Ref.

No VEW-PRD-P-03

Rev. No 02

VEW Procedure for Rework Date of Rev. 26.09.2022

Page No. 1 of 2

1.0 Purpose

To Establish a documented procedure to ensure that the rework confirmation in accordance with the control

plan or relevant documented information to verify compliance to original specifications..

2.0 Scope

This is applicable to:

Identification of defects for rework,

Re-Inspection of reworked parts as per Control Plan

Rework risk analysis (FMEA)

Retain the documented information

3.0 References

Nil

4.0 Definitions

Compliances with original Specification

5.0 Responsibilities

Quality I/c is responsible for the identification defects for rework, Re-Inspection after rework & Retain the documented

Information

Production I/c is responsible for to get original specification -Rework

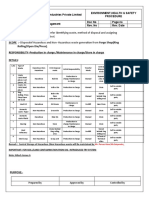

6.0 Process Inputs

Input Description Source Reference (if any)

PFMEA for Rework Quality I/c

Control Plan Quality I/c

SOP/ WI Production I/c

7.0 Process Description:

S No. Activity Responsibilit Reference (if any)

y

7.1 Identify the defects through the Stage wise inspection and mark “X” Quality I/c Q Chart

for Rework by Quality Inspector, same handover to production

supervisor of each section with documented information through Q

Chart

7.2 Rework will be done for following defects: Production NCRegister

- Dent, Scratches, Slot dent, Burrs, Rivet position variations, I/c & Zone VEW/QA/R/01

cutting damages Leader

- Powder coating defects

- Lock loose/ cross fitment in assembly

- Stopper loose / cross fitment in assembly

- Sliding tight in assembly

- Wiper gap variations in assembly

- Sealant finishing uneven & sealant gap

- Removal of broken Tap.

7.2 Reworked defects will be shown to the operator during rework and Quality N C Register

retained as limit defined

7.4 Risk Analysis /Rework PFMEA will study the nature of rework to be Production PFMEA for

carried out. Production & Quality personal will study rework defects I/c rework

and take necessary action for rework based on nature of rework.

Procedure for Rework Ref. No VEW-PRD-P-03

VEW

� Rev. No 02

Date of Rev. 26.09.2022

Page No. 2 of 2

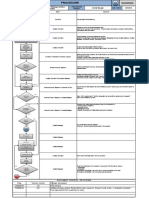

7.5 Take approval from Quality I/c or Customer if required Production

I/c

7.6 Based on requirement production zone leader /operator will carry out Quality I/c

rework on “X “Marked defects and offer it to quality personnel for re- &Production

inspection. I/c

7.7 Quality I/c recheck the “X” mark defects as per check list and re- Quality I/c Re-inspection in

inspection status will maintained Rework &

Repaired register

7.8 Take Approval from MP after rework done, If not approved, repeat the Quality I/c Re-inspection in

above points Rework &

Repaired register

7.9 Identify the reworked parts & maintained the traceability of reworked Quality I/c Re-inspection in

parts, Take customer approval before commencing the rework of the Rework &

product Repaired register

7.10 If rework done for any new defects, same defects updated in this Quality I/c & Rework PFMEA

procedure in Sl. No.7.2 and Rework PFMEA Production

I/c

7.11 All reworked parts will be rechecked / re-inspected and status will be Quality I/c & Rework Tracking

documented in Rework Tracking Register Production register

I/c VEW/QA/R/03

7.12 On daily bases rework tracking register will be reviewed and updated QMS Rework Tracking

if rework done Coordinator register

& Quality I/c

8.0 Process Outputs

Output Description To Reference (if any)

Re-inspection in Rework & Repaired register Quality I/c

PFMEA for Rework – Risk analysis Production & Quality

Rework Tracking register Production & Quality VEW/QA/R/03

9.0 Key Performance Indicators

Indicator details Review frequency Reference (if any)

Reduce the rework Every month Production KPI

10.0 Revision History:

Revision no. Effective Date Author Change Description

00 01.04.2018 New release

01 08.12.2021 Production I/c New Rework defects added in 7.2 and 7.10 added for Rework

PFMEA review and updation requirements added

02 26.09.2022 Quality I/c Rework system review mechanism added

Prepared By Approved By

& Date & Date