0% found this document useful (0 votes)

2K views14 pagesGin Wheel

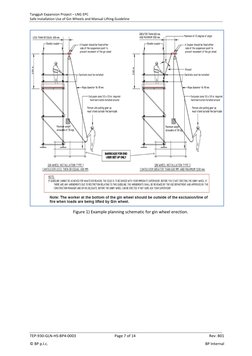

This document provides guidance for planning, assessing, supervising, and conducting safe manual lifting and material hoisting activities using gin wheels and ropes. It establishes a hierarchy of lifting methods and outlines roles and responsibilities. Standards and cross references are also included.

Uploaded by

ANDREYCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views14 pagesGin Wheel

This document provides guidance for planning, assessing, supervising, and conducting safe manual lifting and material hoisting activities using gin wheels and ropes. It establishes a hierarchy of lifting methods and outlines roles and responsibilities. Standards and cross references are also included.

Uploaded by

ANDREYCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd