0% found this document useful (0 votes)

117 views21 pagesTurning Machine

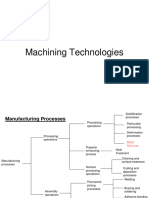

The document is a lecture on the fundamentals of manufacturing processes, focusing on the classification of these processes into non-cutting, metal joining, and cutting shaping processes. It details various cutting machines, particularly the turning/lathing machine, and describes its operations such as turning, facing, drilling, boring, threading, knurling, contouring, chamfering, and cut-off. The lecture also includes a process planning task for a specific workpiece.

Uploaded by

ziyadnader1897Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

117 views21 pagesTurning Machine

The document is a lecture on the fundamentals of manufacturing processes, focusing on the classification of these processes into non-cutting, metal joining, and cutting shaping processes. It details various cutting machines, particularly the turning/lathing machine, and describes its operations such as turning, facing, drilling, boring, threading, knurling, contouring, chamfering, and cut-off. The lecture also includes a process planning task for a specific workpiece.

Uploaded by

ziyadnader1897Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd