BHARAT PETROLEUM CORPORATION LIMITED

MUMBAI URAN PIPELINE PROJECT

PROCEDURE

Arc Strike Repair

A 28/03/2011 PA ISSUED FOR REVIEW MS RK

RE EIL /

DATE BY DESCRIPTION CHECK APPR

V BPCL

TOTAL OR PARTIAL REPRODUCTION AND/OR UTILIZATION OF THIS DOCUMENT ARE

FORBIDDEN

WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE OWNER

PUNJ LLOYD LIMITED

ENGINEERS INDIA LIMITED MUPL Project Office

Plot No. 88, Sector 10A, Vashi,

Navi Mumbai - 400703, India

REMARK Document No. REVISION STATUS

MUPL-000-31-PCD-4-012-00 A

� MUMBAI URAN PIPELINE PROJECT

Bharat

Petroleum Engineers

Punj Lloyd Limited

Corporation India Limited

Limited

Doc No.: MUPL-000-31-PCD-4-012-00

Doc Name: Arc Strike Repair - Procedure

Rev. A

TABULATION OF REVISED PAGES

SHEET REVISIONS SHEET REVISIONS

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

1 47

2 48

3 49

4 50

5 51

6 52

7 53

8 54

9 55

10 56

11 57

12 58

13 59

14 60

15 61

16 62

17 63

18 64

19 65

20 66

21 67

22 68

23 69

24 70

25 71

26 72

27 73

28 74

29 75

30 76

31 77

32 78

33 79

34 80

35 81

36 82

37 83

38 84

39 85

40 86

41 87

42 88

43 89

44 90

45 91

46 92

Page 2 of 5

� MUMBAI URAN PIPELINE PROJECT

Bharat

Petroleum Engineers

Punj Lloyd Limited

Corporation India Limited

Limited

Doc No.: MUPL-000-31-PCD-4-012-00

Doc Name: Arc Strike Repair - Procedure

Rev. A

TABLE OF CONTENTS

1.0 PURPOSE 04

2.0 SCOPE 04

3.0 REFERENCES 04

4.0 RESPONSIBILITY 04

5.0 METHODOLOGY 04

6.0 HEALTH , SAFETY & ENVIRONMENT 07

7.0 QUALITY ASSURANCE & QUALITY CONTROL 06

8.0 DOCUMENTATION 07

Page 3 of 5

� MUMBAI URAN PIPELINE PROJECT

Bharat

Petroleum Engineers

Punj Lloyd Limited

Corporation India Limited

Limited

Doc No.: MUPL-000-31-PCD-4-012-00

Doc Name: Arc Strike Repair - Procedure

Rev. A

1.0 PURPOSE

The purpose of this procedure is to lay guidelines and requirements and to establish a method

or a system to control the arc strike repair activity and inspection to be used in MUMBAI URAN

PIPELINE PROJECT, executing the Project by Punj Lloyd Ltd. (PLL).

2.0 SCOPE

The scope covers the defining of norms for repairs of Arc Strike / Arc Burns observed on the

pipe surface outside the weld of pipe line.

3.0 REFERENCES

EIL Spec No.-6-77-0007 Rev.1 & A037-0001-06-41-SP-05 Rev. 0

Standard for welding of pipelines and related Facilities-API 1104 & DNV OS F101

4.0 RESPONSIBILITIES

Site Engineer

Shall report to the Resident Construction Manager

Providing adequate resources for implementation of this activity

QA/QC Engineer

Shall reports to Quality Manager / Project Manager and shall be responsible for

Checks and verifies the activity

Verifies and countersigns report

5.0 METHODOLOGY

Accidental arc Strike or arc Burn on the pipe surface outside the weld, which are caused by

electrical arc between the electrode, electrode holder, welding cable and the pipe or by an in-

appropriate or poorly fitted earth clamps. Such Arc Strikes shall be smoothened by careful

grinding.

The ground area shall be blended with the adjoining pipe surface by smooth transition and shall

avoid notches and stress concentration. After completion of the grinding work the thickness of the

ground area shall be checked with ultrasonic thickness gauge.

The pipe wall thickness after grinding shall not be less than the minimum thickness limit permitted

for the pipe. If the thickness is found to be less than acceptable tolerance limits, then the piece

Page 4 of 5

� MUMBAI URAN PIPELINE PROJECT

Bharat

Petroleum Engineers

Punj Lloyd Limited

Corporation India Limited

Limited

Doc No.: MUPL-000-31-PCD-4-012-00

Doc Name: Arc Strike Repair - Procedure

Rev. A

shall be cut up to the affected area and fresh bevels shall be prepared, Inspected as per

approved procedures.

If the thickness is found to be within the acceptable limits then such ground area shall be

checked by DP/MT method. The DP /MT shall be carried out in presence of EIL/BPCL

representatives. In case of doubtful cracks UT or RT shall be carried out as per instructions of

EIL.

PLL shall ensure that Arc Strikes are not repaired by welding.

Arc strike repair information shall be record in Welding inspection report format.

6.0 HEALTH, SAFETY & ENVIRONMENT

The approved procedure for Health, Safety & Environment shall be followed during execution.

PPE is a must in this activity.

Only trained rigging personnel to be deployed for this activity.

All Measuring & Test Equipment used must be well maintained.

All lifting devices & Tolls used shall be well maintained and approved by a competent

authority.

7.0 QUALITY ASSURANCE & QUALITY CONTROL

Quality Assurance shall be maintained by ensuring the systematic implementation of this

procedure and ensure that necessary quality records are generated as appended to this

procedure.

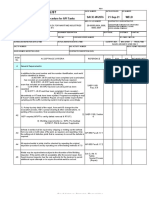

8.0 APPENDIX

Inspection & Test Plan

Page 5 of 5