0% found this document useful (0 votes)

15 views21 pagesJSA For

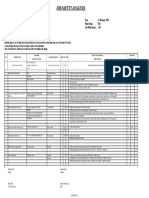

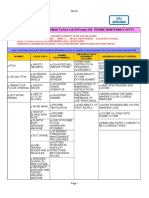

The document is a Job Safety Analysis Record Sheet outlining safety procedures and requirements for various work activities, including isolation processes, exposure to hazards, and emergency protocols. Each section specifies tasks, responsibilities, and stop work triggers if safety measures are not met. The document emphasizes the importance of proper training, equipment inspection, and adherence to safety standards to prevent accidents and injuries.

Uploaded by

Rech GepitulanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

15 views21 pagesJSA For

The document is a Job Safety Analysis Record Sheet outlining safety procedures and requirements for various work activities, including isolation processes, exposure to hazards, and emergency protocols. Each section specifies tasks, responsibilities, and stop work triggers if safety measures are not met. The document emphasizes the importance of proper training, equipment inspection, and adherence to safety standards to prevent accidents and injuries.

Uploaded by

Rech GepitulanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd