Water Treatment Plant Processes Explained

Uploaded by

pranavingale2007Topics covered

- Filter cleaning,

- Backwashing,

- Pretreatment,

- Turbidity,

- Head loss,

- Coagulation,

- Filter operation,

- Mechanical mixing,

- Plant augmentation,

- Floc quality

Water Treatment Plant Processes Explained

Uploaded by

pranavingale2007Topics covered

- Filter cleaning,

- Backwashing,

- Pretreatment,

- Turbidity,

- Head loss,

- Coagulation,

- Filter operation,

- Mechanical mixing,

- Plant augmentation,

- Floc quality

Common questions

Powered by AITo optimize sedimentation for handling high turbidity source waters, it is imperative to increase coagulant dosages appropriate for the turbidity level, as higher dosages allow for better solids agglomeration and settling . Sedimentation basins should be designed with adequate detention time and surface area to enhance the removal efficiency of suspended solids larger than 50 mg/l . Operational practices like conducting jar tests help determine the optimal coagulant dosages for varying water qualities . These strategies effectively enhance overall process efficiency by dealing with high turbidity efficaciously .

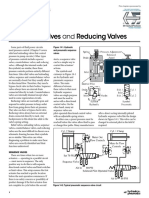

The filtration rate in slow sand filters is critical as it affects the filter's efficiency and longevity. The rate of filtration is controlled by a regulating valve on the effluent delivery, which starts partially closed and is incrementally opened to maintain a constant rate as bed resistance increases due to clogging . If the filtration rate is poorly managed, it can cause either clogging of the filter bed if too high, or insufficient filtration if too low . This mismanagement can result in decreased water quality and necessitate more frequent cleaning, which interrupts filter operation .

Sludge removal in sedimentation basins is crucial to maintaining the effectiveness of the water treatment process. If not removed, sludge can interfere with the settling process by causing resuspension of solids, creating anaerobic conditions, and reducing the detention time by decreasing the cross-sectional area of the basin . Proper sludge management prevents these issues, ensuring consistent removal of solids, thus reducing the load on subsequent filtration stages and maintaining high water quality . Regular sludge removal also prevents clogging and promotes efficient operation of filter units downstream .

Dissolved oxygen is crucial in preventing anaerobic conditions, which can cause operational issues within the filter bed . Algae in the supernatant reservoir can oxygenate the water, but in areas where algal growth is inhibited, additional measures such as aeration of the incoming raw water may be necessary . Ventilation systems should also be ensured to function properly to maintain adequate oxygen levels . Preventing anaerobic conditions is important to avoid problems like microbial growth that can adversely affect water quality .

Algal presence in water treatment processes can cause operational challenges such as clogging filters and producing undesirable tastes and odors in the treated water . These challenges are managed through pretreatment steps such as using microstrainers to remove algae before they reach the filters . Additionally, proper control of algal growth in the supernatant reservoir can help maintain dissolved oxygen levels, preventing anaerobic conditions that further complicate treatment operations . Without effective management, algae can significantly impair water treatment efficiency and quality .

Regular sampling and analysis of water are essential in monitoring both raw and treated water quality, providing crucial data on the treatment process's effectiveness . Sampling performed daily in large plants enables detection of changes that might affect treatment efficiency and allows timely adjustments to maintain water quality . In smaller plants, even if not daily, consistent sampling helps in early identification of quality deviations. Regular analysis ensures the plant operates efficiently by providing a feedback loop to optimize the treatment processes .

Rapid sand filter plants are primarily divided into two main components: the pretreatment works and the filter units. The pretreatment works include coagulation-flocculation units, which involve chemical dosing and rapid mixing facilities, and sedimentation units to handle the effluent from the coagulation-flocculation units . These processes are essential in removing particulate matter and preparing the water for filtration. The filter units further purify the water by filtering through sand to remove finer particulates . This combination of treatment steps ensures the production of safe and potable drinking water .

Proper record-keeping significantly impacts the operational success of water treatment plants by providing essential data about process performance and water quality. Maintaining daily logs of influent and effluent turbidity, temperature, and the amount of water processed helps in monitoring and making informed decisions on process adjustments . Such records allow for tracking long-term trends and identifying deviations in sedimentation efficiency or water quality, enabling timely interventions to prevent operational issues . Regular data collection supports compliance with safety and regulatory standards, improving overall plant reliability and efficiency .

To maintain an effective sedimentation process, visual checks of floc settling characteristics and clarity of settled water should be conducted regularly . The floc should be evenly distributed at the basin inlet, and abnormal conditions such as uneven floc distribution may signal changes in raw water quality or operational issues . Observing the depth and density of sludge blankets, especially in up-flow clarifiers, aids in adjusting sludge removal frequency or chemical dosages for coagulation-flocculation . These measures are vital in preventing issues like density currents and ensure the sedimentation process runs smoothly .

Designing and operating filtration systems to prevent negative pressures within the filter bed involve several key considerations. Adequate planning must ensure that devices such as weirs are installed, as these prevent the occurrence of negative pressures, which can cause filter bed structural issues and inefficiencies . Proper regulation of the filtration rate through careful valve adjustments helps maintain adequate pressure levels . Additionally, designing the system to facilitate consistent water delivery and removal under controlled conditions is crucial for preventing negative pressure and ensuring operational continuity .