100% found this document useful (1 vote)

688 views7 pages6M Root Cause

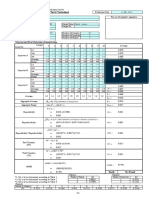

The document outlines a root cause analysis using the 6M Tool for issues related to the reconciliation of approved and rejected labels, identifying factors such as human error, equipment malfunctions, and ineffective processes. Recommendations include training, process improvements, and technology integration to enhance compliance with SOPs and eliminate stock mismatches. The analysis emphasizes the importance of corrective and preventive actions to mitigate risks associated with label reconciliation discrepancies.

Uploaded by

Vadla HanmandluCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

688 views7 pages6M Root Cause

The document outlines a root cause analysis using the 6M Tool for issues related to the reconciliation of approved and rejected labels, identifying factors such as human error, equipment malfunctions, and ineffective processes. Recommendations include training, process improvements, and technology integration to enhance compliance with SOPs and eliminate stock mismatches. The analysis emphasizes the importance of corrective and preventive actions to mitigate risks associated with label reconciliation discrepancies.

Uploaded by

Vadla HanmandluCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd