0% found this document useful (0 votes)

154 views6 pagesFiring Order 1

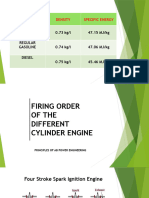

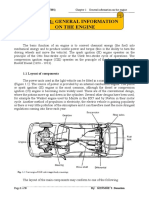

The document discusses the importance of firing order in inline 4-cylinder engines, detailing how it affects vibrations, heat dissipation, ride quality, and engine sound. It explains the firing process through diagrams and formulas, illustrating how cylinders fire in sequence and the concept of companion cylinders. Additionally, it outlines the steps required to change the firing order, emphasizing the potential impact on engine performance and the need for careful consideration before making modifications.

Uploaded by

bonniedugumaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

154 views6 pagesFiring Order 1

The document discusses the importance of firing order in inline 4-cylinder engines, detailing how it affects vibrations, heat dissipation, ride quality, and engine sound. It explains the firing process through diagrams and formulas, illustrating how cylinders fire in sequence and the concept of companion cylinders. Additionally, it outlines the steps required to change the firing order, emphasizing the potential impact on engine performance and the need for careful consideration before making modifications.

Uploaded by

bonniedugumaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd