Professional Documents

Culture Documents

HR 500

Uploaded by

vukimchi76Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HR 500

Uploaded by

vukimchi76Copyright:

Available Formats

Hardness Measuring

WIZHARD HR-500

Rockwell / Rockwell Superficial / Brinell hardness tester

Wizhard HR-500

The Wizhard HR-500 gives you a choice of thr ee different hardness testing methods Rockwell, Rockwell Superficial and Brinell in a single unit. Integrated into this compact unit, in addition to counterweights, is a unique electr onic test load system. Real-time load control ensures precise, continuous test force, supported by a large amount of data from various national standards. The newly designed beak-shaped extension arm considerably widens the field of application as it enables testing on parts that are difficult to access. Features Varying Rockwell, Rockwell Superficial and Brinell test forces (up to 1839 N). Beak-shaped extension arm for improved access to internal (min. 40 mm / 22 mm*) and exter nal surfaces. Electronic real-time load control for precise adjustment. This avoids the possibility of applying excessive test force. The return action of the extension ar m for continuous testing with a fixed table position prevents instability due to table movement. Auto-stop elevating table with automatic application of preliminary test force. Compact instrument body with a large working range. Various data output options: RS-232C, Centronics and Digimatic output.

*When using the diamond indenter Code No. 19BAA292

HR-522

Touch-screen operation with background-lit LCD graphics display. External control panel and selection of test for ce corresponding to the selected hardness scale. Extremely user friendly with the choice of display language: English, German, French, Spanish, Italian or Japanese. Measured value compensation with cylindrical and spherical surfaces. Conversion to other hardness scales or tensile strength. Powerful statistical data processing with flexible individual data processing options and storage capacity for 1024 values. OK / Not OK tolerance monitoring.

Rockwell / Rockwell Superficial / Brinell* har dness tester Wizhard series 810

Standard equipment Code No. 19BAA073 Diamond indenter, min. bore up to 40 mm Code No. 19BAA074 Steel ball indenter 1/16" Code No. 810-039 Flat table 64 mm Code No. 810-040 V-Anvil 40 mm, aperture 30 mm, 120 - Hardness comparison plates 30-35 HRC / 60-65 HRC / 90-95 HRB / 64-69 HR30N / 74-79 HR30T - Dust cover Optional accessories Code No. 19BAA072 Diamond indenter, min. bore 40 mm inclu. MPA certificate Code No. 19BAA292 Diamond indenter, min. bore 22 mm Code No. 19BAA075 Steel ball indenter 1/8 Code No. 810-037 Round table 180 mm Code No. 810-038 Round table 250 mm Code No. 810-041 V-anvil 40 mm, aperture 6 mm, 90 Code No. 810-042 V-anvil 10 mm, aperture 8 mm, 120 Code No. 810-029 V-anvil length 400 mm, aperture 50 mm, 120 Code No. 810-030 Point anvil (diamond tip for Rockwell Superficial) Code No. 810-043 Point anvil 12 mm Code No. 810-044 Point anvil 5.5 mm Optional accessories for Brinell hardness measurement Code No. 19BAA277 Tungsten carbide ball indenter 1 mm Code No. 19BAA279 Tungsten carbide ball indenter 2.5 mm Code No. 19BAA280 Tungsten carbide ball indenter 5 mm Code No. 19BAA284 Tungsten carbide ball indenter 10 mm Code No. 19BAA281 Replacement tungsten carbide ball indenter 1 mm (5 units) Code No. 19BAA283 Replacement tungsten carbide ball indenter 2.5 mm (5 units) Code No. 19BAA162 Replacement tungsten carbide ball indenter 5 mm (1 unit) Code No. 19BAA163 Replacement tungsten carbide ball indenter 10 mm (1 unit) Code No. 19BAA318 Microscope 40X Code No. 19BAA319 Microscope 100X Further certified hardness comparison plates are available on request.

Model Test force control Data offset Measured value compensation with measurement on cylindrical or spherical surfaces Conversion to other hardness scales Statistical functions

HR-521/HR-522/HR-523 HV, HK, HBS, tensile strength, HRA, HRB, HRC, HRD, HRF, HRG, HR15T, HR30T, HR45T, HR15N, HR30N, HR45N, HS, HB (HBS) Number of values, max., min., average value, range, upper limit, lower limit, standar d deviation, Number of OK / Not OK evaluations, histogram, X-R contr ol card (only via data output), storage and editing of 1024 values

Tolerance evaluation

Model Code No. Preliminary test force (N) Test force Rockwell (N) Rockwell Superficial (N) Brinell* (ball , mm / load, kgf)

HR-521 810-202-01E

HR-522 810-203-01E 29.42; 98.07 588.4; 980.7; 1471 147.1; 294.2; 441.3

HR-523 810-204-01E

HBW 2.5/187.5

HBW 2.5/6.25; HBW 1/10; HBW 2.5/15.625; HBW 5/25; HBW 1/30; HBW 2.5/31.25; HBW 2.5/62.5; HBW 5/62.5; HBW 10/100; HBW 5/125; HBW 2.5/187.5 Automatic (load, dwell, unload) LCD touch screen Via touch screen 0 to 120 seconds (in 1 second incr ements)

Load process Display unit Test load selection Effective dwell time Maximum reach Standard Long** Table movement Data output Power supply Dimensions (W x D x H) Mass

205 mm above table, 150 mm fr om centre of indenter 350 mm above table, 150 mm fr om centre of indenter Manual RS-232C, Digimatic, Centronics 230 VAC, 50/60 Hz Main unit 250 x 670 x 605 mm Main unit approx. 60 kg Fully automatic

* Indentations must be measured using a measuring microscope (not supplied with the instrument). ** Long reach models are HR-521L, HR-522L and HR-523L.

Note: All our pr oduct details, in particular the illustrations, drawings, dimension and per formance details and other technical specifications contained in this publication are to be considered to be approximate average values. To this extent, we reserve the right to make changes in design, technical data, dimensions and weight. Our specified standar ds, similar technical r ules and technical specifications, descriptions and illustrations of the pr oducts are correct at the time of printing. The curr ent version of our general terms and conditions also apply. Only offers which we have submitted can be consider ed to be definitive.

Mitutoyo (UK) Ltd West Point Business Park Andover, Hampshire SP10 3UX, England Tel: (01264) 353123 Fax: (01264) 354883 E-mail: enquiries@mitutoyo.co.uk www.mitutoyo.co.uk

Mitutoyo UK Ltd.

You might also like

- Equotip 3Document6 pagesEquotip 3raveeceeNo ratings yet

- Soundwel SUB100 Ultrasonic Flaw DetectorDocument26 pagesSoundwel SUB100 Ultrasonic Flaw DetectorSatwant SinghNo ratings yet

- Sony FH-B700 - HCD-H61/H61MDocument52 pagesSony FH-B700 - HCD-H61/H61MkrlstsNo ratings yet

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogElectromateNo ratings yet

- QuikCal 190 Quick StartDocument12 pagesQuikCal 190 Quick StartsuberecNo ratings yet

- RSF Electronik MS3x Series CatalogDocument20 pagesRSF Electronik MS3x Series CatalogElectromateNo ratings yet

- Catalogo de Punzones Dayton ProgreDocument28 pagesCatalogo de Punzones Dayton ProgreOdiseo Kratos SacuraguiNo ratings yet

- Technical Information RIA452: Panel MeterDocument16 pagesTechnical Information RIA452: Panel MeterAhmad AbunassarNo ratings yet

- Durable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceDocument12 pagesDurable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceCristhian Graef100% (1)

- Bosch PACO ProductDocument8 pagesBosch PACO ProducttceterexNo ratings yet

- BSPW/ BSPT Series: 5-6 kVA 6,5-10 kVADocument9 pagesBSPW/ BSPT Series: 5-6 kVA 6,5-10 kVAArief Wicaksono100% (1)

- RSF Electronik MSA373 374 375 SpecsheetDocument2 pagesRSF Electronik MSA373 374 375 SpecsheetElectromateNo ratings yet

- YCM TV SeriesDocument20 pagesYCM TV SeriesCNC SYSTEMSNo ratings yet

- Romana T-3805-EDocument19 pagesRomana T-3805-EjorgeNo ratings yet

- D-Head W-80 5-06 LTRDocument4 pagesD-Head W-80 5-06 LTRNguyen Tho VanNo ratings yet

- Logger UCAM-70A PDFDocument3 pagesLogger UCAM-70A PDFjbmune6683No ratings yet

- B131CDocument6 pagesB131CMarcelo SánchezNo ratings yet

- 2 4 GHZ Directional Parabolic Antenna A2419 2424NJ DB DatasheetDocument2 pages2 4 GHZ Directional Parabolic Antenna A2419 2424NJ DB DatasheetSebastian Morales ToledoNo ratings yet

- Crown Sasija 5P19E 29T05,29T07,29D10 PDFDocument44 pagesCrown Sasija 5P19E 29T05,29T07,29D10 PDFpedavNo ratings yet

- DA 9000 Tech SpecDocument9 pagesDA 9000 Tech SpecJenrri Herhuay Huaman100% (1)

- Product Sheet Load CellsDocument2 pagesProduct Sheet Load CellssakarisoNo ratings yet

- 47-DeVEREAUX - Superfinish & Grinding - ASETS Defense '11Document22 pages47-DeVEREAUX - Superfinish & Grinding - ASETS Defense '11dimitrisNo ratings yet

- Hmaxseries DRDSFSDDocument6 pagesHmaxseries DRDSFSDMarius UrzicăNo ratings yet

- INTERFLEX Catalogue (Conduits and Fittings)Document8 pagesINTERFLEX Catalogue (Conduits and Fittings)cherif yahyaouiNo ratings yet

- WestWeld YK Series Plasma Torch Catalog 2023Document24 pagesWestWeld YK Series Plasma Torch Catalog 2023bhaaNo ratings yet

- EV7-S Inox Weighing Terminal Product InfoDocument2 pagesEV7-S Inox Weighing Terminal Product Infopatitay036817No ratings yet

- Softening PointDocument8 pagesSoftening PointMauricio CruzNo ratings yet

- E 180 000 2 11 13Document408 pagesE 180 000 2 11 13spaszko54No ratings yet

- Advantest R6441aDocument3 pagesAdvantest R6441aangelo_lopez1993No ratings yet

- Rotex Pneumatic Cylinder CatalogueDocument4 pagesRotex Pneumatic Cylinder Cataloguekumar ambujNo ratings yet

- dt109 01Document2 pagesdt109 01Mihai PetrescuNo ratings yet

- Volume Flowmeter: Probe Selection Thin ProbesDocument1 pageVolume Flowmeter: Probe Selection Thin ProbesINGENIERIA BIOMEDICA IMQUIRURGICOS100% (1)

- Black Body Temperature Source Bcal 502-V1Document6 pagesBlack Body Temperature Source Bcal 502-V1TPM BMPNo ratings yet

- SwitzerDocument4 pagesSwitzerJove MultisystemsNo ratings yet

- F HeadDocument2 pagesF HeadVishal_Gupta_5203No ratings yet

- Technical Bulletin: Three Bond 2217HDocument3 pagesTechnical Bulletin: Three Bond 2217HbehzadNo ratings yet

- Pa System1 PDFDocument8 pagesPa System1 PDFToàn Vũ ĐìnhNo ratings yet

- Footswitch enDocument44 pagesFootswitch enrassielitoNo ratings yet

- Ifs4000 - AquafluxDocument18 pagesIfs4000 - Aquafluxavikbhai100% (1)

- Traceability ChartDocument1 pageTraceability Chartdimchien100% (1)

- Battery Operated Electromagnetic Flow Meter - SS1020 - Manas Microsystems Pvt. Ltd.Document2 pagesBattery Operated Electromagnetic Flow Meter - SS1020 - Manas Microsystems Pvt. Ltd.manas100% (1)

- A - General Bray InternationalDocument16 pagesA - General Bray InternationalNestor QuevedoNo ratings yet

- Instek GOS 6200 User ManualDocument32 pagesInstek GOS 6200 User ManualMazaya NoveriwaNo ratings yet

- MultiCam 6000-Series CNC PlasmaDocument10 pagesMultiCam 6000-Series CNC PlasmaDaniel AustinNo ratings yet

- Quanto DeskDocument4 pagesQuanto DeskDiego Fernado AvendañoNo ratings yet

- Sansui Digital Weighbridge DetailsDocument11 pagesSansui Digital Weighbridge DetailsShreepad ChandolkarNo ratings yet

- Va2016w 20 LCD MonitorDocument79 pagesVa2016w 20 LCD MonitorFABRI311No ratings yet

- HT2010 Digital - Megger Meter - User ManualDocument9 pagesHT2010 Digital - Megger Meter - User Manualyo8rmhNo ratings yet

- NFASDocument4 pagesNFASgolesfredyNo ratings yet

- Actuationproducts: Product CatalogDocument55 pagesActuationproducts: Product CatalogDwi Sandi Argo ArnowoNo ratings yet

- PS-1250 (Batería 12 V) - DatasheetDocument2 pagesPS-1250 (Batería 12 V) - DatasheetnandosinternetNo ratings yet

- XR04.48/XR08.48 Rectifier Data Sheet Features & SpecsDocument2 pagesXR04.48/XR08.48 Rectifier Data Sheet Features & SpecsСлободан ИлићNo ratings yet

- Connectra 28 HP Butt Fusion MAchineDocument1 pageConnectra 28 HP Butt Fusion MAchineDesli MunarsaNo ratings yet

- IC-3005 Series DatasheetDocument2 pagesIC-3005 Series DatasheetNeneng SukriaNo ratings yet

- Dfa500 Brochure 04-13 Us HRDocument2 pagesDfa500 Brochure 04-13 Us HREngr Irfan AkhtarNo ratings yet

- DSP-1760 Gyro - KVHDocument115 pagesDSP-1760 Gyro - KVHalerueda100% (1)

- Portable hardness tester - Thiết bị đo độ cứng cầm tay- Liên hệ: 0989653832Document15 pagesPortable hardness tester - Thiết bị đo độ cứng cầm tay- Liên hệ: 0989653832Đặng Đình TuấnNo ratings yet

- Product Information Rockwell Hardness Tester ZHR4045/4150/8150Document4 pagesProduct Information Rockwell Hardness Tester ZHR4045/4150/8150Ricardo Morales MorenoNo ratings yet

- BRINELL BH3000 - WilsonHardnessDocument2 pagesBRINELL BH3000 - WilsonHardnessKhoa Bui AnhNo ratings yet

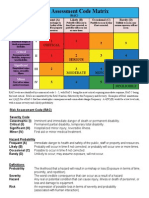

- Risk Assessment Code MatrixDocument1 pageRisk Assessment Code MatrixSanjoy ChowdhuryNo ratings yet

- ISO31000yNS AustralianaDocument61 pagesISO31000yNS AustralianaMarco Antonio GuillenNo ratings yet

- ISO31000yNS AustralianaDocument61 pagesISO31000yNS AustralianaMarco Antonio GuillenNo ratings yet

- ISO31000yNS AustralianaDocument61 pagesISO31000yNS AustralianaMarco Antonio GuillenNo ratings yet

- Checklist: Is my risk assessment approach suitable and sufficientDocument1 pageChecklist: Is my risk assessment approach suitable and sufficientafic219473No ratings yet

- Phân tích & Quản lý rủi ro: Khoa CNTT - Trường ĐHKHDocument50 pagesPhân tích & Quản lý rủi ro: Khoa CNTT - Trường ĐHKHvukimchi76No ratings yet

- 9146:2016 Ballot Draft: Foreign Object Damage (Fod) Prevention Program Guidance Material March 2016Document26 pages9146:2016 Ballot Draft: Foreign Object Damage (Fod) Prevention Program Guidance Material March 2016María Ro DíazNo ratings yet

- Practitioner Guide To Deploying AS13004 (FMEA) - Rolls RoyceDocument144 pagesPractitioner Guide To Deploying AS13004 (FMEA) - Rolls RoyceRushyanth K R100% (3)

- Effective Root Cause Analysis with 3 Legged 5 WhyDocument42 pagesEffective Root Cause Analysis with 3 Legged 5 WhySerchecko JaureguiNo ratings yet

- QRS-104 Special Processes: Quality Requirements For SuppliersDocument18 pagesQRS-104 Special Processes: Quality Requirements For Suppliersvukimchi76No ratings yet

- Ngoaitruong 2010 96Document8 pagesNgoaitruong 2010 96vukimchi76No ratings yet

- Page 1 of 20 Msds For #01586 - Accents Gift SetDocument20 pagesPage 1 of 20 Msds For #01586 - Accents Gift Setvukimchi76No ratings yet

- Terms and Conditions Template 14Document6 pagesTerms and Conditions Template 14vukimchi76No ratings yet

- Strength of Materials Lecture NotesDocument272 pagesStrength of Materials Lecture NotesVignesh Vicky67% (3)

- Building Technology ReviewerDocument117 pagesBuilding Technology ReviewerJess AndanNo ratings yet

- Alkasite Restorative Material: Exural and Compressive Strength EvaluationDocument5 pagesAlkasite Restorative Material: Exural and Compressive Strength EvaluationMiguel Sánchez Marco AntonioNo ratings yet

- ISO 9001 - Until Dec, 2018Document5 pagesISO 9001 - Until Dec, 2018Benjamin YusuphNo ratings yet

- Two-Phase Anaerobic Digestion For Class A Biosolids: Epa CertifiedDocument2 pagesTwo-Phase Anaerobic Digestion For Class A Biosolids: Epa CertifiedLTE002No ratings yet

- Service: Golf 2004 Golf Plus 2005 Passat 2006 Touran 2003Document299 pagesService: Golf 2004 Golf Plus 2005 Passat 2006 Touran 2003George Sas100% (1)

- TUTORIAL3 Series-Paralel-Branched Pipe SystemDocument5 pagesTUTORIAL3 Series-Paralel-Branched Pipe SystemNurul QurratuNo ratings yet

- Ur3569 TDS (En)Document2 pagesUr3569 TDS (En)Alexandre GoulartNo ratings yet

- SBBI4303 Environmental Biology (Worksheet)Document24 pagesSBBI4303 Environmental Biology (Worksheet)Ruslan LanNo ratings yet

- Production Engineering BFF3503: Assembly Line SetupDocument10 pagesProduction Engineering BFF3503: Assembly Line SetupMuhd ZackuanNo ratings yet

- Kelvinator No Frost Wiring DiagramDocument3 pagesKelvinator No Frost Wiring DiagramLuis Pereira Peña100% (1)

- A330 21 L3Document341 pagesA330 21 L3Thanh Vinh Nguyen100% (3)

- Snap-Action Temperature Controls: 36T SeriesDocument17 pagesSnap-Action Temperature Controls: 36T SeriesbandihootNo ratings yet

- United States Patent (19) : Ogle 11 4,177,779Document11 pagesUnited States Patent (19) : Ogle 11 4,177,779Zavorra ZavorratoNo ratings yet

- ROCHEM RO-Wasserbehandlung GMBH PDFDocument117 pagesROCHEM RO-Wasserbehandlung GMBH PDFhdf1788% (8)

- JAA ATPL BOOK 02 - Oxford Aviation - Jeppesen - Airframes and SystemsDocument421 pagesJAA ATPL BOOK 02 - Oxford Aviation - Jeppesen - Airframes and SystemsJacquie Jimenez100% (3)

- Millipore MM DS1249EN00Document6 pagesMillipore MM DS1249EN00Elena Rojo de BenitoNo ratings yet

- Flat Slabs: Design of Flat Slabs With and Without Drops by Direct Design Method of IS Code-Design and DrawingDocument23 pagesFlat Slabs: Design of Flat Slabs With and Without Drops by Direct Design Method of IS Code-Design and DrawingSenthil KumarNo ratings yet

- IMS Guardian Manual PorscheDocument15 pagesIMS Guardian Manual PorscheIceman 29No ratings yet

- How desliming cyclones remove ash and fines from coalDocument3 pagesHow desliming cyclones remove ash and fines from coalRodrigo GarcíaNo ratings yet

- Drill Collar Severing Tools Dual Fire - EBW Initiated: MAN-REC-SEV (R06)Document10 pagesDrill Collar Severing Tools Dual Fire - EBW Initiated: MAN-REC-SEV (R06)Sarah FloresNo ratings yet

- Phil2008 AtienzaDocument25 pagesPhil2008 Atienza1sabellNo ratings yet

- Graphitisation Cast IronDocument28 pagesGraphitisation Cast IronKurnia BijaksanaNo ratings yet

- Catalogue Myrra Version 2013Document84 pagesCatalogue Myrra Version 2013Axone CommunicationNo ratings yet

- Data Sheet 2007 Strenx 700 CR 2017-04-20 52 371857150 enDocument2 pagesData Sheet 2007 Strenx 700 CR 2017-04-20 52 371857150 enThainã NavarroNo ratings yet

- Utilization Prospects of Eggshell Powder in Sustainable ConstructionDocument15 pagesUtilization Prospects of Eggshell Powder in Sustainable Constructionfelipemontoya11No ratings yet

- Civil Engineering Materials ConstructionDocument36 pagesCivil Engineering Materials ConstructionJerry Mors0% (1)

- Separation of Cations by Paper ChromatographyDocument4 pagesSeparation of Cations by Paper Chromatographyapi-281104735100% (1)

- SG653PB1 ADocument5 pagesSG653PB1 ADANILO MEDINA OSORIONo ratings yet

- Catalysis & Catalysts - Impregnation and Reaction MechanismDocument19 pagesCatalysis & Catalysts - Impregnation and Reaction MechanismZamri Fadilah IINo ratings yet