Professional Documents

Culture Documents

IFD174056150

IFD174056150

Uploaded by

Arun JaisonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IFD174056150

IFD174056150

Uploaded by

Arun JaisonCopyright:

Available Formats

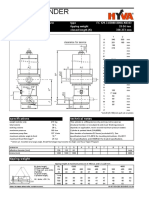

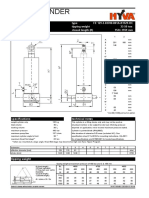

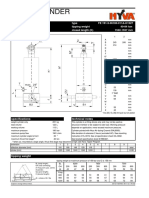

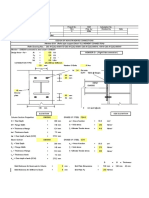

TECHNICAL SPECIFICATION

CYLINDER TYPE: FC-174-05-6150 TIPPING WEIGHT : 42 - 68 TONS

A : 245 mm

B : 325 mm

C : 50 mm

D : mm

J ±10

60

E : 50 mm

ØI

L ±10

F : 60 mm

G : 1" BSP

C B ±2 C

K =M+20 ( Mounting dimension)

H : 197 mm

ØD

ØD

I : 234.5 mm

J : 1248 mm

M ±5

K : mm

G

ØH 343

ØF

ØF

L : 1616 mm

E A ±2 E

M : 323 mm

FRONT COVER, SINGLE ACTING TELESCOPIC CYLINDR Part No : IFC174056150

Stages 1 2 3 4 5 6 No. of stages : 5

Diameter (mm) 174 154 135 116 98

Stroke (mm) 1228 1225 1229 1230 1238 Total stroke : 6150 mm

Oil (L) 29.2 22.8 17.6 13 9.3 Working volume : 91.9 L

Thrust (KN) @ P max 476 373 286 211 151 Avg. working load : 207 KN

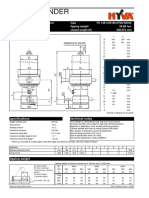

TECHNICAL NOTE

Mounting dimension (K) 323 +20 (-5,+30)mm minimum pull out Max pressure : 200 bar Weight : --- Kg

Seal ring Temperature : -40 C to +100 C Max linear speed : 0.5 m/s

Outer stage powder coated to semi glossy finish min thickness 30μm, RAL 9005

Piston rod chrome plated to min 15μm

This cylinder has been designed to provide only a linear pushing force. This cylinder is not a structural member and must not used as a stabliizer or subjected to side or

pushing load.. This cylinder will not prevent the dump body or trailer from rollover or lateral tilt. Cylinder rated pressure reflect only the capability of the pressure-

containing envelop and not the force trassmitting capability of mounting configurations. The original use of telescopic cylinder will not requiered any coating since the

telescopic stages are exposed to atmospheric agents only duirng the tip-up operation. if duration is below 2 hours.

The tipping body weight + max payload are the maximum tipping weight that can be raised by this cylinder. This value calculated at the max pressure is a rough

indication o fht etipping load of the cylinder and must be used as a first criteria for the selection of the cylinder. The real tipping weight can only be calculated by the

design engineer and must take into account the geometry of the tipping body, operating condition and all the reasonably forseeable users.

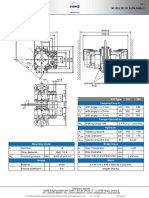

Cylinder bottom bracket Cylinder top bracket

118 400 229

41

57

76

32

60

77

70

70

60 183 26 60 R8.

57 57

50

303 368

390 25

328(B+3)

248 (A+3)

For reference only.

You might also like

- IFD154044930Document1 pageIFD154044930Arun JaisonNo ratings yet

- A790201001 - BRAKE PADS JURID 839 (24mm)Document1 pageA790201001 - BRAKE PADS JURID 839 (24mm)gitarista007No ratings yet

- Front Type Telescopic Cylinder CODE: MC 1124: SpecificationsDocument1 pageFront Type Telescopic Cylinder CODE: MC 1124: SpecificationsUrban CanahuireNo ratings yet

- Ficha Tecnica Cilindro ParkerDocument1 pageFicha Tecnica Cilindro ParkerJuan Jose PalaciosNo ratings yet

- HyvaDocument1 pageHyvaWILDERNo ratings yet

- Hyva CylinderDocument2 pagesHyva CylinderDinifaanNo ratings yet

- Cylinder Top PDFDocument1 pageCylinder Top PDFpushpender bajajNo ratings yet

- Cilindro Hidraulico de Volquete PDFDocument1 pageCilindro Hidraulico de Volquete PDFEnrique Escobar LozanoNo ratings yet

- Cilindro HidraulicoDocument1 pageCilindro HidraulicoEnrique Escobar LozanoNo ratings yet

- Parts Book 71901540Document2 pagesParts Book 71901540Marcos Quispe FuentesNo ratings yet

- Hyva ЦилиндрDocument2 pagesHyva ЦилиндрСергей ГоровойNo ratings yet

- HyvaDocument2 pagesHyvaRudi SyamNo ratings yet

- Elaflex CatalogueDocument1 pageElaflex CatalogueBabyface888No ratings yet

- Silownik Hydrauliczny Teleskopowy Hyva 71505404 fc149 4 05180 070a k0343 KH KipperDocument2 pagesSilownik Hydrauliczny Teleskopowy Hyva 71505404 fc149 4 05180 070a k0343 KH Kipperseptian wahyu widodoNo ratings yet

- Hyva Cylinder FE169-4-05180-011ADocument2 pagesHyva Cylinder FE169-4-05180-011AFrans MetinNo ratings yet

- Hyva CylinderDocument2 pagesHyva CylinderDinifaanNo ratings yet

- Hywa Tipping Cylinder-71534201Document2 pagesHywa Tipping Cylinder-71534201manoj_doshi_1No ratings yet

- Calculo Laje MistaDocument11 pagesCalculo Laje MistaMAURONo ratings yet

- Acoplamento de Lamina Lp2 1565111767Document2 pagesAcoplamento de Lamina Lp2 1565111767Adilson GabuNo ratings yet

- Catálogo Hyva de Cilindro 71901750KDocument2 pagesCatálogo Hyva de Cilindro 71901750KMarcos Quispe FuentesNo ratings yet

- Updated Anchor C20Document6 pagesUpdated Anchor C20anwarNo ratings yet

- Cooled Panel EAF ElectrodeDocument1 pageCooled Panel EAF Electrodekawan kamelNo ratings yet

- Steel Moment-Connection-Beam-Column (IS800)Document11 pagesSteel Moment-Connection-Beam-Column (IS800)Selva KumarNo ratings yet

- Acc Serie 229Document1 pageAcc Serie 229leonardo caicedo mesaNo ratings yet

- Acc Serie 229Document1 pageAcc Serie 229leonardo caicedo mesaNo ratings yet

- 01 - Ficha Tecnica y Despiece - Cil 5 EtapasDocument2 pages01 - Ficha Tecnica y Despiece - Cil 5 Etapashumberto zamarNo ratings yet

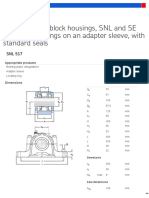

- Split Plummer Block Housings, SNL and SE Series For Bearings On An Adapter Sleeve, With Standard Seals - SNL 517 + 1217 K + H 217Document3 pagesSplit Plummer Block Housings, SNL and SE Series For Bearings On An Adapter Sleeve, With Standard Seals - SNL 517 + 1217 K + H 217Sadok KzadriNo ratings yet

- Fe169 4 05180 PDFDocument2 pagesFe169 4 05180 PDFAji AryandieNo ratings yet

- Fe169 4 05180 PDFDocument2 pagesFe169 4 05180 PDFAji AryandieNo ratings yet

- UNI - Z241 - 17 - 5 - 600x300 ModifiedDocument23 pagesUNI - Z241 - 17 - 5 - 600x300 ModifiedpaulaNo ratings yet

- Design of Steel I Section BS5950Document7 pagesDesign of Steel I Section BS5950chaNo ratings yet

- Bracing Back To Back (Version 1)Document118 pagesBracing Back To Back (Version 1)Tameem AnsariNo ratings yet

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDocument29 pagesPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENo ratings yet

- Licad86061000010 F06Document1 pageLicad86061000010 F06Sakeel WagirkhanNo ratings yet

- Moment Connection Beam Column Is Bs Section For Is800Document27 pagesMoment Connection Beam Column Is Bs Section For Is800Ramesh SelvarajNo ratings yet

- KGHK40 B PP AsDocument1 pageKGHK40 B PP AsGabriel OliveiraNo ratings yet

- Y-Bearing Plummer Block Units - SYJ 20 KFHDocument2 pagesY-Bearing Plummer Block Units - SYJ 20 KFHVisitOn.T.witte.rNo ratings yet

- ESFLE 208 2248883.htmlDocument2 pagesESFLE 208 2248883.htmlAndrei DumitruNo ratings yet

- 8040SRM16 10Document6 pages8040SRM16 10Roberto MammolaNo ratings yet

- Support-Glcd Cop Lop RevbDocument1 pageSupport-Glcd Cop Lop RevbhabibullaNo ratings yet

- Baseplate (Fixed Type 6 Bolts) 123Document15 pagesBaseplate (Fixed Type 6 Bolts) 123vijay10484No ratings yet

