Professional Documents

Culture Documents

Product Description Sheet Silver Grade Anti-Seize Lubricant: Maintenance, Repair & Operations, December 1998

Uploaded by

Toddy SamuelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Description Sheet Silver Grade Anti-Seize Lubricant: Maintenance, Repair & Operations, December 1998

Uploaded by

Toddy SamuelCopyright:

Available Formats

Product Description Sheet

1001 Trout Brook Crossing

Rocky Hill, CT 06067-3910

Telephone: (860) 571-5100

Silver Grade Anti-Seize Lubricant

FAX: (860) 571-5465

Maintenance, Repair & Operations, December 1998

PRODUCT DESCRIPTION Torque vs. Elevated Temperatures

LOCTITE® Silver Grade Anti-Seize Lubricant is a heavy-duty, The following chart shows break and prevail torque values for

high-temperature anti-seize thread compound applicable for plain steel 3/8-16 fasteners degreased, coated, pre-torqued to

heavy pressure applications. It can be used in high 30 ft-lbs, heat soaked at an elevated temperature for 24 hours,

temperature areas up to 870°C (1600°F). cooled to room temperature and disassembled. (No signs of

galling or seizing were visible.)

TYPICAL APPLICATIONS

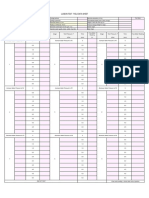

Silver Grade Anti-Seize Lubricant is used to lubricate and to Temperature Torque (in-Lbs)

permit easy disassembly of assemblies exposed to high Break Prevail

temperatures and heavy contact pressures, such as boiler and -54°C (-65°F) 270 6

oven parts, jet engines, and industrial turbines. 22°C (72°F) 264 6

537°C (1000°F) 96 7

DIRECTIONS FOR USE 760°C (1400°F) 262 160

1. For best results, ensure part surfaces are clean and free of 870°C (1600°F) 132 89

debris.

Corrosion Resistance

2. Apply a light coating of product to parts requiring

Degreased steel specimens (3/8-16 Grade 5 bolts) were treated

lubrication.

with an even coating of Anti-seize and assembled into test

3. Assemble parts. blocks of aluminum and carbon steel drilled and tapped with

4. When part is assembled, wipe away any excess compound. 3/8-16 holes. A small amount of Anti-seize was applied under

the bolt heads where high bearing stresses are present. The

PROPERTIES OF MATERIAL assemblies were placed in a 95°F condensing humidity salt fog

Typical Value chamber for 180 hours. After conditioning, the bolts were

Chemical Type Synthetic grease removed and inspected visually for corrosion both in the threads

Appearance Aluminum (silver) paste and under the bolt heads. There were no visible signs of

Odor Petroleum corrosion on any of the treated specimens.

Specific Gravity 1.17 (base)

Viscosity Flow similar to Peanut Butter

Flash Point (TCC), ºF >200

The product was tested for corrosive effects on plain copper

Particle Size(µm) 22.5 strips. There was no sign of corrosion, discoloration, pitting or

etching upon completion of the test.

TYPICAL PERFORMANCE PROPERTIES

Static Coefficient of Friction Physical Properties (Base)

The following chart shows the static coefficient of friction Typical

Value Range

between controlled mating surfaces subjected to a compressive Unworked Penetration (ASTM D-217) 312 325 to 299

stress that approximates the bearing stress acting on fastener Worked Penetration (ASTM D-217) 324 310 to 338

threads under load (60% of proof for a 3/8-16 Grade 5 steel). Dropping Point (ASTM D-217) °C 232

NLGI Grade 1

Temperature Coefficient of Friction

-65°F (-54°C) 0.043 Wear Resistance

68°F (20°C) 0.077 Extreme pressure testing with a Timken Lubricant Tester (ASTM

1400°F (870°C) 0.164 D2509) indicated Silver grade Anti-Seize Lubricant would resist

seizure, scoring and wear under adverse pressure conditions.

Torque Tension The test on Anti-seize consisted of a rotating spindle loaded and

Tested on degreased 3/8x16 nuts & bolts in a Skidmore- held constant for a ten-minute interval. If no scoring of the test

Wilhelm apparatus. Data reported are the k-factors calculated block was noted, the load was increased and the test run.

from torque @ 5000 lbs tension. The following chart shows the load at which failure occurred.

The load at which failure occurs is then reported to be the fail

Lubricity “k” Factor 0.18 load. The last acceptable load is considered to the OK load, or

non weld load

CAUTION Load Type Pressured Applied

Silver Grade Anti-Seize Lubricant is not a high-speed load OK load, lbs 47

carrying lubricant and should not be used on ball or roller Fail Load, lbs 52

bearings, or on parts where lubrication is critical. Scar width at failure, mm 0.83

2

Stress value at failure, N/mm (psi) 65 (9458)

NOT FOR PRODUCT SPECIFICATIONS

THE TECHNICAL DATA CONTAINED HEREIN ARE INTENDED AS REFERENCE ONLY.

PLEASE CONTACT LOCTITE CORPORATION QUALITY DEPARTMENT FOR ASSISTANCE AND RECOMMENDATIONS ON SPECIFICATIONS FOR THIS PRODUCT.

ROCKY HILL, CT FAX: +1 (860)-571-5473 DUBLIN, IRELAND FAX: +353-(1)-451 - 9959

PDS Silver Grade Anti-Seize Lubricant, December 1998

Torque, Galling and Seizing

Five (5) bolts, 3/4”-10 were pre-torqued to approximately 230 ft

lbs. (based on elongation) then conditioned for three six hour

cycles @ 1050°F with retorquing after each cycle. After heating,

the entire block assembly was exposed to a 20% salt solution

for seven days. Break torque didn’t exceed 250 ft lbs. There

was no seizing of any nuts during the test. There was no galling

evident on the threads of the nuts or studs.

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Ordering Information

Part Number Container Size

80209 4 oz. Net Wt. Brush Can

76732 8 oz. Net Wt. Brush Top

76759 12 oz. Net Wt. Aerosol

76764 1 lb. Net Wt. Brush-Top

80206 1 gal. Can

76775 5 gal. Pail

Storage

Product shall be ideally stored in a cool, dry location in

unopened containers at a temperature between 8°C to 28°C

(46°F to 82°F) unless otherwise labeled. Optimal storage is at

the lower half of this temperature range. To prevent

contamination of unused product, do not return any material to

its original container. For further specific shelf life information,

contact your local Technical Service Center.

Data Ranges

The data contained herein may be reported as a typical value

and/or range. Values are based on actual test data and are

verified on a periodic basis.

Note

The data contained herein are furnished for information only and are

believed to be reliable. We cannot assume responsibility for the results

obtained by others over whose methods we have no control. It is the

user's responsibility to determine suitability for the user's purpose of any

production methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons against

any hazards that may be involved in the handling and use thereof. In

light of the foregoing, Loctite Corporation specifically disclaims all

warranties expressed or implied, including warranties of

merchantability or fitness for a particular purpose, arising from

sale or use of Loctite Corporation’s products. Loctite Corporation

specifically disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion herein of

various processes or compositions is not to be interpreted as

representation that they are free from domination of patents owned by

others or as a license under any Loctite Corporation patents that may

cover such processes or compositions. We recommend that each

prospective user test his proposed application before repetitive use,

using this data as a guide. This product may be covered by one or more

United States or foreign patents or patent applications.

Loctite is a Trademark of Loctite Corporation U.S.A.

You might also like

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Iso 3507 en PDFDocument8 pagesIso 3507 en PDFSebastian AyalaNo ratings yet

- Mukavemet 9Document18 pagesMukavemet 9Uğur DorukNo ratings yet

- Datasheet CG60Document3 pagesDatasheet CG60ouss oussNo ratings yet

- High Performance Lubricants: Molykote HP-870 GreaseDocument2 pagesHigh Performance Lubricants: Molykote HP-870 GreaseBruno FranNo ratings yet

- MOLYKOTE BR2 Plus Grease 80-3104A-01Document2 pagesMOLYKOTE BR2 Plus Grease 80-3104A-01Sophia RoseNo ratings yet

- Product Description SheetDocument2 pagesProduct Description SheetFabio ParceroNo ratings yet

- BP Energrease Ls and Ls-Ep: DescriptionDocument2 pagesBP Energrease Ls and Ls-Ep: DescriptionbenjaminNo ratings yet

- Series 2000 Synthetic Racing Grease Data BulletinDocument2 pagesSeries 2000 Synthetic Racing Grease Data Bulletinbrian5786No ratings yet

- 4622 Monolec® Multiplex Lubricant - TDSDocument4 pages4622 Monolec® Multiplex Lubricant - TDSEngineering MP CikupaNo ratings yet

- MOLYKOTE - HP-300 - Grease - 80-3103E-01Document2 pagesMOLYKOTE - HP-300 - Grease - 80-3103E-01jtelloNo ratings yet

- Carpenter 158Document7 pagesCarpenter 158RedNo ratings yet

- TDS MOLYKOTE DX Paste EngDocument2 pagesTDS MOLYKOTE DX Paste EngWanderson FIALHONo ratings yet

- Hoja Tecnica - OmnilithDocument1 pageHoja Tecnica - OmnilithJhosbrield Pacheco ZegarraNo ratings yet

- MOLYKOTE 165 LT Gearwheel Grease 71-0179D-01Document2 pagesMOLYKOTE 165 LT Gearwheel Grease 71-0179D-01bravindranath5768No ratings yet

- Castrol Molub-Alloy 243 ArcticDocument2 pagesCastrol Molub-Alloy 243 ArcticMaciejNo ratings yet

- Bel Ray GEO Ashless PDSDocument1 pageBel Ray GEO Ashless PDSDaniel ColinsNo ratings yet

- Technical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDocument1 pageTechnical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDon HowardNo ratings yet

- Ultrapaste Cu 12 SF - 2017 (E)Document1 pageUltrapaste Cu 12 SF - 2017 (E)HANIF AKBARNo ratings yet

- TC30 IntlDocument1 pageTC30 IntlWilliam ContrerasNo ratings yet

- TDS Nycogrease GN3058 1E10Document1 pageTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- Ceran-Xm-220 TDS v171128Document2 pagesCeran-Xm-220 TDS v171128phucdc095041No ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Dowcorning BR-2-Plus TdsDocument2 pagesDowcorning BR-2-Plus TdsDicky PratamaNo ratings yet

- Carter Ogl 1000 M PDFDocument1 pageCarter Ogl 1000 M PDFAnibal RiosNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Mobilgrease 28Document2 pagesMobilgrease 28Jeef100% (1)

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamNo ratings yet

- Unirex N Series PDFDocument3 pagesUnirex N Series PDFAbdulSattarNo ratings yet

- Caliber 460 M TDS 2081Document1 pageCaliber 460 M TDS 2081Jose Luis Ramirez RamirezNo ratings yet

- Molykote® Longterm 2 Plus Datasheet EngDocument2 pagesMolykote® Longterm 2 Plus Datasheet EngAlaa HassanNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- ANTI-SEIZE Stainless - GBDocument3 pagesANTI-SEIZE Stainless - GBHasan RazaNo ratings yet

- 4622 Product InfoDocument4 pages4622 Product InfoVendy KurniawanNo ratings yet

- Moylkote DX Paste Technical Data SheetDocument2 pagesMoylkote DX Paste Technical Data SheetMihai AlexNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Varnishes For Electric EquipmentsDocument2 pagesVarnishes For Electric EquipmentsAnonymous KeBaAOY3T100% (1)

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- 1.envirolube TDS EnglishDocument1 page1.envirolube TDS EnglishThắng Phạm NguyênNo ratings yet

- Molykote G 1001 PdsDocument2 pagesMolykote G 1001 PdsDicky PratamaNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Adeco Lithium Grease 2: Technical Data SheetDocument1 pageAdeco Lithium Grease 2: Technical Data SheetVelibor KaranovicNo ratings yet

- GPCDOC Local TDS Pakistan Shell Turbo Oil T 46 (ur-PK) TDS PDFDocument2 pagesGPCDOC Local TDS Pakistan Shell Turbo Oil T 46 (ur-PK) TDS PDFSefa yıldızNo ratings yet

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsMOHAMED GamalNo ratings yet

- Chersterton Arc 982 PDFDocument2 pagesChersterton Arc 982 PDFMohamed Nouzer100% (1)

- Mak Lanthax Ep GreaseDocument2 pagesMak Lanthax Ep GreaseTaqudas AhmedNo ratings yet

- High Voltage Grease: Approvals Rohs Compliant (2015/863/eu) : YesDocument2 pagesHigh Voltage Grease: Approvals Rohs Compliant (2015/863/eu) : YestlnferreiraNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- Grasa AeroShell 5Document2 pagesGrasa AeroShell 5epesanoNo ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Turmosynthgrease Al 4602 Ti enDocument1 pageTurmosynthgrease Al 4602 Ti enOmin PostingNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- 300.024 Lustran Elite 1891Document2 pages300.024 Lustran Elite 1891Enrique ChavezNo ratings yet

- Mobilith AW SeriesDocument3 pagesMobilith AW SeriesDavid SalgueroNo ratings yet

- Molykote 1000 Paste PDFDocument2 pagesMolykote 1000 Paste PDFGyanaranjan NayakNo ratings yet

- Molykote 41 Grease 80-3096a-01Document2 pagesMolykote 41 Grease 80-3096a-01Dicky PratamaNo ratings yet

- Schaeffer # 229Document3 pagesSchaeffer # 229Ingeniero aicNo ratings yet

- Ina Lis 1 2 and 3 111344Document1 pageIna Lis 1 2 and 3 111344Pero Plemeniti SimicNo ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- MSDS - Loctite Silver Grade Anti-SiezeDocument8 pagesMSDS - Loctite Silver Grade Anti-SiezeToddy SamuelNo ratings yet

- MSDS - Loctite 577Document5 pagesMSDS - Loctite 577Toddy SamuelNo ratings yet

- Product 577: Technical Data SheetDocument2 pagesProduct 577: Technical Data SheetToddy SamuelNo ratings yet

- Form Lugeon Test Field Data - 9 Step by Toddy SamuelDocument1 pageForm Lugeon Test Field Data - 9 Step by Toddy SamuelToddy SamuelNo ratings yet

- AGC 2019 - Hydrogeology of The ELang Copper Project, Sumbawa Island, IndonesiaDocument17 pagesAGC 2019 - Hydrogeology of The ELang Copper Project, Sumbawa Island, IndonesiaToddy SamuelNo ratings yet

- Stress ManagementDocument21 pagesStress ManagementToddy SamuelNo ratings yet

- Constant Rate Pressure Injection TestDocument1 pageConstant Rate Pressure Injection TestToddy SamuelNo ratings yet

- Abstract For The Australasian Groundwater Conference 2019Document1 pageAbstract For The Australasian Groundwater Conference 2019Toddy SamuelNo ratings yet

- Syllabus - Introduction To Propulsion SystemsDocument5 pagesSyllabus - Introduction To Propulsion SystemsCoursePin100% (1)

- The Photoelectric Effect: Summary From Last TimeDocument6 pagesThe Photoelectric Effect: Summary From Last TimeNitin SharmaNo ratings yet

- NumaView™ Remote Software User GuideDocument2 pagesNumaView™ Remote Software User GuideSergio Toral RebolledoNo ratings yet

- II PUC - Mathematics (TARGET CENTUM) - Question BankDocument68 pagesII PUC - Mathematics (TARGET CENTUM) - Question BankKumkum Kumbarahalli100% (1)

- Supports For Uninsulated PipesDocument12 pagesSupports For Uninsulated Pipesdepinfor lusofabrilNo ratings yet

- Tabakovic 2018Document36 pagesTabakovic 2018hayet debbichNo ratings yet

- LECTURE 14 (Ch. 5) DC-DC Converters: ECE 452 Power ElectronicsDocument24 pagesLECTURE 14 (Ch. 5) DC-DC Converters: ECE 452 Power ElectronicsHarsha AnantwarNo ratings yet

- Blueprint ProjectDocument2 pagesBlueprint ProjectAlina KuryloNo ratings yet

- Aeronautical Karpagam University 1Document20 pagesAeronautical Karpagam University 1karthi_mbeNo ratings yet

- Zero Dynamics SurveyDocument10 pagesZero Dynamics SurveyDaniel AmbrizNo ratings yet

- 08 - Hoist Gear ManualDocument21 pages08 - Hoist Gear ManualIng FermínNo ratings yet

- 15321581482018-19 M.sc. Organic Chemistry Part-IIDocument17 pages15321581482018-19 M.sc. Organic Chemistry Part-IIArnab ChakrabortyNo ratings yet

- ACI 318M-11 Terminators - PDF 2Document3 pagesACI 318M-11 Terminators - PDF 2amr ashrafNo ratings yet

- Autoclave Full CatalogDocument481 pagesAutoclave Full CatalogGabriel Jamariqueli BueresNo ratings yet

- Arndt Schultz Law and HomoeopathyDocument7 pagesArndt Schultz Law and HomoeopathyDr. Rajneesh Kumar Sharma MD Hom100% (4)

- Diary Curriculum Map: Subject: Mathematics Grade Level: Grade 10 Unit/Strands: 2Nd Quarter Teachers: Ms. Shirlyn F. TanDocument3 pagesDiary Curriculum Map: Subject: Mathematics Grade Level: Grade 10 Unit/Strands: 2Nd Quarter Teachers: Ms. Shirlyn F. TanMary Grace FresnediNo ratings yet

- Union Metal SemiconductorDocument4 pagesUnion Metal SemiconductorskinhugoNo ratings yet

- HYDRAULICS LECTURE Fundamentals of Fluid FlowDocument30 pagesHYDRAULICS LECTURE Fundamentals of Fluid FlowJeloy PiloNo ratings yet

- Dust CollectorDocument24 pagesDust Collectorafroz ahmedNo ratings yet

- Biphasic Calcium PhosphateDocument9 pagesBiphasic Calcium PhosphateZephir Hundemberg100% (1)

- 0 4588 1 Vol1Document366 pages0 4588 1 Vol1atulNo ratings yet

- Vibrating Screen Deck - Required Screening Area FormulaDocument2 pagesVibrating Screen Deck - Required Screening Area FormulajnmanivannanNo ratings yet

- Momentum 23 24Document12 pagesMomentum 23 24Kavishka TrimanneNo ratings yet

- Calipsol H 443-HD 88Document2 pagesCalipsol H 443-HD 88Oscar CabreraNo ratings yet

- Flowchart of Softening Point of AsphaltDocument2 pagesFlowchart of Softening Point of AsphaltteguhNo ratings yet

- APP Note UV0042 Haze ValueDocument3 pagesAPP Note UV0042 Haze ValuePaoloMMNo ratings yet

- Buckling TestDocument10 pagesBuckling TestSanket AntreNo ratings yet

- Calculation of Safe Bearing Capacity of Soil: - Based On IS: 6403Document31 pagesCalculation of Safe Bearing Capacity of Soil: - Based On IS: 6403sourabh_gupta_54100% (1)