaRicardor123No ratings yet

- Berulit GA 800 FluidDocument1 pageBerulit GA 800 FluidJohan TeoNo ratings yet

- Belex Wireline LubricantDocument2 pagesBelex Wireline LubricantdhowardjNo ratings yet

- Ravenol Awd-H Fluid: Click Here For The Oil Test AnalysisDocument2 pagesRavenol Awd-H Fluid: Click Here For The Oil Test AnalysisTudor RatiuNo ratings yet

- P000258 Motorbike 4T 10W 40 Scooter 42 en GBDocument1 pageP000258 Motorbike 4T 10W 40 Scooter 42 en GBimranrezaNo ratings yet

- EfekDocument2 pagesEfekGasa RafliNo ratings yet

- Repsol MXR Platinum 10W50Document1 pageRepsol MXR Platinum 10W50KuncoroNo ratings yet

- EagleBurgmann Statotherm SSTC-TAL 9592 P enDocument1 pageEagleBurgmann Statotherm SSTC-TAL 9592 P enkeyur1109No ratings yet

- Ficha Tecnica Lubricante F-611 XL-6000 Aw 68Document2 pagesFicha Tecnica Lubricante F-611 XL-6000 Aw 68Velandia Blanco Wilmer JuliánNo ratings yet

- GPCDOC X Cbe 24855 Key 140008284476 201504141143 PDFDocument2 pagesGPCDOC X Cbe 24855 Key 140008284476 201504141143 PDFCesar Estrada Estrada MataNo ratings yet

- TD - Rhenus LKZ 2Document1 pageTD - Rhenus LKZ 2Teknik LasallefoodNo ratings yet

- AbraSphere PulvDocument2 pagesAbraSphere PulverikaNo ratings yet

- Cataloge - DJ THERMAL SPRAY SPARE PARTS PRODUCTDocument14 pagesCataloge - DJ THERMAL SPRAY SPARE PARTS PRODUCTNgo BinhNo ratings yet

- Book - Study of Sliding Wear Behavior of Plasma Sprayed Red Mud Composite Coatings On Mild SteelDocument89 pagesBook - Study of Sliding Wear Behavior of Plasma Sprayed Red Mud Composite Coatings On Mild SteelNgo BinhNo ratings yet

- Cataloge - Diamond-Jet™-Spray-Gun-Parts-List-ENDocument26 pagesCataloge - Diamond-Jet™-Spray-Gun-Parts-List-ENNgo BinhNo ratings yet

- Book - Plasma Spray TorchesDocument54 pagesBook - Plasma Spray TorchesNgo BinhNo ratings yet

- ẤN Độ - High-Performance Al2O3 Coating by Hybrid-LVOF (Low-Velocity Oxyfuel) Process 2020Document10 pagesẤN Độ - High-Performance Al2O3 Coating by Hybrid-LVOF (Low-Velocity Oxyfuel) Process 2020Ngo BinhNo ratings yet

- Properties of Aluminum Deposited by A HVOF Process 2003Document6 pagesProperties of Aluminum Deposited by A HVOF Process 2003Ngo BinhNo ratings yet

- A Test For Coating Adhesion On Flat Substrates 1994Document7 pagesA Test For Coating Adhesion On Flat Substrates 1994Ngo BinhNo ratings yet

- A Review of Testing Methods For Thermal Spray Coatings 2014Document45 pagesA Review of Testing Methods For Thermal Spray Coatings 2014Ngo BinhNo ratings yet

- An Improved Specimen Geometry For ASTM C633-79 To Estimate Bond Strengths of Thermal Spray Coatings 1993Document6 pagesAn Improved Specimen Geometry For ASTM C633-79 To Estimate Bond Strengths of Thermal Spray Coatings 1993Ngo BinhNo ratings yet

- Salt Analysis ProcedureDocument6 pagesSalt Analysis ProcedureMoscowNo ratings yet

- Unibraze ER316L PDFDocument1 pageUnibraze ER316L PDFsmpoe017No ratings yet

- 42crmo4: Steel GradeDocument3 pages42crmo4: Steel GradeMada TetoNo ratings yet

- Material Specification: Specification: B-1 Revision Date: 09/06/2016 Revision Level: AEDocument13 pagesMaterial Specification: Specification: B-1 Revision Date: 09/06/2016 Revision Level: AEReginaldo SantosNo ratings yet

- NADCA Defects Troubleshooting GuideDocument69 pagesNADCA Defects Troubleshooting GuideashwindranNo ratings yet

- Machining ProcessDocument23 pagesMachining ProcessAshish KatariaNo ratings yet

- Solon Belleville Springs CatalogDocument72 pagesSolon Belleville Springs CatalogKamasani PraveenaNo ratings yet

- Introduction of Machine Shop Operation and Layout Tools: Prepared by Group 1Document14 pagesIntroduction of Machine Shop Operation and Layout Tools: Prepared by Group 1Allan Gabriel LariosaNo ratings yet

- SCI Ductile Iron Flanged FittingDocument12 pagesSCI Ductile Iron Flanged FittingSajad PkNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- Data Pengambilan Material Workshop 2021Document77 pagesData Pengambilan Material Workshop 2021Amelia RanjaniNo ratings yet

- Valery Marinov Manufacturing Technology PDFDocument168 pagesValery Marinov Manufacturing Technology PDFMostafa Adil50% (2)

- BPSC ME Practice-Questions - SET 1Document29 pagesBPSC ME Practice-Questions - SET 1gaurav singhNo ratings yet

- Nanyang Technological University: Manufacturing Lab ReportDocument5 pagesNanyang Technological University: Manufacturing Lab ReportPrayogo TioNo ratings yet

- Fasilitas & Produk PTKSDocument48 pagesFasilitas & Produk PTKSArief WisnuNo ratings yet

- App10 Fundamentals of ConnectionsDocument23 pagesApp10 Fundamentals of ConnectionsjdmacbookNo ratings yet

- BS 499-1 Welding Terms and Symbols 2009Document68 pagesBS 499-1 Welding Terms and Symbols 2009Geraldo MaraisNo ratings yet

- September 2014Document188 pagesSeptember 2014Imran MohammadNo ratings yet

- Ipsen Vacuum TechnologyDocument6 pagesIpsen Vacuum TechnologyJacques GillesNo ratings yet

- FINAL Clear and Present Danger 2 (QT or TMT Rebars in Seismic Zone 4 3333333333Document48 pagesFINAL Clear and Present Danger 2 (QT or TMT Rebars in Seismic Zone 4 3333333333emmoralesNo ratings yet

- Rusting of Metal - Home ExperimentDocument5 pagesRusting of Metal - Home ExperimentJustine Ryan L. MalgapoNo ratings yet

- SS MaterialsDocument9 pagesSS MaterialsStephen RajNo ratings yet

- Handy Flo 6Document2 pagesHandy Flo 6Tecnoserv Ingenieros S.A:No ratings yet