0% found this document useful (0 votes)

125 views16 pagesPlastics Welding Supervisor Guidelines

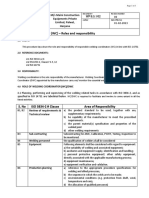

PD CEN/TR 16862:2015 outlines the tasks, responsibilities, knowledge, skills, and competencies required for a plastics welding supervisor (PWS) involved in thermoplastic welding processes. It emphasizes the importance of quality management in welding activities and provides guidelines for pre-welding, during-welding, and post-welding responsibilities. The document serves as a technical credential for organizations to demonstrate sound management practices in achieving welded product performance requirements.

Uploaded by

alxo01Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

125 views16 pagesPlastics Welding Supervisor Guidelines

PD CEN/TR 16862:2015 outlines the tasks, responsibilities, knowledge, skills, and competencies required for a plastics welding supervisor (PWS) involved in thermoplastic welding processes. It emphasizes the importance of quality management in welding activities and provides guidelines for pre-welding, during-welding, and post-welding responsibilities. The document serves as a technical credential for organizations to demonstrate sound management practices in achieving welded product performance requirements.

Uploaded by

alxo01Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd