Professional Documents

Culture Documents

Guidetodesign SCADApaper

Guidetodesign SCADApaper

Uploaded by

bitseee RandDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidetodesign SCADApaper

Guidetodesign SCADApaper

Uploaded by

bitseee RandDCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/360773117

A Guide to Design a PLC and SCADA based Industrial Automation System

Article in International Journal of Innovative Research in Science Engineering and Technology · May 2022

CITATIONS READS

2 1,757

3 authors, including:

Manisankar Dhabal

Department of Atomic Energy

4 PUBLICATIONS 2 CITATIONS

SEE PROFILE

All content following this page was uploaded by Manisankar Dhabal on 22 May 2022.

The user has requested enhancement of the downloaded file.

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

A Guide to Design a PLC and SCADA based Industrial

Automation System

Manisankar Dhabal1, Durgesh Lingampalle2, O P Ullas3

1,2,3

Hot Lab Utility & Engineering Services Section, NFG, Bhabha Atomic Research Centre

Abstract - PLC and SCADA based industrial automation system for their plant. They need to hire a consultancy

system is the most widely used control system employed to design a system who brings a system integrator. [5,

in present scenario and its application is increasing very p.265]. System integrator executes the overall

fast. Starting from a small equipment control to a large

automation work with the help of other electrical,

plant control these systems are used. Manufacturer also

mechanical contractor. It has been found that if the

finds it very convenient to use PLC in place of embedded

control for their flexibility. Although PLC and SCADA plant or industry person does not adequate

system is a generic term the ranges of product available understanding of the design, the finally installed

have wide variety. It depends upon the requirement of automation platform is not optimally designed. It is

the system. Very often it is selected based on manipulated necessary to have a knowledge of an automation

suggestion received from the system integrator or a system design for any plant person who want to

vendor. It may either results into a costly or a purchase and install such system. Online survey and

compromised product due to lack of basic knowledge literature study has been done on design of an

about design techniques. This paper describes a very

automation platform with PLC and SCADA system.

simple method to PLC and SCADA based system. It will

The available literature are specific to a particular type

be useful for the actual process engineers who gives the

whole work to a turnkey vendor or to a consultant. The of a process control design with custom made

method helps to design an architecture as well as select controller or software. A manufacturer product

seize of major components. While explaining a general catalogues explains various hardware configuration

building services system has been taken as an example and architecture however those require a very depth

knowledge in automation system. There are lot of

Index Terms - PLC,RIO, IO, SCADA books and documents available PLC programming,

SCADA programming however no such literature is

Abbreviation: RIO: Remote IO Module, PL: Plant, B1:

therefore for designing overall system which is

Building 1, B2: Building 2, FO: Fibre Optics, LAN: Local

understandable to a person not much familiar with

Area Network, L2: Layer 2, L3: Layer 3, LIU: Live

Interface Unit, SFP: small form-factor pluggable automation components design. The intent of writing

this article is to help any plant or industry to design

INTRODUCTION PLC and SCADA based automation system without

need of in-depth knowledge of such components. The

Automation system is used in most of the industries, paper in a very small article explains how to assess the

and they are applied in all sectors. The widely used capacity of automation system and then guide the

industrial automation is PLC and SCADA based reader to calculate size of each of the component of the

system. There are industry standards available for automation system. The calculation method based on

PLC, SCADA which defines specification and few simple approaches which is very obvious but is

performance requirements. Online tools are available not found any book or literature. It also gives an idea

with various manufacturer to select their package or of the safety aspect which a plant may or may not

product. But it does not help to design a complete consider. Very often it has been found that

system. PLC programming is done by a certified miscellaneous redundancy is considered to make the

engineer only whereas programming in SCADA is plant safer but an important aspect is missed out. This

also done by an expert only. All plant or industry does document will help a reader to optimally design a PLC

not have an in-house expert with them to design a

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 74

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

and SCADA based automation system even though he

does not have adequate knowledge of such system.

BASIC INDUSTRIAL AUTOMATION SYSTEM

The basic intent of industrial automation system is to

monitor and control an equipment from a PC based

system from a remote place which is often called as a

control room.

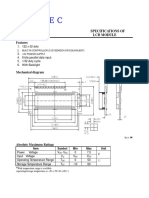

Fig 2: Components of an Industrial Automation

System

SCADA System is obviously the heart of the system

which is surrounded by PLC, RIO and their

interconnecting network, various sensor and

equipment pertaining to the process and the signal

cables establishing their connection with the RIO.

DESIGN THE CAPACITY OF AN AUTOMATION

Fig 1 Basic Industrial Automation Scheme

SYSTEM

A basic flow diagram is given in Fig 1. This require an

equipment needs to be connected one or multiple input

Before designing the automation system equipment, it

output module which is referred as a Remote Input

is necessary to design the capacity of the automation

Output Module (RIO). These modules are also

system required. In order to design the system first step

referred as RTU [2, p.89] by some vendor. The status

is to break the overall system of process into smaller

of the equipment is given to the RIO panel which send

process, then break into sub process, subsequently to

the data to a programmable logic controller (PLC).

individual equipment, sub equipment. The process of

PLC send the data to a SCADA system which is run in

breaking into smaller process is shown in Fig 3. It may

a PC based environment running on windows

be noted that the abbreviation used in the figure are not

Operating system. The status of the equipment and

standard. It is used solely for explanation purpose.

process is shown in a graphical environment through

various animation and P&I diagram. Buttons are also

designed in animated text to send command to the

equipment. The command is processed by the PLC

which sends back the data to the RIO. The RIO with

the help of its various output module changes the

equipment and process as directed by SCADA. The

connection between RIO, PLC and SCADA is a

communication cable whereas the connection between

the RIO and the main equipment or process is control

cables. This gives the idea of various components of

an industrial automation system which is shown in Fig

2.

Fig 3: Method to break into small process

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 75

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

The next to be to take a practical example of a large control the process. For the explanation a suction

process. The method is explained with a Ventilation damper and a starter is taken which will cover all types

and Utility Control plant which is divided into small of input and output parameters used in the industrial

systems in Fig 4. A Plant Utility Services (PL) is automation system. In this process it is required to ask

broken into three major process which are Building 1 yourself what is the thing you want to monitor for this

Services (B1), Building 2 services (B2) and Common equipment and what is the thing you to control for this

services. For explanation only B1 services is broken equipment. In the figure 5 the breaking down activity

into small process which are listed as compressed air is shown.

services, effluent storage system, One through

ventilation system, re-circulatory ventilation system , ANALOG INPUT AND OUTPUT PARAMETERS

Fire Alarm System (FAS), Power system, Air

sampling system. Again for explanation purpose one The suction damper is a modulating device which is

though ventilation system is broken into 3 major used to block percentage of air. In this case it is a

systems which are Fume Hood Exhaust plant (FH) motorised damper which vary its position depending

,exhaust air plant and supply air system. It may be upon the electrical signal given to it. We may like

noted that once through ventilation system is used for monitor how much percentage the damper is opened

area where potentially contaminated air is there and in a running plant. So it is an IO and is called Analog

materials are handled which may generate toxic gas or input (AI). Electrical signal given is an Analog output

contaminated particles. Here one major equipment (AO) which is another IO.

exhaust system is selected to break into small

equipment such as a blower, suction side damper, SOFT IO PARAMETERS

discharge side damper, a motor driving the blower, a

starter for start stop control of the motor and air If the starter is taken it has some other important and

filtration system. In the same method all major process distinct equipment as a part of the system. A

has to be broken into smallest equipment and make a microprocessor based relay (µP) , a smart meter and

list all equipment. the control circuit. In the case shown the

microprocessor relay and smart meter has a

communicable device inbuilt and it can share data to a

third party system vide serial communication [7,p.34].

These devices sometimes available in form of IOT

devices [6, p.65] also. In microprocessor based relay

the protection setting is required to be monitored from

a SCADA system and hence the parameters will be a

soft IO parameters.

Fig 4: An Utility Plant Services system broken into

small equipment

CALCULATION OF IO

As we have broken to the process into small equipment

Fig 5: Breaking into IO Parameters

the next step is to calculate the no of input and output

The protection system may be required to change from

parameters (IO). An input parameter is used to read the

SCADA and hence control of the setting also are soft

status of a system where as output parameter is to

IO parameters. Similar is the case of a smart meter

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 76

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

where Voltage, current and power is required to be other process. Only a part of the process may be there.

monitored and hence they will be a part of the soft IO In Fig 6 exhaust blower one part is in RIO1 whereas

parameter. As in meter there is nothing to controlled the remaining part is RIO2.

hence no control function is listed for the matter.

DIGITAL INPUT AND OUTPUT PARAMETERS

In the starter control circuit there are contactor and

relays which gives status of the motor whether running

or tripped. Hence for the list of parameters to be

monitored are ON Status, Trip Status, Status of

Local/Remote hardware selector switch status. This Fig 6: Constructing a Local RIO for IOs located in

information is digital and hence these are Digital input same geographic location

(DI) parameters. Start and stop command to the blower In RIO1 there are other equipment pertaining to Once

is given through the starter and hence start and stop through ventilation system as well other common

will be the control parameter and are Digital output process also. Similar is the case of RIO2. Thus IOs are

(DO) parameters as these are discrete in value. The segregated into various RIO not in form of functional

blower may be required to keep in auto and manual groups but in form of geographical distribution.

mode but there is no hardware button required for auto

and manual. It can be set from the SCADA or PLC MAIN COMPONENTS OF RIO

program and hence these will be soft IO parameters

discrete in nature. As per the type of IOs used four cards are used in the

RIO for connecting to field equipment and these are

CAPACITY OF AUTOMATION DI Module, DO Module, AI module and AO Module.

If there are soft IO devices available serial network

The parameters have been divided into DI, DO, AI, card is required and a module for appropriate serial

AO and soft IO parameter. The way explained above communication is required. If the soft IOs are of IOT

needs to be applied for all the process and a total of all based and support TCP/IP communication [7, p.14] a

the parameters will be the basis of selection for all the TCP/IP card would be necessary. The data from the

automation equipment. RIO is sent to PLC with the help of Co-processor

where all digital data is processed and converted into

RIO a digital and communication platform. The most

widely used communication platform is Ethernet

An RIO as already discussed is a remote input output communication [3, p.112] works on TCP/IP protocol

module which is in form of a panel. If there are large although there are various other methods available and

no of IOs distributed over a large area, it is divided into it may be consulted with the respective vendor for the

various RIO. availability. All these cards are housed in a slotted

electronic card based plane which is called back plane.

CONSTRUCTION OF A LOCAL RIO A power supply card is required for the backplane as

well as for specific cards. Fig 7 shows the various

It is very important to note that IOs are geographically cards housed in a backplane. The quantity of each type

scattered in very large areas. Hence RIOs are used. It of card will depend on the no of IO and channel

is basically a part of PLC distributed in various density [4] used for the particular card.

location. Only the logic part is in PLC. This helps to

save wire and has other advantages also and breaking

into smaller RIO is a standard practice in distributed

IO. We need to geographically separate the IOs and

make cluster. In each area total no of different types of

IOs needs to be calculated. It may be from various

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 77

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

Fig 7: Various Components and their mounting in an different rack. If multiple racks are chosen then it is

RIO called backplane redundancy This is to be noted that

complicacy in program increases as we go on adding

OTHER COMPONENTS INSIDE AN RIO multiple IO cards. Other redundancy does not have

much involvement in programming.

Other components used in RIO panel are relays for

isolation of field equipment from PLC, SMPS for RIO TO PLC CONNECTION

providing power to Analog module, cooling fan for

cooling of the panel components, fuses for channel In a plant or in a control system there might be a

protection. number of RIO and a PLC and SCADA. Connection

of RIO to PLC is in a network. This network can be

star or ring or bus or a combination of them [1, p.357].

This may be noted that based on the component we

select the corresponding networking card type will get

changed.

SELECTION OF PLC

There are huge number of PLC available in market and

the interesting part is that most of them are capable to

carry out a majority of the functions normally used in

the control system. Basic selection will be dependent

on no of IO handling capacity. However as we go on

adding features as per other requirements which are

also important the PLC becomes more advanced.

Programming becomes easier when software supports

real text based IO parameter names. Online changes

possible [1, p.199] on higher version is selected.

Remote connection, maintenance, downloading

capability, local display etc are available in far more

advanced version. If safety and security aspects are

required in depth further higher version required. As

features are added price also increases. So an

Fig 8: Various Components inside an RIO awareness of these functionality and their use is

required. Fig 8 shows that the price increases as the

REDUNDANCY IN RIO features are added.

If we want our control system not to be dependent on

a specific equipment some commonly available

redundancy needs to be considered. Available

redundancies are power level redundancy where

multiple power supply cards is used. Communication

level redundancy used by providing multiple

communication cards as well as considering some

other aspects in the network design Card redundancy

to perform same task with two card. Say we are

measuring static pressure. It can be measured by two Fig 9: Selection of PLC with various advanced

instruments giving feedback to two separate IO card. features

If multiple cards like power, communication and IO

cards are used they can be placed in same rack or in COMPONENTS OF A STANDARD PLC RACK

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 78

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

In a standard PLC rack main PLC controller is kept in 800 nos of DI shall be 3200. IED are intelligent

backplane along with network card for scanning of IOs devices [6, p.19] and each device may contain a large

from RIO panels and another network card for no of data. Consider a smart meter where three phase

communication with SCADA system. Power supply Voltage, current and power is monitored and is used

card is required as usual for any backplane and hence for SCADA system. The no of data used in each

for the PLC rack also. However as there is no IO system and the useful data may really vary in different

capacity of power supply card may be chosen less. system. In the figure average 10 useful data is

considered and for each data 5 tags are considered. In

this method total no of tags shall be calculated and

some spare tags of 10 to 20% must be kept.

Fig 10: Components of a PLC Rack

REDUNDANCY IN PLC PART

Similar power, communication redundancy is

available for the PLC panel also. Interesting part is Fig 11: SCADA Tag Calculation

controller redundancy. Here two controller stays in

synch mode with a fibre optics or cat-6 connection. SCADA SYSTEM LICENSE

These two controllers can be in same panel, separate

panel or at two different building also. While using SCADA software licenses are available in different

power and communication redundancy source of form. A SCADA system require a server and a client.

power to the PLC can be taken from independent The server is called an IO Server. Server licenses are

sources to make it further independent of the source available in limited or unlimited license form. Control

availability. client license are also available in tag based but it may

be a static license where the USB dongle is locally kept

SCADA TAG CALCULATION on the client computer. A floating license means the

client station will be authorised from server and no

Capacity of SCADA system is expressed in terms of separate hardware will be attached. Other license are

SCADA tag. Tags are various variables directly view only client which is only for viewing , web view

linked and used in PLC as well as in graphical only client which is only viewing from an web browser

interface of SCADA. Let us take an example of a tank and web control client which is control and view from

level which is sensed by an AI module and the sensor an web browser based application.

is used for automatic pumping for a level control. This

data is received in voltage or current form and digitally HISTORIAN SERVER SELECTION

converted in the range of 10000 depending upon the

type of ADC [4] used in the AI module. It require a Historian server is used for generating a report and

variable to use in SCADA and hence will be one tag. storing old statistical data as well as carrying out

Now we need scaling variable for low- and high-level analysis. Its license is also available in tag form. We

scaling. We need set points variable for low, high level need not consider all the data or tags for the reports.

alarm, set points for auto pumping ON and OFF. On For a 15000 tag based SCADA it may happen that only

an average 15 variables may be required to use in 3000 data is required for the report and storage. So

SCADA and hence 15 tags on average can be taken for Historian will be for 3000 tags only.

SCADA tag calculation. In the same way depending In the example given in Fig 12 Exhaust blower all

upon the use of the DI, DO, AI, AO no of tags shall be SCADA data is shown. However only 5 data is

considered. In the Figure 11 for each DI total 4 nos of required for the report as balance data is not so

tags is considered for each DI and total no of tags for important for checking historical records

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 79

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

available other methods[15]. A control client can be

used in multiple and each device can be provided

communication redundancy if IPC is used. Power

redundancy requires additional hardware as it is

normally not available in COTS [16] products.

Redundancy in historian server level is available but

not very common to use.

Fig 12: Historian Tag selection example

HARDWARE COMPONENTS OF SCADA

Hardware components of SCADA means various

types of computers. Commercial PC is preferable only Fig 14: Various Redundancy in SCADA system

for viewing station of web view stations. For SCADA

client station touch screen industrial PC is the OTHER COMPONENTS IN SCADA SYSTEM

preferred one. Higher grade windows PC are used for

the IO server application although Server grade PC is Other components of automation systems are various

mostly preferable for historian and SCADA IO server. types of cables and networking components, sensors,

Fig 13 shows different types of PC and their uses in transmitters etc. as shown in Fig 15. These

SCADA systems components are also equally important and a good

design require proper selection of these components

also.

Fig 15 Other Components of SCADA system

Fig 13: Use of Computers in SCADA system

SECURITY ASPECTS

REDUNDANCY IN SCADA

Security and safety aspect is vast topic. Security means

mostly cyber security for the networking components

Redundancy is available in SCADA system also. Fig

and the computer-based systems such as SCADA,

14 shows various redundancy available in SCADA. IO

PLC, RIO etc [6, p.15]. Many components of the

Server can be used in hot standby configuration. In

automation system are connected in a network. Some

each device level hardware level redundancy is given

components are computer-based system. Those needs

in form of power and communication level. With a

to protected for unauthorised access, malicious

server grade PC of very high configuration power and

software etc. especially when the application is of

communication redundancy option is available

although it can be made externally also by commonly

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 80

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

critical nature. Following are few major security SAFETY ASPECTS

threats

(a) Operating system of the SCADA station gets Safety issues arises when the components failed

corrupted. Malicious software is supressing prematurely leading to unsafe incidents. Therefore,

various alarms. As a result of that operator will redundancy is considered as discussed in each section.

not come to know about the abnormality. However, redundancy in field equipment level also

(b) PLC and RIO logics are once developed does not required. As we require more safety more number and

require any maintenance. If it is accessed by level of redundancy would be required. An index

unauthorised person logic can be deliberately called safety Integrity Level [9, p.8] is used

changed resulting in unsafe situation. automation system for assessing the amount of safety

(c) As a result of attack on the automation required to be considered. This index is determined

components wrong information are displayed and both by quantitative and qualitative analysis of any

based on that operator may take wrong action process control. Commonly used techniques are fault

(d) Malicious Software infection causes force tree analysis, consequence analysis, likelihood

shutdown of the complete control system analysis, event tree analysis, Layer of protection

(e) In chemical industry important recipe is written analysis (LOPA) Based on safety requirement

on the logic which may be stolen by attacker as a selection of components gets changed. A power

result of cyber-attack. This information are supply module part number will get changed when it

intellectual property of the respective industry is redundant type although of same rating. Similarly

owner. the backplane, network module, IO cards will get

changed when those are redundant type or with

COUNTER MEASURES NEEDED FOR specific safety integrity level.

SECURITY THREATS

IMPLEMENTATION AND COMMISSIONING

All computer-based stations should have updated

antivirus. Plugging of portable USB device must be Once the design of the scheme and selection of the

restricted. PLC and RIO should be kept in a separate components are done detailed specification is made

network. Which is isolated from any business network and components are procured. PLC, RIO panels are

or internet. If the data needs to be shared in the taken up for fabrication and assembling the

internet it should be through multiple firewall. Even components. Meanwhile a logic document is required

though the systems are isolated from internet it may to be prepared so that a programmer can refer them

happen that through removable storage device and make the program independently. This is called

malicious software gets injected in the whole control process control logic document (PCLD) which

system. Additional pre-caution needs to be taken consists of overall process, equipment and parameters

during firmware upgradation process Remote access is involved with each process, list of set points, details of

often allowed for PLC for getting support from vendor various modes of operation, special requirements of

over internet. It opens up a path for the hacker. Hence interlocks and safety. On getting the PCLD

remote access should be avoided. Common network programmer starts developing PLC logic and SCADA

security features are available with major components programmer stars developing graphics in SCADA

however smart field devices sometimes lag security screen. In parallel to this activity cabling at site is

features. Again as higher version networking done. Once the PLC and RIO panels are ready it is

components are selected more layer [8, p.22] of important to check all input outputs terminals. PLC

security will be available. But most important is program and SCADA program developed are required

awareness about the security events and threats by all to be vetted in simulation. In this a big logic is tested

users of the SCADA station. Internal threats due to in small parts. Once logic is checked it is downloaded

disgruntled employee of the same organization is also in PLC. PLC and RIOs are installed at site and all field

a potential threat which should be combat with access terminals are connected. A process may have multiple

control with multiple layers. individual equipment controlled by many sub

equipment. During commissioning process each of the

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 81

© September 2021| IJIRT | Volume 8 Issue 4 | ISSN: 2349-6002

small equipment are tested with PLC logic. It may be [5] Industrial Automation Hands ON, Frank Lamb,

found that logic is required to be changed multiple McgrawHillEducation,

times during this process. After all individual [6] Cyber-security of SCADA and Other Industrial

equipment are tested the overall process is checked. Control Systems, Edward J. M. Colbert

Again during this stage logic may be required to Alexander Kott, Volume 63,

change further. Once the functionality of the overall [7] How to Plan, Install, and MaintainTCP/IP

system is checked it is tested for various abnormal Ethernet Networks: The BasicReference Guide

conditions. System should not develop unsafe for Automation andProcess Control Engineers,

incidents in none of the abnormal situation. PLC logic Perry S. Marshalland John S. Rinaldi, ISA 2004

and hardware connections must ensure it. [8] Industrial Network Security, Securing Critical

Infrastructures for smart Grid , SCADA and other

CONCLUSION Industrial Control Systems, Eric Knapp, James

Broad, Elsevier

The article explains how capacity of required [9] Safety Integrity Level Selection, Systematic

automation system can be worked out from a list of Methods Including Layer of Protection Analysis,

available process and equipment. Once capacity of Edward M. Marszal, P.E., C.F.S.E. Dr. Eric W.

automation system is obtained it is very simple to Scharpf, MIPENZ, ISA

select rest of the components. With this knowledge a

plant owner may design his own automation system

and directly consult a system integrator for

procurement and do not miss out any important aspect.

The techniques can be employed for small system

containing 5 to 10 equipment’s as well as for large

systems also. The method is same for any process. The

safety and security aspect will get changed depending

upon the criticality and vulnerability of the system.The

article is expected to be helpful for many people who

wants to put PLC and SCADA based automation for

their plant. The article has covered only the design

part. During execution of the project lot of challenges

are faced due to lack understanding of the process

required and actual logic made by a programmer. In

this paper execution and implementation part is not

discussed in details. In future a document will be made

which covers a simple method to write a logic

document of a very complex process.

REFERENCE

[1] Introduction to Industrial Automation,

StamatiosManesis, George Nikolakopolous,

[2] SCADA: Supervisory Control and Data

Acquisition , Stuart A. Boyer, ISA, 2004

[3] Understanding TCP/IP: A clear and

comprehensive guide to TCP/IP protocols, Libor

Dostalek Alena Kabelova, Packet Publishing.

[4] Industrial Digital IO Design Guide, WWW.

Maximintegrated.com

IJIRT 152687 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 82

View publication stats

You might also like

- Scada SRSDocument11 pagesScada SRSRana WaqasNo ratings yet

- Core Java Career Essentials PDFDocument542 pagesCore Java Career Essentials PDFNAGENDRA PRASADNo ratings yet

- BILL GATES PresentationDocument7 pagesBILL GATES PresentationNaz ッ WanyNo ratings yet

- Test: Section 1 QuizDocument70 pagesTest: Section 1 QuizMihaelaIlieNo ratings yet

- July Univ - 375Document7 pagesJuly Univ - 375Nils BickelNo ratings yet

- Scada PaperDocument6 pagesScada PaperhafizgNo ratings yet

- Temperature Sensor Interfacing With Embedded PLCDocument5 pagesTemperature Sensor Interfacing With Embedded PLCInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Networking Programmable Logic Controllers: Pneumatic Cylinder Modelling and ControlDocument12 pagesNetworking Programmable Logic Controllers: Pneumatic Cylinder Modelling and Controlquangvu16No ratings yet

- Final ReportDocument124 pagesFinal ReportNishant SinhaNo ratings yet

- PLC and Scada Based Distribution and Substation AutomationDocument4 pagesPLC and Scada Based Distribution and Substation AutomationMohammed IliazNo ratings yet

- Design and Simulation of Remote Monitoring of The Intelligent Automatic Control System in The Production LineDocument10 pagesDesign and Simulation of Remote Monitoring of The Intelligent Automatic Control System in The Production LineIAES IJAINo ratings yet

- Simulation and Implementation of PLC Based For Detecting Burned Potato Chips and Remove Using PLCSIM and HMIDocument6 pagesSimulation and Implementation of PLC Based For Detecting Burned Potato Chips and Remove Using PLCSIM and HMIEditor IJTSRDNo ratings yet

- Design of A SCADA Graphical User Interface For An Industrial ProcessDocument5 pagesDesign of A SCADA Graphical User Interface For An Industrial ProcessvighneshNo ratings yet

- Scada ReportDocument15 pagesScada ReportmadhulavNo ratings yet

- Supervisory Control and Data Acquisition (SCADA) : July 2017Document24 pagesSupervisory Control and Data Acquisition (SCADA) : July 2017Royal Ritesh SharmaNo ratings yet

- Scada ReportDocument26 pagesScada Reportkiswah computers100% (1)

- SCADA - Topic - 1 - Updated (Background To SCADA)Document33 pagesSCADA - Topic - 1 - Updated (Background To SCADA)Fazil Məmmədli100% (1)

- Scada PDFDocument3 pagesScada PDFJasmine Athifa AzzahraNo ratings yet

- Scada Based Power Control System Using PLC: Mrs Bhavna Pancholi, Damor Mehul ManubhaiDocument3 pagesScada Based Power Control System Using PLC: Mrs Bhavna Pancholi, Damor Mehul ManubhaiYihenew MengistNo ratings yet

- Seminar ON Scada & PLCDocument38 pagesSeminar ON Scada & PLCVikas ChoudharyNo ratings yet

- Analyzing An OT Network, What To ExpectDocument6 pagesAnalyzing An OT Network, What To ExpectRodrigo José SouzaNo ratings yet

- Electrical Equipment Operation and Maintenance: Main Functions of SCADADocument4 pagesElectrical Equipment Operation and Maintenance: Main Functions of SCADAkingjam dimacaling2019No ratings yet

- Intership (PLC&SCADA)Document24 pagesIntership (PLC&SCADA)rahulmeenameenarahul26No ratings yet

- National Institute of Technology, Kurukshetra Haryana: Submitted To Submitted byDocument31 pagesNational Institute of Technology, Kurukshetra Haryana: Submitted To Submitted byÄkshãy SaçhånNo ratings yet

- SCADA System Architecture, Types and ApplicationsDocument21 pagesSCADA System Architecture, Types and ApplicationsVidya SisaleNo ratings yet

- PLC Scada Training ReportDocument31 pagesPLC Scada Training ReportÄkshãy SaçhånNo ratings yet

- Home Automation Using PLC and ScadaDocument28 pagesHome Automation Using PLC and Scada544D GamingNo ratings yet

- SCADA, DCS, PLC, RTU & Smart Instrumentation Terminology DefinedDocument14 pagesSCADA, DCS, PLC, RTU & Smart Instrumentation Terminology Definedkvrao44No ratings yet

- Scada SystemDocument23 pagesScada SystemMazen Al-mahbashiNo ratings yet

- Sarang R. Deshmukh Je T.P.S. Paras K53, KTC KoradiDocument34 pagesSarang R. Deshmukh Je T.P.S. Paras K53, KTC KoradiVikrant OkeNo ratings yet

- JETIR2206863Document7 pagesJETIR2206863Kishore MNo ratings yet

- PLC m5Document14 pagesPLC m5Goutham KNo ratings yet

- Training Report: Bachelor of TechnologyDocument46 pagesTraining Report: Bachelor of TechnologyHelloprojectNo ratings yet

- Chapter 2Document68 pagesChapter 2Niño AntoninoNo ratings yet

- Lec#02 Intro To Programmable Logic ControllerDocument12 pagesLec#02 Intro To Programmable Logic Controllermido AANo ratings yet

- Scada System - MohammedDocument23 pagesScada System - MohammedMazen Al-mahbashiNo ratings yet

- Introduction To PLCDocument59 pagesIntroduction To PLCAbdisa BegnaNo ratings yet

- Ayman Habib (207) AssignmentDocument12 pagesAyman Habib (207) AssignmentSiKandar AKbar100% (1)

- The PLC Based Approach For Automation of Power Distribution in RadarDocument6 pagesThe PLC Based Approach For Automation of Power Distribution in RadarKhaled OuniNo ratings yet

- SCADADocument11 pagesSCADApaluru sandeepNo ratings yet

- Summer Training Report On PLC and Scada11Document31 pagesSummer Training Report On PLC and Scada11Sahil SamotraNo ratings yet

- Rohit ReportDocument37 pagesRohit ReportRohitNo ratings yet

- 563 2046 1 PB PDFDocument11 pages563 2046 1 PB PDFWaleed AliNo ratings yet

- ScadaDocument13 pagesScadamdayyub50% (6)

- Voice Controlled Wheel ChairDocument48 pagesVoice Controlled Wheel ChairAjith manjuNo ratings yet

- Five Terms You MUST Be Familiar With SCADA, DCS, PLC, RTU and Smart Instrument EEPDocument1 pageFive Terms You MUST Be Familiar With SCADA, DCS, PLC, RTU and Smart Instrument EEPwahbaabassNo ratings yet

- Scada PLC HmiDocument4 pagesScada PLC HmiM. S. ChikkamaniNo ratings yet

- Programmable Logic Controller (PLC) : The Structure and Features of Programmable LogiccontrollerDocument6 pagesProgrammable Logic Controller (PLC) : The Structure and Features of Programmable LogiccontrollerSaad AliKhanNo ratings yet

- Application of Industrial PLC For Controlling Intelligent Traffic LightsDocument4 pagesApplication of Industrial PLC For Controlling Intelligent Traffic LightsAFAFNo ratings yet

- PLC ScadaDocument4 pagesPLC ScadaRajeshNo ratings yet

- Automation of Conveyor Using PLC PDFDocument4 pagesAutomation of Conveyor Using PLC PDFchinnavenkateswarluNo ratings yet

- Dokumen - Tips - PLC and Scada Summer Training Report Government Engineering College Ajmer PDFDocument41 pagesDokumen - Tips - PLC and Scada Summer Training Report Government Engineering College Ajmer PDFNaresh VermaNo ratings yet

- Unit1 2Document30 pagesUnit1 2CHETAN SETIYANo ratings yet

- PLC and SCADA TrainingDocument60 pagesPLC and SCADA Trainingdeepak_297No ratings yet

- PLCDocument39 pagesPLCVishwadhar ShreedharNo ratings yet

- PLC Programming: Jhon Achury Vega 20615Document5 pagesPLC Programming: Jhon Achury Vega 20615jhon achury vegaNo ratings yet

- PLC Unit 5 PDFDocument19 pagesPLC Unit 5 PDFMahesh Shende100% (1)

- 09 1361685115 Initial Face of AutomationDocument13 pages09 1361685115 Initial Face of AutomationMohammed SelmanNo ratings yet

- Automation of Ac System Employing PLC and ScadaDocument10 pagesAutomation of Ac System Employing PLC and Scadaeyob feshaNo ratings yet

- 1634 PAC White Paper PDFDocument6 pages1634 PAC White Paper PDFLoganathan KrishnanNo ratings yet

- Assignment 4Document12 pagesAssignment 4SiKandar AKbarNo ratings yet

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- 31 Icest2015 Scada Nar enDocument10 pages31 Icest2015 Scada Nar enbitseee RandDNo ratings yet

- Speed Control of DC Motor Using PID andDocument5 pagesSpeed Control of DC Motor Using PID andbitseee RandDNo ratings yet

- Arc Fab Lab Cts Submission FormDocument1 pageArc Fab Lab Cts Submission Formbitseee RandDNo ratings yet

- 19ges20 - Renewable Energy SourcesDocument49 pages19ges20 - Renewable Energy Sourcesbitseee RandDNo ratings yet

- Kems821 Lecture 02Document31 pagesKems821 Lecture 02bitseee RandDNo ratings yet

- Industrial Automation and ControlDocument215 pagesIndustrial Automation and ControlPradhunya KambleNo ratings yet

- MD-46 en Brochure - FOCUS-ONDocument8 pagesMD-46 en Brochure - FOCUS-ONAndrew XuguomingNo ratings yet

- Exercise 2 RequirementsDocument4 pagesExercise 2 RequirementsKarthik V KalyaniNo ratings yet

- Flash Memory TestingDocument75 pagesFlash Memory Testinggreentea601No ratings yet

- Calix 844G UserGuideDocument113 pagesCalix 844G UserGuideRobert FitzgeraldNo ratings yet

- Fix For BSODDocument8 pagesFix For BSODComan IulianNo ratings yet

- Visual C++ Optimization With Assembly CodeDocument357 pagesVisual C++ Optimization With Assembly CodeLuke Hanscom100% (1)

- V.Kannan E-Mail Id: Mobile:: BvckupDocument3 pagesV.Kannan E-Mail Id: Mobile:: Bvckupkarthi_kuttyNo ratings yet

- XVR5232AN-I3 Datasheet 20230113Document3 pagesXVR5232AN-I3 Datasheet 20230113juan g perezNo ratings yet

- S1d15200doa or EquivalentDocument10 pagesS1d15200doa or EquivalentArduinoBeto RojasNo ratings yet

- Input and Output DevicesDocument13 pagesInput and Output DevicesSaksham JainNo ratings yet

- 21 01 2022 07 08 50 NetDocument44 pages21 01 2022 07 08 50 NetAlarcón Cruz Miguel ÁngelNo ratings yet

- PM-02 06 Time ConfirmationDocument4 pagesPM-02 06 Time ConfirmationNeeraj GuptaNo ratings yet

- WL0F00043000WGAAASA00Document9 pagesWL0F00043000WGAAASA00Vegard SømliøyNo ratings yet

- CR Touch Firmware Version For 32-Bit MotherboardDocument1 pageCR Touch Firmware Version For 32-Bit MotherboardAlex111carreto alonsoNo ratings yet

- Graphics and Multimedia Question Bank With AnswerDocument21 pagesGraphics and Multimedia Question Bank With AnswerSaira KhanNo ratings yet

- How To Send Text Messages With PHP - Envato Tuts+Document20 pagesHow To Send Text Messages With PHP - Envato Tuts+All In OneNo ratings yet

- Exercise 1 (Openmp-I)Document10 pagesExercise 1 (Openmp-I)Dhruv SakhujaNo ratings yet

- Citra Log - Txt.oldDocument12 pagesCitra Log - Txt.oldGlenn SoriaNo ratings yet

- HA033270 - 2 EPC2000 - Controller - Data - SheetDocument8 pagesHA033270 - 2 EPC2000 - Controller - Data - SheetRavi Kant GuptaNo ratings yet

- FAQ On MSI Packaging and RepackagingDocument15 pagesFAQ On MSI Packaging and RepackagingTanmaya Ranjan SwainNo ratings yet

- AlgolDocument3 pagesAlgolTaniya FaisalNo ratings yet

- Ripley's Believe It or Not Manual Ripley's Believe It or - Stern Pinball (PDFDrive)Document191 pagesRipley's Believe It or Not Manual Ripley's Believe It or - Stern Pinball (PDFDrive)ReggieNo ratings yet

- Floating Point: Adders and MultipliersDocument45 pagesFloating Point: Adders and Multipliers2243501No ratings yet

- Firmware Manual Internal PDFDocument190 pagesFirmware Manual Internal PDFPrasanna Kumar VilluriNo ratings yet

- CMPSB Instruction in Assembly Language of 8086 MicroprocessorDocument6 pagesCMPSB Instruction in Assembly Language of 8086 MicroprocessorJanna Tammar Al-WardNo ratings yet

- I-V Characteristics of Diode-Final-RUBEL MIA-5096190105Document12 pagesI-V Characteristics of Diode-Final-RUBEL MIA-5096190105Md Rubel hosainNo ratings yet