- Connection ShearDocument6 pagesConnection ShearthaksinprcNo ratings yet

- Vdocuments - MX Moment Connection Beam Column Is Bs Section For Is800xlsDocument27 pagesVdocuments - MX Moment Connection Beam Column Is Bs Section For Is800xlsDhimant ParmarNo ratings yet

- Inova Ball Joints JBDocument2 pagesInova Ball Joints JBSympatyagaNo ratings yet

- Lben-M0602 04 GBR en Ca 180123 HDocument12 pagesLben-M0602 04 GBR en Ca 180123 HnataliaNo ratings yet

- Typical Bolt Connection of Truss Diagonal Web MemberDocument7 pagesTypical Bolt Connection of Truss Diagonal Web Membermsh741053515No ratings yet

- ArcelorMittal Beams Calculator PDFDocument8 pagesArcelorMittal Beams Calculator PDFAndreja GjureskiNo ratings yet

- Calliper Brake SHI 251 & 252Document19 pagesCalliper Brake SHI 251 & 252Shaiju NarayananNo ratings yet

- Fiat 4061 PDFDocument6 pagesFiat 4061 PDFSamir YehyaNo ratings yet

- Fiat 4061 PDFDocument6 pagesFiat 4061 PDFSamir YehyaNo ratings yet

- 8041i06.55 8041i40.55Document6 pages8041i06.55 8041i40.55Roberto MammolaNo ratings yet

- Montagehandleiding - Assembly Manual - Montageanleitung - Manuel de MontageDocument46 pagesMontagehandleiding - Assembly Manual - Montageanleitung - Manuel de MontageSalim SalimNo ratings yet

- Job Layout: OccurrencesDocument4 pagesJob Layout: OccurrencesArmando Yarlaque RamosNo ratings yet

- H SectionDocument3 pagesH SectionchaNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- I Metric BSPDocument85 pagesI Metric BSPArun JaisonNo ratings yet

- Eulers FormulaDocument4 pagesEulers FormulaArun JaisonNo ratings yet

- Grade 8.8Document6 pagesGrade 8.8Arun JaisonNo ratings yet

- Equivalent Material STDDocument4 pagesEquivalent Material STDArun JaisonNo ratings yet

- Engineering InfoDocument1 pageEngineering InfoArun JaisonNo ratings yet

- Torque Chart0Document2 pagesTorque Chart0Arun JaisonNo ratings yet

- ESSO Univis HVIDocument2 pagesESSO Univis HVIArun JaisonNo ratings yet

- Ncut Antiextrusion Ring For Standard Ing: MaterialDocument2 pagesNcut Antiextrusion Ring For Standard Ing: MaterialArun JaisonNo ratings yet

- Ut Antiextrusion Ring For Standard Ing: MaterialDocument2 pagesUt Antiextrusion Ring For Standard Ing: MaterialArun JaisonNo ratings yet

- Ncut Antiextrusion Ring For Metric Ing: MaterialDocument4 pagesNcut Antiextrusion Ring For Metric Ing: MaterialArun JaisonNo ratings yet

- Ncut Antiextrusion Ring For Standard Ing: MaterialDocument6 pagesNcut Antiextrusion Ring For Standard Ing: MaterialArun JaisonNo ratings yet

- Piral Type Antiextrusion Ring For Standard Ingp: MaterialDocument2 pagesPiral Type Antiextrusion Ring For Standard Ingp: MaterialArun JaisonNo ratings yet

- Valve Regulated Lead-Acid Rechargeable Battery: o o o oDocument2 pagesValve Regulated Lead-Acid Rechargeable Battery: o o o oArun JaisonNo ratings yet

- Sec7pg343 347HydacClampsDocument5 pagesSec7pg343 347HydacClampsArun JaisonNo ratings yet

- Clamp Overview: Standard SolutionsDocument32 pagesClamp Overview: Standard SolutionsArun JaisonNo ratings yet

- QRC Quick Release Coupling.Document114 pagesQRC Quick Release Coupling.Arun JaisonNo ratings yet

- Car Carrier Rolfo PDFDocument12 pagesCar Carrier Rolfo PDFArun JaisonNo ratings yet

- KS VSPDocument15 pagesKS VSPIhya UlumudinNo ratings yet

- The Transportation and Travel Evolution in The: Pre-Industial Travel System ERADocument2 pagesThe Transportation and Travel Evolution in The: Pre-Industial Travel System ERAAntonio Andres AlabaNo ratings yet

- Sip Abhishek SharmaDocument50 pagesSip Abhishek SharmadivsdaveNo ratings yet

- 1839-Article Text PDF-5402-1-10-20130303Document7 pages1839-Article Text PDF-5402-1-10-20130303ajay dattNo ratings yet

