0% found this document useful (0 votes)

68 views6 pagesMy Responsibility

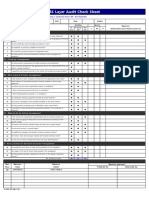

The document is a 5S audit check sheet for Kaza Industrial Corporation, detailing various responsibilities and tasks across five zones, each assigned to different individuals. It includes a list of tasks related to cleanliness, maintenance, and organization, with a scoring system to evaluate compliance. Additionally, there is a section for summarizing issues and corrective actions taken during the audit process.

Uploaded by

Jeya GaneshCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

68 views6 pagesMy Responsibility

The document is a 5S audit check sheet for Kaza Industrial Corporation, detailing various responsibilities and tasks across five zones, each assigned to different individuals. It includes a list of tasks related to cleanliness, maintenance, and organization, with a scoring system to evaluate compliance. Additionally, there is a section for summarizing issues and corrective actions taken during the audit process.

Uploaded by

Jeya GaneshCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd