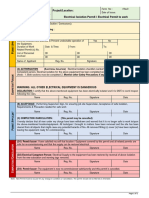

GTG-HSE-EXP-TEM-XXXX

ENERGY ISOLATION INSPECTION CHECKLIST

Inspector full name: Position: Date&Time:

Permit number: Location:

Description of job carried out:

Ite

General requirements YES NO NA

m

1 Before beginning the isolation, a risk assessment is carried out.

During job planning, an isolation plan is developed that identify all locations to be isolated, types of

2

isolating devices to be used and site/job-specific procedures for isolating the equipment.

All necessary isolation and blinding equipment/devices (locks, tags, properly rated blinds, etc.)

3

are made ready and inspected before commencing work

All forms of isolation (electrical, mechanical or otherwise) use the Lock/Hold Tag at every isolation

4

point.

Is the following information available on all tags: 1. The nature of the work 2. Plant number/location.

5

3. Date and time of lockout. 4. the individual who installed the isolation device.

6 Are the keys returned to a specific key box? (PTW office).

7 Isolation is done through the use of isolation certificates, attached to a work permit.

Ite

Process/Mechanical isolation requirements YES NO NA

m

Piping or equipment is isolated and/or blinded and the contents drained, vented or purged before

1

work is performed.

2 The levels of isolation are applied according isolation procedure GTG-HSE-EXP-PRO-0031-rev01.

3 Single block valve is utilized, fluid is removed and valve tested for leakage before commencing work.

4 DB&B is utilized, vents and drains are verified and clear of obstruction.

DB&B is utilized, a hose or hard piping is attached to the drain valve to ensure that any liquid that

5

might pass is carried away from the work site.

Safety precautions are taken (e.g., use of respiratory equipment) for removing blinds since

6 hazardous materials might have accumulated between the blind and the corresponding isolated

valve if the valve was passing.

A Permit is issued before commencing blinding activity. associated equipment and piping are

7

isolated by closing block valves, depressurization, draining and purging.

Ite

Electrical isolation YES NO NA

m

It is not possible to lock out, isolation is accomplished by removal of fuses, disconnection of

1 electrical cables, or physical removal of a component of the system supplying energy to the

equipment. The point of physical interruption is identified with a fully completed hold tag.

2 Appropriate personal protective equipment provided and used during the isolation

3 Verified that the equipment is de-energized. (VAT)

Remarks and recommendations: