Professional Documents

Culture Documents

Hydractive1 Fault Finding

Uploaded by

Jovan GavrilovićOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

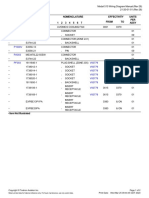

Available Formats

Hydractive1 Fault Finding

Uploaded by

Jovan GavrilovićCopyright:

Available Formats

A Level Three Diagnostic on an XM.

Written by : John Davidson Published in : The Citronian (Journal of the UK Citron Club) August 1996 With apologies to Star Trek and the crew of the Starship Enterprise it would be nice to diagnose faults on our XMs by simply pointing a Tri-corder and reading the fault condition, but back here in the Twentieth Century we have to do it the hard way. I thought, therefore, that I would share my findings on the fault generally found on the Hydractive suspension of our early cars, where the suspension is stuck in SPORTS mode, either intermittently or permanently. I am not setting myself up as any sort of expert but merely pointing out a few things that I have discovered trying to find a solution to the problem on my own car. A broad understanding of the system is necessary and to this end my thanks must go to that Guru of the North, Andy Burnett for his help and advice and to my local independent Citron speciatist Lee Rumney for the use of his publications. Needless to say the Citron dealers showed little interest and could offer no solution to the problem. The Hydractive system is quite brilliant and if working as designed makes the XM a superb, safe and comfortable car to drive. However when not working properly it has a very hard, rigid suspension that is akin to a high performance sports car. In the AUTO setting (selected by the driver) the soft suspension is normal but can change rapidly to the SPORT mode, maintaining optimum roadholding and safety. In addition there is an anti-jolt function which prevents the car vertically jumping due to an imbalance of pressure in the hydraulic system when the ignition is switched off. The main component of the system is the Electronic Control Unit (ECU) which lies in the black plastic box on the offside front wing. Other boxes and the odd relay can be found there but the Hydractive ECU can be identified by two 15-pin plugs and sockets, one black and one white. Five sensors feed information to the ECU and depending on that information will result in the ECO supplying (or not) a voltage to the electrovalve which is the interface between the electronics and the hydraulics. There is also an output for Citron's Fault Code Reader (ELIT). The five sensors, the electrovalve and their functions are as follows: Steering (Primary) Pedal Travel (Primary) Located below the steering wheel. Detects rapid movement of the wheel, e.g. swerving to avoid something Attached to the accelerator pedal. Detects rapid acceleration, e.g. flooring the pedal.

Body Movement Located externally below the driver's footwell and (Secondary) connected by linkage to the anti-roll bar. Detects movement of the bodyshell, e.g. going over a hump-backed bridge. Brake (Secondary). Located on left hand front sub-frame. Detects hard braking

When operated any of the above sensors will cause a suspension change from AUTO to SPORT almost instantaneously. Speed (Primary) Located at the lower end of the speedometer cable where it connects to the gearbox, Will switch the suspension to AUTO when the speed drops below 18 mph. In this condition all other sensors are inoperative. Located externally below the driver's floor to the rear of the body sensor. When energised from the ECU the valve will direct hydraulic fluid to the two additional spheres located beneath the car front and rear. This condition will result in the suspension being in 'soft'

Electrovalve (Primary)

(AUTO) mode. De-energising of the valve results in the electrovalve closing, isolating the additional spheres and the suspension reverts to the 'stiff' (SPORT) mode. If a fault condition occurs in a primary sensor the suspension is forced to operate in the SPORT mode but a fault in a secondary sensor will not affect the mode. However in all instances the fault is recorded by the ECU and can be read as a fault code by the ELIT equipment. As for fault finding, it can be seen that specialised test equipment is certainly necessary but in my car, when it was tested with ELIT and no fault was found, the mechanic admitted there was a fault but probably the test equipment was wrong or that all my spheres required checking. Complicated the system may appear to be but with care, a few reasonably simple checks can be made by a competent owner. They are listed below in order of progression. 1) Remove and check fuses F34 (+) and F19 (IGN). Leave them out for the following checks. 2) Check earth connections on offside front wing. If they are the multi-terminal block type change them to well secured crimped or soldered eye connectors and connect them directly to the earth post with a spring/serrated washer interspersed between the terminals and the nut. There are only three cables, contained in a separate loom, two Yellow and a Brown which concern the suspension but modifying the rest makes good sense to avoid future problems. 3) Disconnect the seven-pin black connector situated near to the offside front sphere and examine and clean any deposits/verdigris from the terminals (I find a fibreglass brush very handy for this). Pay particular attention to this task as the power supply to the electrovalve (Pin 6) and its earth return (Pin 7) is routed through this connector. Pin 1 is the power supply to the brake sensor with its earth return via the thin brown wire connected to the electrovalve. The others, Pins 2, 3, 4 and 5 are all connected to the body sensor with Pin 3 the power supply direct from Fuse 19. 4) Disconnect the white two-pin connector situated below the nearside sphere. This is the feed and return to the speed sensor with an additional white connector well down at the back of the engine where the speedometer enters the gearbox. Repeat the cleaning of the terminals as detailed above. 5) The brake sensor can be found by removing the cover in the nearside wheelarch (four plastic fixings) after turning the steering to full left lock and setting the suspension on high to gain access. There is a blue two-pin connector which should be treated like the others. 6) The two sensors inside the car are the steering, five-pin green connector and the accelerator pedal travel, three-pin white connector and both can be found after removing the trim panel below the steering wheel and the metal tray (two bolts). It is doubtful if corrosion will be a problem here but the connections will benefit from a clean-up. 7) The two most inaccessible components are the body movement sensor and the electrovalve itself. Ideally a pit or ramp should be used but if the car is properly jacked and supported then the work can commence. Remember, NEVER GO UNDER A VEHICLE THAT IS SUPPORTED ONLY BY HYDRAULIC PRESSURE. The body sensor has a brown five-pin connector and should be treated as the rest but in addition check to see if the operating arm and its linkage is free to move. The electrovalve two-pin brown connector has three cables, two yellow and a thin brown. The brown and its associated yellow goes to earth on the front offside wing. 8) In the ECU housing remove (press the wire clips) the black and white fifteen-pin plugs and examine the connections. Clean if necessary. At this stage it might be advisable to carefully remove the ECU to establish the system you have on the car as in the early models the Hl ECU had an external timer relay and diodes connected to the door and boot lid cover light switches that form part of the anti-jolt system. The timer relay is situated close to the ECU and its connector should be subjected to the same rigorous inspection. Be careful not to mistake the fuel injection relay for the timer relay. The H2 ECU has no external relay and has the diodes internally but the operation of the anti-jolt system is similar. 9) Ensure that all connectors are securely located and the fuses replaced.

10) Andy Burnett's suggestion of positioning a small indicating lamp in the car connected across the two large yellow cables of the Electrovalve is sound. This will enable the driver to monitor the system when driving, establishing when the various sensors operate. When AUTO is selected the rule is: Electrovalve energised (Lamp lit): Soft suspension. Electrovalve de-energised (Lamp out): Hard suspension. NOTE: This has nothing to do with the warning lamp on the dashboard. As a sensor operates the light should go out and if it fails to do so, that particular sensor and associated wiring is suspect. Unfortunately in my particular case no supply voltage is present at the Electrovalve at any time, therefore it can be assumed that my problem is either a sensor indicating to the ECU that the suspension should be in SPORT or there is an internal fault in the ECU. Those of you with a similar fault Kondition should not be tempted to connect the Electrovalve to a separate 12 Volt supply. As the valve operates around 5-6 Volts there is a danger of damage to the coil windings of the valve or even to the ECU itself. 11) Another check to make concerns the Selector Switch in the car. Carefully lift the centre console panel and remove the four-pin Brown connector from the back of the switch and bridge connections 3 and 4 with a short piece of cable. The other two connections 1 and 2 are for the illumination and are powered from the lighting switch. If the fault still persists we have now reached the stage where more aggressive fault finding must be done. For the owner who has a multi-meter and knows how to use it, checking the resistance values of the sensors whilst cleaning the connectors would make good sense and a continuity check of any doubtful cables should be made. Here are some of the sensor resistance values: Pedal travel 4k Ohms between pins 1 and 3 6-6.5k Ohms between pins 1 and 2 pedal up 2.6k Ohms between pins 1 and 2 pedal down Speed Brake pressure Electrovalve 300 Ohms 0 Ohms, engine running, pedal released Infinity, engine running, pedal depressed 3-5 Ohms.

The remaining sensors (Steering and Body movement) contain photo-diodes which can only be checked for correct operation by measuring the voltage from these devices with the system functioning. The problem is now more difficult because we lack the 'in-between box' (Citron 4109T connection box and cables). This box is fitted between the ECU plugs and sockets and allows the measurement of various voltages (using a multi-meter) with all the connections made and the system up and running. If it was possible to obtain the 15-pin plug and sockets it would be a relatively easy job to manufacture a simple version, unfortunately the alternative is to snip all the cables to the ECU plugs and insert strip connectors to measure voltages, etc. using the terminal screws as contacts for the meter !!! Drastic problems may require drastic actions. A friend of mine has suggested we remove the ECU, open it and look at every soldered joint with a magnifying glass hoping to spot a dry joint or a damaged component. My car, as it is at present is just not acceptable to me or my family and I will go to extreme lengths to return the car to the comfort we had when we bought the car in 1994 - even to the extent of dispensing with the SPORT mode altogether! I know the purists will condemn this action but this is not what I expect from a car of this calibre. Numerous people have said 'it's your spheres' but I think this is highly unlikely. Yes, I agree that low pressure in the spheres will result in a harder than normal suspension but selecting between AUTO and SPORT should result in some discernible difference to the suspension unless ALL the spheres are at zero pressure which is again highly unlikely. I do, however, think that all the owners with this problem will eventually find that there will be numerous causes and not one thing common to all cars. I hope that at least some of you will have found this article useful even though it does not offer a concrete remedy to this obscure XM fault. Please feel free to contact me with any feedback, suggestions or criticisms, because the greater the understanding the more chance we have of reaching a solution."

You might also like

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Passat 3c b6 Auto Hold DIYDocument34 pagesPassat 3c b6 Auto Hold DIYOctavian Gheorghiu86% (7)

- BMW 4HP22, 4HP24 Transmission No Upshift, Stuck in 1st Gear, Limp Mode Troubleshooting GuideDocument5 pagesBMW 4HP22, 4HP24 Transmission No Upshift, Stuck in 1st Gear, Limp Mode Troubleshooting GuidegoogleheadNo ratings yet

- Apexi Timer Installation GuideDocument4 pagesApexi Timer Installation GuideRayseanKangNo ratings yet

- KE Jetronic Diagnosis Eha, Pot Testing Etc.Document7 pagesKE Jetronic Diagnosis Eha, Pot Testing Etc.Csaba László100% (3)

- Pajero 4WD Flashing Light Fix and TroubleshootingDocument13 pagesPajero 4WD Flashing Light Fix and TroubleshootingAren MendozaNo ratings yet

- BMW v12 Using Oem Ecu'sDocument14 pagesBMW v12 Using Oem Ecu'sEngine Tuning UpNo ratings yet

- How To Replace An ABS Control UnitDocument53 pagesHow To Replace An ABS Control UnitاحمدميدوNo ratings yet

- Installation Manual: 12V & 24V ECU Series B-2Document8 pagesInstallation Manual: 12V & 24V ECU Series B-2Piotr GrzechnikNo ratings yet

- Oxygen Sensor Simulator - JumperDocument7 pagesOxygen Sensor Simulator - JumperBrianssrt4100% (2)

- Adding Cruise Control MK 1Document12 pagesAdding Cruise Control MK 1sebifuente100% (5)

- Wabco C Type - p38Document0 pagesWabco C Type - p38Richard Andrianjaka LuckyNo ratings yet

- Mondeo Alarm I Double LockDocument7 pagesMondeo Alarm I Double Lockkaliopa kaliopaNo ratings yet

- 3 Engine Management System 11 Engine Management System SensorsDocument14 pages3 Engine Management System 11 Engine Management System SensorsJoel's iPadNo ratings yet

- Acumen Install Guide Rev 1Document13 pagesAcumen Install Guide Rev 1api-3706381No ratings yet

- Techtalk Sep 2006Document1 pageTechtalk Sep 2006ภูเก็ต เป็นเกาะNo ratings yet

- EFIE Wideband O2 Installation & Operation GuideDocument11 pagesEFIE Wideband O2 Installation & Operation GuideDanilo SaldañaNo ratings yet

- Abs Mod I Troubleshooting Guide: No Special Diagnostic Tools Needed. For Trailers Built Between 2/28/98 and 2/28/01Document2 pagesAbs Mod I Troubleshooting Guide: No Special Diagnostic Tools Needed. For Trailers Built Between 2/28/98 and 2/28/01Eduardo AlvarezNo ratings yet

- AW 450 KwicknotesDocument36 pagesAW 450 KwicknotesNuman2100% (6)

- T1 Cam Trigger Instructions 1Document10 pagesT1 Cam Trigger Instructions 1Initial_BG100% (1)

- ECU Fault CodesDocument24 pagesECU Fault CodesmnbvqwertNo ratings yet

- Flyin' Miata piggy back ECU installation tuning guide for 1999-2004 MiatasDocument27 pagesFlyin' Miata piggy back ECU installation tuning guide for 1999-2004 MiatasclistingacctNo ratings yet

- Magicar: 1. Installation Tips & RecommendationsDocument12 pagesMagicar: 1. Installation Tips & RecommendationsAravnai DondogNo ratings yet

- Pajero 4WD flashing light fix guideDocument11 pagesPajero 4WD flashing light fix guidedaniel lacerdaNo ratings yet

- Abs HaldexDocument2 pagesAbs HaldexBom_Jovi_681No ratings yet

- Abs 4Document2 pagesAbs 4ภูเก็ต เป็นเกาะNo ratings yet

- Distribuidor Mopar 318Document17 pagesDistribuidor Mopar 318Lalo LeloNo ratings yet

- Installation of the On-Board computer Astra G MIDDocument5 pagesInstallation of the On-Board computer Astra G MIDSlaviša AleksićNo ratings yet

- S13 SR20 DETto Datsun Engine Harness InstallDocument3 pagesS13 SR20 DETto Datsun Engine Harness InstallSamuel MorenoNo ratings yet

- Opel Blink CodesDocument9 pagesOpel Blink CodesBabei Ionut-MihaiNo ratings yet

- DP6013 Jeep 1992-96 Rev 08292022Document10 pagesDP6013 Jeep 1992-96 Rev 08292022Eduar AcvdoNo ratings yet

- Bulldog Security SystemDocument14 pagesBulldog Security SystemphilipisaiaNo ratings yet

- Magicar 9000BDocument13 pagesMagicar 9000BDavid MartinNo ratings yet

- P38 SYSTEM _ABS,SRS,HEVAC,GEARBOX,HELLA CCDocument16 pagesP38 SYSTEM _ABS,SRS,HEVAC,GEARBOX,HELLA CCandrianjaka27No ratings yet

- TT 134Document2 pagesTT 134warbunnyNo ratings yet

- 68RFE Transmission Relearn ProcedureDocument17 pages68RFE Transmission Relearn ProcedureStewart Firearms100% (1)

- Installation Instructions for Intake Manifold Flap Control Motor Testing DeviceDocument8 pagesInstallation Instructions for Intake Manifold Flap Control Motor Testing DevicebruNo ratings yet

- Continental Workshop Manual Anti-Lock Brake Traction Control DiagnosisDocument43 pagesContinental Workshop Manual Anti-Lock Brake Traction Control DiagnosiskallatisNo ratings yet

- A604 CodesDocument10 pagesA604 CodesRod NelsonNo ratings yet

- Coduri Opel EroriDocument16 pagesCoduri Opel EroriOana AlexandraNo ratings yet

- EGR Diesel CircuitsDocument10 pagesEGR Diesel CircuitsMarcelo MonteroNo ratings yet

- MS3 PRO LS - 24x - User-Manual - 10-20-16Document23 pagesMS3 PRO LS - 24x - User-Manual - 10-20-16Matt HillenNo ratings yet

- Allison Lockup Switch Instructions 5-Spd v5Document8 pagesAllison Lockup Switch Instructions 5-Spd v5nikodjole100% (1)

- Riparazione EcmDocument17 pagesRiparazione Ecmjalvarez_385073No ratings yet

- O2 Sensor Simulator CircuitDocument4 pagesO2 Sensor Simulator CircuitTeddy Khant100% (1)

- GPX U01 InstallGuide enDocument3 pagesGPX U01 InstallGuide enDražen HorvatNo ratings yet

- 4x4 Flashing Lights PajeroDocument12 pages4x4 Flashing Lights PajeroTawanda NyakupindaNo ratings yet

- GMLAN Communication Issues, No Crank, Warning Lamps & More FixedDocument12 pagesGMLAN Communication Issues, No Crank, Warning Lamps & More Fixedأمجد راضي هادي /A1No ratings yet

- ABS (Anti-Lock Brake System)Document34 pagesABS (Anti-Lock Brake System)LiviaChirtopNo ratings yet

- BMW E34 5 Series 1988 V2b Electrical DDocument27 pagesBMW E34 5 Series 1988 V2b Electrical DLuke Lucas50% (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- A Through Zs of Learning to Drive, Accident Free!: Drivers HandbookFrom EverandA Through Zs of Learning to Drive, Accident Free!: Drivers HandbookNo ratings yet

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Toyota Trouble Code Info: 96 & Later Are OBD2 Systems and Require A ScantoolDocument8 pagesToyota Trouble Code Info: 96 & Later Are OBD2 Systems and Require A ScantoolCesar Vega100% (1)

- CS2106 Tutorial 8Document2 pagesCS2106 Tutorial 8weitsangNo ratings yet

- GE UNI24R DL control unit installation guideDocument16 pagesGE UNI24R DL control unit installation guideLuis Jesus100% (1)

- .625 DIA & HEX: Outline/Installation Drawing, MODEL 3100D24Document2 pages.625 DIA & HEX: Outline/Installation Drawing, MODEL 3100D24info5280No ratings yet

- 17mb18 4Document88 pages17mb18 4domisoftNo ratings yet

- SN 74 Aup 1 G 74Document38 pagesSN 74 Aup 1 G 74DaniNo ratings yet

- 8 Devendra Singh Kushwaha 1437 Review Article VSRDIJEEC March 2Document4 pages8 Devendra Singh Kushwaha 1437 Review Article VSRDIJEEC March 2satyasheels@gmail.comNo ratings yet

- MAX485 module titleDocument2 pagesMAX485 module titleBubai BhattacharyyaNo ratings yet

- Lab 09 - Power SuppliesDocument47 pagesLab 09 - Power SuppliescrackintheshatNo ratings yet

- Colombian Olympiad PhysicsDocument120 pagesColombian Olympiad Physicssanits591100% (8)

- Understanding the MIPS Processor PipelineDocument149 pagesUnderstanding the MIPS Processor Pipelineayylmao kekNo ratings yet

- Spectrum Analyzer Tutorial and BasicsDocument25 pagesSpectrum Analyzer Tutorial and BasicsAlamgir Kabir ShuvoNo ratings yet

- Seca 703s, 704s Scale - User ManualDocument19 pagesSeca 703s, 704s Scale - User ManualJack WhitenerNo ratings yet

- Commodore Magazine Vol-08-N06 1987 JunDocument132 pagesCommodore Magazine Vol-08-N06 1987 JunSteven DNo ratings yet

- RC Phase Shift OscillatorDocument25 pagesRC Phase Shift Oscillatorahmed omarNo ratings yet

- 23 Vidiyal-Mar11 PDFDocument20 pages23 Vidiyal-Mar11 PDFmicroteksaroNo ratings yet

- Datasheet 1273389 Gas Sensor Tgs 5042 Figaro Suitable For Gases Carbon Monoxide o X L 141 MM X 497 MMDocument12 pagesDatasheet 1273389 Gas Sensor Tgs 5042 Figaro Suitable For Gases Carbon Monoxide o X L 141 MM X 497 MMEngr Shahrukh SiddiquiNo ratings yet

- Chapter 21 Air Conditioning PDFDocument67 pagesChapter 21 Air Conditioning PDFIman GhNo ratings yet

- ICOM IC-80AD BrochureDocument4 pagesICOM IC-80AD Brochuregus289No ratings yet

- 150kV GIS and Underground Cable Installation ServicesDocument7 pages150kV GIS and Underground Cable Installation ServicesReinhard Jesaya SimbolonNo ratings yet

- PF-1D/AD-3: Service ManualDocument48 pagesPF-1D/AD-3: Service ManualMauricio Yamamoto PNo ratings yet

- PiC900 HardwareManual en-US Rev13Document508 pagesPiC900 HardwareManual en-US Rev13Ramon MariscalNo ratings yet

- Icom IC-T7H Instruction ManualDocument36 pagesIcom IC-T7H Instruction ManualYayok S. AnggoroNo ratings yet

- Introduction to Control SystemsDocument39 pagesIntroduction to Control SystemsJMNo ratings yet

- Symbol Electrical PDFDocument9 pagesSymbol Electrical PDFPhan VirakNo ratings yet

- Avr AnillosDocument4 pagesAvr AnillosEduardo VicoNo ratings yet

- Monitor LCD Samsung Gg15as 15as R 15L 15L R 15v 15v R 15e 15e RDocument43 pagesMonitor LCD Samsung Gg15as 15as R 15L 15L R 15v 15v R 15e 15e RvideosonNo ratings yet

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDocument10 pagesVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorNo ratings yet

- Carrier Billing in The Middle East North Africa - 2015 Market Report by FortumoDocument9 pagesCarrier Billing in The Middle East North Africa - 2015 Market Report by FortumoMuhammad SyarifuddinNo ratings yet

- LG 20LS5R Chassis LP68A PDFDocument30 pagesLG 20LS5R Chassis LP68A PDFPaulo SimõesNo ratings yet