Professional Documents

Culture Documents

c300 350 Opc Sog

Uploaded by

Eslam SamyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

c300 350 Opc Sog

Uploaded by

Eslam SamyCopyright:

Available Formats

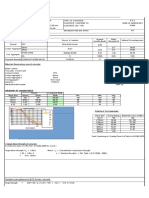

DATE 04-Jan-23 Fine Agg Grading

Mix Description C300/350 OPC - SOG 100

Consultant EHAF

Contractor Orascom Co. 90

Project Magdi Yacoub Hospital 80

Mix Description: SOG 70

Required Characteristic Strength 300 Kg/cm²

% PASSING

60

Workability required : Slump 200 ±20 mm

Raw Material Description Weights per m³

50

Cement OPC Content kg350 40

Micro Silica kg 0

30

Dolomite Size (12.5-19) mm kg551

Dolomite Size (4.75-12.5) mm kg551 20

Natural Sand kg758

Crushed Sand kg 0 10

Free Water kg156

0

Total Water kg193 0.1 1 10

Egyptian Code 203.2018

MasterRehbuild 880 EG or Weber 101U or Ncc X4 Kg6.6

Using at site if required RH1110 .5 : 1.0 Lit

Combined Coarse Aggregate Grading Curve

100

Density 2410 kg

Material Breakdown 90

Dolomite Size (12.5-19) mm 30%

80

Dolomite Size (4.75-12.5) mm 30%

Natural Sand 41% 70

Crushed Sand 0.0%

Water / Cement Ratio 0.45

% PASSING

60

Aggregate / Cement Ratio 5.32

50

Sources and Alternative of Raw Material

Cement Wadi El Nile /Arabia / Army 40

Fly Ash GEOS

Aggregates Attaka 30

Natural Sand SAF or Mostakabl Masr Quarriers

20

Crushed Sand N.A

Water Government

10

Micro silica Master Builder or MAST

Water Proof Master Builder 0

1 10 100

Polypropylene Fiber GEOS

Egyptian Code 203.2018

Admixture Master Builder or Weber or NCC

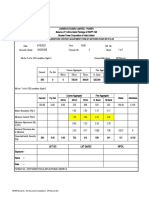

AGGREGATES Combined Egyptian Code FINES

Combined

Coarse

SIEVE SIZES 20mm 14mm Sand1 Sand2 Aggregate

Fine LOWER HIGHER LOWER HIGHER

37.50 mm 100% 100% 100% 100% 100% 100% 100% 100%

25.00 mm 100% 100% 100% 100% 100% 100%

20.00 mm 96% 100% 100% 100% 98% 100% 90% 100%

14.00 mm 27% 98% 100% 100% 65% 100%

10.00 mm 4% 65% 100% 100% 40% 100% 30% 60% 100% 100% 0%

5.00 mm 0% 2% 100% 84% 1% 100% 0% 10% 89% 100% 0%

2.36 mm 0% 1% 97% 71% 1% 97% 65% 100% 3%

1.18 mm 81% 48% 81% 45% 100% 19%

0.60 mm 40% 33% 40% 25% 80% 60%

0.30 mm 19% 20% 19% 5% 48% 81%

0.15 mm 4% 10% 2% 0% 10% 98%

Fine Agg. Breakdown 100.0% 0.0%

FINENESS MODULUS 2.6

Agg. Breakdown 29.6% 29.6% 40.7% 0.0%

* The Admixture has been used as per Manufacturer certificate and advises and the dosage can be vary based on the winter to summer seasons, according to

the technical data sheet; the admixture can be vary from the min dosage 3.5 Kg/M³ to Max dosage 10.5 Kg/M³ to achieve the required performance.

*All the alternative material submitted in the mix design can be used without prior notification.

* The above Mix design based on S.S.D for Aggregates. . . .

* Admixture may be added at site in order to maintain workability critical for placing.

*Coarse and Fine aggregates quantities could be changed based on material properties " FM variation by 0.1%" from mix design FM 2.6%.

Fm=Fcu+1.64*S = 351 Kg/cm²

*As per ECP the Miniumm Accepted margin for C 300 is 60 Kg/Cm² So Fm will be = 360 Kg/cm²

Compressive Strength Test Result

* 7 Day Result is 322 Kg/Cm²

* 28 Days Result is 401 Kg/Cm²

We trust that the above meets your requirements.

*This Mix design and any attachments transmitted with it are confidential , are intended only for the use of the individual or entity to which they are addressed and

may contain information that is confidential, subject to copyright and its constitutes a trade secret

You might also like

- C150 250 Opc - PCDocument1 pageC150 250 Opc - PCEslam SamyNo ratings yet

- C400 425 OPC - Modified C40 For Manhole+WP 707Document1 pageC400 425 OPC - Modified C40 For Manhole+WP 707Eslam SamyNo ratings yet

- C500 450 OPC 25 MS Screed WP ES 7 Days - Option 4 Roof ShellDocument1 pageC500 450 OPC 25 MS Screed WP ES 7 Days - Option 4 Roof ShellEslam SamyNo ratings yet

- Oriana Phase 3 CFC: Project ContractorDocument1 pageOriana Phase 3 CFC: Project ContractorCivil SanamNo ratings yet

- Oriana Phase 3 CFC: Project Contractor JetDocument1 pageOriana Phase 3 CFC: Project Contractor JetCivil SanamNo ratings yet

- Oriana Phase 3 CFC: Project ContractorDocument1 pageOriana Phase 3 CFC: Project ContractorCivil SanamNo ratings yet

- Light Smart 900-1000Document1 pageLight Smart 900-1000Civil SanamNo ratings yet

- Standard Deviation Calculation SheetDocument3 pagesStandard Deviation Calculation SheetH.b. DawudNo ratings yet

- M25 (PPC)Document2 pagesM25 (PPC)Jagdev GuleriaNo ratings yet

- M25 (PPC)Document2 pagesM25 (PPC)Jagdev Guleria100% (1)

- Mix Design Calculation M50Grade: For Nirvana SiteDocument1 pageMix Design Calculation M50Grade: For Nirvana SiteAnkur DalalNo ratings yet

- 01-Concrete Mix + MED CertDocument21 pages01-Concrete Mix + MED CertAnwar SadathNo ratings yet

- Project:: Type of Concrete: RCC Concrete Confirms To: IS456 Concrete Mix For: Pump / ManualDocument2 pagesProject:: Type of Concrete: RCC Concrete Confirms To: IS456 Concrete Mix For: Pump / ManualKrishnaraj Cnt.No ratings yet

- Concrete Mix Design: Lab. Trial No.7 #2 R Date: 6/7/2013 Concrete Class 4500 PsiDocument2 pagesConcrete Mix Design: Lab. Trial No.7 #2 R Date: 6/7/2013 Concrete Class 4500 PsiazharNo ratings yet

- Concrete Mix Design: Lab. Trial No. 4 Date: 21/6/2013 Concrete Class 2000 PsiDocument2 pagesConcrete Mix Design: Lab. Trial No. 4 Date: 21/6/2013 Concrete Class 2000 PsiazharNo ratings yet

- Slurry Design For PumpingDocument1 pageSlurry Design For PumpingverdihzekonNo ratings yet

- Diarab RoadDocument6 pagesDiarab RoadHishmat EzzelarabNo ratings yet

- Readymix Abu Dhabi LTD: Breakdown Dust Content RatiosDocument1 pageReadymix Abu Dhabi LTD: Breakdown Dust Content RatiosSyed AbuthahirNo ratings yet

- Summary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCDocument3 pagesSummary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCmeerut nazibabad projectNo ratings yet

- DLC Design Mix Stipulation1Document8 pagesDLC Design Mix Stipulation1abhishek negiNo ratings yet

- Adjustment of Concrete Mix Proportion For Batching Plant: Posco E&CDocument1 pageAdjustment of Concrete Mix Proportion For Batching Plant: Posco E&CHasan al MahmudNo ratings yet

- SCC - M30 (BGS) NTH3-2015NewDocument4 pagesSCC - M30 (BGS) NTH3-2015NewrajupetalokeshNo ratings yet

- M20 Mix DesignDocument1 pageM20 Mix DesignSaurav MukherjeeNo ratings yet

- Jobmix Formula: Trial Mix: InternalDocument2 pagesJobmix Formula: Trial Mix: InternalH.E. Veronico RamadhanNo ratings yet

- 440 KG Cement ContentDocument1 page440 KG Cement ContentIsaiahogedaNo ratings yet

- Pavement Types: Concrete PavementsDocument20 pagesPavement Types: Concrete PavementsMohamedNo ratings yet

- Sand BrochureDocument4 pagesSand BrochureKTSivakumarNo ratings yet

- 2.1 Tests On Cement: Sr. No. Properties ResultsDocument3 pages2.1 Tests On Cement: Sr. No. Properties ResultsBIPL REPORTNo ratings yet

- M40 With Fly AshDocument1 pageM40 With Fly Ashscribdfree anytimeNo ratings yet

- Rank - M25 &M40 Mix Design With GGBS & FlyashDocument8 pagesRank - M25 &M40 Mix Design With GGBS & FlyashNaresh CharyNo ratings yet

- Ashoka Buildcon LTD.: Design Stipulation Code RefferedDocument1 pageAshoka Buildcon LTD.: Design Stipulation Code RefferedAnil UdaleNo ratings yet

- M55 With GGBS and MicrosilicaDocument1 pageM55 With GGBS and MicrosilicaLegendary GamingNo ratings yet

- M10 PDFDocument3 pagesM10 PDFranjeet Chikane50% (2)

- Concrete Moisture Correction SheetDocument7 pagesConcrete Moisture Correction SheetAmit MaityNo ratings yet

- Trial Mix Data Sheet - M50Document1 pageTrial Mix Data Sheet - M50kiranrvgowdaNo ratings yet

- MIx Disign - Dipak Ducon PDFDocument1 pageMIx Disign - Dipak Ducon PDFShub KotiNo ratings yet

- Self Compacting Concrete SCCDocument17 pagesSelf Compacting Concrete SCC8790922772100% (1)

- First Trial Prestressed Concrete Sleepers - Faury MethodDocument4 pagesFirst Trial Prestressed Concrete Sleepers - Faury Methodopulithe100% (1)

- Mix Design by Imtisal Ahmad: Required DataDocument5 pagesMix Design by Imtisal Ahmad: Required DataAbdullahNo ratings yet

- Concrete Mix Design - Grout Mix (SRC) : Cement Ggbs M.Silica Temp (Fresh Conc-) Mix ClassDocument1 pageConcrete Mix Design - Grout Mix (SRC) : Cement Ggbs M.Silica Temp (Fresh Conc-) Mix ClassAlbert NajjarNo ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument6 pagesTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- Concrete Mix Design PQC M40Document5 pagesConcrete Mix Design PQC M40Pirpasha Ujede50% (2)

- Grout MixDocument2 pagesGrout MixAhmed MassadehNo ratings yet

- C40 Concrete Mix DesignDocument2 pagesC40 Concrete Mix DesignIsaiahogeda50% (2)

- Rate Analysis For Reinforced Cement ConcreteDocument3 pagesRate Analysis For Reinforced Cement ConcretekavithaNo ratings yet

- N35 Neat Cement MoistureDocument4 pagesN35 Neat Cement MoistureBagish Upadhyay UpadhyayNo ratings yet

- Concrete Mix Design C40/20-400 KG MSRC: Combined GradingDocument1 pageConcrete Mix Design C40/20-400 KG MSRC: Combined GradingkamakshiNo ratings yet

- M30 With GGBS Self Compacting ConcreteDocument1 pageM30 With GGBS Self Compacting ConcretePritha Das100% (1)

- RCC PDFDocument21 pagesRCC PDFRuwan ThilankaNo ratings yet

- India Crete RMC: A. Mix StipulationDocument2 pagesIndia Crete RMC: A. Mix StipulationAnil UdaleNo ratings yet

- DLC Mix Design - WHRP 82.25% - 18.75% Ultratech (Own, Daroda)Document11 pagesDLC Mix Design - WHRP 82.25% - 18.75% Ultratech (Own, Daroda)Car ThickNo ratings yet

- Form - Trial Mix Report: Technical Marketing Department CustomerDocument6 pagesForm - Trial Mix Report: Technical Marketing Department CustomerRedi PascaNo ratings yet

- Green SandDocument2 pagesGreen SandPranjal PatilNo ratings yet

- Calcium Carbonate (Caco) : Lost Circulation MaterialDocument2 pagesCalcium Carbonate (Caco) : Lost Circulation MaterialHasril Fauzul AziNo ratings yet

- Mix Design As Per BSDocument10 pagesMix Design As Per BSChetan SohalNo ratings yet

- Particle Size (MM)Document5 pagesParticle Size (MM)Rubai GangulyNo ratings yet

- Rate Analysis For Concrete Production at SiteDocument5 pagesRate Analysis For Concrete Production at SiteRahul BadgujarNo ratings yet

- Sample Name: Cement Type Concrete Grade - G 40 Time Min Slump MM Material Target 200 +/-25 Per m3 Trial 02 - Wet Mix Ppc/Insee RF + Target S. MMDocument1 pageSample Name: Cement Type Concrete Grade - G 40 Time Min Slump MM Material Target 200 +/-25 Per m3 Trial 02 - Wet Mix Ppc/Insee RF + Target S. MMYasndra AbeygunewardhaneNo ratings yet

- Chap 018Document38 pagesChap 018Eslam SamyNo ratings yet

- Chap 025Document42 pagesChap 025Eslam SamyNo ratings yet

- L6 - ILLUSTRATIONsDocument4 pagesL6 - ILLUSTRATIONsEslam SamyNo ratings yet

- L3 - Financial StatementsDocument36 pagesL3 - Financial StatementsEslam SamyNo ratings yet

- MGMT 026 Chapter 17 SlidesDocument43 pagesMGMT 026 Chapter 17 SlidesNguyen Dac ThichNo ratings yet

