Document Title - Doc No.

:

Revision No. :

Process for Rework & Repair confirmation Effective Date :

Doc Owner - Production

Starting point: Determine the rework & repair to be done

End point : Make the record of rework & repair included with quantity, disposition, disposition date & applicable traceability information

Scope: Covers rework & repair of any products in the organization ( clause no. 8.7.1.4 & 8.7.1.5 )

Overall Responsibility : Overall responsibility of this procedure lies with production department. Cross functional team is responsible for risk assessment of rework & repair activity. QA department is responsible for confirmation as well as

taking customer appproval of reworked product if required by customer.

A. Input / Output Table:

Reason for Existence / Purpose Trigger Inputs From Outputs To

The purpose of this procedure is to ensure confirmation of the product as per specification after Nonconforming Nonconforming Production Confirmation of QA

rework & repair product product need to Reworked or Repaired

rework or repair product

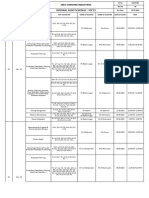

B. Process Map:

Symbols used: Activity - Decision - Travel - Hold / Delay -

Sr. No Activity Responsibility Mfg QA CFT Control Point Reference

1 Determine the rework & repair to be done Production Supervisor As per plan

2 Conduct risk analysis to assess the risk in the process of Cross Function Team Before Rework DFMEA (UTPL/D&D FR/12)

rework / repair. PFMEA (UTPL/DOC/QA/012)

3 Obtain customer approval if required QA Engineer Before Rework

Work Instruction for rework & repair

4 Carry our rework & repair of the product Production Supervisor As per plan (SOP-09) included with re-inspection &

traceability requirement

Control Plan

5 Confirm the product with respect to specification QA Engineer After rework (UTPL/DOC/QA/012)

Make the record of rework & repair included with Rework & Repair Record

6 quantity, disposition, disposition date & applicable Production Supervisor After rework (UTPL/F/QA/008)

traceability information

ADEQUACY CHECKED BY CFT Hard Copies in PU/Dept. other than Q. System Cell are uncontrolled copies.

Prepared by - Production Manager Prints taken are only for reference and must be confirmed by users for their validity

against the soft copies in common folder.

Released by - Production Manager

Revision History

Rev. Date Summary of change Authorized by