Professional Documents

Culture Documents

Job Title: Pressure Leak Test Discharge Hose: HSE Notes

Uploaded by

Ihwan AsrulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Title: Pressure Leak Test Discharge Hose: HSE Notes

Uploaded by

Ihwan AsrulCopyright:

Available Formats

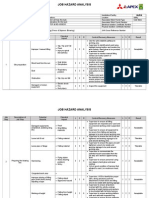

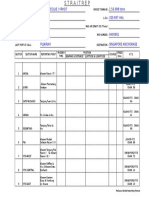

JOB SAFETY ANALYSIS

Job Title : Pressure Leak Test Discharge Hose

Location

Leader

Crew List

: Sesiil Shelter Area - FSO

: Max Polla

: See attachement

Date

: 14 February 2008

Work Permit

: YES

Hot Work Permit : NO

HSE Notes :

PPE Standard : Coverall; Safety Shoes; Safety Hat; Safety Glass; Hand Gloves.

Issue Work Permit and conduct tool box meeting before commencement the job.

Working above or on the water and personal transfer by boat, personnel should wear work vest or life jacket if needed.

Communication among personnel in charge should be well maintained.

Diver crew should be standby just in case any leak from floating hose flange.

NO

WORK STEPS

Basic step & tool used

Work Site Preparation

HAZARDS

IDENTIFICATION

How can people get

injured use checklist on

form 2

HAZARDS EFFECT

Type of injury worst case

Slip

Squeeze

Bad weather

Twisted/Keseleo

Injured

Bruised

Line up Air supply from Concord

facility

Pressure up & any leak from

the connection

Eye injured

Start pressurize the line

Pressure spread out from

flange

Pressure or any liquid spread

out from the venting line on

top point.

Eye injured

RISK FACTOR

SAFETY MEASURES &

RESIDUAL

PREVENTION

RISK FACTOR

HE

RF

Assign Responsible Person for each action

HE

RF

L2

NS

L1

L2

1. Make sure that working area is not slippery and free from obstructions

that may obstruct work activity and make activity unsafe.

NS

L1

L2

2.

3.

4.

5.

NS

L1

Install barricade as needed.

Do not hurry.

Double check equipment / Tools / Materials needed.

Wind speed < 20 kts and wave 1.5 m

H10 1. Maintain good and clear communication between Concord crew and KEI or Rigger crew.

L2

M4 2. Make sure that the from discharge compressor is open and no leak line to the manifold.

3. Check the line, from manifold and open the top point for venting the air.

4. Provide Pressure gauge and watch the pressure in the line.

L2

M4 1. Make sure pressure is increase slowly.

2. When press out from venting line, close the valve.

3. Maintain good and clear communication among Concord crew, man who watch the

pressure on the manifold.

4. Pressurize the line up to 50 psi slowly, then make sure the pressure up to 70 psig only,

and hold for about half an hour.

L2

L1

L2

Check the leak on each join

Pressure spread out.

Eye injured

L

L

M

M

L2 1. Wear safety glass.

L2

NS

L1

Depressurize the line.

Air / any material spread out

Eye injured

M4 1. Wear safety glass.

2. Bleed the pressure slowly.

L2

L2

L2

VL

L1

Block the air supply inlet

House Keeping

Hand injured

Slippery floor.

bruised

Injured

L2

L2

Bruised

1. Make sure the the valve close and Air Compressor shut off.

2. Keep people away and disconnect the line from 1" inlet air to reducer.

1. Tidy up work place and put back all tools to their place.

2. Separate all used materials/trash by following the hazardous materials types.

3. Before leaving the work place, make sure that work place is safe and clean.

Prepared by

signed

Approved by

signed

Max Polla

PT. Arah Prana

Robert Porsiana.

KEI

343333973.xls

You might also like

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- JSA-Test Pressure Hose - Feb, 08Document2 pagesJSA-Test Pressure Hose - Feb, 08Ihwan AsrulNo ratings yet

- JSA-Discharging & Flushing CoargoDocument2 pagesJSA-Discharging & Flushing CoargoIhwan AsrulNo ratings yet

- Takudzwa M. Mteliso Support Rig Drilling and InstallationDocument14 pagesTakudzwa M. Mteliso Support Rig Drilling and InstallationTakudzwa MtelisoNo ratings yet

- Installing Pneumatic Rubber Fenders Job Safety AnalysisDocument3 pagesInstalling Pneumatic Rubber Fenders Job Safety AnalysisIhwan AsrulNo ratings yet

- Safety Training Hydrojetting of Exchangers GeneralDocument15 pagesSafety Training Hydrojetting of Exchangers GeneralandinumailNo ratings yet

- Job Safety Analysis: Job Title: Membongkar Hose Strings Dari Mini PlatformDocument2 pagesJob Safety Analysis: Job Title: Membongkar Hose Strings Dari Mini PlatformIhwan AsrulNo ratings yet

- JHA Pneumatic Test Using N2Document4 pagesJHA Pneumatic Test Using N2Luqman Osman89% (9)

- Halliburton job safety analysis for unloading jetting flow CTU, nitrogen and pumpingDocument2 pagesHalliburton job safety analysis for unloading jetting flow CTU, nitrogen and pumpinganeshseNo ratings yet

- BOP-08 - (Koomey Unit, Bleed Off Pressure) - RV (1) Jan. '05Document1 pageBOP-08 - (Koomey Unit, Bleed Off Pressure) - RV (1) Jan. '05Abdul Hameed OmarNo ratings yet

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanNo ratings yet

- Procedure Leak Test Dan VacuumDocument5 pagesProcedure Leak Test Dan VacuumwahyuNo ratings yet

- RA For High Pressure Cleaning Using HPCE 520-330Document3 pagesRA For High Pressure Cleaning Using HPCE 520-330George CristianNo ratings yet

- Scott Rit-Pak IiiDocument38 pagesScott Rit-Pak IiioquirogacNo ratings yet

- Compressed Air AwarenessDocument7 pagesCompressed Air Awarenessasimnaqvi2003No ratings yet

- User Manual: Unitor Immersion Suit 7PDocument10 pagesUser Manual: Unitor Immersion Suit 7PPedro EscarráNo ratings yet

- HAZOP Analysis of Well Test OperationsDocument4 pagesHAZOP Analysis of Well Test OperationsMohamed SamirNo ratings yet

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Document4 pagesHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinNo ratings yet

- Air Powered ToolsDocument9 pagesAir Powered ToolsHadrien FaryalaNo ratings yet

- Cleaning at Kiln Take Up Pulley SOPDocument147 pagesCleaning at Kiln Take Up Pulley SOPu10ch019No ratings yet

- SOP For Hydro TestDocument2 pagesSOP For Hydro Testashfaque khanNo ratings yet

- Diving Gear Setup InstructionsDocument7 pagesDiving Gear Setup InstructionsmaustanichNo ratings yet

- JSA Chemical Tank EntryDocument22 pagesJSA Chemical Tank EntryAariz ZaidNo ratings yet

- HSC User ManualDocument47 pagesHSC User ManualReza Jafari50% (6)

- RMIT CO2 Refrigeration Lab Risk ManagementDocument1 pageRMIT CO2 Refrigeration Lab Risk ManagementPrestoneKNo ratings yet

- Pigging ProceduresDocument3 pagesPigging Procedurespreventing becejNo ratings yet

- Everfresh Controlled Atmosphere Model 69Nt40-489-100 Series: Operation & ServiceDocument170 pagesEverfresh Controlled Atmosphere Model 69Nt40-489-100 Series: Operation & ServiceSerhiiNo ratings yet

- Washing Machine Service ManualDocument55 pagesWashing Machine Service ManualDavid LovatoNo ratings yet

- Sandblaster ManualDocument12 pagesSandblaster ManualgmelloyNo ratings yet

- RA 002 - HFO Line Pressure TestDocument4 pagesRA 002 - HFO Line Pressure Testdassi99100% (1)

- EverFresh Controlled Atmosphere Model 69NT40-489-100 SeriesDocument170 pagesEverFresh Controlled Atmosphere Model 69NT40-489-100 SeriescloviskrellingNo ratings yet

- Cutting Anchor Chain Job Safety AnalysisDocument2 pagesCutting Anchor Chain Job Safety AnalysisIhwan AsrulNo ratings yet

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- Safe Work Method Statement - PlumbingDocument4 pagesSafe Work Method Statement - PlumbingJohn KurongNo ratings yet

- Stopple ProceduresDocument3 pagesStopple ProceduresBensmatNo ratings yet

- Blower & Vacuum Pump: IRS-32A・IRS-40A・IRS-50H/L・IRS-65H/L IRS-80H/L・IRS-100L・IRS-125R/L・IRS-150R/LDocument68 pagesBlower & Vacuum Pump: IRS-32A・IRS-40A・IRS-50H/L・IRS-65H/L IRS-80H/L・IRS-100L・IRS-125R/L・IRS-150R/Ladamnassir91No ratings yet

- Hydrostatic Pressure Test Safety ChecklistDocument3 pagesHydrostatic Pressure Test Safety ChecklistJerry Faria60% (5)

- Job Safety Analysis Work SheetDocument20 pagesJob Safety Analysis Work SheetBarkat Ullah50% (2)

- Series TK-9A Installation InstructionsDocument4 pagesSeries TK-9A Installation InstructionsWattsNo ratings yet

- Standard Operating Procedures For FS EquipmentsDocument24 pagesStandard Operating Procedures For FS EquipmentsAnonymous LFgO4WbIDNo ratings yet

- Donaldson Compressed Air Dryer Operating InstructionsDocument46 pagesDonaldson Compressed Air Dryer Operating InstructionsClaudiuNo ratings yet

- Washing Machine Service Manual Safety GuideDocument57 pagesWashing Machine Service Manual Safety GuideDavid Lovato100% (2)

- Method of Statement For Pressure Test PDFDocument2 pagesMethod of Statement For Pressure Test PDFBen Lim0% (1)

- STEAM BLOWING CHECKLISTDocument2 pagesSTEAM BLOWING CHECKLISTrama_saravanan2568100% (5)

- Instructions For Changing A Complete Burnout CompressorDocument25 pagesInstructions For Changing A Complete Burnout Compressorapi-242281017No ratings yet

- Operating Manual SIRIUS 1000-2000 LIN Storage Vessel Art. No 78211329 Da...Document29 pagesOperating Manual SIRIUS 1000-2000 LIN Storage Vessel Art. No 78211329 Da...Bogdan CorbescuNo ratings yet

- Peco Filter CaseDocument11 pagesPeco Filter CaseLuis MaureraNo ratings yet

- Operation and Service Everfresh Controlled Atmosphere: 69Nt40-489-100 SeriesDocument178 pagesOperation and Service Everfresh Controlled Atmosphere: 69Nt40-489-100 SeriesHéctor AraujoNo ratings yet

- Risk assessment for anchor handling vessel PT. SWIBER BERJAYADocument3 pagesRisk assessment for anchor handling vessel PT. SWIBER BERJAYADevi Ratna PratiwiNo ratings yet

- Compressed Air: or Deep Holes in Parts: Use Low Pressure-30Document1 pageCompressed Air: or Deep Holes in Parts: Use Low Pressure-30Wahid AkramNo ratings yet

- Liq Nitro Sop ChemDocument3 pagesLiq Nitro Sop ChemSandeep ShettyNo ratings yet

- Job HAzard Analysis Welding Operations MiftahDocument3 pagesJob HAzard Analysis Welding Operations MiftahLukmanElekAe100% (2)

- Chase Method Statement Dry Riser TestingDocument6 pagesChase Method Statement Dry Riser Testingarmagan55No ratings yet

- EverFresh Operation and Service PDFDocument170 pagesEverFresh Operation and Service PDFIgnacio OsorioNo ratings yet

- MSDS - NitrogenDocument7 pagesMSDS - NitrogenSatish Kumar MauryaNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Air Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811From EverandAir Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811No ratings yet

- Reporting Format: Format of Ship ReportDocument4 pagesReporting Format: Format of Ship ReportIhwan AsrulNo ratings yet

- Link WsiteDocument11 pagesLink WsiteIhwan AsrulNo ratings yet

- SBC PTW IqsbDocument4 pagesSBC PTW IqsbIhwan AsrulNo ratings yet

- Bunkering Process Adopted by M/V Magnus CarriersDocument1 pageBunkering Process Adopted by M/V Magnus CarriersIhwan AsrulNo ratings yet

- Cara InstalasiDocument1 pageCara InstalasiIhwan AsrulNo ratings yet

- Alleged Short DeliveryDocument1 pageAlleged Short DeliveryIhwan AsrulNo ratings yet

- Sampling: Magnus Carriers CorporationDocument1 pageSampling: Magnus Carriers CorporationIhwan AsrulNo ratings yet

- Singapore VHF ReportingDocument1 pageSingapore VHF ReportingIhwan AsrulNo ratings yet

- Job Risk Assesment OfftakeDocument7 pagesJob Risk Assesment OfftakeIhwan Asrul100% (1)

- Cara InstalasiDocument1 pageCara InstalasiIhwan AsrulNo ratings yet

- Authorization To Sign BLDocument1 pageAuthorization To Sign BLIhwan AsrulNo ratings yet

- Gangway Air Hose BurstDocument3 pagesGangway Air Hose BurstIhwan AsrulNo ratings yet

- Forecast 2Document2 pagesForecast 2Ihwan AsrulNo ratings yet

- Works Carried Out Since Last PMSDocument1 pageWorks Carried Out Since Last PMSIhwan AsrulNo ratings yet

- Iv. Daily Forecast (06 May - 12 May 2017) For Oyong Terminal Madura ( (07 17' 20.00" S / 113 21' 22" E)Document2 pagesIv. Daily Forecast (06 May - 12 May 2017) For Oyong Terminal Madura ( (07 17' 20.00" S / 113 21' 22" E)Ihwan AsrulNo ratings yet

- Daftar Pengiriman DokumenDocument1 pageDaftar Pengiriman DokumenIhwan AsrulNo ratings yet

- Forecast 1Document1 pageForecast 1Ihwan AsrulNo ratings yet

- Daftar Pengiriman Dokumen - January 2017Document2 pagesDaftar Pengiriman Dokumen - January 2017Ihwan AsrulNo ratings yet

- Pt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementDocument3 pagesPt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementIhwan AsrulNo ratings yet

- Pt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementDocument3 pagesPt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementIhwan AsrulNo ratings yet

- Job Risk Assesment OfftakeDocument7 pagesJob Risk Assesment OfftakeIhwan Asrul100% (1)

- Submitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Document2 pagesSubmitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Ihwan AsrulNo ratings yet

- Daftar Pengiriman Dokumen Mar 15Document4 pagesDaftar Pengiriman Dokumen Mar 15Ihwan AsrulNo ratings yet

- Documents Sent to Company in October 2014Document2 pagesDocuments Sent to Company in October 2014Ihwan AsrulNo ratings yet

- Investigation Report MT.PETRO EASKEM Echo Sounder FaultDocument1 pageInvestigation Report MT.PETRO EASKEM Echo Sounder FaultIhwan AsrulNo ratings yet

- Job Risk Assesment OfftakeDocument7 pagesJob Risk Assesment OfftakeIhwan Asrul100% (1)

- Digital Charts and Publications - NAVTORDocument3 pagesDigital Charts and Publications - NAVTORIhwan AsrulNo ratings yet

- CSE Risk Assessment - For COTDocument6 pagesCSE Risk Assessment - For COTIhwan AsrulNo ratings yet

- 2O StatementDocument1 page2O StatementIhwan AsrulNo ratings yet

- ECDIS Mandatory ECDIS Marine Equipment For Merchant Marine FURUNODocument11 pagesECDIS Mandatory ECDIS Marine Equipment For Merchant Marine FURUNOIhwan AsrulNo ratings yet

- W.C. Hicks Appliances: Client Name SKU Item Name Delivery Price Total DueDocument2 pagesW.C. Hicks Appliances: Client Name SKU Item Name Delivery Price Total DueParth PatelNo ratings yet

- SWOT Analysis of Standard Chartered BankDocument4 pagesSWOT Analysis of Standard Chartered BankparthNo ratings yet

- Cortisol II 2020-03 v6Document5 pagesCortisol II 2020-03 v6Parishan SaeedNo ratings yet

- Analyze The Uses of Concepts, Variables and Data Types.: at The End of The Exercise, The Student Should Be Able ToDocument4 pagesAnalyze The Uses of Concepts, Variables and Data Types.: at The End of The Exercise, The Student Should Be Able ToROCELLE SALENo ratings yet

- A European Call Option Gives A Person The Right ToDocument1 pageA European Call Option Gives A Person The Right ToAmit PandeyNo ratings yet

- 2023 Congressional Baseball Sponsorship PackagesDocument2 pages2023 Congressional Baseball Sponsorship PackagesSpencer BrownNo ratings yet

- Case Study:: Barangay HallDocument13 pagesCase Study:: Barangay HallReiner Gatdula50% (2)

- Electrovalvula Norgren V51Document4 pagesElectrovalvula Norgren V51Base SistemasNo ratings yet

- AarushDocument88 pagesAarushCgNo ratings yet

- ART. 1326 - ART 1335 DiscussionDocument20 pagesART. 1326 - ART 1335 DiscussionJessica JamonNo ratings yet

- Chapter # 18: ElectronicsDocument18 pagesChapter # 18: ElectronicsShahzad AslamNo ratings yet

- What is Reliability Centered Maintenance and its principlesDocument7 pagesWhat is Reliability Centered Maintenance and its principlesRoman AhmadNo ratings yet

- LogProcessing-TEICH v2Document23 pagesLogProcessing-TEICH v2slides courseNo ratings yet

- Hotel Room Booking System Use-Case DiagramDocument5 pagesHotel Room Booking System Use-Case DiagramCalzita Jeffrey0% (1)

- Acramin Prefix KDocument3 pagesAcramin Prefix KB.M. RasheduzzamanNo ratings yet

- Chemical Weekly Jun13Document256 pagesChemical Weekly Jun13Arun SaxenaNo ratings yet

- Flipkart vs Amazon comparison studyDocument6 pagesFlipkart vs Amazon comparison studysunnyNo ratings yet

- 8200.47 Transponder Landing SystemDocument28 pages8200.47 Transponder Landing SystemLê Khánh DuyNo ratings yet

- Instrument Installation Checklist Êîíò Îëüíàß Âåäîìîñòü Óñòàíîâêè Êîíò Îëüíî-Èçìå Èòåëüíûõ Ï Èáî ÎâDocument2 pagesInstrument Installation Checklist Êîíò Îëüíàß Âåäîìîñòü Óñòàíîâêè Êîíò Îëüíî-Èçìå Èòåëüíûõ Ï Èáî ÎâAdrianNo ratings yet

- Tech Elevator School Catalog, 2020 PDFDocument29 pagesTech Elevator School Catalog, 2020 PDFjohanmulyadi007No ratings yet

- Distillation TypesDocument34 pagesDistillation TypesJoshua Johnson100% (1)

- KemmyDocument22 pagesKemmyKemi HamzatNo ratings yet

- Why Coolant Plays a Critical Role in Engine LongevityDocument57 pagesWhy Coolant Plays a Critical Role in Engine LongevityPETER ADAMNo ratings yet

- Wolf Marshall's Guide To C A G E DDocument1 pageWolf Marshall's Guide To C A G E Dlong_tu02No ratings yet

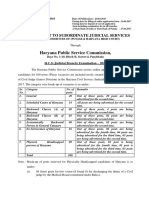

- HPSC Haryana Civil Service Judicial ExamDocument6 pagesHPSC Haryana Civil Service Judicial ExamNDTV100% (1)

- Al-Cu Phase DiagramDocument4 pagesAl-Cu Phase DiagramSandeep YadavNo ratings yet

- Amgen PresentationDocument38 pagesAmgen PresentationrajendrakumarNo ratings yet

- Statement-Jan 2019 PDFDocument4 pagesStatement-Jan 2019 PDFPatricio Rodriguez Jr100% (1)

- Class 11 Constitutional Law Model QuestionDocument3 pagesClass 11 Constitutional Law Model QuestionanuNo ratings yet

- TOtal Quality ControlDocument54 pagesTOtal Quality ControlSAMGPRONo ratings yet