- L2 - Accounting Equation & Transaction Analysis - Edited With AnsswerDocument39 pagesL2 - Accounting Equation & Transaction Analysis - Edited With AnsswerEslam SamyNo ratings yet

- L1 IntroductionDocument28 pagesL1 IntroductionEslam SamyNo ratings yet

- Our Final ReportDocument3 pagesOur Final ReportEslam SamyNo ratings yet

- Assignment 1 Islam Box PlotDocument1 pageAssignment 1 Islam Box PlotEslam SamyNo ratings yet

- Airbnb CaseDocument12 pagesAirbnb CaseEslam SamyNo ratings yet

- Losses in PipesDocument19 pagesLosses in Pipesphanirajinish100% (1)

- Construction and DemolitionDocument6 pagesConstruction and DemolitionTara MiltonNo ratings yet

- UNIT 3 - Practical SkillsDocument55 pagesUNIT 3 - Practical SkillsSarah BinabdiNo ratings yet

- Spiral Weld PipeDocument52 pagesSpiral Weld PipePRASHANTNo ratings yet

- Airbase 13671Document6 pagesAirbase 13671ssarangNo ratings yet

- Ic Engine Lab ManualDocument80 pagesIc Engine Lab ManualMuhammadKhizarSiddiqueNo ratings yet

- 05 GT13E2+Rotor+Information HandoutsDocument21 pages05 GT13E2+Rotor+Information HandoutsShangker Kanesh100% (2)

- ABC of PhyscrometricsDocument50 pagesABC of Physcrometricsbibinme_b4uNo ratings yet

- MA 3000 NIC 600 2233 01 Simplified Operation ManualDocument10 pagesMA 3000 NIC 600 2233 01 Simplified Operation ManualPaul PlimNo ratings yet

- Lower Peace River and Shell Creek FinalDocument590 pagesLower Peace River and Shell Creek FinalRavi Chander NalamothuNo ratings yet

- Bonus Assignement No1 Sanjay DubeyDocument6 pagesBonus Assignement No1 Sanjay DubeySanjay Kailashnath DubeyNo ratings yet

- Water Turbine - Wikipedia, ..Document9 pagesWater Turbine - Wikipedia, ..manbkkNo ratings yet

- Lab Report 1 Sku 3043Document9 pagesLab Report 1 Sku 3043Nelviana NahNo ratings yet

- 15 TOP Compressors, Gas Turbines & Jet Engines LAB VIVA Questions and Answers PDF Gas Turbines & Jet Engines LAB VIVA Questions and AnswersDocument4 pages15 TOP Compressors, Gas Turbines & Jet Engines LAB VIVA Questions and Answers PDF Gas Turbines & Jet Engines LAB VIVA Questions and AnswersAB MalikNo ratings yet

- Technical Information ASSET DOC LOC 1543316Document1 pageTechnical Information ASSET DOC LOC 1543316inbNo ratings yet

- Control Loop HardwareDocument56 pagesControl Loop Hardwarecharleselitb92No ratings yet

- Boundary Conditions E and HDocument3 pagesBoundary Conditions E and HAamod ShankerNo ratings yet

- Steam Yachts and Launches - Their Machinery and Management - 1887Document160 pagesSteam Yachts and Launches - Their Machinery and Management - 1887Clyde Steamers0% (1)

- Carberry 1960Document4 pagesCarberry 1960maiNo ratings yet

- IJETR032566Document3 pagesIJETR032566erpublicationNo ratings yet

- Cat Filtrazione 2017 enDocument80 pagesCat Filtrazione 2017 enTed ThomsonNo ratings yet

- Determination of Compacted Granular Layer ThicknessDocument5 pagesDetermination of Compacted Granular Layer ThicknessbusyspiderNo ratings yet

- Bell (1977)Document6 pagesBell (1977)Jéssica OliveiraNo ratings yet

- Basic Mechanical EngineeringDocument46 pagesBasic Mechanical EngineeringNguyễn Khánh Tùng100% (1)

- Design and Analysis of Tall Reinforced Concrete Buildings To EurocodesDocument90 pagesDesign and Analysis of Tall Reinforced Concrete Buildings To EurocodesdikunNo ratings yet

- Case StudyDocument3 pagesCase StudyJayNo ratings yet

- BS en 12396-1-1999Document12 pagesBS en 12396-1-1999DoicielNo ratings yet

- Low Cost Eco Friendly Building Material A Case Study in EthiopiaDocument6 pagesLow Cost Eco Friendly Building Material A Case Study in EthiopiakidusNo ratings yet

- Lab PH Meter: Instruction Manual ForDocument17 pagesLab PH Meter: Instruction Manual ForVictor GonzálezNo ratings yet

- TGN-D-04 Distortion Control in ShipbuildingDocument9 pagesTGN-D-04 Distortion Control in ShipbuildingKomkamol ChongbunwatanaNo ratings yet