0% found this document useful (0 votes)

25 views24 pagesRBTPL - EHSPlan..

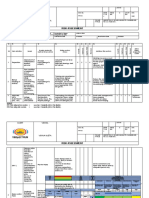

The EHS Plan for Rajshree Buildtech Pvt. Ltd. outlines comprehensive safety measures and responsibilities for all employees and subcontractors involved in the Accenture Innovation Center Project. It emphasizes the importance of incident reporting, safety training, and adherence to safety policies to ensure a safe working environment. The plan also includes a penalization system for safety breaches and a commitment to continuous improvement in health, safety, and environmental practices.

Uploaded by

raghunandanbadekar02Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

25 views24 pagesRBTPL - EHSPlan..

The EHS Plan for Rajshree Buildtech Pvt. Ltd. outlines comprehensive safety measures and responsibilities for all employees and subcontractors involved in the Accenture Innovation Center Project. It emphasizes the importance of incident reporting, safety training, and adherence to safety policies to ensure a safe working environment. The plan also includes a penalization system for safety breaches and a commitment to continuous improvement in health, safety, and environmental practices.

Uploaded by

raghunandanbadekar02Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd