Professional Documents

Culture Documents

HC - HAM - Product Information

HC - HAM - Product Information

Uploaded by

fvtolosa2022a11Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HC - HAM - Product Information

HC - HAM - Product Information

Uploaded by

fvtolosa2022a11Copyright:

Available Formats

www.hcarbon.

com

PRODUCT INFORMATION

Woven Fabrics / Paper / CSM / Roving Cloth / AAF / Resin System

HANKUK CARBON CO., LTD.

WOVEN FABRICS

Hankuk Carbon / Hankuk Advanced Materials produces carbon fiber fabric for various weaving types and width having characteristics of high

strength and heat resistance. Carbon spread fabric can be weaved wider than 10mm which is excess width limits of carbon yarn and it is

possible to manufacture specific design of carbon hologram shape type. We are able to produce hybrid fabric in various types of designs for

decorations use which mixed by three fabrics carbon fabric, aramid fabric and glass fiber fabric.

CARBON

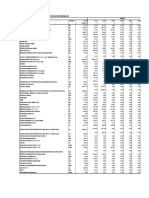

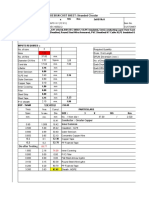

Yarn Description FAW Count(count/in)

STYLE Thickness Weave

Warp Weft (g/m²) Warp Weft (mm)

CF1114 CARBON 1K CARBON 1K 95 ± 6 17.5 17.5 0.14 ± 0.025 PLAIN

CF1115 CARBON 1K CARBON 1K 122 ± 7 22.5 22.5 0.15 ± 0.025 PLAIN

CF1115-1 CARBON 1K CARBON 1K 122 ± 7 22.5 22.5 0.15 ± 0.025 TWILL

CF1240-1 CARBON 12K CARBON 12K 409 ± 25 6.4 6.4 2:2 TWILL

CF1260 CARBON 12K CARBON 12K 607 ± 36 9.5 9.5 0.60 ± 0.075 PLAIN

CF1260-1 CARBON 12K CARBON 12K 607 ± 36 9.5 9.5 0.60 ± 0.075 2:2 TWILL

CF1277 CARBON 1K CARBON 1K 283 ± 17 54 50 0.77 ± 0.075 8H

CF1277 CARBON 1K CARBON 1K 274 ± 16 50 54 0.30 ± 0.050 PLAIN

CF3322 CARBON 3K CARBON 3K 160 ± 7 10 10 0.22 ± 0.025 PLAIN

CF 3324-1 CARBON 3K CARBON 3K 240 ± 14 15 15 0.23 ± 0.025 2:2 TWILL

CF3325 CARBON 3K CARBON 3K 232 ± 14 15 14 0.25 ± 0.025 PLAIN

CF3326 CARBON 3K CARBON 3K 256 ± 15 16 16 0.26 ± 0.050 TWILL

CF3327 CARBON 3K CARBON 3K 208 ± 12 13 13 0.27 ± 0.050 PLAIN

CF3327-1 CARBON 3K CARBON 3K 208 ± 12 13 13 0.27 ± 0.050 TWILL

CF3327-6 CARBON 3K CARBON 3K 320 ± 19 20 20 0.27 ± 0.050 4:4 TWILL

CF6637-1 CARBON 6K CARBON 6K 364 ± 22 11.5 11.5 0.45 ± 0.075 2:2 TWILL

CF6637-3 CARBON 6K CARBON 6K 364 ± 22 11.5 11.5 0.45 ± 0.075 5H SATIN

ARAMID

Yarn Description Count (count / in)

FAW Thickness

STYLE Weave

Warp Weft (g/m²) Warp Weft (mm)

K-29 1500 K-29 1500

HK170 166 ± 10 13 12 0.25 ± 0.025 PLAIN

DEN DEN

K-49 1140 K-49 1140

HK285 170 ± 10 17 17 0.241 ± 0.0254 Crowfoot

DEN DEN

K-49 1140 K-49 1140

HK285 -1 172 ± 10 17 17 0.25 ± 0.025 PLAIN

DEN DEN

K-29 3000 K-29 3000

HK1033 533 ± 32 20 20 0.62 ± 0.075 4*4 BASKET

DEN DEN

HYBRID HYBRID

Yarn Description FAW Count(count/in) Thickness Yarn Description FAW Count(count/in) Thickness

STYLE Weave STYLE Weave

Warp Weft (g/m²) Warp Weft (mm) Warp Weft (g/m²) Warp Weft (mm)

CK3115 CARBON 3K K-49195 DEN 112 ± 7 13 10 0.15 ± 0.025 PLAIN

SEA 3K 3K+SEA75 1/0 SEA 75 1/0 187 ± 11 13+13 18 0.13 ± 0.025 PLAIN

CG199 CARBON 3K D 450 1/0 199 ± 12 24 18 0.19 ± 0.025 PLAIN

CR246 CARBON 3K ER300 400 Tex 312 ± 19 13 13 0.29 ± 0.050 PLAIN

CF3325-1 CARBON 3K (1,800DEN) 232 ± 14 15.0 14.0 0.25 ± 0.025 PLAIN

CR199 3K+ER300 Tex 3K+ER300 Tex 216 ± 13 3+7 3+7 0.20 ± 0.025 PLAIN

6K FABRIC 6K+SEA75 1/0 SEA 75 1/0 203 ± 12 8+8 20 0.38 ± 0.050 3:1 TWILL

CP1114 CARBON 3K 600DEN 94 ± 6 17.5 17.5 0.14 ± 0.025 PLAIN 3K FABRIC 3K+SEA75 1/0 SEA 75 1/0 187 ± 11 13+13 18 0.13 ± 0.025 3:1 TWILL

CF3327 3K+ST

3K+SILVER 218 ± 13 13 13 0.27 ± 0.050 PLAIN

CK3160 CARBON 3K K-49195 DEN 170 ± 10 13 13 0.22 ± 0.025 PLAIN (SILVER) SILVER

CF3327 3K+ST

CK3130_1 3K+1140DEN 3K+1140 DEN 215 ± 13 8.5+8.5 8+8 0.25 ± 0.025 PLAIN 3K+RED 218 ± 13 13 13 0.27 ± 0.050 PLAIN

(RED) SILVER

CK3130 3K+1140DEN 3K+1140 DEN 215 ± 13 8.5+8.5 8+8 0.25 ± 0.025 3:1 TWILL CF3327 3K+ST

3K+GOLD 218 ± 13 13 13 0.27 ± 0.050 PLAIN

(GOLD) SILVER

CK3118 CARBON 3K K-49195 DEN 119 ± 7 13 20 0.18 ± 0.025 PLAIN

CF3327 3K+ST

3K+BLUE 218 ± 13 13 13 0.27 ± 0.050 PLAIN

(BLUE) SILVER

COPYRIGHT(C)2019HANKUK CARBON CO.,LTD. ALLRIGHT RESERVED

GLASS FABRICS

Glass fabrics are widely used in many areas such as aviation, LNG vessels, electronics, sports leisure, and construction for its excellent

tensile strength, dimensional stability, electrical insulation, heat resistance and chemical resistance. Hankuk Carbon / Hankuk Advanced

Materials is capable of producing 30,000,000m annually. With the nation’s largest weaving machines capacity, the equipment can handle

to meet customer’s requirements such as thicknesses (0.03~0.8mm) and widths (25~3600mm).

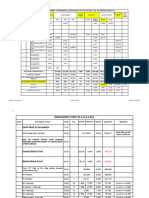

ELECTRICAL & ELECTRONICS SPORTS & LEISURE

Yarn Description Count(count/in) Yarn Description FAW Count(count/in) Thickness

FAW Thickness STYLE Weave

STYLE Weave Warp Weft (g/m²) Warp Weft (mm)

Warp Weft (g/m²) Warp Weft (mm)

792 D900 1/0 D900 1/0 23 ± 1 66 38 0.03 ± 0.013 PLAIN

106 D900 1/0 D900 1/0 25 ± 2 56 56 0.03 ± 0.01 PLAIN 1952 D900 1/0 D900 1/0 25 ± 2 52 60 0.03 ± 0.013 PLAIN

102 D450 1/0 D450 1/0 36 ± 2 50 30 0.05 ± 0.013 PLAIN 1960 D900 1/0 D900 1/0 25 ± 2 60 52 0.03 ± 0.013 PLAIN

209 E225 1/0 D450 1/0 76 ± 5 70 30 0.09 ± 0.025 4HS

153 D450 1/0 G150 1/0 144 ± 9 126 65 0.15 ± 0.025 PLAIN

210 G150 1/0 E225 1/0 108 ± 7 64 25 0.10 ± 0.025 4HS

771 D450 1/0 D900 1/0 33 ± 2 61 25 0.05 ± 0.013 PLAIN

212 G150 1/0 E225 1/0 133 ± 8 74 37 0.12 ± 0.025 4HS

1080 D450 1/0 D450 1/0 49 ± 3 61 48 0.05 ± 0.013 PLAIN 213 G75 1/0 E225 1/0 165 ± 10 52 28 0.13 ± 0.025 4HS

60 56 0.10 ± 0.025 PLAIN 215 G75 1/0 E225 1/0 183 ± 11 58 30 0.15 ± 0.025 4HS

2113 E225 1/0 D450 1/0 79 ± 5

218 G75 1/0 G150 1/0 207 ± 12 64 26 0.24 ± 0.025 4HS

2116 E225 1/0 E225 1/0 105 ± 6 60 57 0.10 ± 0.025 PLAIN

224 G37 1/0 G150 1/0 307 ± 18 50 26 0.24 ± 0.025 4HS

7628 G75 1/0 G75 1/0 208 ± 12 44 33 0.18 ± 0.025 PLAIN 345R ER300TEX ER300TEX 348 ± 21 14.5 14.5 0.35 ± 0.050 TWILL

FILTERING INSULATION

Yarn Description Count(count/in) Yarn Description FAW Count (count/in) Thickness

FAW Thickness STYLE Weave

STYLE Weave Warp Weft (g/m²) Warp Weft (mm)

Warp Weft (g/m²) Warp Weft (mm)

432 G37 1/0 G37 1/0 372 ± 22 34 34 0.32 ± 0.050 3:1 TWILL

IMITATION

546 G75 1/2 G75 1/2 389 ± 23 33 39 0.46 ± 0.075 451 TH13.7 TH13.7 688 ± 41 26 25 0.50 ± 0.075 2:2 TWILL

GAUZE

451-2 TH13.7 G25 1/0 552 ± 33 26 25 0.46 ± 0.075 2:2 TWILL

3107 G75 1/5 G75 1/5 270 ± 16 10 10 0.41 ± 0.075 PLAIN

451-3 K18 1/0 K18 1/0 573 ± 34 26 25 0.46 ± 0.075 2:2 TWILL

SCREEN K126 G37 1/0 G37 1/0 273 ± 16 30 20 0.26 ± 0.050 PLAIN

K618 G37 1/0 G3 7 1/0 197 ± 12 18 18 0.18 ± 0.025 PLAIN

Width Yarn Description FAW Count(count/in) Thickness

STYLE Weave K132 G37 1/0 G37 1/0 306 ± 18 34 22 0.32 ± 0.050 PLAIN

(mm) Warp Weft (g/m²) Warp Weft (mm)

7516 G75 1/0 G75 1/0 84 ± 5 16 15 0.12 ± 0.025 PLAIN

HM3741 2553 G37 1/0 G37 1/0 289 ± 17 32 21 0.26 ± 0.050 PLAIN 7517 G75 1/0 G75 1/0 92 ± 6 17 17 0.12 ± 0.025 PLAIN

HM7626 2130 G75 1/0 G75 1/0 178 ± 11 34 32 0.18 ± 0.025 PLAIN G612 G75 1/0 G75 1/0 97 ± 6 18 18 0.12 ± 0.025 PLAIN

G118-1 G75 1/0 G75 1/0 173 ± 10 34 30 0.18 ± 0.050 PLAIN

HM7628 2480 G75 1/0 G75 1/0 208 ± 12 44 33 0.18 ± 0.025 PLAIN

412 H45 2/3 G75 1/0 876 ± 53 20 ± 2 12.5 ± 1 1.10 ± 0.075 PLAIN

HM 7678 2553 G75 1/0 G75 1/0 194 ± 12 44 28 0.15 ± 0.025 PLAIN

TRANSPORTATION BUILDING MATERIALS

Yarn Description FAW Count (count/in) Thickness Yarn Description FAW Count(count/in) Thickness

STYLE Count (count/in) Weave STYLE Weave

Warp Weft (g/m²) Warp Weft (mm) Warp Weft (g/m²) Warp Weft (mm)

T650 TG7.40 TG7.40 529 ± 32 10 8 0.50 ± 0.075 PLAIN 310 G150 1/0 G75 1/0 54 ± 3 10 10 0.13 ± 0.025 LENO

7581 G75 1/0 G75 1/0 299 ± 18 57 54 0.23 ± 0.025 8H SATIN 381 G150 1/0 G75 1/0 43 ± 3 8 8 0.10 ± 0.025 LENO

7626 G75 1/0 G75 1/0 178 ± 11 34 32 0.18 ± 0.050 PLAIN 609 G150 1/0 G75 1/0 81 ± 5 20 10 0.09 ± 0.025 LENO

CHESSBOARD

7781 DE75 1/0 DE75 1/0 299 ± 18 57 54 0.25 ± 0.025 8H SATIN 917 G75 1/0 G75 1/0 229 ± 14 50 35 0.17 ± 0.025

PATTERN

G118-1

- G75 1/0 G75 1/0 173 ± 10 34 30 0.18 ± 0.050 PLAIN 918 G150 1/0 G75 1/0 245 ± 15 56 35 0.20 ± 0.025 BROKEN TWILL

FGC(M) G75 1/2 G75 1/2 334 ± 20 32 30 0.27 ± 0.050 PLAIN 920 G150 1/0 TG37 1/0 212 ± 13 56 25 0.20 ± 0.025 BROKEN TWILL

HG-120 D450 1/2 D450 1/2 106 ± 6 60 58 0.11 ± 0.025 4H SATIN 12H DERIV-A

922 G150 1/0 G37 1/0 212 ± 13 56 25 0.21 ± 0.025

TIVE TWILL

HG-1581 G150 1/2 G150 1/2 299 ± 18 57 54 0.25 ± 0.025 8H SATIN 923 G150 1/2 G75 1/2 286 ± 17 56 25 0.20 ± 0.025 BROKEN TWILL

T345 G37 1/0 G37 1/0 339 ± 22 32 30 0.27 ± 0.050 PLAIN G118-1 G75 1/0 G75 1/0 173 ± 10 34 30 0.18 ± 0.025 PLAIN

650 TH6.88 TH6.88 492 ± 30 10 8 0.50 ± 0.075 PLAIN R362 G37 1/0 ER 270 135 ± 8 6.2 6.2 0.26 ± 0.050 LENO

GRINDING

Yarn Description Count(count/in)

FAW Thickness

STYLE Weave

(g/m²) (mm)

Warp Weft Warp Weft

356 G75 1/3 H50 1/4 162 ± 10 5 5 0.32 ± 0.050 LENO

385 H45 1/3 H45 1/3 216 ± 13 8 8 0.35 ± 0.050 PLAIN

389 H45 1/4 H45 1/4 288 ± 17 8 8 0.34 ± 0.050 PLAIN

396 H50 1/4 H50 1/4 291 ± 17 9 9 0.35 ± 0.050 PLAIN

376 H45 2/3 H45 2/3 378 ± 23 7 7 0.41 ± 0.075 PLAIN

R329 H25 1/0 ER 400 235 ± 14 7.6 7 0.29 ± 0.050 LENO

COPYRIGHT(C)2019HANKUK CARBON CO.,LTD. ALLRIGHT RESERVED

GLASS PAPER

Glass Paper division is producing Glass Paper in the wet by glass fiber as a main ingredient. Glass Paper has a dimensional stability,

heat resistance, chemical resistance, electrical insulation, print process ability, heat insulation and so on. Due to its advanced quality,

the Glass Paper is used by many manufacturers globally for floorings, buildings, and exterior electronics.

Hankuk Carbon / Hankuk Advanced Materials has two machines for Glass Paper which can produce 30~200(g/㎡)

and the maximum width of 2,300mm according to customer’s needs. Capacity per a month is 3,000,000m,

and there are Pulp Type and Non-Pulp Type glass paper. The thickness range is from 0.220mm to 1.200mm. The mechanical

properties can be different based on resin matrix. Also, Hankuk Carbon / Hankuk Advanced Materials can produce

and develop new product according to customers’ request.

FLOOR DECORATION MATERIALS

STYLE Basis weight (g/m²) Thickness (mm) Lg loss (%)

GP - 32 32±2 0.22±0.02 29±2

GP - 40 40±2 0.25±0.02 29±2

GP - 45 45±3 0.29±0.02 30±2

GP - 50 50±2 0.32±0.03 29±2 PRINT SUBSTRATE & HEAT INSULATION PANEL

GP - 60 60±3 0.38±0.03 29±2 STYLE Basis weight (g/m²) Thickness (mm) Lg loss (%)

AG - 62 62±3 0.44±0.33 17±3

AG - 78 78± 3 0.58±0.03 10.5±1.5

TILE CARPETS

STYLE Basis weight (g/m²) Thickness (mm) Lg loss (%)

AG - 30 30±3 0.24±0.03 17±3 FILTER

AG - 40 40±3 0.30±0.03 17±3 STYLE Basis weight (g/m²) Thickness (mm) Lg loss (%)

AG - 50 50±3 0.36±0.03 17±3 AG - 90 90±3 0.64±0.03 11±3

CSM / ROVING CLOTH / AAF ROVING CLOTH

Yarn Description Count(count/in)

CSM became one of the finest products used in FRP equipment. STYLE FAW Thickness Weave

Warp Weft (g/m²) Warp Weft (mm)

Glass fiber strand is spread out in every direction and adheres

with polyester binder to form as a mattress type. 345R ER 300 ER 300 348 ± 21 14.5 14.5 0.35 ± 0.050 TWILL

Its strengths are equal strengths of every directions, and its 420R ER 600 ER 600 421 ± 42 9.1 8.6 0.35 ± 0.050 PLAIN

price is affordable. 580R ER 1200 ER 1200 580 ± 58 6.1 6.1 0.60 ± 0.075 PLAIN

800R ER 2400 ER 2400 800 ± 80 4.2 4.2 0.65 ± 0.075 PLAIN

CHOPPED STRAND MAT

STYLE Width (mm) Weight(g/m²) Moisture Content(%)

CM series 250~3000 300~600 ≤ 0.2

AAF

Thickness

Weight Width

CONTINUOUS STRAND MAT STYLE

Cloth Al - Foil (g/m²) (mm)

STYLE Width (mm) Weight(g/m²) Moisture Content (%) 612 #AAF 10 0.12 0.01 151 1015

CSM series 250~3000 230~480 ≤ 0.2

612 #AAF 40 0.12 0.04 240 1015

618 #AAF 10 0.18 0.01 216 1015

FABMAT

618 #AAF 20 0.18 0.02 243 1015

STYLE Width (mm) Weight(g/m²) Moisture Content(%)

618 #AAF 40 0.18 0.04 305 1015

5830 1000 880 ≤ 0.2

5838 1000 960 ≤ 0.2 G612 #AAF 10 0.12 0.01 116 1015

5845 1000 1030 ≤ 0.2 G612 #AAF 40 0.12 0.04 205 1015

COPYRIGHT(C)2019HANKUK CARBON CO.,LTD. ALLRIGHT RESERVED

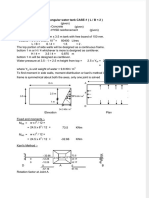

RESIN SYSTEM

Hankuk Carbon / Hankuk Advanced Materials has been developing a various resin formulation for prepreg system to enhance lightweight,

fireproof and durability for over 20 years. Based on our continuous development,

we have provided proper solutions to aviation, defense, rail road car, and electronic industries.

In addition to that, we manufacture various impregnated products using thermosetting resin and thermoplastic resin.

HOT MELT COATING

Resin Resin System Features Cure Process Cure Temperature Tg Tack Flow Remark Applications

RS-101 Autoclave, Oven, Press 120℃ / 2hr 120℃ High High General system Fishing Rod

SE019 Autoclave, Oven, Press 120℃ / 2hr 120℃ High High General system Fishing Rod, Bicycle

SE-019K Autoclave, Oven, Press 120℃ / 2hr 120℃ High High General system Fishing Rod, Bicycle

K-1 Autoclave, Oven, Press 120℃ / 2hr 120℃ Low Low General system Fishing Rod, Bicycle

L3 Autoclave, Oven, Press 120℃ / 2hr 120℃ Low Medium General system Fishing Rod, Bicycle

E-7 Autoclave, Oven, Press 120℃ / 2hr 120℃ High n/a Semi-toughened system Fishing Rod, Bicycle

4545B Autoclave, Oven, Press 120℃ / 2hr 120℃ Low Low Toughened system Fishing Rod, Golf Shaft

4545M Autoclave, Oven, Press 120℃ / 2hr 120℃ Medium Low Toughening system Fishing Rod, Golf Shaft

Low temperature

4545S Autoclave, Oven, Press 120℃/2hr, 80℃/10hr 120℃ High Medium Toughening system Fishing Rod, Golf Shaft

curing system

Low temperature Fishing Rod, Golf Shaft,

4545P Autoclave, Oven, Press 120℃/2hr, 90℃/6hr 120℃ High Medium Toughening system

curing system Industrial

RS250T Autoclave, Oven, Press 120℃ / 2hr 110℃ High Medium Toughening system Fishing Rod, Golf Shaft,

Bycicle

B1HT Autoclave, Oven, Press 180℃ / 2hr 180℃ High Medium Toughening system Fishing Rod, Bicycle

Epoxy Low temperature

W002 Autoclave, Oven 80℃ / 10hr 120℃ High High Low temperature cure Industrial

curing system

E-8 Autoclave, Oven, Press 120℃ / 2hr 120℃ High n/a Semi-toughened system Industrial

R11 Autoclave, Oven, Press 150℃ / 1hr 150℃ High n/a Medium-High Tg Industrial

RS3232 Autoclave 180℃ / 2hr 180℃ High High High Tg, 350F system Industrial

RS3434-3E Autoclave 180℃ / 2hr 200℃ n/a n/a n/a Industrial

Industrial

C004 FR Resin Autoclave, Oven 120℃ / 2hr 110℃ Low High General system

(Flame Retardant)

Industrial

HFE-A Halogen Freee FR Resin Autoclave, Oven 130℃ / 1hr 120℃ Medium Medium General system

(Flame Retardant)

Industrial

HFE-P Halogen Freee FR Resin Press 130℃ / 1hr 110℃ Low Low Toughening system

(Flame Retardant)

R11-FC05-04 Press 150℃ / 15min 150℃ Medium Medium Fast cure / Medium Tg

G101 Autoclave 120℃ / 2hr 105℃ Medium High High transparency (surface)

G101-1 Autoclave 120℃ / 2hr 105℃ High High High transparency (surface) Automotive

FC702T PCM / Press 150℃ / 5min 150℃ Medium Medium Fast cure (PCM)

FC703T PCM / Press 150℃ / 3min 160℃ Medium Medium Fast cure (PCM)

SOLVENT COATING

Resin Resin System Cure Process Cure Temperature Tg Tack Flow Applications

HD430 Press 120℃ / 2hr 120℃ Tack Free Low

HM445 Press 120℃ / 2hr 140℃ Tack Free Low Eletric Insulation

HP580 Press 120℃ / 2hr 160℃ Tack Free Low

Epoxy

FR2(Fishing Rod) Autoclave, Oven 120℃ / 2hr 120℃ Medium High Industrial, Fishing Rod

RS1212 Autoclave, Oven 120℃ / 2hr 120℃ High Medium Industrial, Aerospace

LP7 Autoclave, Oven 120℃ / 2hr 120℃ High Medium Industrial, Frp Pipe

Phenol PHC Autoclave, Oven 130℃ / 1hr 120℃ Medium / Low High / Medium / Low Industrial, Aerospace, Railroad

Urethane UTC - Tack Free Medium Industrial

Acrylic ABC - Tack Free Medium Industrial

Silicone

Rebber SRC - Tack Free High Industrial

PVC PVC - Tack Free Low Industrial

COPYRIGHT(C)2019HANKUK CARBON CO.,LTD. ALLRIGHT RESERVED

HANKUK CARBON OFFICE LOCATION

UK

Birmingham MIRA Technology Park

CHINA

Weihai Office

KOREA

Seoul Office

Miryang Headquater, Plant I, II

Sapo Plant

Siheung Plant

Hamyang Plant

Geojae Plant

VIETNAM

Binh Phuoc Industrial Park

Please contact us for more information

trade@hcarbon.com

You might also like

- Rating Sheet HSK NC IIDocument23 pagesRating Sheet HSK NC IIMaria Sophia Dp Castro100% (2)

- Assignment On Decision Making ProcessDocument27 pagesAssignment On Decision Making ProcessRubayat Rajeev80% (5)

- ClothDocument2 pagesClothRajulapati VinodkumarNo ratings yet

- Ds Torayca ClothDocument2 pagesDs Torayca ClothNoor MalakNo ratings yet

- Owner Storey Residential Cost EstimateDocument33 pagesOwner Storey Residential Cost EstimateLouis James BonsayNo ratings yet

- EstimatesDocument30 pagesEstimatesSamuel RegaladoNo ratings yet

- Material Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementDocument3 pagesMaterial Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- Brand, Source, Tests Etc. Units RequirementDocument1 pageBrand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- Bulk Material StockDocument8 pagesBulk Material StockAshanmugam SunfaceNo ratings yet

- Design of Precast Pier Cap - 1Document24 pagesDesign of Precast Pier Cap - 1Ankush SharmaNo ratings yet

- Fora 400Document4 pagesFora 400PeterWayNo ratings yet

- Emmision Diesel 350HP BarrickDocument1 pageEmmision Diesel 350HP BarrickEnrique RafaelNo ratings yet

- Material Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementDocument4 pagesMaterial Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- Fyp 2017 2Document18 pagesFyp 2017 2fahad jamilNo ratings yet

- Fora 400 eDocument4 pagesFora 400 enedunchiNo ratings yet

- Cement ConstantDocument2 pagesCement Constantimpressive_abhayNo ratings yet

- ASTM Grades For Insulating Fire BrickDocument2 pagesASTM Grades For Insulating Fire BrickrajachemNo ratings yet

- BIS0148 - C2L9P2 - Spec Sheet - Wear 450 Steel - WebDocument1 pageBIS0148 - C2L9P2 - Spec Sheet - Wear 450 Steel - Webidontlikeebooks100% (1)

- TC Statement 13Document1 pageTC Statement 13Amit Raj GuptaNo ratings yet

- IFB 2300 - BNZ MaterialsDocument2 pagesIFB 2300 - BNZ Materialsmiltone87No ratings yet

- Rate AnalysisDocument14 pagesRate AnalysisStephen Raj0% (1)

- BOQ - Base Rate FileDocument3 pagesBOQ - Base Rate FileSaleem khanNo ratings yet

- Nomenclator Retete Beton 2021 Model Excel (1) SemnatDocument3 pagesNomenclator Retete Beton 2021 Model Excel (1) SemnatZgripcea CristianNo ratings yet

- Relacion de Insumos Por Peso #Descripción Und. Cantidad Peso Unitario Peso TNDocument8 pagesRelacion de Insumos Por Peso #Descripción Und. Cantidad Peso Unitario Peso TNLeonid Contreras CusiNo ratings yet

- BBS Link OrderDocument4 pagesBBS Link OrderLallamaNo ratings yet

- c300 350 Opc SogDocument1 pagec300 350 Opc SogEslam SamyNo ratings yet

- AV. TULLUMAYO - Crong de AdquisicionesDocument4 pagesAV. TULLUMAYO - Crong de AdquisicionesYordan DelgadoNo ratings yet

- Fin Wt. Surface Area Solid Fins: 0.039 3.5 0.049 4.4 Ratio 0.80Document3 pagesFin Wt. Surface Area Solid Fins: 0.039 3.5 0.049 4.4 Ratio 0.80BoilerNo ratings yet

- Total Cement Cost (Fuel+Material+Power) : Kiln Feed Option-1 Option-2Document6 pagesTotal Cement Cost (Fuel+Material+Power) : Kiln Feed Option-1 Option-2Amir HabibNo ratings yet

- Packed Tower Rating Data Registered To: ROG, TR KG-TOWER® Software V 5.2Document1 pagePacked Tower Rating Data Registered To: ROG, TR KG-TOWER® Software V 5.2vasudhaNo ratings yet

- CIVIL Rate Analysis (Siraha) 2075-76Document159 pagesCIVIL Rate Analysis (Siraha) 2075-76Sirhali Builders100% (1)

- 308L StainlessSteel 62Document1 page308L StainlessSteel 62Paola CernaNo ratings yet

- Annexture 1Document9 pagesAnnexture 1BalajiYachawadNo ratings yet

- 2nd R.A Bill (mlcp-2)Document65 pages2nd R.A Bill (mlcp-2)almamunmolla96No ratings yet

- Cement Bag 120 RSB Bag 150 Sand Bag 600 Gravel Bag 500 Plywood Bag 800 CHB 4 Pcs 14 CHB 6 Pcs 18Document6 pagesCement Bag 120 RSB Bag 150 Sand Bag 600 Gravel Bag 500 Plywood Bag 800 CHB 4 Pcs 14 CHB 6 Pcs 18Marvin DimaguilaNo ratings yet

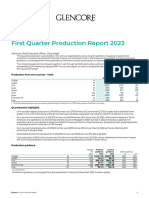

- GLEN 2023-Q1 ProductionReportDocument18 pagesGLEN 2023-Q1 ProductionReportAsset KanatovNo ratings yet

- Oriana Phase 3 CFC: Project ContractorDocument1 pageOriana Phase 3 CFC: Project ContractorCivil SanamNo ratings yet

- Copy of وحدة التكرير الجويةDocument67 pagesCopy of وحدة التكرير الجويةcement drNo ratings yet

- BBS Flocculation and Sedimendation TanksDocument49 pagesBBS Flocculation and Sedimendation TanksYohan LimNo ratings yet

- Taihan. Introduction To Tfo Opgw Fiberoptics. August 11, 2014Document25 pagesTaihan. Introduction To Tfo Opgw Fiberoptics. August 11, 2014jesus salazarNo ratings yet

- Sand Gravel Cement CHB 6" CHB 4": Kilo To Cu. M Kilo To Cu. M 0.165 0.13 0.3 0.3 0.4 0.4Document2 pagesSand Gravel Cement CHB 6" CHB 4": Kilo To Cu. M Kilo To Cu. M 0.165 0.13 0.3 0.3 0.4 0.4Clyde VillanuevaNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)ery achjariNo ratings yet

- P.E. Grava y ArenaDocument12 pagesP.E. Grava y ArenaNelson Flores MunozNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Mohd Said Mohd ZakariaNo ratings yet

- Mat Boundary Spring Generator: Input Data & Design SummaryDocument1 pageMat Boundary Spring Generator: Input Data & Design SummaryafvilavilanoriegaNo ratings yet

- Material Reconciliation Sheet: Project Name: SHDP Package 362A, 362B and PWD Road Reconciled Upto: 10/30/2021Document2 pagesMaterial Reconciliation Sheet: Project Name: SHDP Package 362A, 362B and PWD Road Reconciled Upto: 10/30/2021yashas sNo ratings yet

- Cv. Mandiri Roof Metal: Daftar HargaDocument2 pagesCv. Mandiri Roof Metal: Daftar HargaRyanhariNo ratings yet

- Temple DesignDocument3 pagesTemple Designraju_420034520No ratings yet

- Oriana Phase 3 CFC: Project Contractor JetDocument1 pageOriana Phase 3 CFC: Project Contractor JetCivil SanamNo ratings yet

- TM SCCDocument1 pageTM SCCjbi.fikriNo ratings yet

- Oriana Phase 3 CFC: Project ContractorDocument1 pageOriana Phase 3 CFC: Project ContractorCivil SanamNo ratings yet

- 3x185 RMDocument5 pages3x185 RMjamilNo ratings yet

- EPDM New Capital ReportDocument1 pageEPDM New Capital Reportahmed hassanNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- SP Project - Vizag Concrete Weighing SheetDocument1 pageSP Project - Vizag Concrete Weighing SheetGobinath GovindarajNo ratings yet

- SoR 2011 12Document21 pagesSoR 2011 12MuraliKrishna NaiduNo ratings yet

- Memoria Cajon VertedorDocument17 pagesMemoria Cajon VertedorCesar TossNo ratings yet

- Special Products & InsulationsDocument1 pageSpecial Products & InsulationsAjit YadavNo ratings yet

- BBI-1E MAG7 ComplDocument43 pagesBBI-1E MAG7 Complfvtolosa2022a11No ratings yet

- Megacarbond Component B MSDSDocument4 pagesMegacarbond Component B MSDSfvtolosa2022a11No ratings yet

- Bbi-1a, 1B, 1C, 1D Copy2 Rev Node DispDocument1 pageBbi-1a, 1B, 1C, 1D Copy2 Rev Node Dispfvtolosa2022a11No ratings yet

- BBI-1A, 1B, 1C, 1D ComplDocument48 pagesBBI-1A, 1B, 1C, 1D Complfvtolosa2022a11No ratings yet

- MX-2314N 20160317 020907Document7 pagesMX-2314N 20160317 020907fvtolosa2022a11No ratings yet

- Scale Factor Calculation BB1ABCD REVDocument5 pagesScale Factor Calculation BB1ABCD REVfvtolosa2022a11No ratings yet

- Vdocuments - MX - Design of Rectangular Water Tank 1Document242 pagesVdocuments - MX - Design of Rectangular Water Tank 1fvtolosa2022a11No ratings yet

- OnlyIAS - Economy - Updated 2023 PDFDocument471 pagesOnlyIAS - Economy - Updated 2023 PDFganesh sonkarNo ratings yet

- Madura Fashion and Lifestyle: CSR Initiatives and CertificationDocument14 pagesMadura Fashion and Lifestyle: CSR Initiatives and CertificationNitesh Kumar PalNo ratings yet

- Fashion-FILM: Application Instructions ForDocument1 pageFashion-FILM: Application Instructions ForEmmanuelNo ratings yet

- Fbs LectureDocument100 pagesFbs Lecturerhodefrancestuazon100% (1)

- Shoes Wholesale Markets - Guangzhou Tour GuideDocument9 pagesShoes Wholesale Markets - Guangzhou Tour GuidejacksparrowNo ratings yet

- NSE BSE - Fundamental DataDocument504 pagesNSE BSE - Fundamental DatashivasharesNo ratings yet

- Business Plan ExampleDocument12 pagesBusiness Plan ExampledendendenisseciousNo ratings yet

- Sewing ToolsDocument2 pagesSewing ToolsKimi AliNo ratings yet

- SWP Vehicle Hoist AS559Document2 pagesSWP Vehicle Hoist AS559WiwinIndahSariEffendiNo ratings yet

- Varun T ReportDocument56 pagesVarun T ReportShruti SharmaNo ratings yet

- Background of ApprenticeshipDocument16 pagesBackground of ApprenticeshipDerisma AiiuNo ratings yet

- Brief Industrial Profile of Malda District West Bengal: LR Eso T RsDocument14 pagesBrief Industrial Profile of Malda District West Bengal: LR Eso T RsSOMSUBHRA SINGHANo ratings yet

- Tudor Fashion Case StudyDocument3 pagesTudor Fashion Case StudyDines Shinde100% (1)

- Elie Saab AssignmentDocument2 pagesElie Saab AssignmentS Ali SajjadNo ratings yet

- Chapter 6 Manufacturing IndustriesDocument10 pagesChapter 6 Manufacturing IndustriesArchana RadhakrishnanNo ratings yet

- RISI 2019 Power ListDocument11 pagesRISI 2019 Power ListLuis Filipe Martins BarrosNo ratings yet

- Project ReportDocument15 pagesProject ReportRuchi KapoorNo ratings yet

- Analysis of Sourcing From India and China. Which Is Better and Procurement Is EasierDocument8 pagesAnalysis of Sourcing From India and China. Which Is Better and Procurement Is Easierishita khannaNo ratings yet

- April May NewsletterDocument7 pagesApril May NewsletterGene McAvoyNo ratings yet

- The Pakistan Textile IndustryDocument95 pagesThe Pakistan Textile IndustryMuhammad Abubakar Riaz100% (3)

- History: Procter & Gamble (P&G) Is ADocument18 pagesHistory: Procter & Gamble (P&G) Is ARahul BhattNo ratings yet

- Sahyadri Brochure 1Document4 pagesSahyadri Brochure 1Rushabh KapadiaNo ratings yet

- Ukay Ukay!Document1 pageUkay Ukay!Lagoy Zyra Mae100% (1)

- Torba 1Document8 pagesTorba 1Lucija CrljenkoNo ratings yet

- 461Document51 pages461Ijar UbNo ratings yet

- Sewing TermsDocument2 pagesSewing TermsmichuttyNo ratings yet

- Week 3 - Lecture 3 - TextilesDocument5 pagesWeek 3 - Lecture 3 - TextilesKunal SharmaNo ratings yet

- Company Profile KnitcraftDocument23 pagesCompany Profile KnitcraftAchint MarjaraNo ratings yet