- Evaluation of Braking Performance of Disc Brake Rotor With Different Pillar Ventilation Structures IJERTV10IS110170Document9 pagesEvaluation of Braking Performance of Disc Brake Rotor With Different Pillar Ventilation Structures IJERTV10IS110170Ivan FonsecaNo ratings yet

- Determining A Bike Wheel's Moment of Inertia (Resistance To Acceleration)Document10 pagesDetermining A Bike Wheel's Moment of Inertia (Resistance To Acceleration)John D Pepin100% (1)

- Agri Crop 78 Module 1 AgricultureDocument36 pagesAgri Crop 78 Module 1 AgricultureAprilNo ratings yet

- 2-Engine Mechanical SystemDocument256 pages2-Engine Mechanical SystemFrankCubidesNo ratings yet

- Howden Blower Method StatementDocument56 pagesHowden Blower Method StatementBaisel Rahuman0% (1)

- Fek Glasner1 0Document33 pagesFek Glasner1 0Állex SanderNo ratings yet

- Kubota B2650 - B3350 - B3350SU Tractor Operators ManualDocument110 pagesKubota B2650 - B3350 - B3350SU Tractor Operators ManualСвятослав ВороновNo ratings yet

- HiTEC-419 PDSDocument2 pagesHiTEC-419 PDSSong Hum KangNo ratings yet

- Toyota Understand Wiring DiagramsDocument10 pagesToyota Understand Wiring DiagramsMike100% (62)

- 0K4285A-C SG 050 6.8L FORD INDUSTRIAL H-100 30 May 2018 PDFDocument6 pages0K4285A-C SG 050 6.8L FORD INDUSTRIAL H-100 30 May 2018 PDFGustavoCalderonNo ratings yet

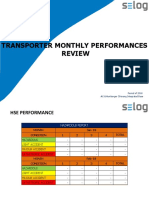

- Performance Review Jan - Feb 2018 SELOGDocument10 pagesPerformance Review Jan - Feb 2018 SELOGApriandi SetiawanNo ratings yet

- 8.1L MY2006 Parts ManualDocument61 pages8.1L MY2006 Parts Manualspammed Scribd userNo ratings yet

- Komatsu D85EX Esquemas Electricos PDFDocument6 pagesKomatsu D85EX Esquemas Electricos PDFJuan Alejandro Apablaza Lefno100% (1)

- Emission and Electrical Diagnose - IsuzuDocument79 pagesEmission and Electrical Diagnose - IsuzuVillaruz Renzy100% (5)

- Chieftain Main Battle TankDocument30 pagesChieftain Main Battle TankJosiah Tedja100% (3)

- Simbolos NeumaticosDocument7 pagesSimbolos NeumaticosSergio Martínez LópezNo ratings yet

- Wheel End - Heavy Duty 807-515: Includes Ref#'S 2-4,6-11,16, 20, & 28-31 INCLUDES REF#'S 12-15, 19, 21, 22, 24, AND 29Document4 pagesWheel End - Heavy Duty 807-515: Includes Ref#'S 2-4,6-11,16, 20, & 28-31 INCLUDES REF#'S 12-15, 19, 21, 22, 24, AND 29МаксNo ratings yet

- Tecumseh Quick Reference: Service InformationDocument73 pagesTecumseh Quick Reference: Service InformationMike CryerNo ratings yet

- Qashqai Maintenance PartsDocument4 pagesQashqai Maintenance PartsAnonymous yuTP0oNo ratings yet

- School of Mechanical Engineering: MEE 1904 Capstone Project Presentation-Review-B.Tech. Mechanical Engineering - SMECDocument13 pagesSchool of Mechanical Engineering: MEE 1904 Capstone Project Presentation-Review-B.Tech. Mechanical Engineering - SMECTarun magantiNo ratings yet

- John Deere 6076 ctm6Document6 pagesJohn Deere 6076 ctm6Luan SantosNo ratings yet

- 2 - Reporte Bombas y Accesorios - FLO FABDocument29 pages2 - Reporte Bombas y Accesorios - FLO FABEmerson ArteagaNo ratings yet

- Vinay Ford MotorsDocument71 pagesVinay Ford MotorshjanagamaNo ratings yet

- 1999 Odyssey Wiring DiagramsDocument98 pages1999 Odyssey Wiring Diagramsmike100% (1)

- Idler Sprockets: Poly Chain GT and Powergrip GTDocument2 pagesIdler Sprockets: Poly Chain GT and Powergrip GTVolodymуr VorobetsNo ratings yet

- FSAE Rules 2024 V1Document140 pagesFSAE Rules 2024 V1ZEUS ARMYNo ratings yet